Expandable Sleeve

a sleeve and expandable technology, applied in the direction of sealing/packing, fluid removal, borehole/well accessories, etc., to achieve the effect of reducing the tendency of the tubular body to relax and thin material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Expandable sleeves in accordance with the invention are particularly useful in wells such as oil and gas wells. They can be applied during the well construction process to stabilise the formation through which the well is drilled, or after completion to repair damage or to seal off perforations that are producing unwanted fluids. Other uses will be apparent.

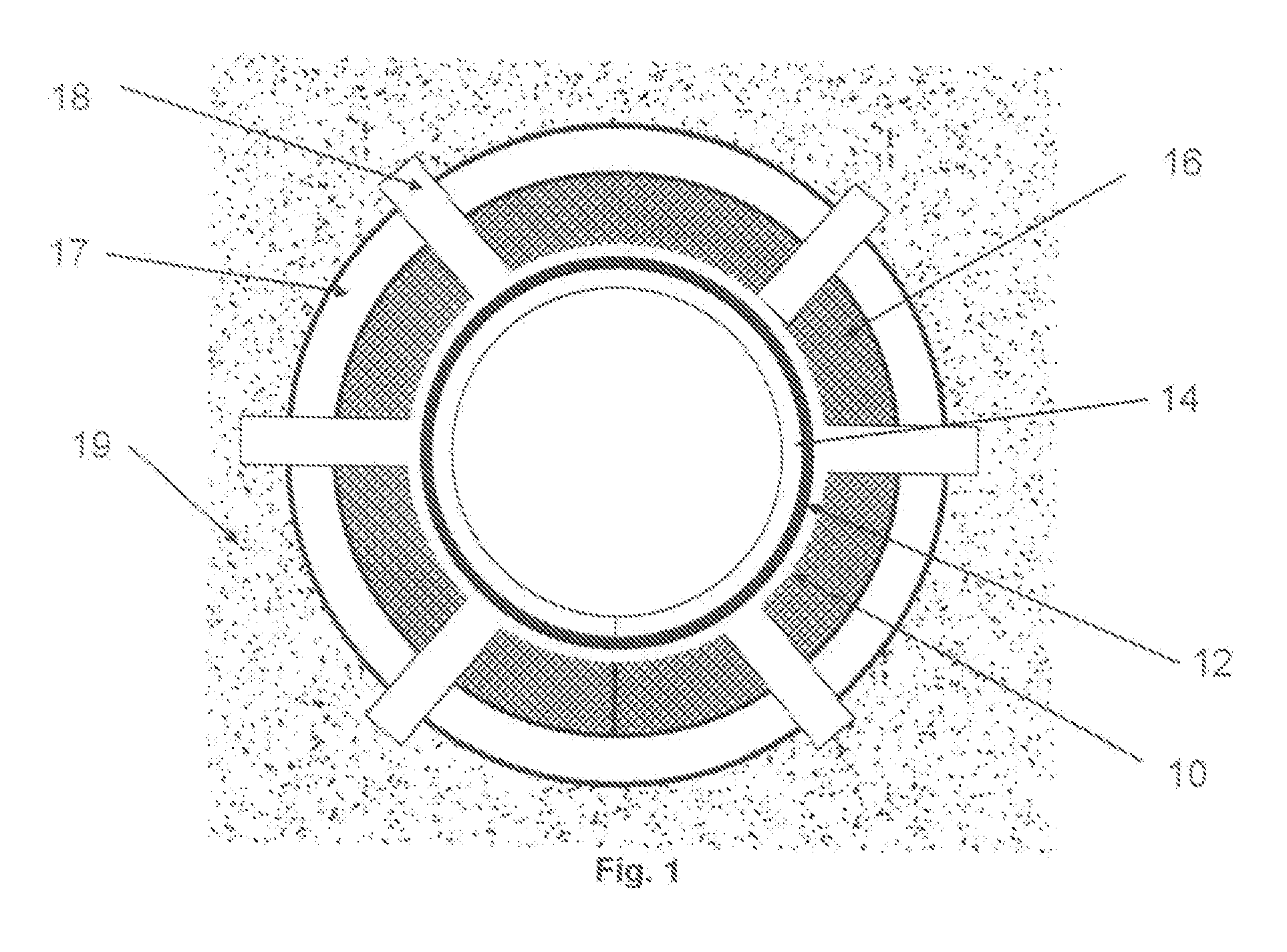

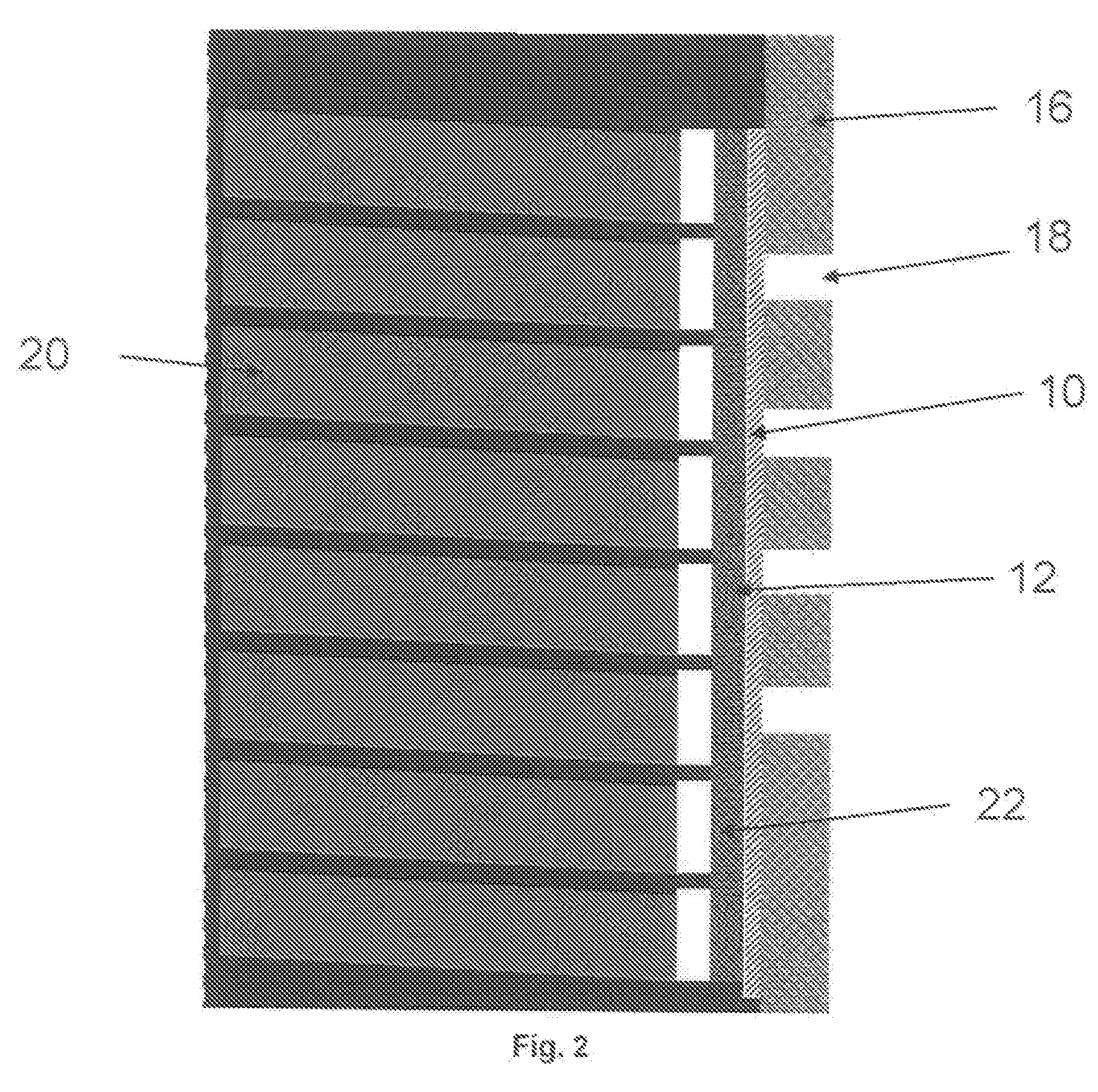

[0036] Referring to FIGS. 1-3, the embodiment of the invention shown comprises a sleeve constructed in three layers; an outside layer 10, and intermediate layer 12 and an internal layer 14. In FIGS. 1-3, the sleeve is installed in a well that has been completed with a steel casing 16 secured in the well by cement 17 to provide zonal isolation and physical support. Communication with the producing formation 19 is via perforations 18 formed through the casing in the usual manner.

[0037] The outside layer 10 comprises a thin layer of a sealing compound such as natural or synthetic rubber. The exact material will be selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com