Permeation consolidation type solvent-free epoxy anticorrosive coating, and preparation method and application thereof

An epoxy anti-corrosion coating, solvent-free technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of lack of permeability, inability to improve concrete compactness, insufficient coating adhesion, etc. Wetting ability, excellent corrosion resistance and mechanical properties, the effect of reducing corrosion factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

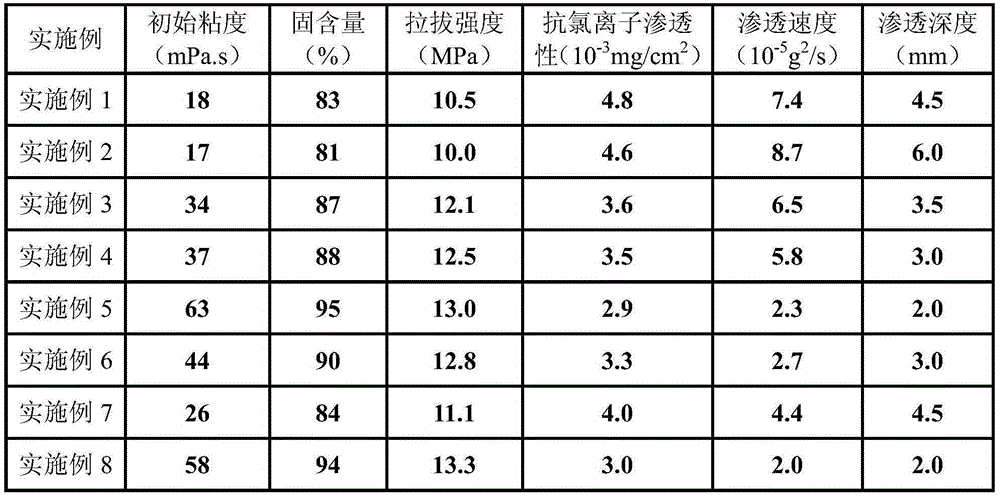

[0041] 28 parts of epoxy resin F-44, 25 parts of enhanced reactive solvent neopentyl glycol diglycidyl ether, 25 parts of enhanced reactive solvent butyl glycidyl ether, 19 parts of penetrating reactive solvent isophorone , 1 part of interface modifier CT-114 and 2 parts of penetration enhancer sodium lauryl polyoxyethylene ether sulfate were stirred and mixed at 500 rpm for 15 minutes to obtain component A; 39 parts of functional curing agent ethylenediamine, 30 parts Curing regulator 591 # , 12 parts of bifunctional curing agent T-31, 17 parts of curing accelerator triphenylphosphine, and 2 parts of condensation catalyst phosphazene were stirred and mixed for 15 minutes at 300 rpm to obtain component B; when used, components A and B were mixed in a ratio of 100:24 Mix by weight ratio, and stir at 200 rpm for 10 minutes to obtain a self-permeable and consolidated epoxy anticorrosion coating; the stated parts are parts by weight. The performance test results of the coating ar...

Embodiment 2

[0043] 18 parts of epoxy resin E-51, 27 parts of enhanced reactive solvent glycerol triglycidyl ether, 20 parts of penetrating reactive solvent diacetone alcohol, 30 parts of penetrating reactive solvent acetone, 2 parts of interface modification Agent KH560, 2 parts of interface modifier CT-56, 0.5 part of penetration enhancer fatty alcohol polyoxyethylene ether AEO-9, 0.5 part of penetration enhancer cetyltrimethylammonium bromide, stirred and mixed at 500rpm for 15min, Get the first component; 22 parts of functional curing agent diethylenetriamine, 30 parts of curing regulator 593 # , 33 parts of dual-function curing agent 810 # , 6 parts of curing accelerator methyltetrahydrophthalic anhydride, 8 parts of curing accelerator dimethylaniline, 1 part of condensation catalyst thiosemicarbazide were stirred and mixed at 300rpm for 15min to obtain component B; 33% by weight, and stirred at 200rpm for 10min to obtain a self-permeable and consolidated epoxy anticorrosion coating;...

Embodiment 3

[0045] 42 parts of epoxy resin F-44, 11 parts of enhanced reactive solvent butyl glycidyl ether, 20 parts of permeable reactive solvent methyl isobutyl ketone, 20 parts of permeable reactive solvent diacetone alcohol, 5 parts Interface modifier KH570, 2 parts of penetration enhancer alkyl trimethyl quaternary ammonium bromide (hexadecyl trimethyl ammonium bromide) were stirred and mixed at 500 rpm for 15 minutes to obtain component A; 5 parts of functional curing agent Triethylenetetramine, 14 parts curing regulator 650 # , 14 parts curing regulator 593 # , 25 parts of dual-function curing agent 810 # , 25 parts of dual-function curing agent 910 # , 5 parts of curing accelerator triethanolamine, 7 parts of curing accelerator 2,4,6-tris(dimethylaminomethyl)phenol, and 5 parts of condensation catalyst cinchona were stirred and mixed for 15 minutes at 300 rpm to obtain component B; When using, mix A and B components in a weight ratio of 100:7, and stir at 200 rpm for 10 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com