No-clean lead-free solder scaling powder and preparation method thereof

A lead-free solder and flux technology, applied in the direction of welding equipment, welding/cutting medium/material, welding medium, etc. Solve problems such as poor wettability, achieve less post-soldering residue, less residue on the board surface, and improve solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

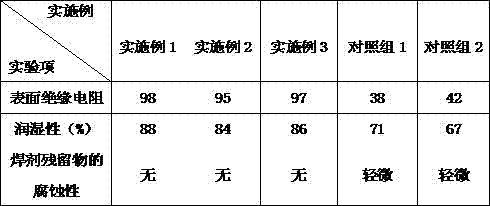

Examples

Embodiment 1

[0022] A no-cleaning lead-free soldering flux, which includes the following raw materials in parts by weight: 20 parts of the super-grade rosin resin, 5 parts of organic acid activators, 2.5 parts of nonionic surfactants, 1 part of antioxidant, wetting 0.8 parts of strengthening agent, 1 part of corrosion inhibitor, 80 parts of organic solvent.

[0023] Wherein, the super-grade rosin resin is one or a mixture of polymerized rosin, hydrogenated rosin, disproportionated rosin, polyacid-modified rosin, acrylic acid-modified rosin and modified water-soluble rosin.

[0024] Wherein, the organic acid active agent is one or a mixture of two or more of succinic acid, glutaric acid, itaconic acid, o-hydroxybenzoic acid, sebacic acid, pimelic acid, malic acid and succinic acid.

[0025] Wherein, the nonionic surfactant is octylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, isooctylphenol polyoxyethylene ether, nonionic fluorosurfactant, perfluorooctylamide quaternary...

Embodiment 2

[0034] A no-cleaning lead-free soldering flux, which comprises the following raw materials in parts by weight: 10-30 parts of super-grade rosin resin, 2 parts of organic acid active agent, 0.5 part of nonionic surfactant, 0.1 part of antioxidant, wetting 0.1 part of strengthening agent, 0.05 part of corrosion inhibitor, 75 parts of organic solvent.

[0035] Wherein, the super-grade rosin resin is one or a mixture of polymerized rosin, hydrogenated rosin, disproportionated rosin, polyacid-modified rosin, acrylic acid-modified rosin and modified water-soluble rosin.

[0036] Wherein, the organic acid active agent is one or a mixture of two or more of succinic acid, glutaric acid, itaconic acid, o-hydroxybenzoic acid, sebacic acid, pimelic acid, malic acid and succinic acid.

[0037]Wherein, the nonionic surfactant is octylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, isooctylphenol polyoxyethylene ether, nonionic fluorosurfactant, perfluorooctylamide quatern...

Embodiment 3

[0046] A no-cleaning lead-free solder flux, which comprises the following raw materials in parts by weight: 30 parts of super-grade rosin resin, 8 parts of organic acid active agent, 5 parts of nonionic surfactant, 2 parts of antioxidant, and wetting enhancer 1.5 parts, 0.5 parts of corrosion inhibitor, 85 parts of organic solvent.

[0047] Wherein, the super-grade rosin resin is one or a mixture of polymerized rosin, hydrogenated rosin, disproportionated rosin, polyacid-modified rosin, acrylic acid-modified rosin and modified water-soluble rosin.

[0048] Wherein, the organic acid active agent is one or a mixture of two or more of succinic acid, glutaric acid, itaconic acid, o-hydroxybenzoic acid, sebacic acid, pimelic acid, malic acid and succinic acid.

[0049] Wherein, the nonionic surfactant is octylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, isooctylphenol polyoxyethylene ether, nonionic fluorosurfactant, perfluorooctylamide quaternary ammonium sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com