Painting Brush

a brush and brush handle technology, applied in the field of painting brushes, can solve the problems of inability to allow a satisfactory amount of coating material to be picked up, inability to hold a small amount of coating material, and inability to meet the needs of cleaning, etc., to achieve excellent bundling of bristles, improve the working efficiency of coating operation, and increase the amount of coating material picked up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experiment examples

[0019] Experiments were conducted on the bristles 1 made up of a mixture of the straight monofilaments and the wavy monofilaments as described above.

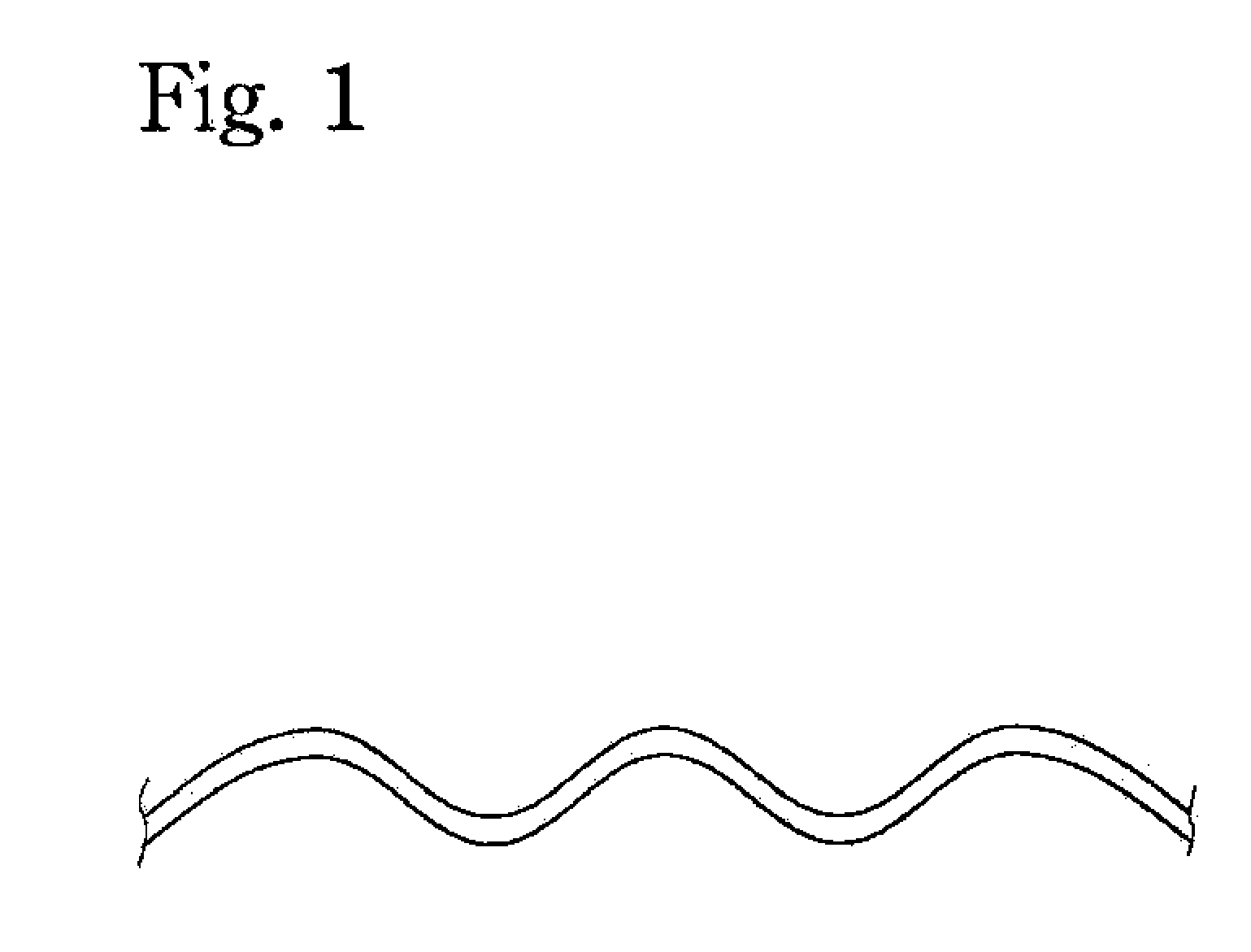

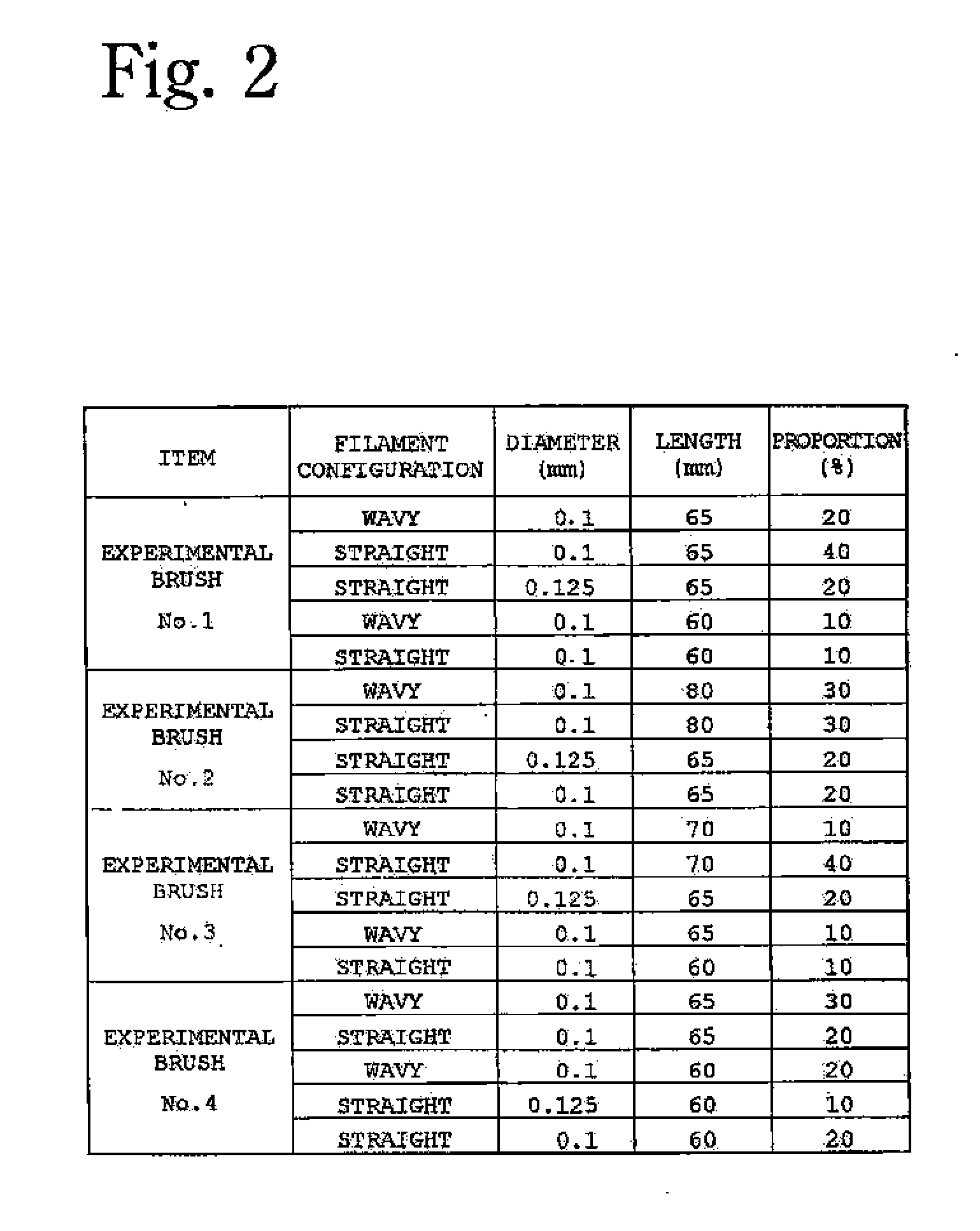

[0020] In the experiments, PBT-made straight monofilaments and PBT-made wavy monofilaments as illustrated in FIG. 1, which form the bristles 1, are used to fabricate experimental brushes No. 1 to No. 4 shown in the table in FIG. 2. The table in FIG. 2 shows the diameter and the length of each monofilament used in experimental brushes No. 1 to No. 4 and the proportion of the mixing of each monofilament.

[0021] In the “monofilament configuration” column of the table in FIG. 2, the configuration of the wavy monofilament subjected to the waving process is designated as “wavy” and the configuration of the straight monofilament is designated as “straight”.

[0022] As seen from the “diameter” column, all the wavy monofilaments used in each experimental brush have a diameter of 0.1 mm, and the straight monofilaments used in each experimental br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com