Glass fiber impregnating compound for polyurethane pultrusion composite material and preparation method of glass fiber impregnating compound

A composite material and glass fiber technology, which is applied in the field of glass fiber sizing for polyurethane pultrusion composite materials and its preparation, can solve the problems of large hairiness and poor stability, and achieve low hairiness, high compatibility, biophase good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

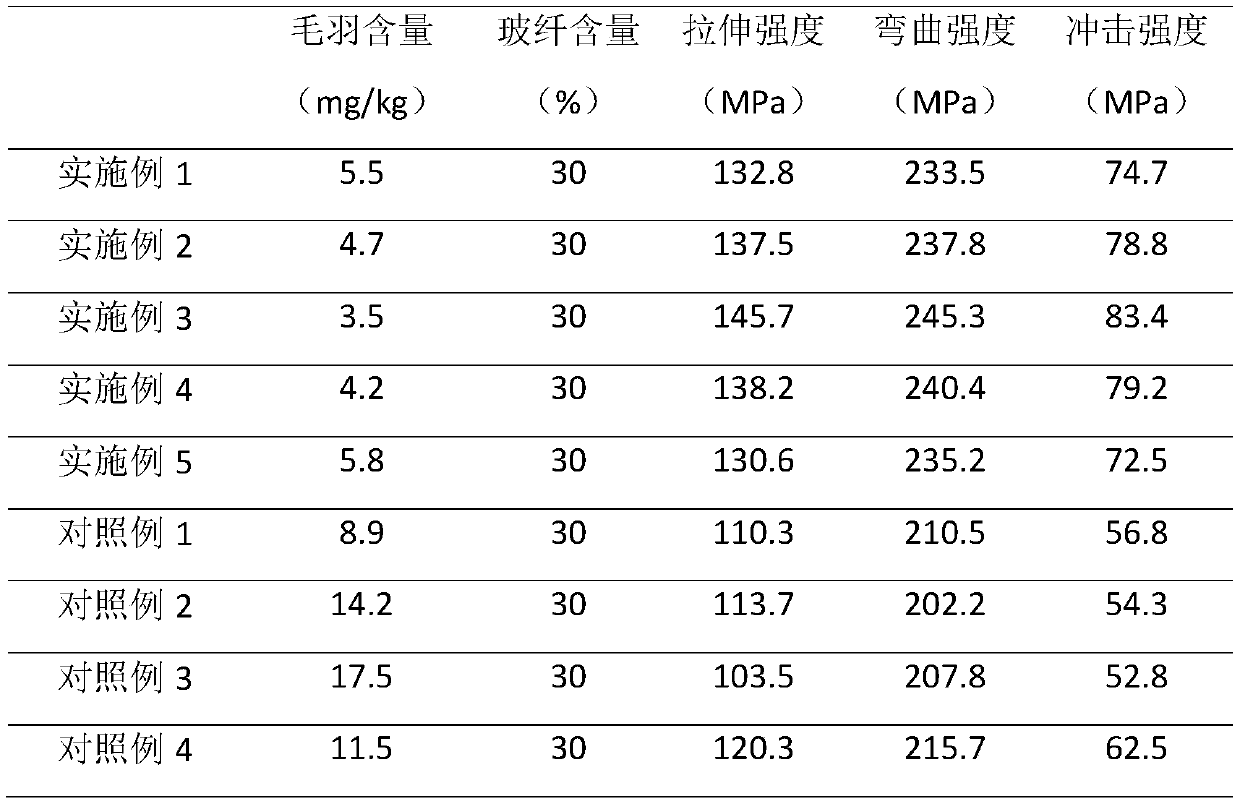

Examples

Embodiment 1

[0028] The glass fiber sizing agent for polyurethane pultrusion composites in this embodiment includes: by percentage, silane coupling agent A 0.2wt%, silane coupling agent B 0.4wt%, film forming agent 6.2wt%, lubricant A0. 3wt%, lubricant B 0.2wt%, auxiliary agent 0.2wt%, pH regulator 0.2wt%, and the rest is water;

[0029] Wherein, silane coupling agent A is 3-aminopropyltriethoxysilane; silane coupling agent B is 3-(2-aminoethylamino)propyltrimethoxysilane; film-forming agent is modified epoxy Emulsion; lubricant A is polyethylene glycol; lubricant B is octadecyltrimethylammonium chloride; pH regulator is glacial acetic acid; auxiliary agent includes starch nanocrystal modified epoxy resin.

[0030] Wherein, the preparation method of modified epoxy emulsion comprises the following steps:

[0031] (1) Chitosan is added to water, and citric acid is added, after being heated to 30 ℃, the chitosan aqueous solution is obtained after stirring until completely dissolved; wherein,...

Embodiment 2

[0042] The glass fiber sizing agent for polyurethane pultrusion composites in this embodiment includes: by percentage, silane coupling agent A 0.3wt%, silane coupling agent B 0.5wt%, film forming agent 6.5wt%, lubricant A0. 4wt%, lubricant B 0.4wt%, auxiliary agent 0.3wt%, pH regulator 0.25wt%, and the rest is water;

[0043] Wherein, silane coupling agent A is 3-aminopropyltriethoxysilane; silane coupling agent B is 3-(2-aminoethylamino)propyltrimethoxysilane; film-forming agent is modified epoxy Emulsion; lubricant A is polyethylene glycol; lubricant B is octadecyltrimethylammonium chloride; pH regulator is glacial acetic acid; auxiliary agent includes starch nanocrystal modified epoxy resin.

[0044] Wherein, the preparation method of modified epoxy emulsion comprises the following steps:

[0045] (1) Chitosan is added to water, and citric acid is added, after being heated to 40°C, the chitosan aqueous solution is obtained after stirring until completely dissolved; wherein, ...

Embodiment 3

[0056] The glass fiber sizing agent for polyurethane pultrusion composites in this embodiment includes: by percentage, silane coupling agent A 0.4wt%, silane coupling agent B 0.6wt%, film forming agent 7.0wt%, lubricant A0. 5wt%, lubricant B 0.5wt%, auxiliary agent 0.4wt%, pH regulator 0.3wt%, and the rest is water;

[0057] Wherein, silane coupling agent A is 3-aminopropyltriethoxysilane; silane coupling agent B is 3-(2-aminoethylamino)propyltrimethoxysilane; film-forming agent is modified epoxy Emulsion; lubricant A is polyethylene glycol; lubricant B is octadecyltrimethylammonium chloride; pH regulator is glacial acetic acid; auxiliary agent includes starch nanocrystal modified epoxy resin.

[0058] Wherein, the preparation method of modified epoxy emulsion comprises the following steps:

[0059] (1) Chitosan is added to water, and citric acid is added, after being heated to 40 ℃, after stirring until fully dissolved, an aqueous solution of chitosan is obtained; wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com