Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

A tin-bismuth and brazing technology, which is applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of mechanical and electrical properties, lower insulation resistance, corrosion of residues, etc., and achieve good mold release , Reduce thermal damage, less corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

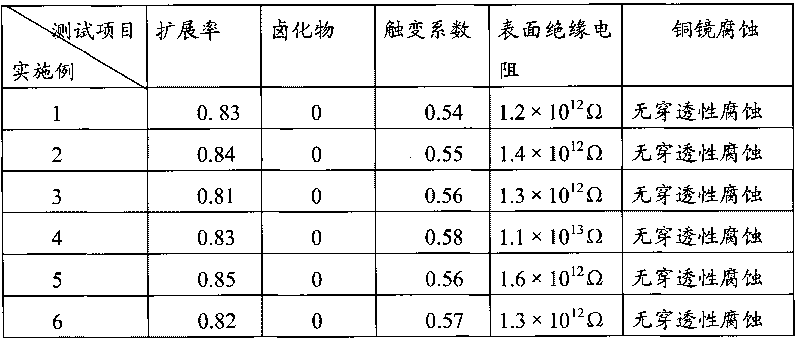

Examples

Embodiment 1

[0036] Flux raw materials: polymerized rosin 35g, rosin amine polyoxyethylene ether 5g, hydrogenated castor oil 6g, sebacic acid 4g, salicylic acid 4g, triethanolamine 6g, hydroquinone 2g, polyoxyethylene glyceryl ether 2g and di Ethylene glycol monobutyl ether 36g,

[0037] Preparation method: Mix 35g of polymerized rosin, 5g of rosin amine polyoxyethylene ether and 36g of diethylene glycol monobutyl ether, and heat them at 140-150°C until completely dissolved; add 6g of hydrogenated castor oil, 4g of sebacic acid, and salicylic acid in sequence 4g, 6g of triethanolamine, 2g of hydroquinone, completely dissolved and cooled to room temperature, added 2g of polyoxyethylene glyceryl ether, stirred evenly, the prepared flux was placed in a refrigerated environment at 5-12°C for 12 hours, and the flux was taken 15g and 85g of Sn82.5Bi17Cu0.5 alloy powder were mixed and stirred in a vacuum disperser, and stirred evenly to obtain a halogen-free tin-bismuth-copper solder paste.

Embodiment 2

[0039] Flux raw materials: polymerized rosin 30g, hydrogenated rosin 8g, disproportionated rosin amine 6g, stearamide 6g, adipic acid 4g, methyl succinic acid 4g, diethanolamine 8g, 2,6-di-tert-butyl-p-cresol 2g , polyoxyethylene glyceryl ether 2g and ethylene glycol dibutyl ether 22g, tetrahydrofuran solvent 8g,

[0040] Preparation method: Mix 30g of polymerized rosin, 8g of hydrogenated rosin, 6g of disproportionated rosinamine, 22g of ethylene glycol dibutyl ether, and 8g of tetrahydrofuran solvent, mix and heat at 140-150°C until completely dissolved; add 6g of stearylamide, oxalic acid in sequence 4g, methyl succinic acid 4g, diethanolamine 8g, 2,6-di-tert-butyl-p-cresol 2g, after completely dissolving, cool to room temperature, add polyoxyethylene glyceryl ether 2g, after stirring evenly, the prepared flux is placed Refrigerate at 5-12°C for 12 hours, take 14g of flux and 86g of Sn82.5Bi17Cu0.5 alloy powder, mix and stir in a vacuum disperser, and stir evenly to obtain ...

Embodiment 3

[0042] Flux raw materials: polymerized rosin 30g, acrylic resin 10g, rosin amine 2g, disproportionated rosin amine 2g, hydroxyglyceride 6g, suberic acid 2g, dimer acid 2g, stearic acid 1g, diethylenetriamine 5g, 2,6 - Di-tert-butyl-p-cresol 1 g, polyoxyethylene glyceryl ether 2 g and ethylene glycol dibutyl ether 27 g and 2-ethyl-1,3-hexanediol 10 g. 104g

[0043] Preparation method: Mix 30g of polymerized rosin, 10g of acrylic resin, 2g of rosinamine, 2g of disproportionated rosinamine, 27g of ethylene glycol dibutyl ether and 10g of 2-ethyl-1,3-hexanediol and heat them at 140-150°C to Completely dissolve; Add 6g of hydroxyglyceride, 2g of suberic acid, 2g of dimer acid, 1g of stearic acid, 5g of diethylenetriamine, 1g of 2,6-di-tert-butyl-p-cresol in sequence, dissolve completely and cool to room temperature , add 2g of polyoxyethylene glyceryl ether, stir evenly, and place the prepared flux in a refrigerator at 5-12°C for 12 hours, take 13g of flux and 87g of Sn82.5Bi17Cu0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com