Taste maintenance method for ice cream machine

An ice cream machine and ice cream technology, applied to frozen desserts, program control in sequence/logic controllers, instruments, etc., can solve problems such as short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

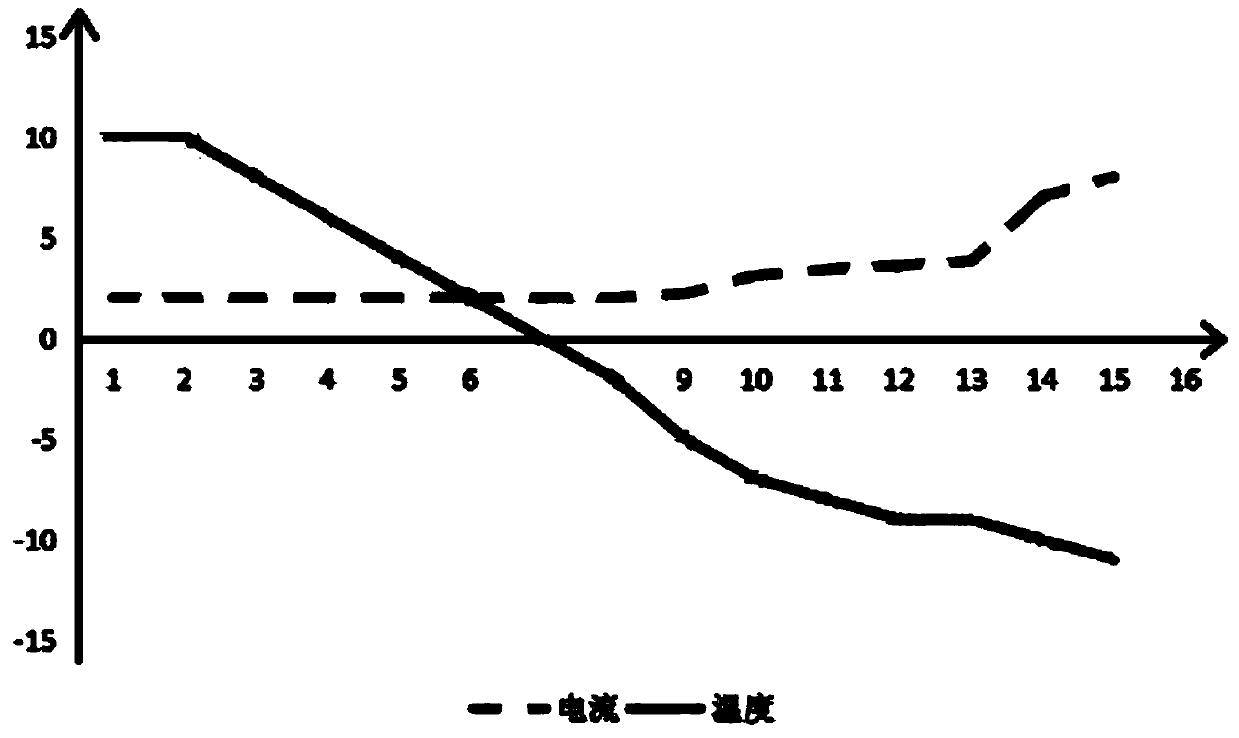

[0078] Such as figure 2 As shown, the present invention discloses a method for maintaining the mouthfeel of an ice cream machine. The ice cream machine is provided with a freezing cylinder, a stirring device, a main refrigeration system and a control system. The control system controls the periodic work of the ice cream machine: first , enter the refrigeration state, that is, control the main refrigeration system to refrigerate the ice cream material in the freezing cylinder, and control the stirring device to stir the ice cream material in the freezing cylinder; then, when the ice cream material in the freezing cylinder When the ice cream material reaches the preset hardness or preset viscosity value, it enters the standby state, that is, controls the main refrigeration system and the stirring device to stop; finally, when the time of entering the standby state reaches the preset time, this cycle ends, and the ice cream is restarted. Enter the cooling state to start the next...

Embodiment 2

[0089] On the basis of the first embodiment above, the second embodiment also adopts the following preferred structure:

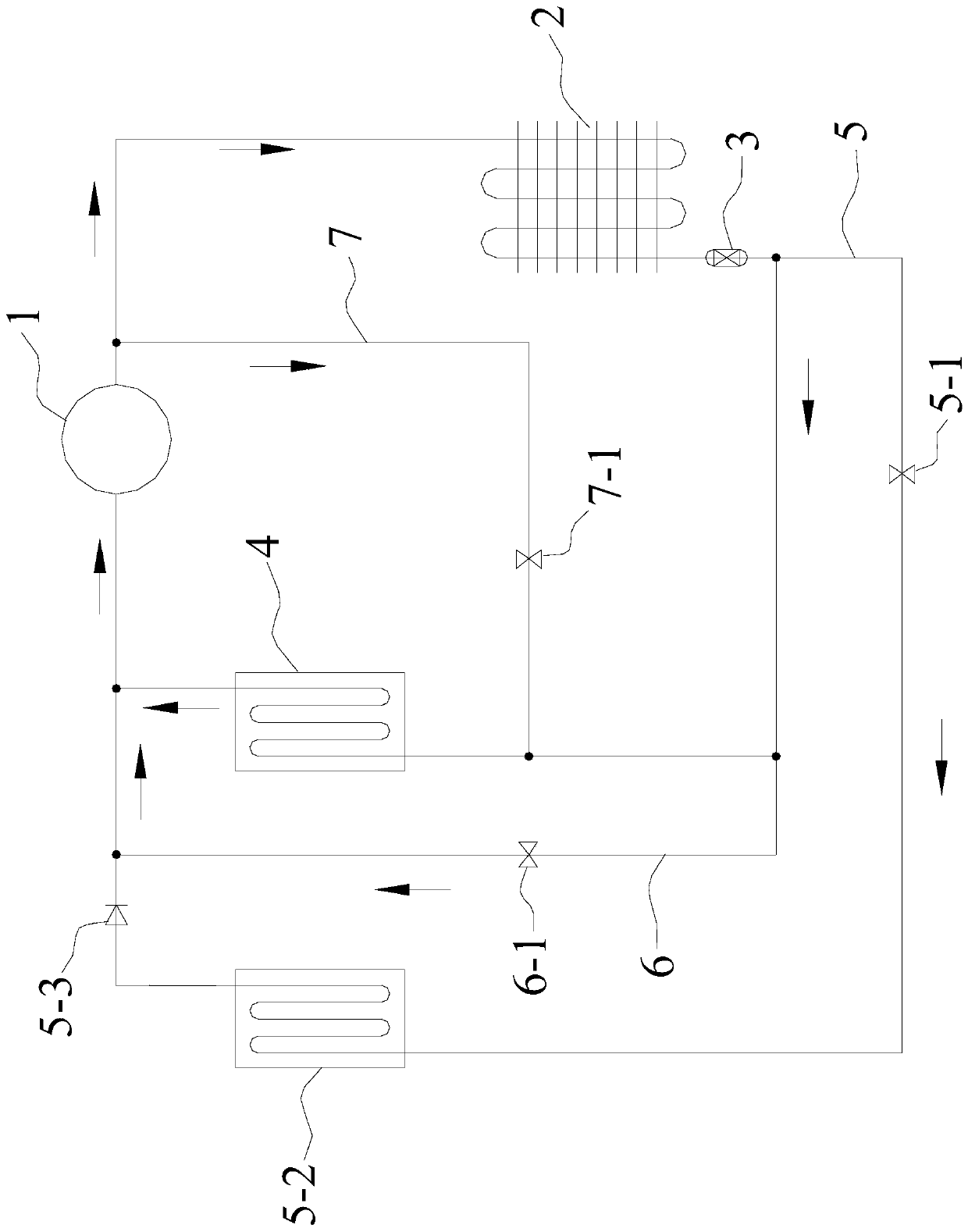

[0090] The main refrigeration system is provided with a compressor 1, a condenser 2, a throttle valve 3 and a freezing cylinder evaporator 4 connected in sequence by pipelines, and the freezing cylinder evaporator 4 is used to refrigerate the ice cream material in the freezing cylinder ; This part is a conventional refrigerating system, and its working principle is: after the low-pressure liquid refrigerant absorbs the heat of the ice cream material in the freezing cylinder in the freezing cylinder evaporator 4, it is vaporized into low-temperature and low-pressure steam, and is vaporized by the compressor. 1. Inhaled and compressed into high-pressure and high-temperature steam and then discharged into the condenser 2. In the condenser 2, it releases heat to the cooling medium (water or air) and condenses into a high-pressure liquid refrigerant, and then pas...

Embodiment 3

[0106] On the basis of the second embodiment above, the method for the control system to judge that the ice cream material in the freezing cylinder is in the forming solid state is as follows:

[0107] The control system collects the rotation speed of the stirring motor in real time, and the stirring motor is used to drive the stirring device to stir the ice cream material in the freezing cylinder;

[0108] The control system is preset with a rotational speed threshold R1 and a rotational speed threshold Rn, wherein the rotational speed threshold R1 is the rotational speed value of the stirring motor when the ice cream material changes from a solid-liquid coexistence state to an all-solid state, and the rotational speed threshold Rn is the rotation speed value of the stirring motor when the ice cream material reaches the preset hardness or preset viscosity value;

[0109] When the rotation speed of the stirring motor is between the rotation speed threshold R1 and the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com