Preparation method of modified calcium carbonate

A calcium carbonate and modification technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve problems such as production line shutdown, loss of use effect, silver streaks, etc., and achieve good printing performance and strong combination , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

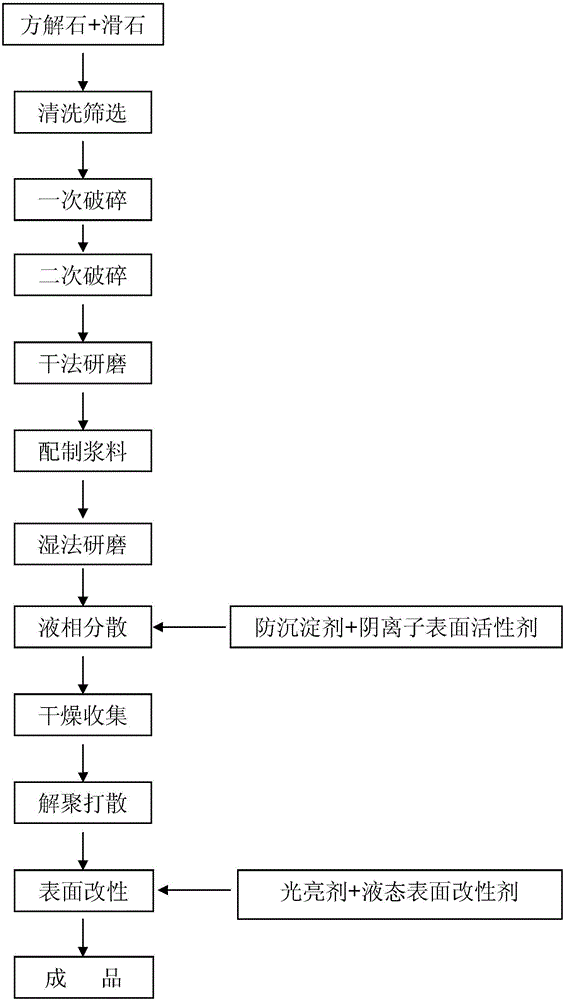

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of modified calcium carbonate, comprising the following steps:

[0035](1) Large calcite ore and talc are crushed at a mass ratio of 100:3, ground into 400 mesh dry powder, configured into a raw slurry with a solid content of 72%, and pumped into a 3600L vertical wet grinder for wet grinding. Grinding by the method, grinding into a cooked slurry with an average particle size of 1 μm;

[0036] (2) Naphthalene sulfonate anti-precipitation agent KM-S and 80°C warm water are prepared into an aqueous solution with a mass fraction of 3-5%;

[0037] (3) The cooked slurry is pumped into the stirring tank for liquid phase dispersion, and the anti-sedimentation agent KM-S aqueous solution of the cooked slurry volume ratio of 1.2%, sodium dodecylbenzenesulfonate and the cooked slurry volume ratio of 0.5% are added simultaneously. An aqueous solution of sodium N-lauroyl glutamate; the conditions for controlling the dispersion of the liquid phase are that the s...

Embodiment 2

[0041] A preparation method of modified calcium carbonate, comprising the following steps:

[0042] (1) Large calcite ore and talc are crushed at a mass ratio of 100:4, ground into 400-mesh dry powder, configured into a raw slurry with a solid content of 75%, and pumped into a 3600L vertical wet grinder for wet grinding. Grinding method, grinding into a cooked slurry with an average particle size of 0.9 μm;

[0043] (2) KM-S and 80°C warm water are prepared into an aqueous solution with a mass fraction of 3-5%;

[0044] (3) Pump the cooked slurry into the stirred tank for liquid phase dispersion, and add the anti-precipitation agent KM-S aqueous solution with a volume ratio of 0.7% of the cooked slurry, sodium dodecylbenzenesulfonate with a volume ratio of 0.7% of the cooked slurry, An aqueous solution of sodium N-lauroyl glutamate and sodium dodecyl phosphate; the conditions for controlling the dispersion of the liquid phase are that the stirring temperature is 80°C, the sti...

Embodiment 3

[0048] A preparation method of modified calcium carbonate, comprising the following steps:

[0049] (1) Large calcite ore and talc are crushed at a mass ratio of 100:5, ground into a 400-mesh dry powder, configured into a raw slurry with a solid content of 70%, and pumped into a 3600L vertical wet grinder for wet grinding. Grinding by the method, grinding into a cooked slurry with an average particle size of 1.1 μm;

[0050] (2) KM-S and 80°C warm water are prepared into an aqueous solution with a mass fraction of 3-5%;

[0051] (3) Pump the cooked slurry into the stirring tank for liquid phase dispersion, and add the anti-sedimentation agent KM-S aqueous solution with a volume ratio of 1.5% of the cooked slurry, sodium dodecylbenzenesulfonate with a volume ratio of 0.9% of the cooked slurry, An aqueous solution of ammonium lauryl sulfate and sodium N-lauroyl acyl glutamate; the conditions for controlling the dispersion of the liquid phase are that the stirring temperature is...

PUM

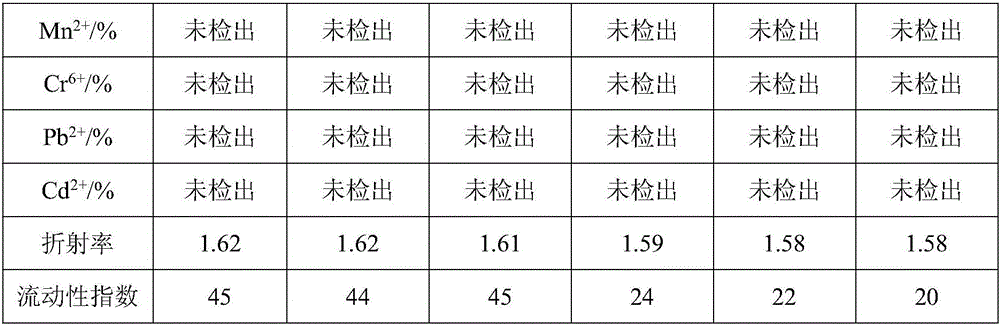

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com