Wetting and penetrating agent for hard surfaces and fabrics

A penetrating agent and hard surface technology, applied in textiles and papermaking, transportation and packaging, chemical instruments and methods, etc., can solve problems such as general effect, peculiar smell, and general product performance, and achieve energy saving, biodegradation, and The effect of strong wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

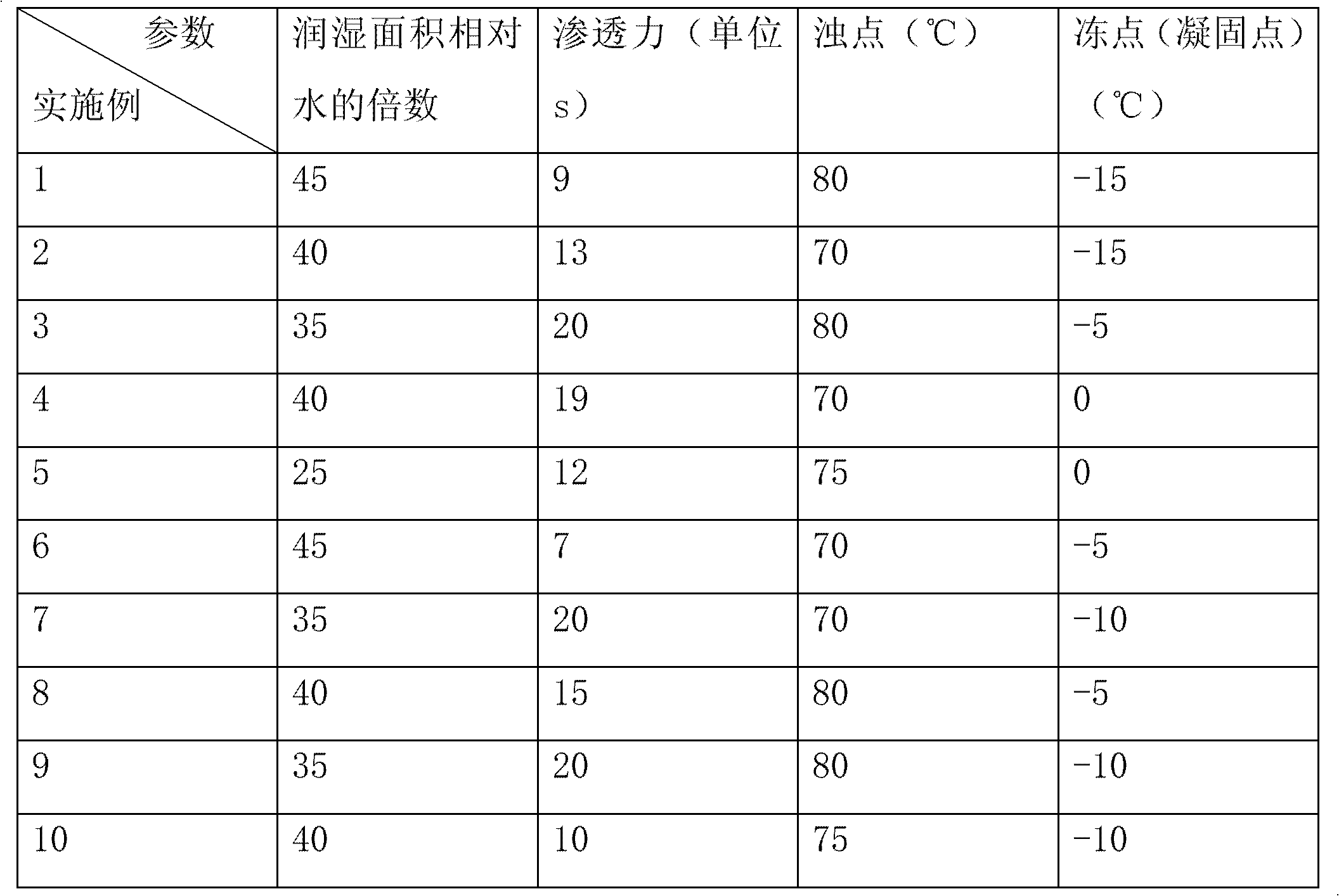

Examples

Embodiment 1

[0027] A wetting and penetrating agent for hard surfaces and textiles, prepared from the following ingredients:

[0028] Isomerized alcohol polyoxyethylene ether 43kg,

[0029] Fatty alcohol polyoxyethylene ether 30kg,

[0030] Anionic surfactant 4.5kg,

[0031] polyethylene glycol 15kg,

[0032] Distilled water 7.5kg.

[0033] The isomeric alcohol polyoxyethylene ether, its hydrophobic base isomeric alcohol is C8-10; its hydrophilic base polyoxyethylene polymerization degree is n=8 and 30; the mass ratio is 7:1;

[0034] The fatty alcohol alcohol polyoxyethylene ether, its hydrophobic fatty alcohol is C8 and C12-14, the mass ratio is 1:1; its hydrophilic polyoxyethylene polymerization degree is n=8 and 25, and its mass ratio is 10 : 1;

[0035] The anionic surfactant is a combination of phosphate and carboxylate with a mass ratio of 4:0.5.

[0036] The degree of polymerization of the polyethylene glycol is n=200-600 and 5000, wherein the combination ratio of n=200-600 a...

Embodiment 2

[0041] A wetting and penetrating agent for hard surfaces and textiles, prepared from the following ingredients:

[0042] Isomerized alcohol polyoxyethylene ether 5kg,

[0043] Fatty alcohol polyoxyethylene ether 20kg,

[0044] Anionic surfactant 3kg,

[0045] polyethylene glycol 20kg,

[0046] Distilled water 52kg.

[0047] The isomerized alcohol polyoxyethylene ether, its hydrophobic base isomerized alcohol is C10; its hydrophilic base polyoxyethylene polymerization degree is n=9;

[0048] The fatty alcohol alcohol polyoxyethylene ether, its hydrophobic fatty alcohol is C12-14; its hydrophilic polyoxyethylene polymerization degree is n=13;

[0049] The anionic surfactant is a sulfonate.

[0050] The degree of polymerization of the polyethylene glycol is n=400.

[0051] Its preparation process is the same as that of the first embodiment and will not be repeated here.

Embodiment 3

[0053] A wetting and penetrating agent for hard surfaces and textiles, prepared from the following ingredients:

[0054] Isomerized alcohol polyoxyethylene ether 35kg,

[0055] Fatty alcohol polyoxyethylene ether 27.5kg,

[0056] Anionic surfactant 7kg,

[0057] polyethylene glycol 20kg,

[0058] Distilled water 10.5kg.

[0059] The isomerized alcohol polyoxyethylene ether, its hydrophobic base isomerized alcohol is C10; its hydrophilic base polyoxyethylene polymerization degree is n=35;

[0060] The fatty alcohol alcohol polyoxyethylene ether, its hydrophobic fatty alcohol is C8; its hydrophilic polyoxyethylene polymerization degree is n=8;

[0061] The anionic surfactant is phosphate.

[0062] The degree of polymerization of the polyethylene glycol is n=1000.

[0063] Its preparation process is the same as that of the first embodiment and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com