Patents

Literature

42results about How to "Enhance wetting power" patented technology

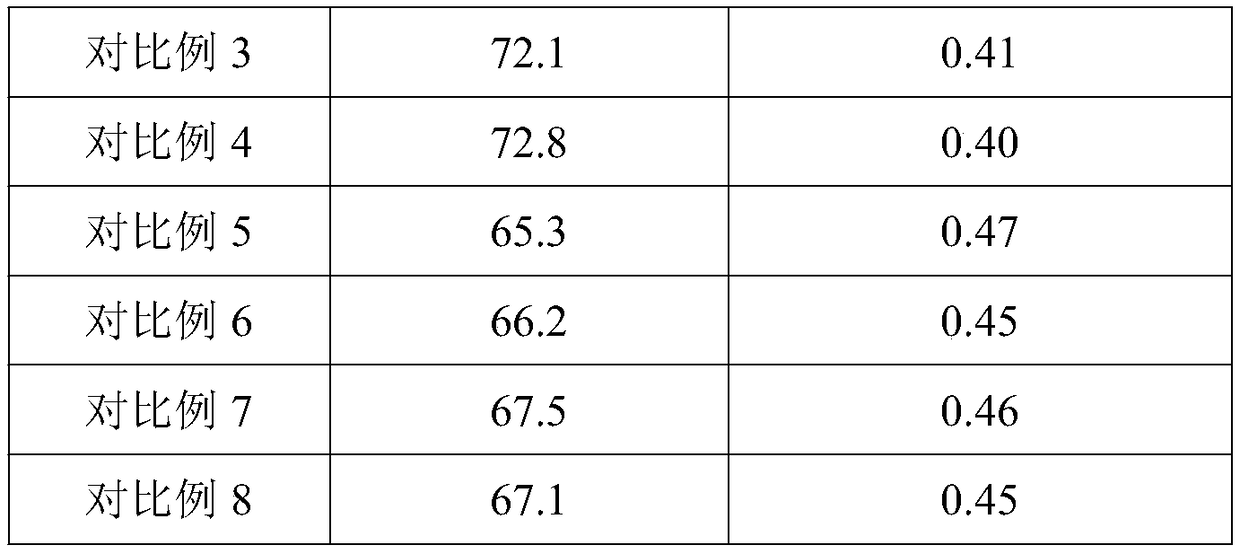

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal salt-free sealing agent for aluminum alloy anodic oxide film

ActiveCN101864589AImprove corrosion resistanceGood gloss and color retentionSurface reaction electrolytic coatingCobaltOrganic compound

The invention provides a metal salt-free sealing agent for an aluminum alloy anodic oxide film, belonging to the technical field of aluminum alloy anodic oxide film post treatment. The sealing agent of the invention is prepared by water solution composed of 1.0-10g / L of a hydration accelerator, 0.01-2g / L of a wetting agent, 0.01-3g / L of an ash inhibitor and 1-15g / L of a pH buffering agent, wherein the pH of workpiece fluid is 5.5-6.5, the operating temperature is 70-90 DEG C, and the sealing speed is 1.0-2.0min / um. The metal salt-free sealing agent creatively adopts organic compounds which are easily subject to biodegradation, does not contain any metal ions of nickel, cobalt, magnesium, calcium, lithium and the like as well as fluorinions, and obtains satisfactory sealing effect of the nano-pores of the aluminum alloy anodic oxide film by virtue of the scientific and coordinated component formula of the water solution; the aluminum alloy anodic oxide film obtained by seal treatment through the sealing agent has the advantages of good corrosion resistance, capability of meeting the requirements of GB 14952.1-94, good light-protection and color-protection properties of a film layer, no ash and pruina, no water stain after drying as well as light flowing color and small color difference change in case of sealing the organic dyeing film; and the metal salt-free sealing agent is widely applicable to sealing treatment of an original-color anodic oxide film, an electrolytic coloring anodic oxide film, a hard oxide film and a dyeing anodic oxide film.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Cleaning-free lead-free solder soldering fluid not containing halide

ActiveCN101367160AReduce surface tensionEnhance wetting powerWelding/cutting media/materialsSoldering mediaSolventCorrosion

The invention discloses halogen-free cleaning-free soldering flux for lead-free solder, which comprises the compositions in percentage by weight: 1.5 to 4.5 percent of organic acid activator, 0.5 to 8.5 percent of high-quality abietic resin, 0.3 to 1.5 percent of activated reinforcer, 0.2 to 0.8 percent of surfactant, 3.0 to 15.0 percent of wet strengthening agent, and the balance being solvent isopropanol, absolute ethyl alcohol or deionized water. The soldering flux fully meets various regulation requirements for limiting halogen. The soldering flux developed by using a novel material which does not contain the halogen can scientifically reduce the surface tension of the lead-free solder, strengthen the wetting power of the lead-free solder, improve the solderability, can be compatible with a plurality of welding materials, and has no corrosion effect on lead-free solder alloy; composing materials are volatilized by stages during the welding process, so after the welding, the surface of a PCB board has less residue, even spread, less ion residue, and reliable electrical insulating property, and does not need to be washed; and the soldering flux is a novel environment-friendly halogen-free cleaning-free soldering flux for the lead-free solder.

Owner:深圳市唯特偶新材料股份有限公司

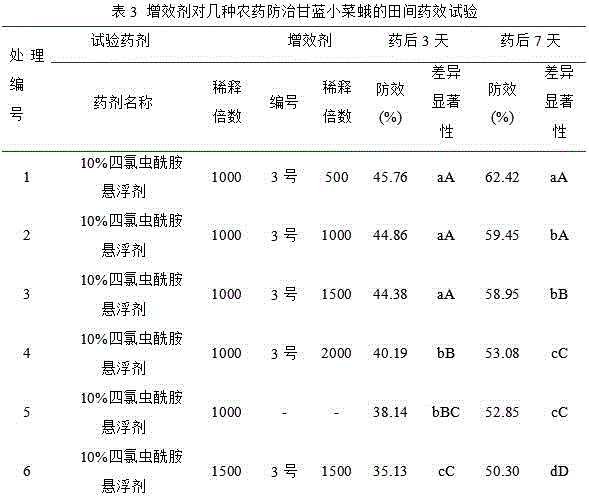

Preparation method and application of botanical pesticide synergist

The invention discloses a preparation method and application of botanical pesticide synergist. The preparation method comprises the steps that ethanol is added to rosin or pine gum, the mixture is stirred and dissolved, and filtering is carried out to obtain a rosin or pine gum solution; alkali liquor is added to the rosin or pine gum solution for reacting, an emulgator is added, and the synergist is obtained after filtering. The raw materials are cheap and easy to obtain, the preparation route is simple, no special reaction equipment is needed, energy is saved, environment friendliness is achieved, cost is low, the yield is high, and the synergist is very suitable for large-scale production. The obtained synergist can reduce the surface tension of pesticide; after the synergist is compounded with multiple kinds of pesticide, acaricide, herbicide and other pesticide, the preventing and control effect of the pesticide can be improved, the amount of adopted pesticide can be reduced, the advantages of being broad in spectrum, efficient, cheap and the like are achieved, good popularization and application prospects are achieved, and economic, social and environmental benefits are remarkable.

Owner:GUANGXI NORMAL UNIV

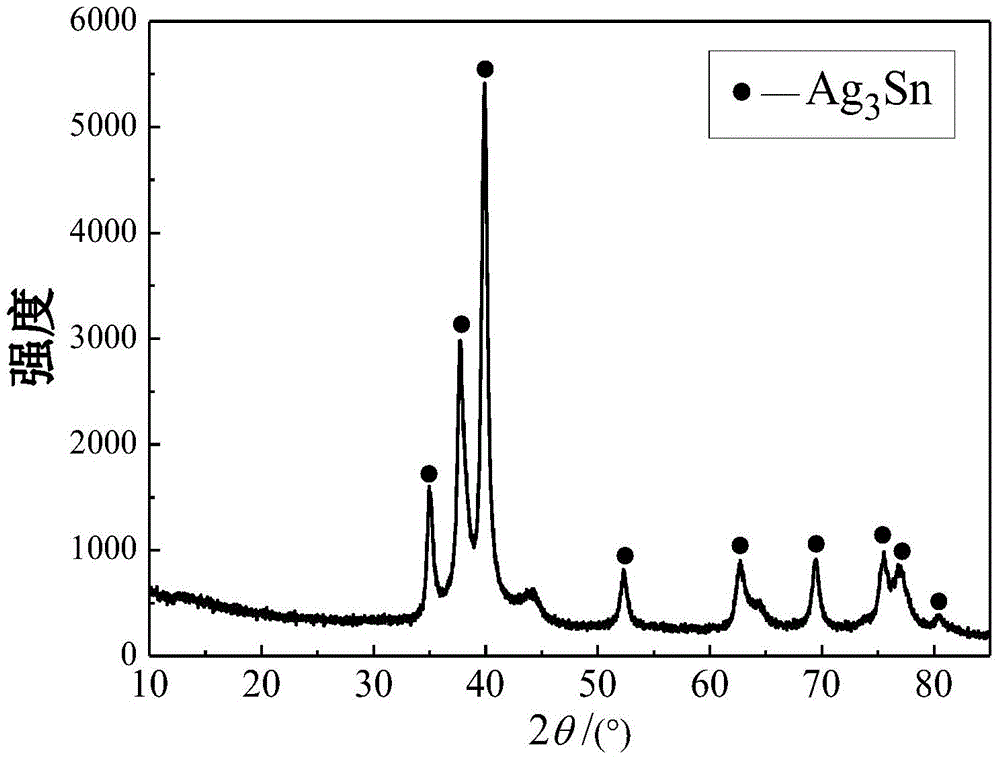

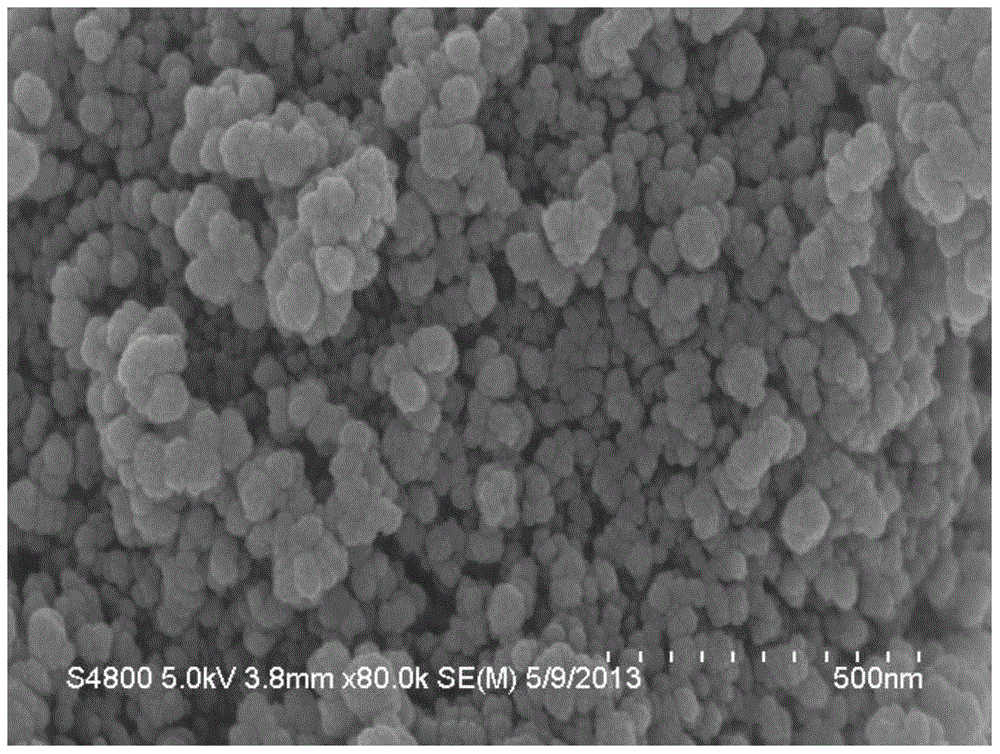

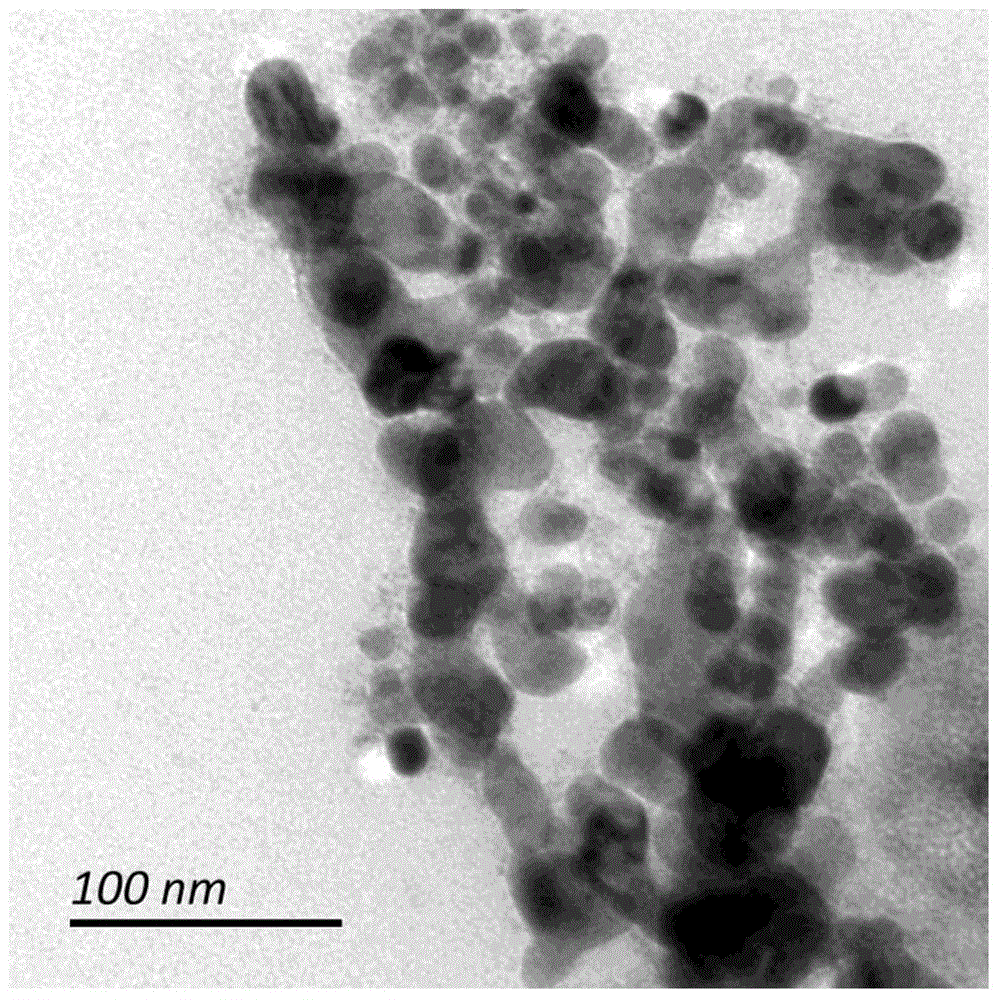

Nanometer Ag3Sn particle reinforced composite lead-free soldering paste and preparation method thereof

InactiveCN104014947AImprove mechanical propertiesLow melting pointWelding/cutting media/materialsSoldering mediaNanoparticleElectronics manufacturing

The invention discloses nanometer Ag3Sn particle reinforced composite lead-free soldering paste and a preparation method thereof, belonging to the technical field of welding materials for assembly of electronic devices. The nanometer Ag3Sn particle reinforced composite lead-free soldering paste is prepared from nanometer Ag3Sn particles and low-Ag lead-free soldering paste through long-time mechanical stirring, and the nanometer Ag3Sn particles are prepared by a chemical reduction method. The preparation method is simple and convenient to operate and has good repeatability. The composite lead-free soldering paste is superior to non-reinforced low-Ag lead-free soldering paste in the processing properties such as melting point, wettability and welding joint mechanical property, and can meet the technological requirements of low cost and high performance on soldering paste in the current electronics manufacturing industry to a great degree.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Halogen-free low-temperature tinol

InactiveCN103302422AEnhance wetting powerImprove acceleration performanceWelding/cutting media/materialsSoldering mediaActive agentFilm-forming agent

The invention discloses halogen-free low-temperature tinol which comprises the following components by mass percent: 85-95% of solder powder and 5-15% of scaling powder, wherein the solder powder is Sn-Bi series solder powder, and the scaling powder comprises the following components by mass percent: 35-45% of solvent, 35-45% of film forming agent, 5-10% of active agent, 1-5% of thixotropic agent, 1-2% of antioxygen and 1-3% of the balance. With the adoption of the mode, the stability of the tinol can be improved; the tinol has very high wetting power and a very high expansion rate; and no residue is remained after soldering.

Owner:WUXI CAIYUN MACHINERY & EQUIP

Soldering flux for circuit board patch and preparation method thereof

InactiveCN107363434AGood welding performanceImprove wetting abilityWelding/cutting media/materialsSoldering mediaAcrylonitrileSuccinic acid

The invention discloses a soldering flux for a circuit board patch. The soldering flux comprises, by weight, 60-80 parts of rosin modified phenolic resin, 30-40 parts of rosin glyceride, 20-30 parts of succinic acid, 10-30 parts of dodecanol ester, 10-20 parts of acrylate, 5-15 parts of benzotriazole, 3-8 parts of benzimidazole, 5-10 parts of acrylonitrile, 2-8 parts of nano-silver, 5-10 parts of phenyl glycidyl ether, 8-15 parts of triethanolamine, 3-8 parts of organic solvents, 2-6 parts of auxiliaries and 40-60 parts of deionized water. The invention provides the soldering flux with good welding performance for the circuit board patch. The soldering flux is high in wettability to solder, can enhance the weldability of the solder, can adapt to the welding temperature of various kinds of solder, has no corrosion effect on solder alloy, has few residues after being welded, is high in insulation resistance, does not need to be cleaned, and is an ideal cleaning-free soldering flux for the solder.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

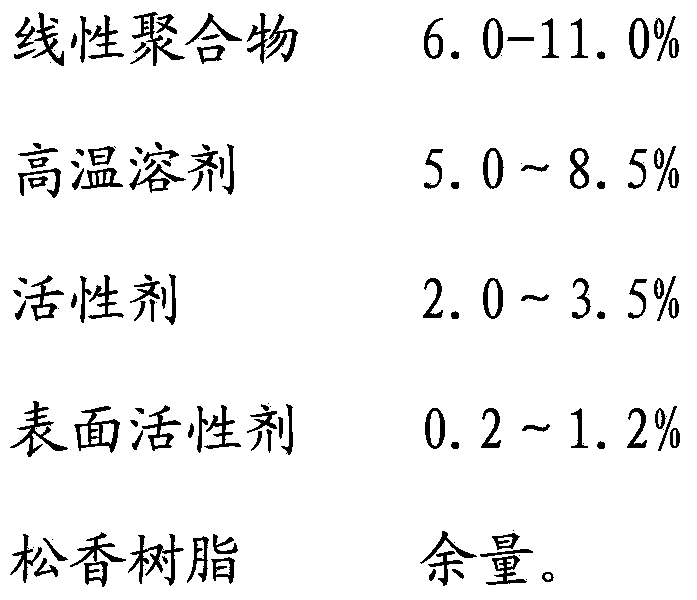

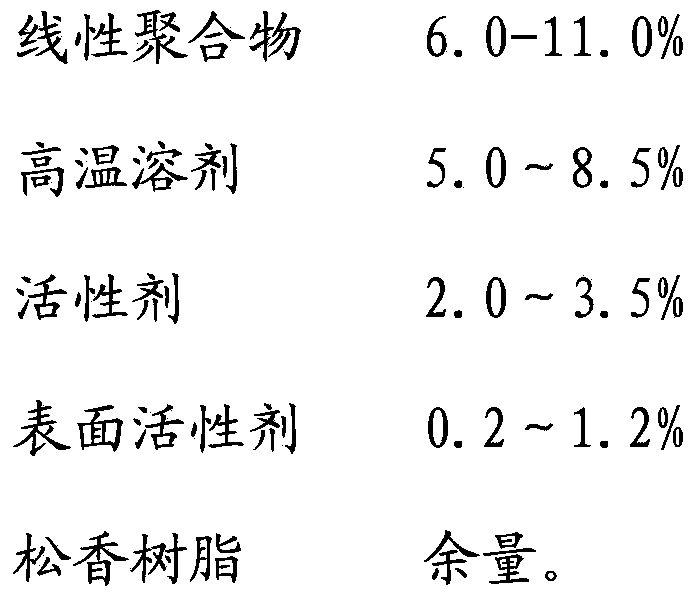

Soldering flux for solder wires for robotic automatic welding and preparation method thereof

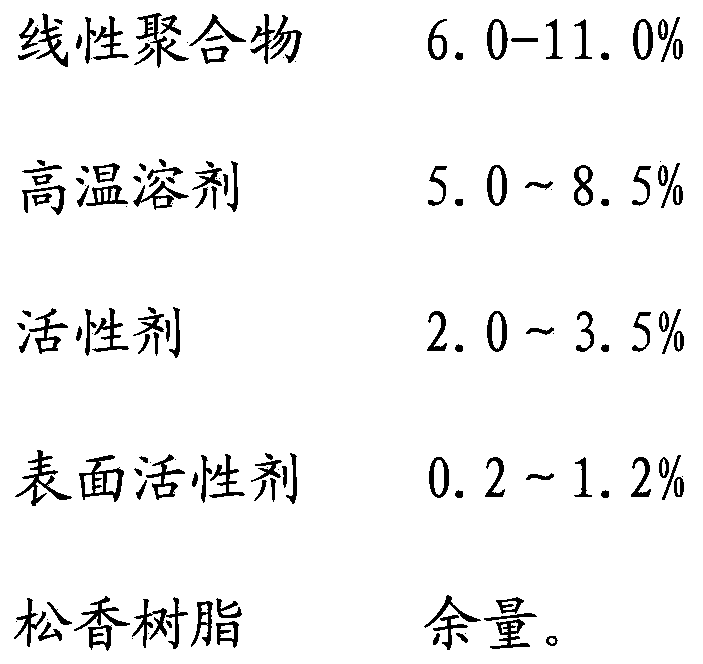

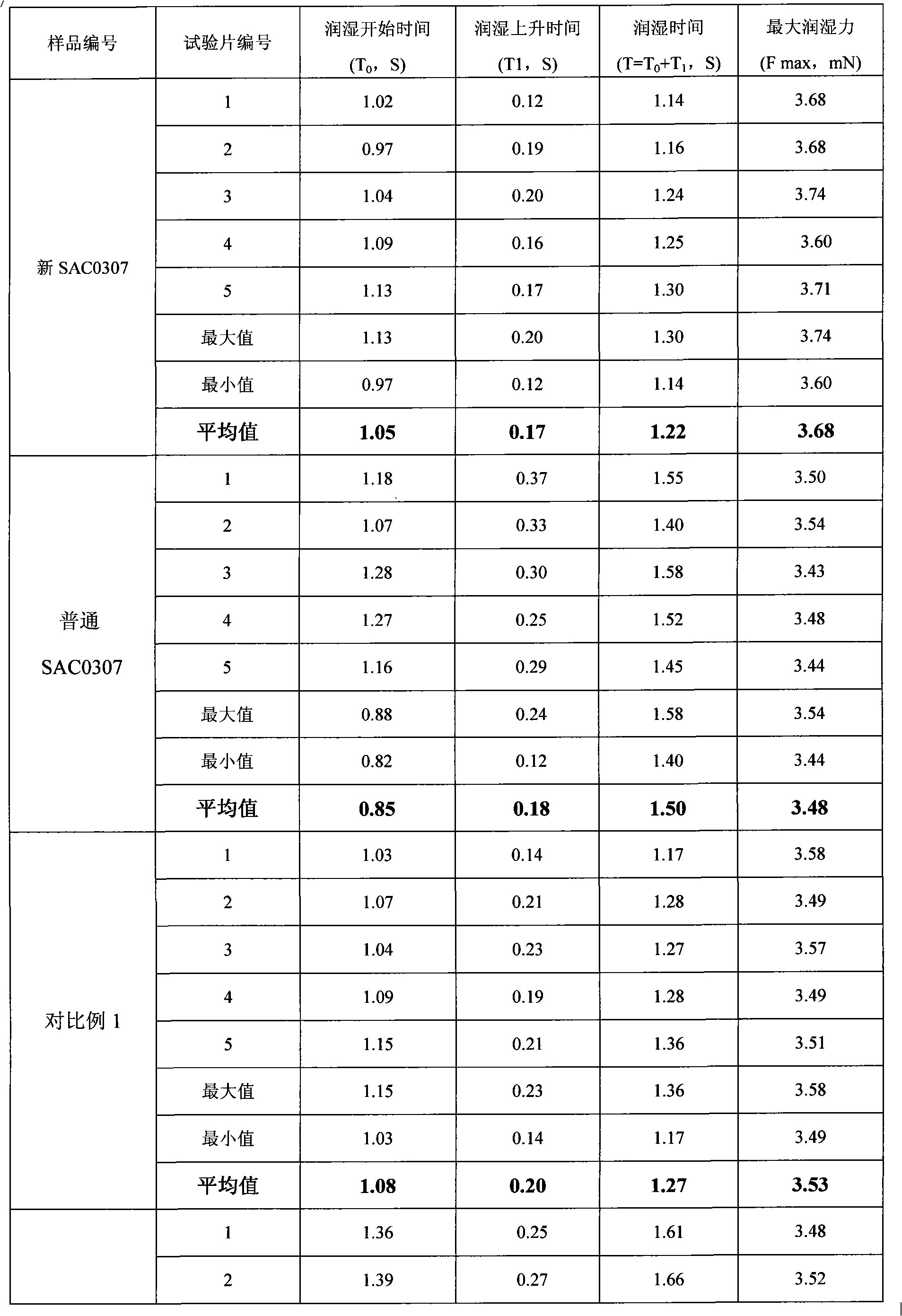

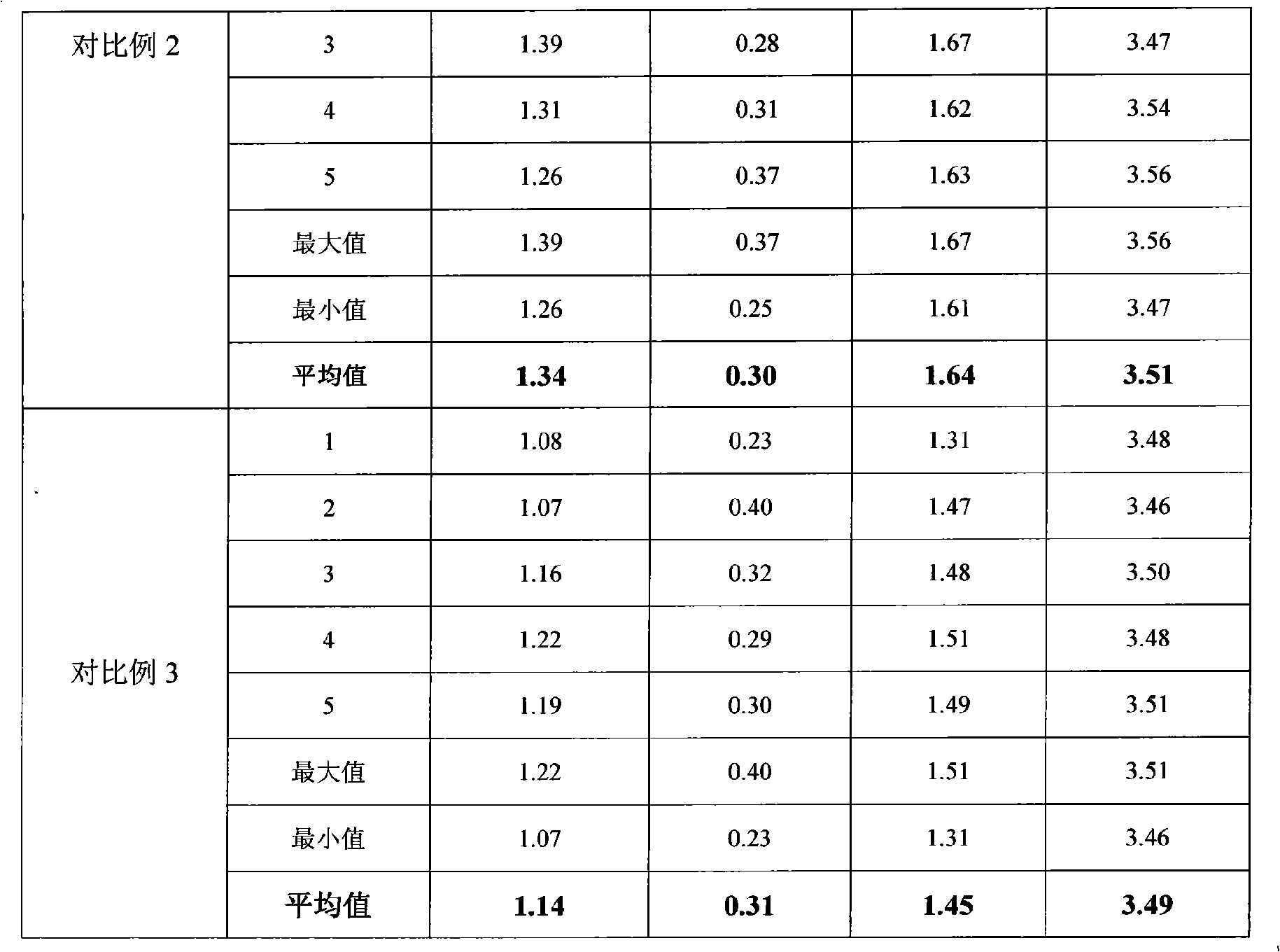

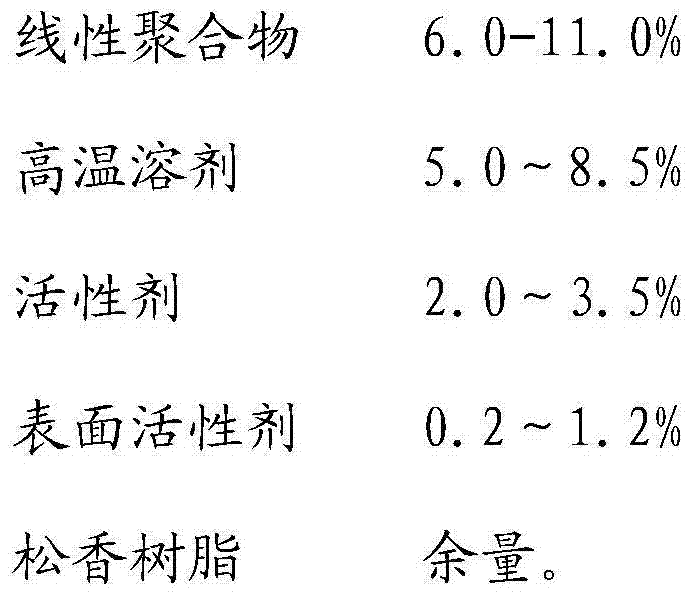

ActiveCN103464932AGood wetting spreadIncrease forceWelding/cutting media/materialsSoldering mediaActive agentRosin

The invention provides soldering flux for solder wires for robotic automatic welding. The soldering flux comprises, by weight, 6.0-11.0% of linear polymer, 5.0-8.5% of high-temperature solvent, 2.0-3.5% of active agent, 0.2-1.2% of surfactant, and the balance of rosin resin. The soldering flux has the advantages that the problem that the flux easily breaks and is easily uneven can be avoided; surface tension of molten solder is reduced, wetting power is increased, weldability of the solder is enhanced, the solder is squeezed to the solder wires at agreeably high temperature and is full and even, and high wetting and expansion rate of the solder wires can be guaranteed; welding defectives such as tin bonding and missing solder during robotic automatic welding can be avoided.

Owner:深圳市唯特偶新材料股份有限公司

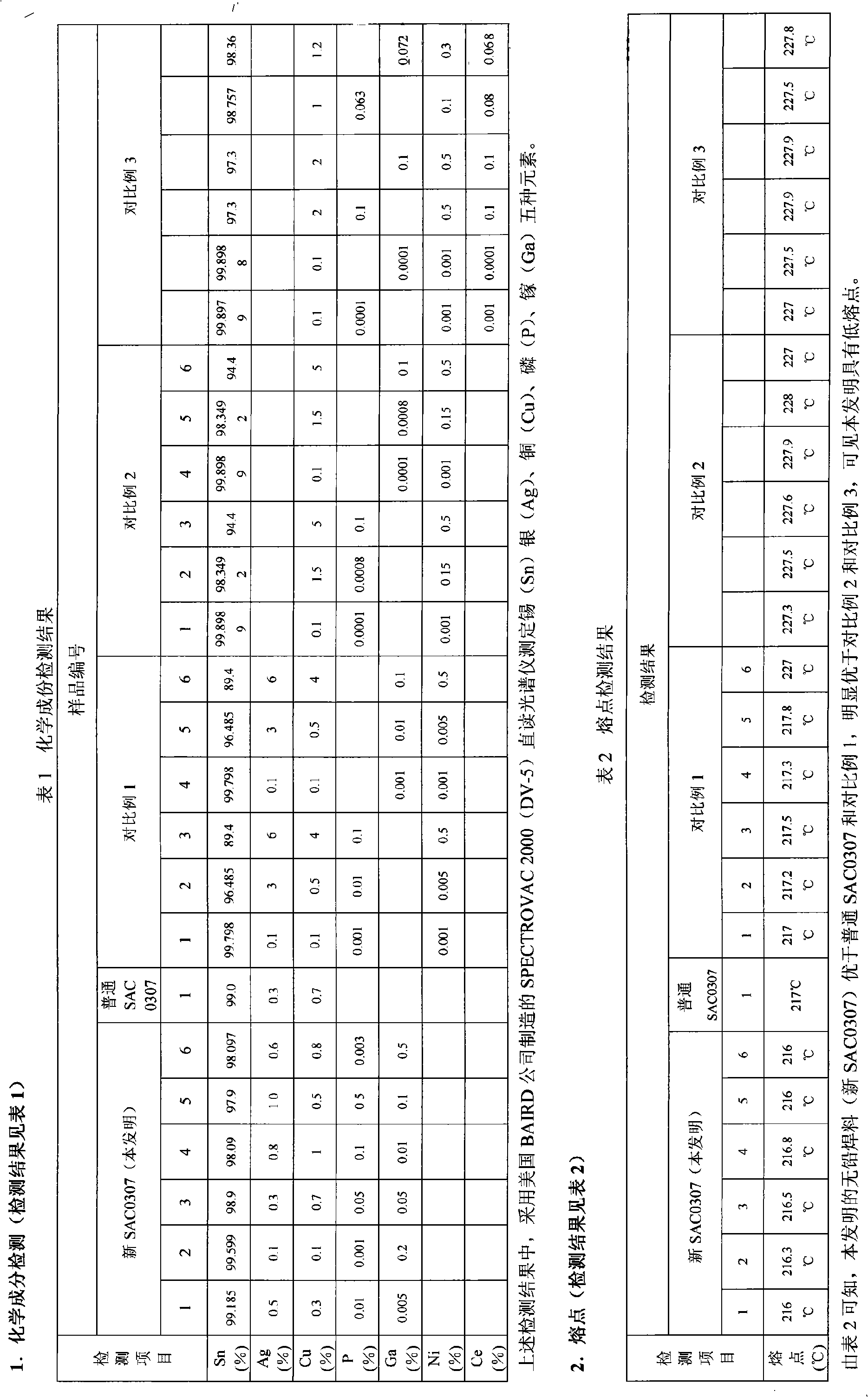

Tin-based lead-free solder and preparing method thereof

ActiveCN101513697AImprove low efficiencyLow efficiencyWelding/cutting media/materialsSoldering mediaPhosphorManganese

The invention relates to a tin-based lead-free solder and a preparing method thereof, the tin-based lead-free solder contains, based on weight percentage, 0.005-0.5% of gallium, 0.1-1% of silver, 0.1-1% of copper, 0.001-0.5% of phosphor and tin as the balance. The method for preparing the tin-based lead-free solder comprises the steps of: first of all, preparing four intermediate alloy ingots including tin-gallium, tin-silver, tin-copper and tin-phosphor; adding the four intermediate alloy ingots according to particular weight parts and then additionally adding the balancing tin; in the meantime, adding the mixture into a manganese alloy pot for melting, and heating up to 450 DEG C; discharging, cooling and casting into the lead-free solder so as to obtain the lead-free solder that contains gallium, silver, copper and phosphor with tin being the balance. The invention has the advantage that the lead-free solder is low in melting point, excellent in wettability, bright in soldering spot, persistent in anti-oxidation under high temperature operation and low in cost.

Owner:宏桥新电子材料(深圳)有限公司

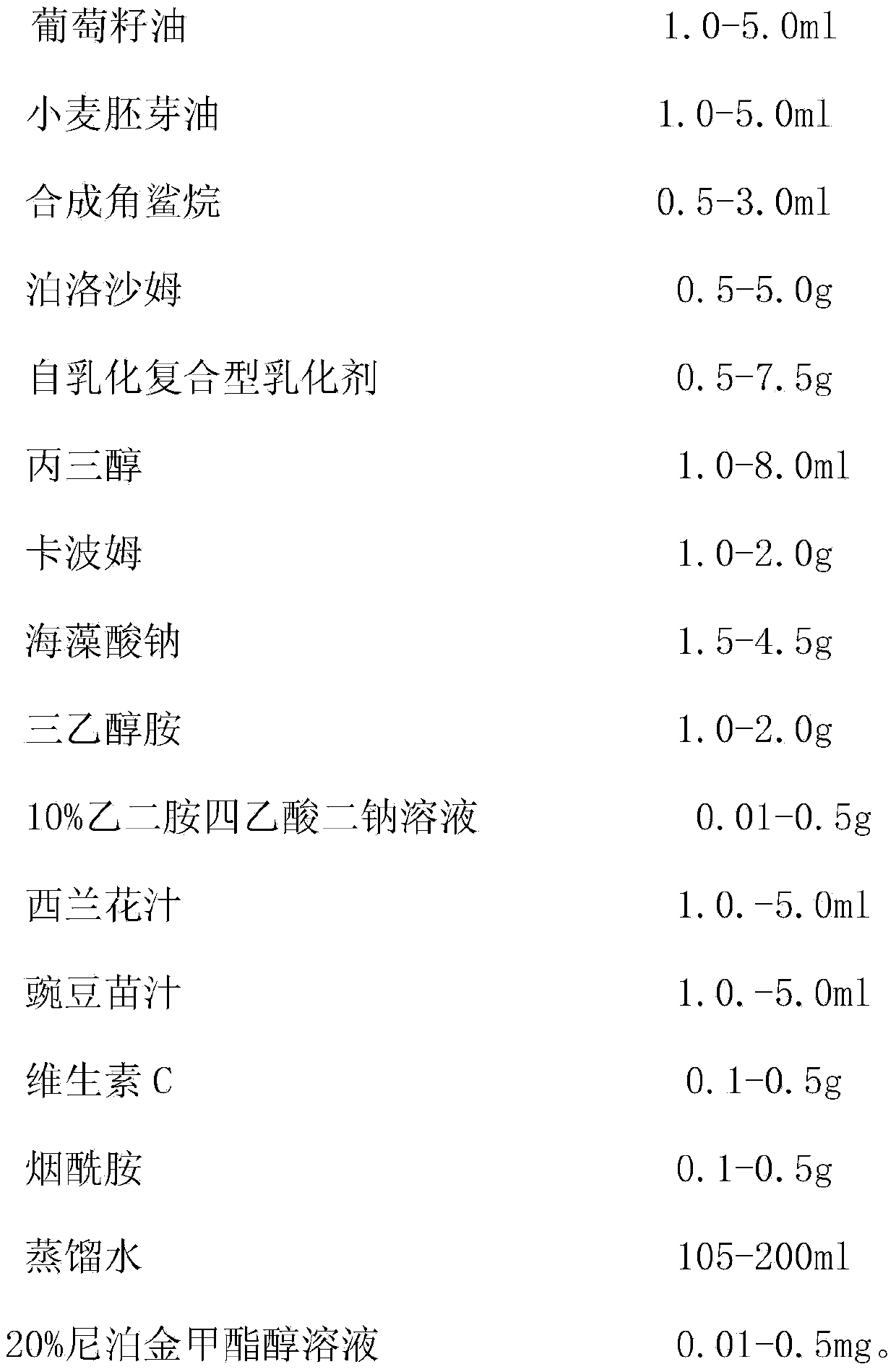

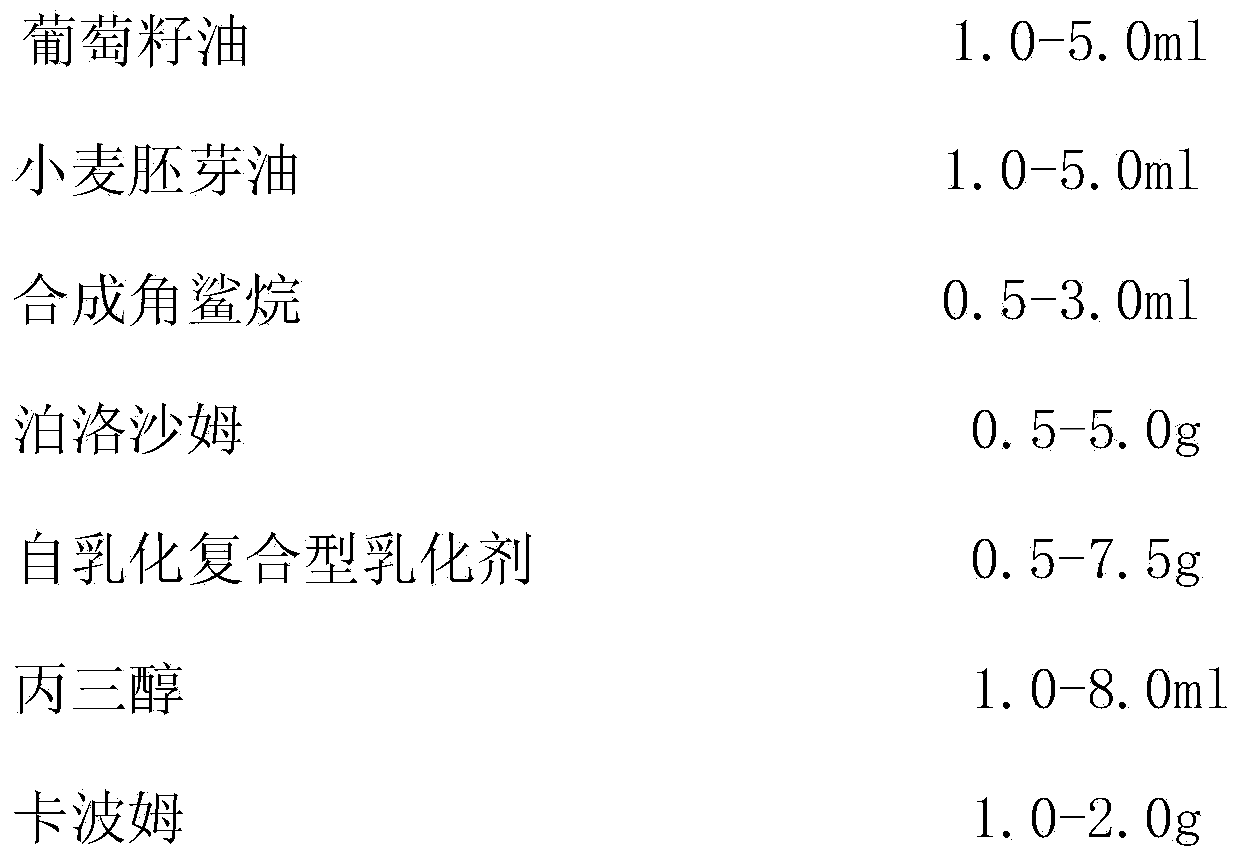

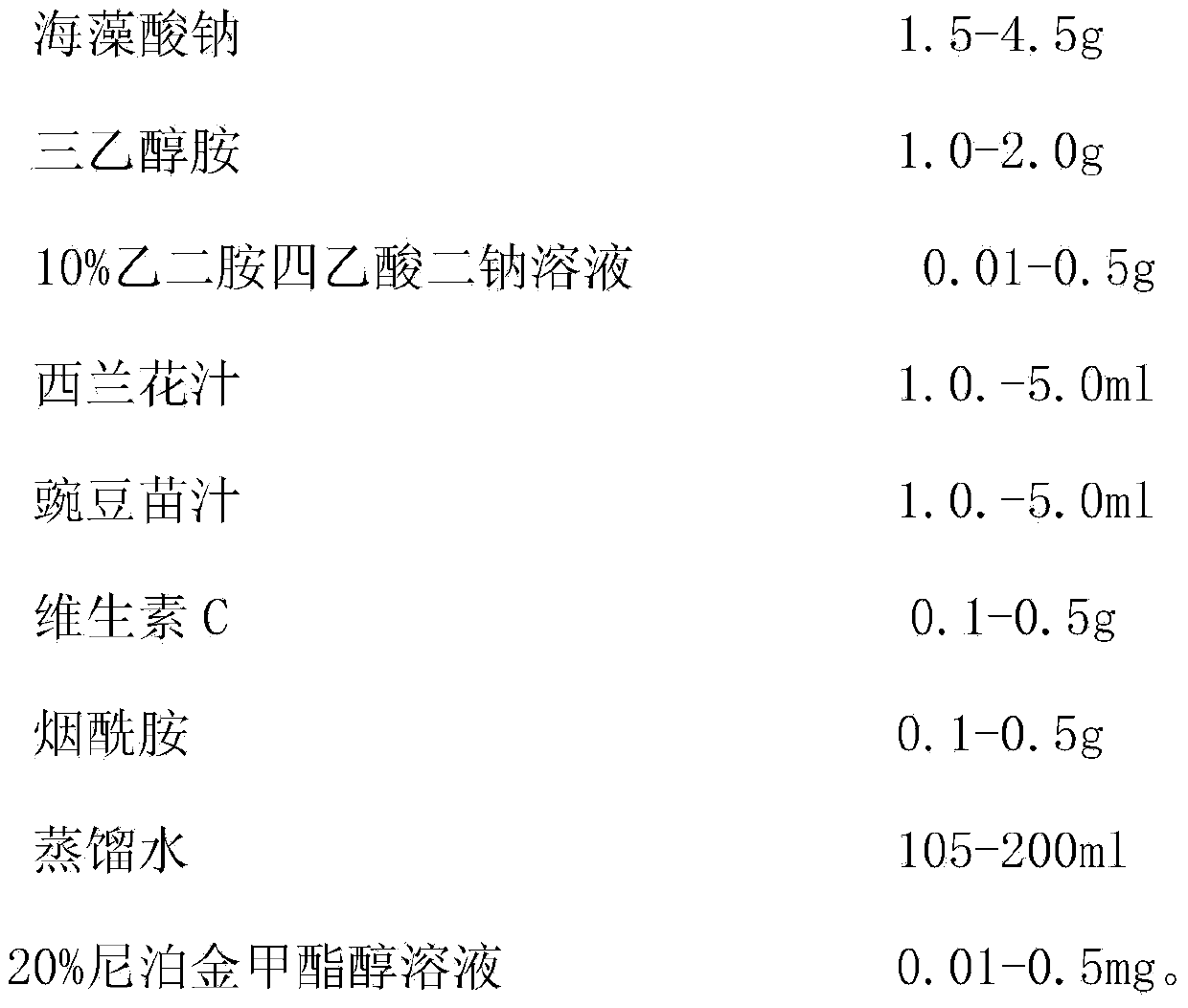

Anti-wrinkle skin-tendering emulsion containing natural component extracts and preparation method thereof

ActiveCN104188859ATo promote metabolismAnti agingCosmetic preparationsToilet preparationsWrinkle skinVitamin C

The invention discloses an anti-wrinkle skin-tendering emulsion containing natural component extracts and a preparation method thereof. The emulsion is prepared from the following substances: grape seed oil, wheat-germ oil, broccoli juice, pea shoot juice, nicotinamide, vitamin C, synthetic squalane, sodium alginate, carbomer, poloxamer, a self-emulsified compound emulsifier, glycerol, triethanolamine, a 10% ethylenediamine tetraacetic acid disodium solution, a 20% methylparaben alcoholic solution and distilled water. Compared with the prior art, the emulsion has the characteristics of mild property and high safety, O / W type emulsion with uniform and fine texture, freshness without greasy feeling can be prepared by adopting a method of combining natural component extracts and plant essential oil. The emulsion is capable of firming skin and smoothing wrinkles, and exerting certain effects of removing spots, whitening and nourishing, so that the tender and moistened activity of skin can be rejuvenized.

Owner:中山市艾奥比生物科技有限公司

Zinc-based soft solder suitable for hot-drip galvanizing repair

ActiveCN104439752AGood antioxidant propertiesGood wetting propertiesWelding/cutting media/materialsSoldering mediaRare-earth elementHot-dip galvanization

The invention relates to a zinc-based soft solder suitable for hot-drip galvanizing repair. Solder alloy comprises, by weight, 50-60 parts of zinc, 0.5-1.5 parts of aluminum, 0.1-0.5 part of rare earth and 38-49 parts of tin. The rare earth is misch metal. After the aluminum and the rare earth are added to the solder, the solder has good oxidation resistance and wetting property, and repair of galvanized steel can be well achieved. The zinc-based soft solder has oxidation resistance and high corrosion resistance, the comprehensive performance of the alloy can be effectively changed by adding the rare earth, a trace of active rare earth can be easily gathered on the interface and the surface of the alloy solder in a liquid state, so that the surface of the alloy is remarkably lowered, the rare earth cooperates with the aluminum to improve the wetting property with the surface of a repair layer (steel), the mechanical property of the solder is improved, and the malleability and the shear strength of the solder are improved.

Owner:STATE GRID CORP OF CHINA +1

Refreshing compound essential oil wet tissue

InactiveCN104688635AEasy to useEasy to carryCosmetic preparationsNervous disorderBiotechnologyBenzoin

The invention discloses refreshing compound essential oil wet tissue. The wet tissue is prepared by, by weight, 1.5-2.5 parts of benzoin essential oil, 1.2-2.0 parts of rosemary essential oil, 0.8-1.5 parts of thyme essential oil, 0.5-1.2 parts of mint essential oil, 0.4-1.0 part of tea plant essential oil, 0.5-1.3 parts of vetiver essential oil and 7.8-8.5 parts of wheat germ oil. The refreshing compound essential oil wet tissue has the advantages that naturally-extracted essential oil serves as a raw material, no toxic irritant substance is contained, no side effect is generated for the human body after the wet tissue is used for a long time, people cannot be addicted to the wet tissue, and the wet tissue is safe and effective. Borneol is added into components, absorption to the essential oil by nasal cavity mucosa is enhanced, and the wet tissue further has heat absorption and cooling effects when used in summer.

Owner:范永启

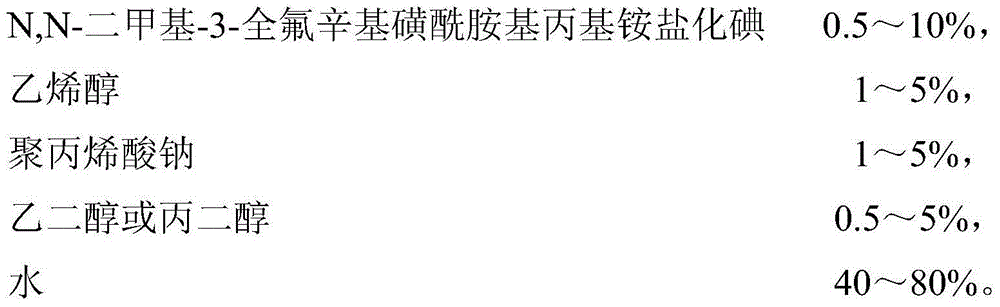

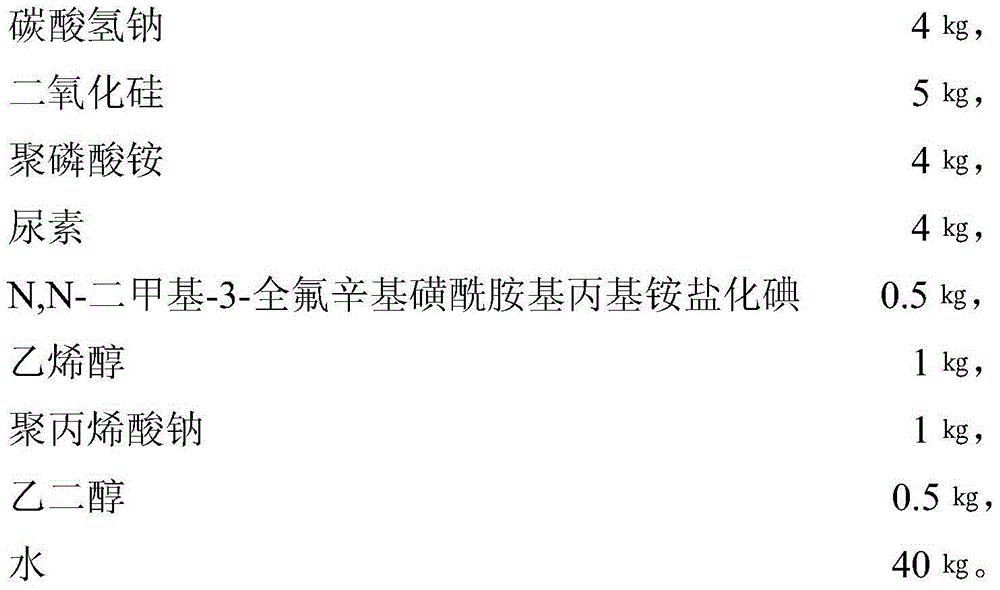

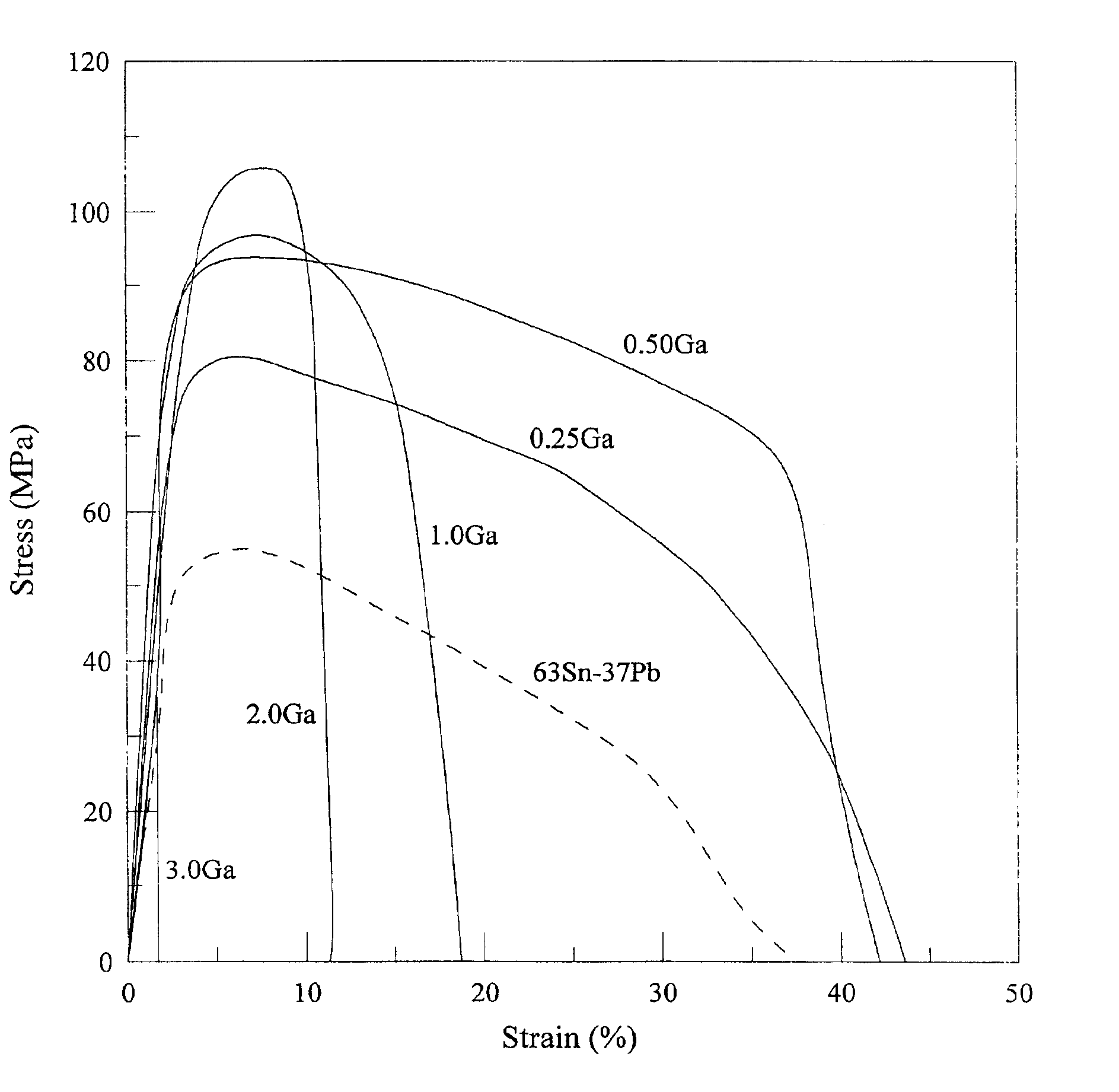

Extinguishing agent for forest fire

ActiveCN103977528ALarge latent heat of vaporizationHigh viscosityFire extinguisherSodium bicarbonateIodide

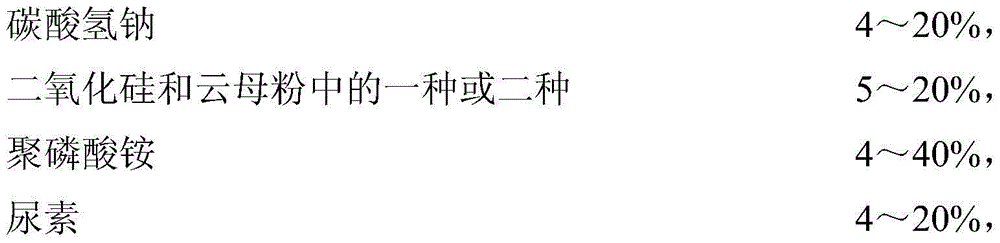

The invention discloses an extinguishing agent for forest fire. The extinguishing agent comprises the following components: 4 to 20% of sodium bicarbonate, 5 to 20% of silicon dioxide, 4 to 40% of ammonium polyphosphate, 4 to 20% of urea, 0.5 to 10% of N-N-dimethyl-3-perfluorooctylsulfonylpropyl-aminium iodide, 1 to 5% of vinyl alcohol, 1 to 5% of sodium polyacrylate, 0.5 to 5% of glycol, and 40 to 80% of water. The production method comprises the following steps: (1) dissolving ammonium polyphosphate, and urea into water; (2) adding N-N-dimethyl-3-perfluorooctylsulfonylpropyl-aminium iodide, vinyl alcohol, sodium bicarbonate, sodium polyacrylate and glycol, and uniformly agitating; and (3) adding silicon dioxide, and uniformly agitating. With the adoption of the agent, the oxygen isolating and cooling capacity of water is improved, the water consumption is decreased, the covering effect is improved with solid particles, and the phenomenon of backfire can be effectively inhibited; and the agent is outstanding in performance, convenient to carry, and beneficial for wide popularization.

Owner:STATE GRID CORP OF CHINA +2

Compound essential oil spray with refreshing function

InactiveCN104740444AEasy to useEasy to carryNervous disorderHydroxy compound active ingredientsBiotechnologyFragrance oil

The invention discloses a compound essential oil spray with a refreshing function. The compound essential oil spray with the refreshing function is prepared from the following active ingredients in parts by weight: 1.5-2.5 parts of benzoin essential oil, 0.5-1.2 parts of peppermint essential oil, 0.5-1.0 parts of sweet marjoram essential oil, 1.2-2.0 parts of rosemary essential oil, 0.8-1.5 parts of thyme essential oil, and 7.5-8.5 parts of wheat germ oil. The compound essential oil spray has good effects that the natural extraction essential oil is taken as the raw material without toxic stimulating substance, the compound essential oil spray does not have side effect or addiction on a human body after being used for a long time and is safe and effective; the essential oils are mixed and cannot generate other dangerous chemical substances and the fragrance is fresh and cool; the fatigue nerve of the human body is completely activated through meridian circulation and qi and blood flow.

Owner:范永启

Quickly absorptive skin-care composition

ActiveCN100372523CImprove permeabilityGood moisturizing effectCosmetic preparationsToilet preparationsCapric triglyceridesWax

The invention provides a skin care composition for rapid absorption which comprises the following raw materials (by weight percent): stearic acid 5-7%, C16-18 alcohols 3-4%, Ceteareth-25 1-3%, Ceteareth-6 1-3%, glyceryl stearate 3-5%, isopropyl myristate 3-5%, caprylic / capric triglyceride 4-6%, glycerol 4-6%, azone 0.5-0.7%, mixed grease liposome 10-20%, safflower 5-7%, hydroxyethyl cellulose 0.1-0.3%, and aluminium magnesium silicate 0.1-0.3%.

Owner:TIANJIN YU MEI JING GRP

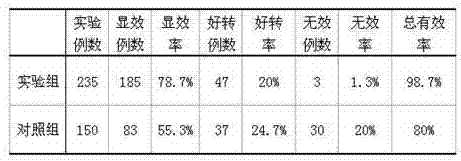

Lead-free solder

InactiveUS6837947B2Low costLow melting pointWelding/cutting media/materialsSoldering mediaMelting pointMetallic Lead

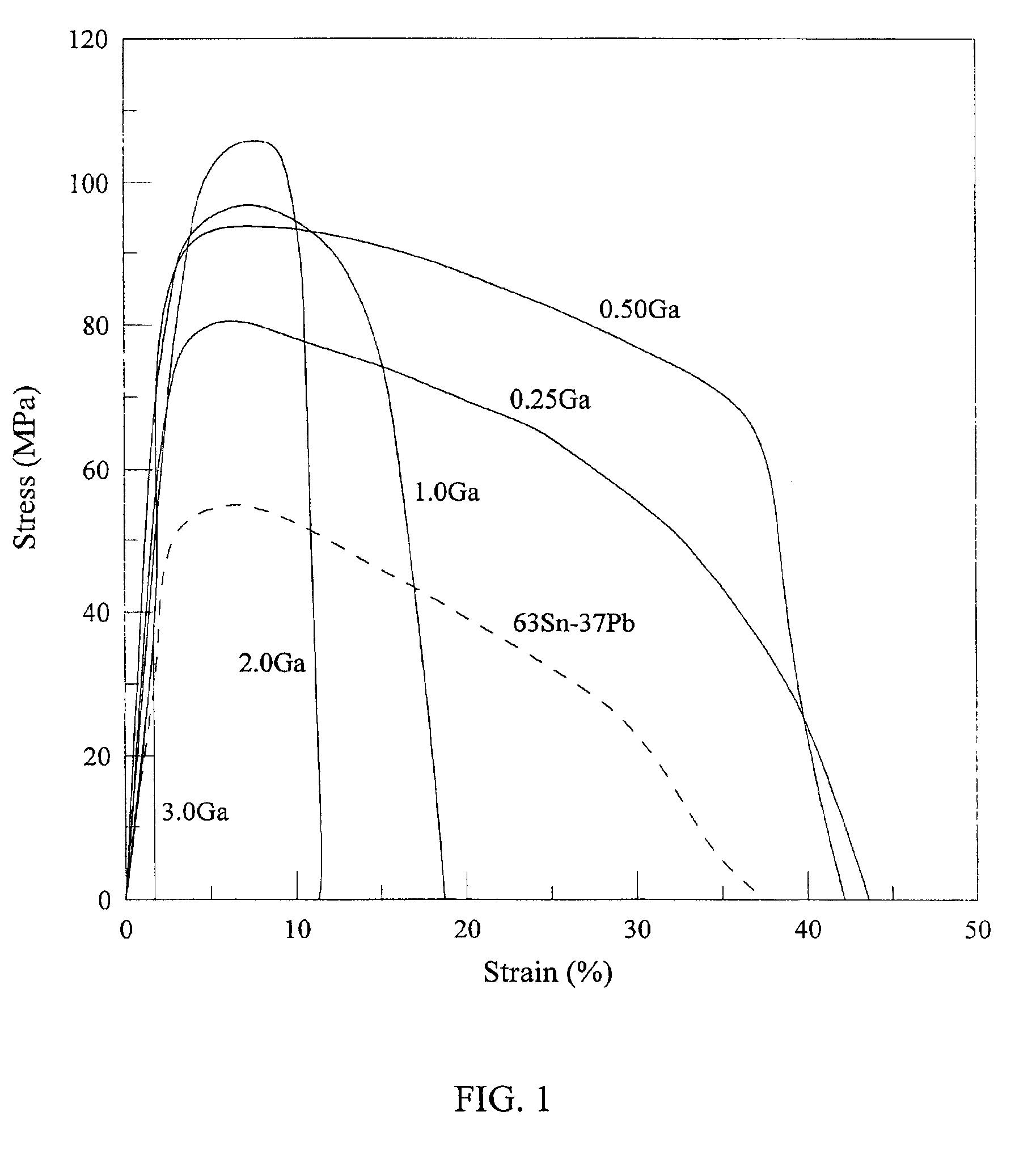

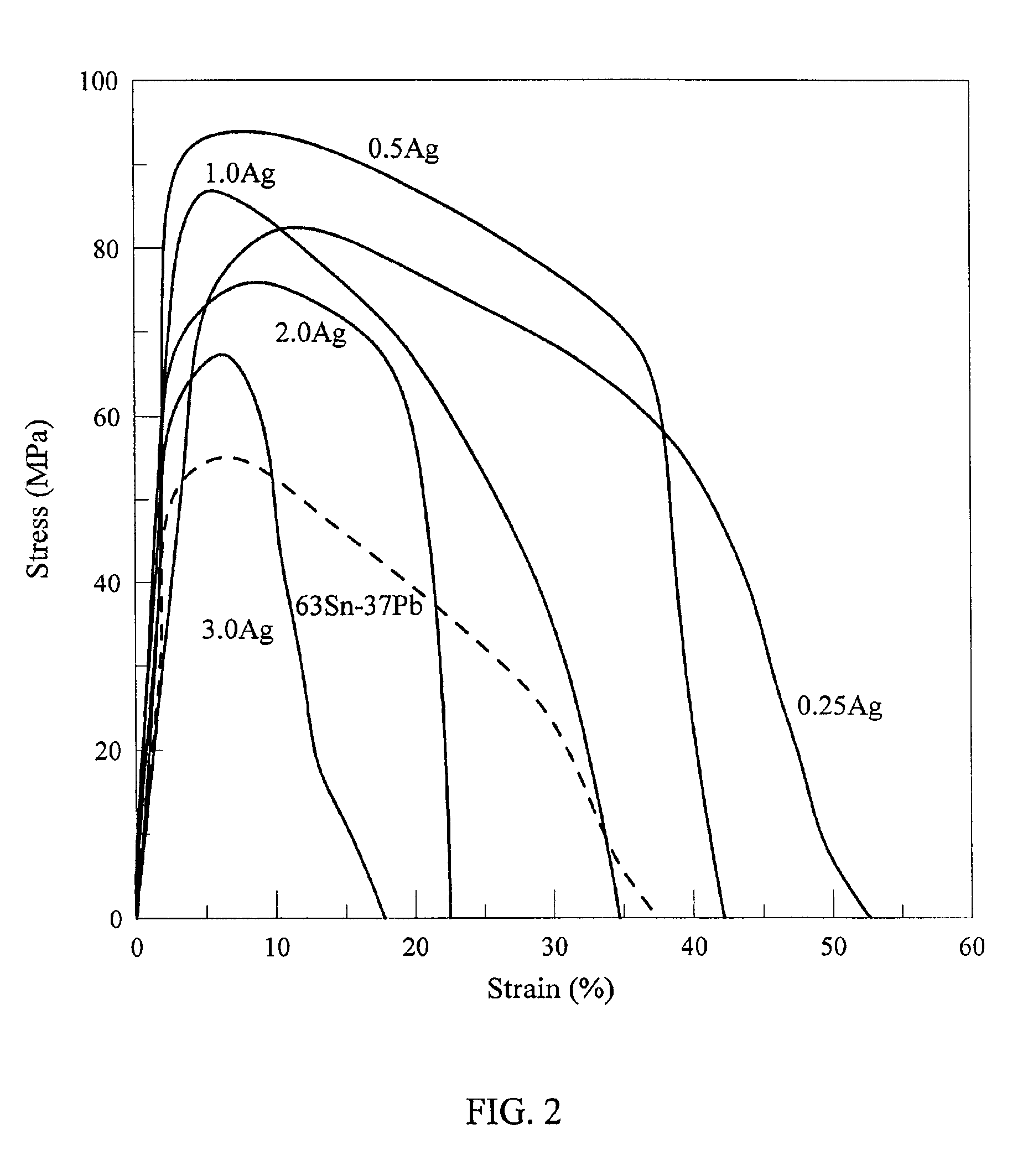

This invention discloses a lead-free Sn—Zn—Al—Ag solder alloy, which is composed of 7-10 wt % of Zn, up to 0.5 wt % of Al, up to 4.0 wt % of Ag, and the balance of Sn; and a lead-free Sn—Zn—Al—Ag—Ga solder alloy, which is composed of 7-10 wt % of Zn, up to 0.5 wt % of Al, up to 4.0 wt % of Ag, up to 4.0 wt % of Ga; and the balance of Sn. The lead-free solder alloys of the present invention have better tensile strength and elongation than the conventional Sn—Pb solder alloys. In addition, the lead-free solder alloys of the present invention have a melting point lower than 200° C., which is close to the 183.5° C. of an eutectic Sn—Pb alloy.

Owner:NAT CHENG KUNG UNIV +1

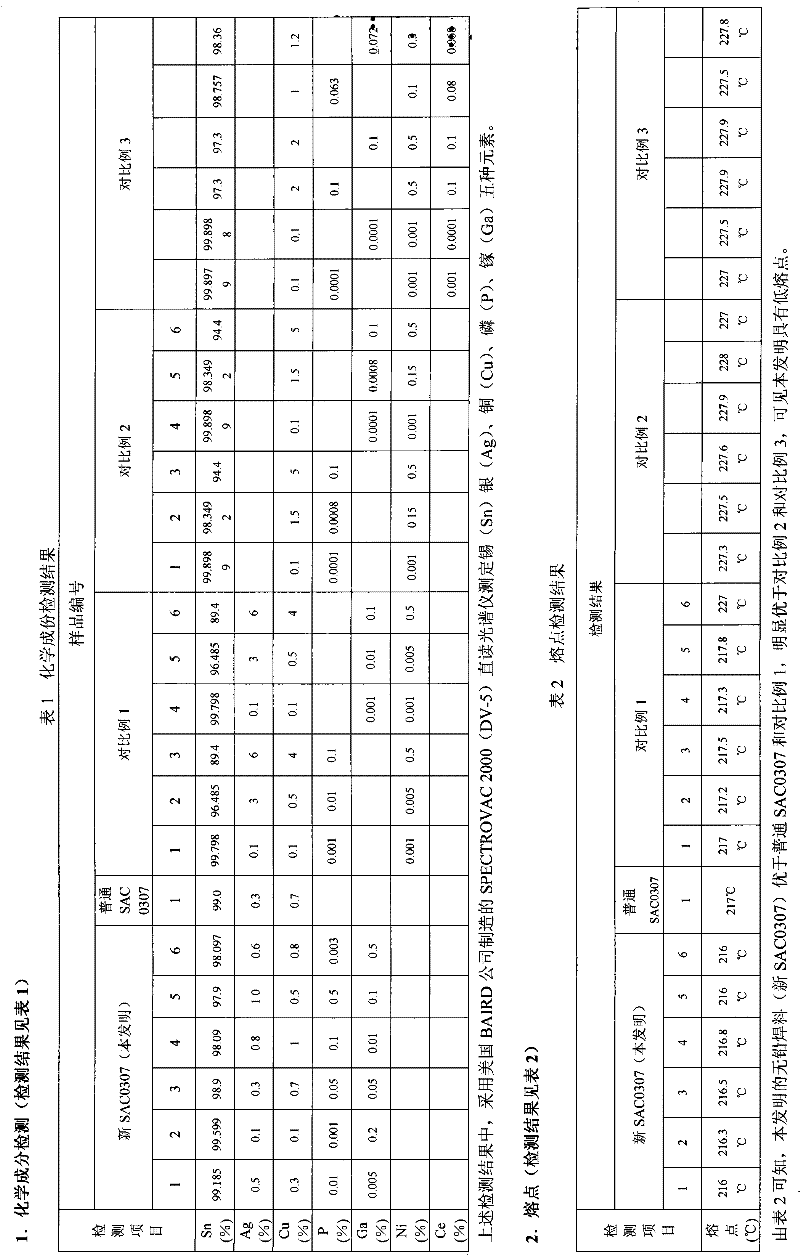

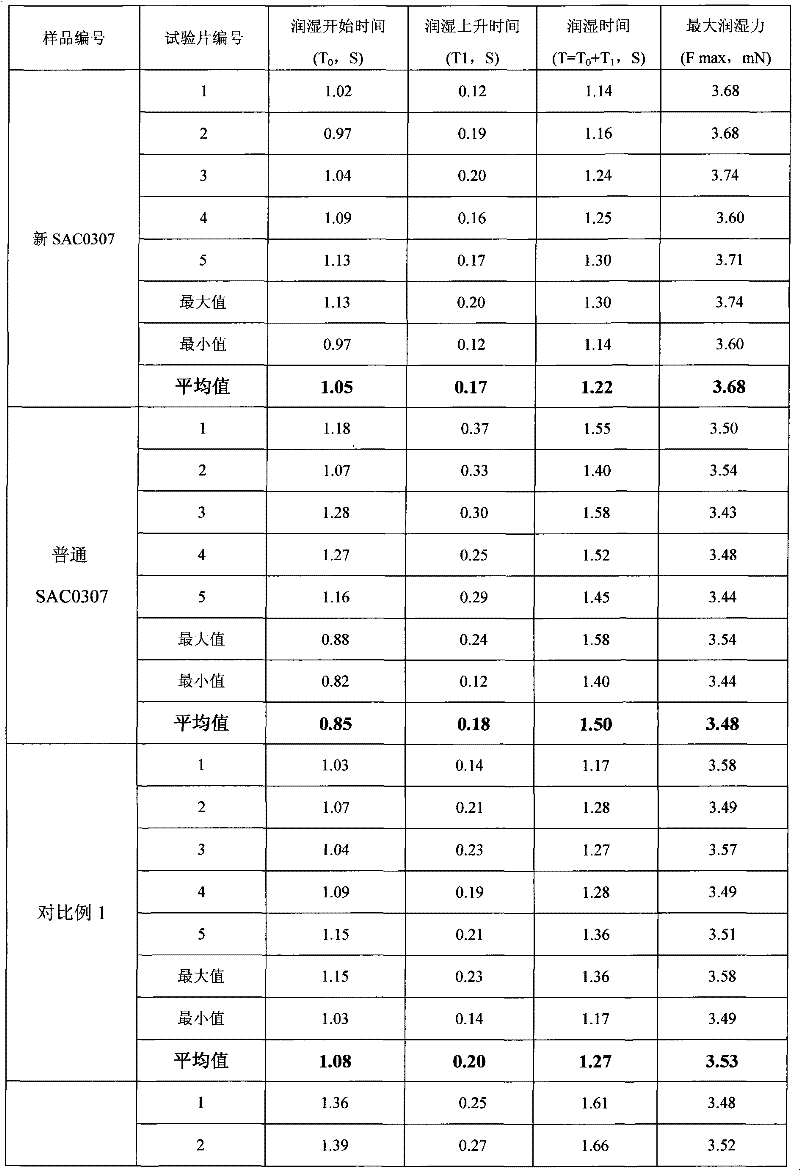

Tin-based lead-free solder and preparing method thereof

ActiveCN101513697BImprove product qualityReduce lossWelding/cutting media/materialsSoldering mediaPhosphorManganese

The invention relates to a tin-based lead-free solder and a preparing method thereof, the tin-based lead-free solder contains, based on weight percentage, 0.005-0.5% of gallium, 0.1-1% of silver, 0.1-1% of copper, 0.001-0.5% of phosphor and tin as the balance. The method for preparing the tin-based lead-free solder comprises the steps of: first of all, preparing four intermediate alloy ingots including tin-gallium, tin-silver, tin-copper and tin-phosphor; adding the four intermediate alloy ingots according to particular weight parts and then additionally adding the balancing tin; in the meantime, adding the mixture into a manganese alloy pot for melting, and heating up to 450 DEG C; discharging, cooling and casting into the lead-free solder so as to obtain the lead-free solder that contains gallium, silver, copper and phosphor with tin being the balance. The invention has the advantage that the lead-free solder is low in melting point, excellent in wettability, bright in soldering spot, persistent in anti-oxidation under high temperature operation and low in cost.

Owner:宏桥新电子材料(深圳)有限公司

Producing method for silver oxide welding material

ActiveCN103737204AImprove conductivityImprove liquidityWelding/cutting media/materialsSoldering mediaToughnessSilver oxide

The invention relates to a producing method for a silver oxide welding material. The method comprises the steps of (1) cleaning the surface of a stainless steel band; (2) feeding silver oxide powder in a spraying machine, and fixing the spraying machine on a movable device to be moved at the uniform velocity; (3) coating a layer of glue on the upper surface of the stainless steel band; (4) starting the spraying machine to spray the upper surface of the stainless steel band to form a coating, repeating spraying for 2 to 4 times, and performing natural cooling; (5) performing same treating on the lower surface of the stainless steel band to obtain the silver oxide welding material eventually. According to the method, the silver oxide welding material is produced through a glue mode, so that the method is simple, the operation is facilitated, the obtained welding material is flat in surface, and as for the performance, silver has good electrical conductivity and mobility, so that the wetting power between the welding material and a substrate during welding is high, and the joint toughness is good. Besides, the welding material can be used as a base material, and welding materials of different specifications after binding pressing are obtained.

Owner:江苏莱讯环境系统技术有限公司

Photovoltaic pre-coating material, pre-coated solder strip and preparation methods thereof

InactiveCN111040632AReduce manufacturing costAvoid pollutionRosin coatingsPhotovoltaic energy generationTinningGlutaric acid

The invention provides a photovoltaic pre-coating material, a pre-coated solder strip and preparation methods thereof, and belongs to the technical field of photovoltaic new energy. The photovoltaic pre-coating material comprises hydrogenated rosin, maleated rosin, rosin ester, succinic acid, glutaric acid and adipic acid; the preparation method comprises the following steps: mixing and heating hydrogenated rosin and maleated rosin, sequentially adding rosin ester, succinic acid, glutaric acid, adipic acid and tetracosanoic acid, stirring, mixing and melting to obtain the photovoltaic pre-coating material. The pre-coated solder strip comprises a base body, a tin coating and the photovoltaic pre-coating material. The preparation method of the pre-coated solder strip comprises the followingsteps: sending the base material into a high-speed tinning machine for tinning so as to obtain a tinned base material; putting the photovoltaic pre-coating material into a coating machine or a spraying machine; putting the tinned base material into the coating machine or the spraying machine, coating the tinned base material with the photovoltaic pre-coating material or blowing the tinned base material with an air knife, and slowly baking the tinned base material until the tinned base material is dry or rapidly cooling at a low temperature to prepare the pre-coated solder strip. The process issimple in process, the cost investment is low, and the material of the invention belongs to an environment-friendly material.

Owner:WUXI SVECK TECH

Skin care combination containing liposome of compound fat

ActiveCN1286447CImprove permeabilityGood moisturizing effectCosmetic preparationsToilet preparationsLipid formationWrinkle skin

A skin-protecting composition for eliminating wrinkles and acne and moistening skin is proportionally prepared from matrix and the mixed oil lipid which is prepared from lecithin as wall material and the mixture as active component of olive oil, graps seed oil and wheat plumula oil.

Owner:TIANJIN YU MEI JING GRP

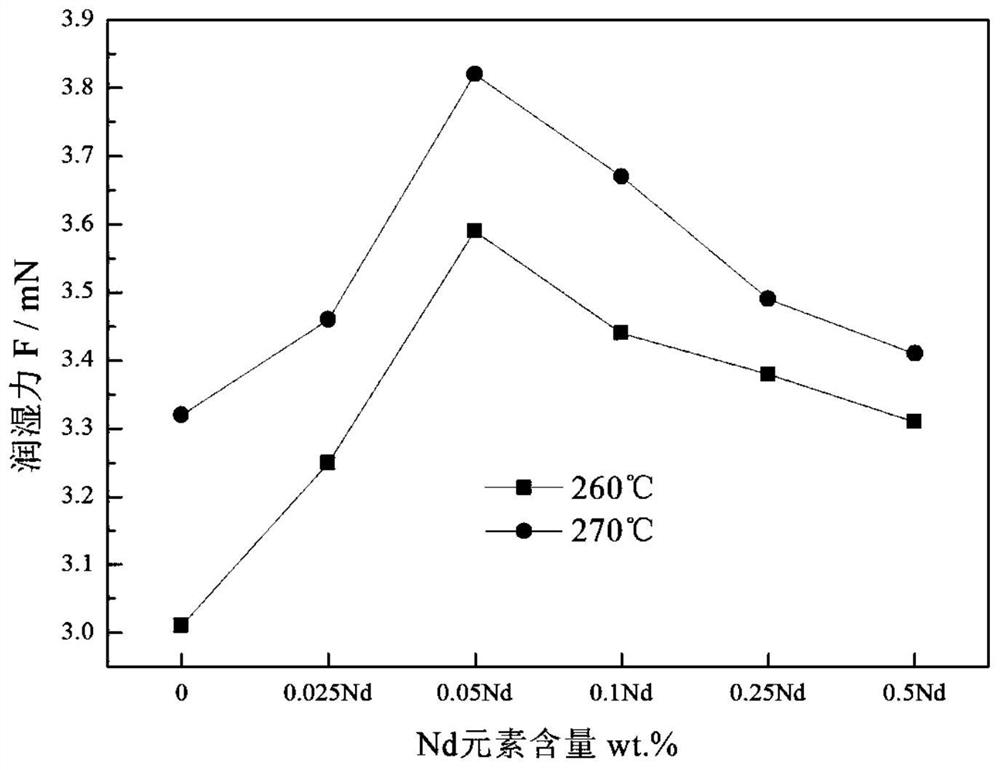

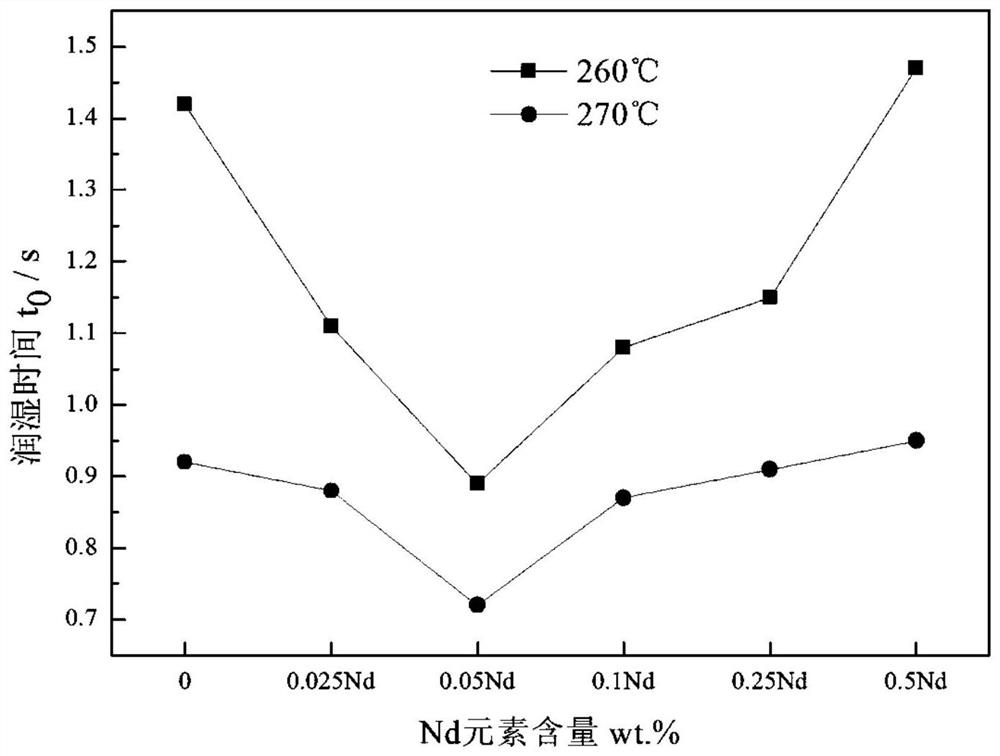

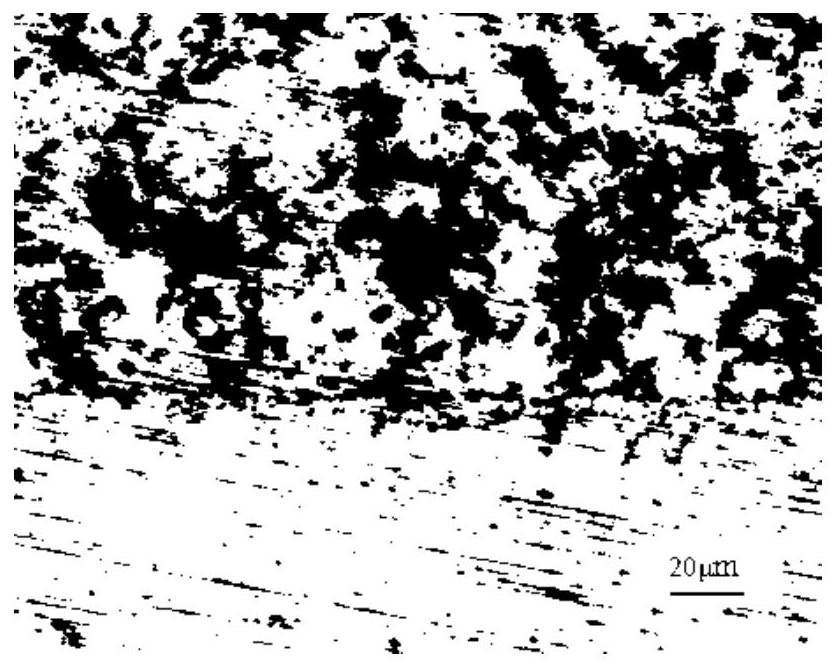

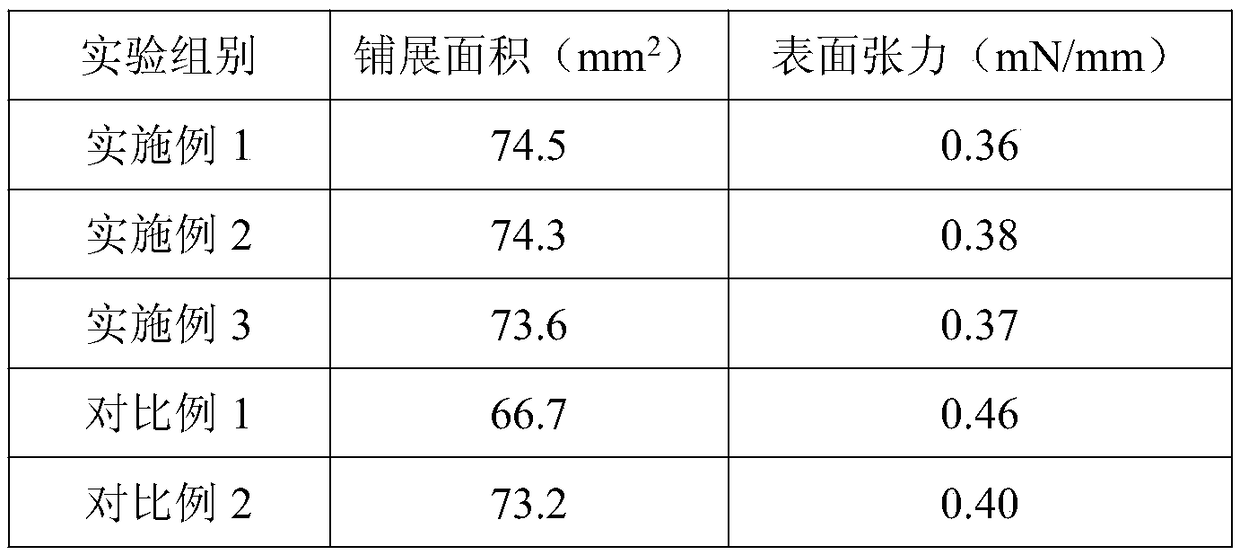

A sn-cu-ni lead-free solder containing ga and nd

ActiveCN109277721BInhibition of thickness growthGrowth inhibitionWelding/cutting media/materialsSoldering mediaChemical compositionMetallic materials

The invention discloses an Sn-Cu-Ni lead-free solder containing Ga and Nd and belongs to the soldering materials in the field of metallic materials and metallurgy. The Sn-Cu-Ni lead-free solder containing Ga and Nd comprises the following chemical components in percentage by mass: 0.5-1.0% of Cu, 0.05-0.35% of Ni, 0.003-0.008% of Se, 0.001-0.003% of Zr, 0.4-0.6% of Ga, 0.04-0.06% of Nd, and the balance Sn, specifically, the addition mass ratio of Ga to Nd is 10:1. The Sn-Cu-Ni lead-free solder has excellent wettability, can effectively restrain growth of thickness of intermetallic compounds ata soldering seam interface as well as growth of tin whiskers of a soldered joint, remarkably improves the reliability of the soldered joint and is suitable for wave-soldering of the electronic industry and other welding modes like reflow soldering.

Owner:CHANGSHU HUAYIN FILLER METALS

Scaling powder for integrated circuit board patch and preparation method thereof

InactiveCN107186388AGood welding performanceImprove wetting abilityWelding/cutting media/materialsSoldering mediaSalicylic acidSuccinic acid

The invention discloses scaling powder for an integrated circuit board patch. The scaling powder is prepared from, by weight, 60-80 parts of modified rosin, 30-40 parts of glycerol ester of rosin, 20-30 parts of butyl acetate, 10-30 parts of texanol, 10-20 parts of pentaerythritol oleate, 5-15 parts of dimethyl imidazole, 3-8 parts of benzimidazole, 5-10 parts of salicylic acid, 2-8 parts of succinic acid, 5-10 parts of tartaric acid, 8-15 parts of adipic acid, 3-8 parts of triethanolamine, 2-6 parts of triisopropanolamine, 4-10 parts of nanometer titania, 20-40 parts of solvents, 1-5 parts of thixotropic agent, 0.3-0.8 part of surface active agent and 0.5-3 parts of coalescing agent. The scaling powder has the high solder wetting capability, can enhance the solder weldability, can adapt to various solder welding temperatures, generates few resides after welding is performed, and is high in insulation resistance, environmentally friendly and free of pollution.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

Lead-free solder alloy and preparation method thereof

InactiveCN109262163AReduce surface tensionImprove wettabilityWelding/cutting media/materialsSoldering mediaWettingRaw material

The invention discloses a lead-free solder alloy and a preparation method thereof, and belongs to the technical field of alloys. The lead-free solder alloy comprises the following raw materials by weight: 3%-5% of Zn, 1%-2% of Bi, 0.5%-1.5% of Ti, 0.001%-0.003% of In, 0.015%-0.035% of Ni, 0.02%-0.06% of Ce, 0.04%-0.06% of Ge and the balance Sn. The wetting property of the lead-free solder alloy isimproved by using a reinforcing system composed of Ni, Ce and Ge.

Owner:长沙浩然医疗科技有限公司

Lead-free solder tin wire applicable to drag soldering technology

InactiveCN107498208AEvenly distributedPrevent splashWelding/cutting media/materialsSoldering mediaOrganic solventBoiling point

The invention discloses a lead-free solder tin wire applicable to the drag soldering technology. The lead-free solder tin wire comprises the following components in percentage by weight: 96.0%-98.5% of lead-free solder and 4.0%-1.5% of scaling powder, wherein the scaling powder comprises the following components in percentage by weight: 1-4% of an organic solvent with a low boiling point, 4-10% of an activator, 0-0.5% of corrosion inhibitor and the balance of modified rosin. The lead-free solder tin wire can rapidly weld a component on a base plate, is high in tin breaking performance, does not cause the continuous tin phenomenon during the continuous application process, greatly improves the working efficiency, lowers the cost, does not contain the forbidden substances including RoHS2.0, REACH and the like, does not cause harm to the environment and meets the environmental protection requirement.

Owner:广东中实金属有限公司

Anti-wrinkle antioxidant smearing mask

InactiveCN109316393AEasy to cleanImprove absorption and utilizationCosmetic preparationsToilet preparationsWrinkle skinCucumber juice

The invention discloses an anti-wrinkle antioxidant smearing mask. The anti-wrinkle antioxidant smearing mask is prepared from the following components in proportion: 10-13 ml of fermented milk, 3-5 ml of aloe juice, 3-5 ml of cucumber juice, 3-4 drops of wheat germ oil and 1-2 drops of sandalwood essential oil; and beer saccharomycete and lactobacilli are added into the fermented milk. The anti-wrinkle antioxidant smearing mask has the advantages of being easy and convenient to use, high in stability, good in absorption effect and high in antioxidant property, and has an effect of wrinkle removal.

Owner:刘必珍

Preparation method of composite titanium dioxide

InactiveCN108395735ASmall particle sizeGood dispersionInorganic compound additionPigment treatment with organosilicon compoundsWater bathsAlcohol

The invention belongs to the field of preparation of composite titanium dioxide, and relates to a preparation method of composite titanium dioxide. The preparation method comprises the following steps: mixing and stirring oxalic acid, absolute ethyl alcohol and deionized water to obtain a stirred solution; mixing tetrabutyl titanate and absolute ethyl alcohol to obtain a mixed solution; adding themixed solution in the stirred solution, standing, placing precipitates in a water bath for evaporation, and drying to obtain a dried material; adding hydrochloric acid, mixing, standing, and filtering to obtain a filter residue, placing the filter residue in hot water, stirring, filtering to obtain a filter residue a, grinding, sieving to obtain a sieved material, adding a coupling agent and an ethanol solution, mixing, oscillating, performing suction filtering, drying, grinding to obtain a ground material, adding absolute ethyl alcohol and deionized water, mixing, stirring, adding a flourescent brightener, centrifuging, and performing vacuum drying on precipitates to obtain a dried material a; and mixing modified calcium carbonate, a dispersant, sodium dodecyl benzene sulfonate and water, grinding, adding the dried material a, grinding, dehydrating, drying, and crushing to obtain the composite titanium dioxide.

Owner:江苏新亿源环保科技有限公司

Metal salt-free sealing agent for aluminum alloy anodic oxide film

The invention provides a metal salt-free sealing agent for an aluminum alloy anodic oxide film, belonging to the technical field of aluminum alloy anodic oxide film post treatment. The sealing agent of the invention is prepared by water solution composed of 1.0-10g / L of a hydration accelerator, 0.01-2g / L of a wetting agent, 0.01-3g / L of an ash inhibitor and 1-15g / L of a pH buffering agent, wherein the pH of workpiece fluid is 5.5-6.5, the operating temperature is 70-90 DEG C, and the sealing speed is 1.0-2.0min / um. The metal salt-free sealing agent creatively adopts organic compounds which are easily subject to biodegradation, does not contain any metal ions of nickel, cobalt, magnesium, calcium, lithium and the like as well as fluorinions, and obtains satisfactory sealing effect of the nano-pores of the aluminum alloy anodic oxide film by virtue of the scientific and coordinated component formula of the water solution; the aluminum alloy anodic oxide film obtained by seal treatment through the sealing agent has the advantages of good corrosion resistance, capability of meeting the requirements of GB 14952.1-94, good light-protection and color-protection properties of a film layer, no ash and pruina, no water stain after drying as well as light flowing color and small color difference change in case of sealing the organic dyeing film; and the metal salt-free sealing agent is widely applicable to sealing treatment of an original-color anodic oxide film, an electrolytic coloring anodic oxide film, a hard oxide film and a dyeing anodic oxide film.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Soldering flux for solder wires for robotic automatic welding and preparation method thereof

ActiveCN103464932BGood wetting spreadIncrease forceWelding/cutting media/materialsSoldering mediaActive agentRosin

The invention provides soldering flux for solder wires for robotic automatic welding. The soldering flux comprises, by weight, 6.0-11.0% of linear polymer, 5.0-8.5% of high-temperature solvent, 2.0-3.5% of active agent, 0.2-1.2% of surfactant, and the balance of rosin resin. The soldering flux has the advantages that the problem that the flux easily breaks and is easily uneven can be avoided; surface tension of molten solder is reduced, wetting power is increased, weldability of the solder is enhanced, the solder is squeezed to the solder wires at agreeably high temperature and is full and even, and high wetting and expansion rate of the solder wires can be guaranteed; welding defectives such as tin bonding and missing solder during robotic automatic welding can be avoided.

Owner:深圳市唯特偶新材料股份有限公司

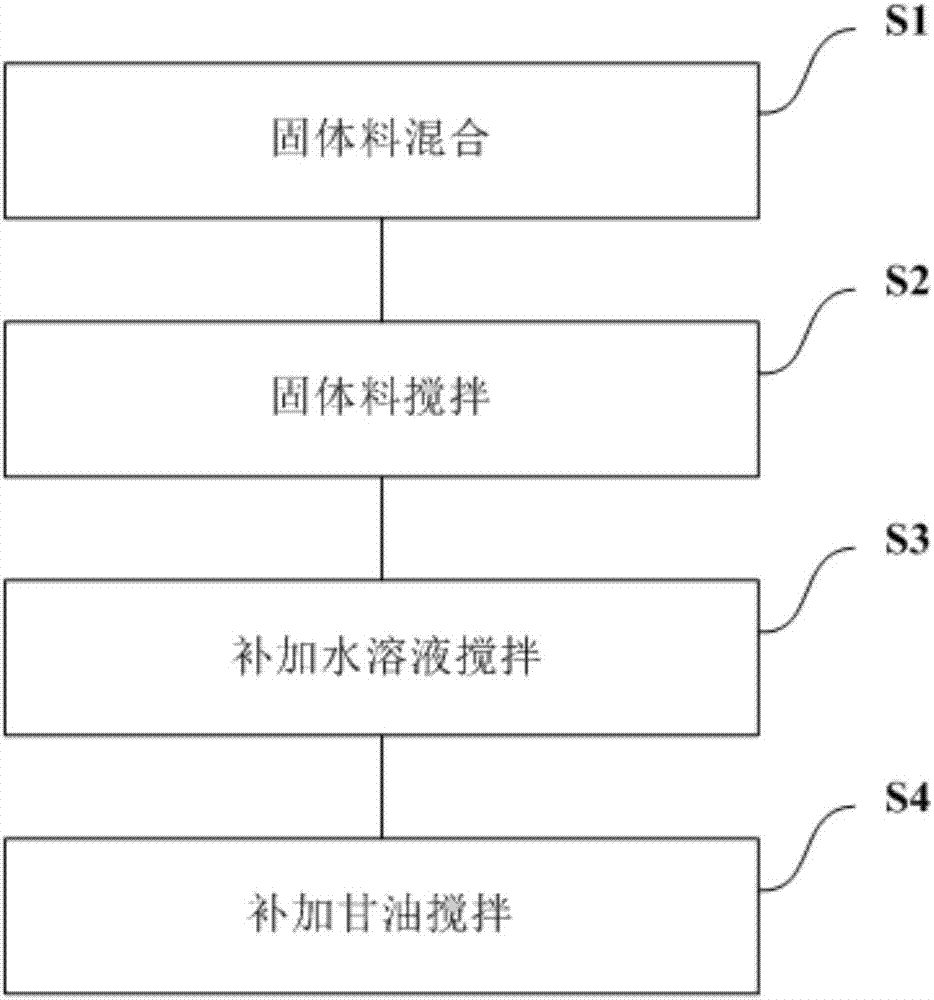

Silicon carbide round pipe material and preparation method thereof

The invention discloses a silicon carbide round pipe material and a preparation method thereof. The silicon carbide round pipe material is composed of 50-70 parts of silicon carbide rough material, 30-50 parts of silicon carbide fine material, 1.5-3 parts of cellulose, 7-10 parts of water solution and 0.2-0.5 part of glycerin. The silicon carbide round pipe material is simple in compositional structure and preparation process, so that cost can be saved when compared with existing silicon carbide round pipe materials. Improving of performance of the silicon carbide round pipe material can be promoted by adjusting proportion of silicon carbide coarse materials and silicon carbide fine materials, adding cellulose to improve adhesiveness of the whole formulation and adding glycerin to improvelubricating capacity and wetting capacity. Finally, through reasonable proportion and composition, the problem that steel pipes made of the silicon carbide round pipe material are low in strength anddensity can be solved, and utilization rate of the silicon carbide round pipe material is increased.

Owner:湖南太子新材料科技有限公司

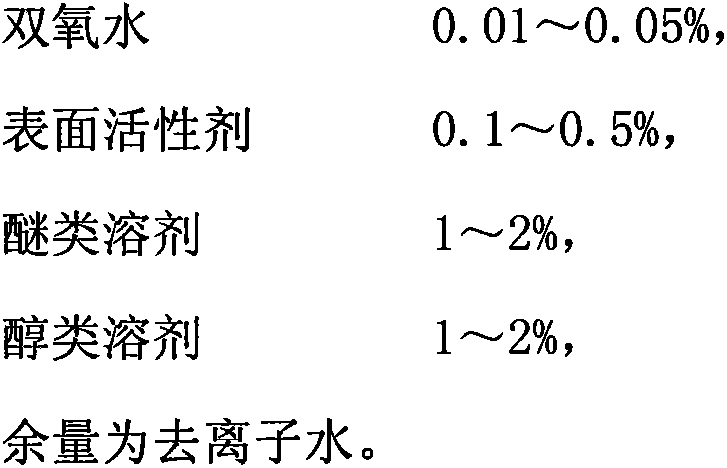

Photovoltaic welding strip detergent

InactiveCN105886167ANo need to diluteEasy to useSurface-active non-soap compounds and soap mixture detergentsForeign matterAlcohol

The invention discloses a photovoltaic welding strip detergent. The photovoltaic welding strip detergent is prepared from the following raw materials by weight percent: 0.01-0.05% of hydrogen peroxide, 0.1-0.5% of surfactant, 1-2% of ether solvent, 1-2% of alcohol solvent and the balance of deionized water. The photovoltaic welding strip detergent has the advantages and beneficial effects that as hydrogen peroxide with low weight percent is added to the detergent, the residues of foreign matters on the surfaces of welding strips can be reduced; meanwhile, as the surfactant is added, the wetting power of the welding strip surfaces can be increased, thus enhancing the decontamination effects; the detergent can be directly used, without dilution, and the photovoltaic welding strips only need to be soaked for several seconds or be directly washed when the detergent is used; therefore the detergent is convenient to use.

Owner:任海涛

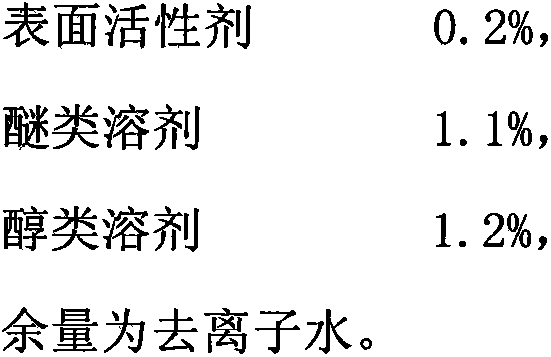

Collagen-based lyophilised glue and the use thereof for producing an adhesive prosthesis

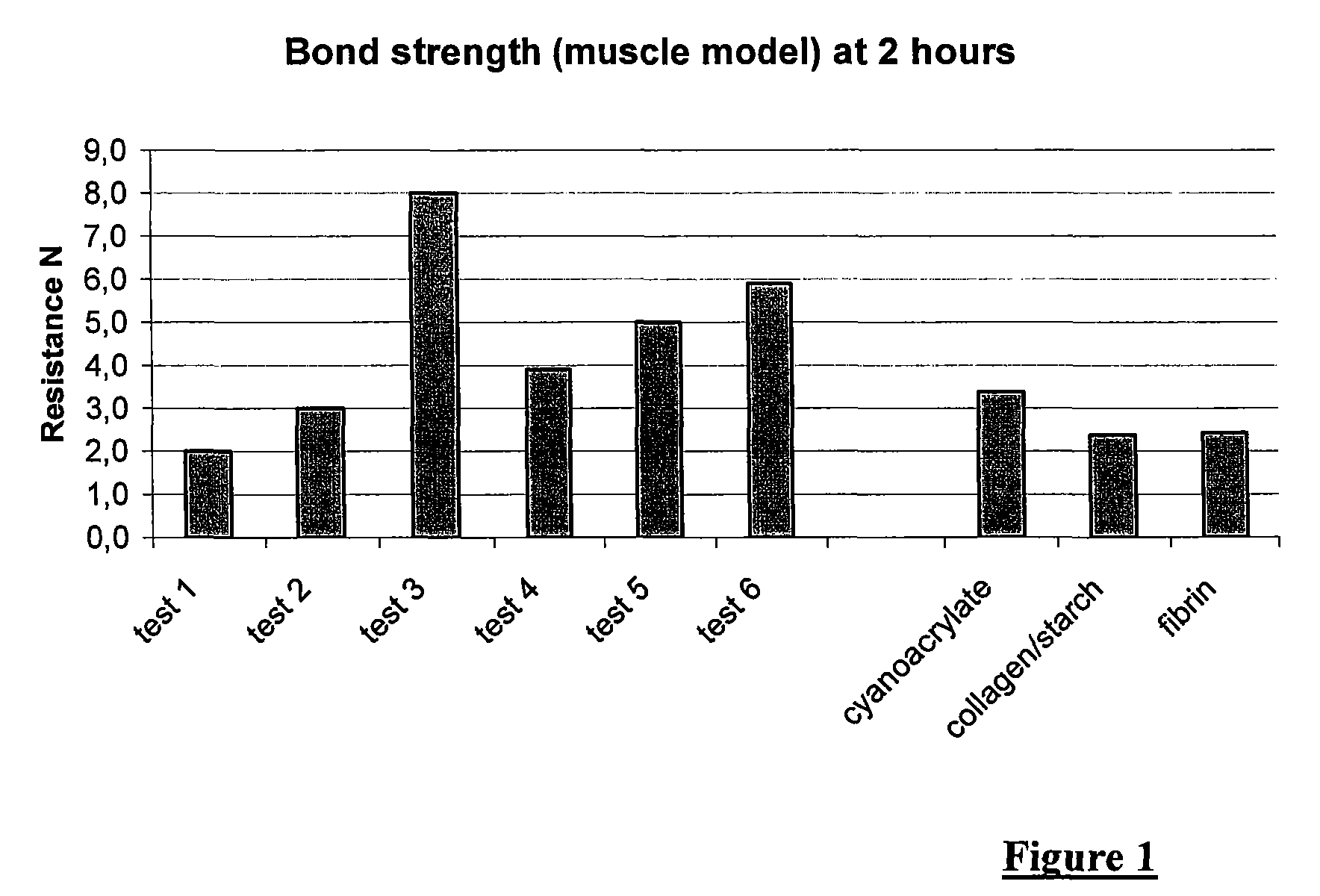

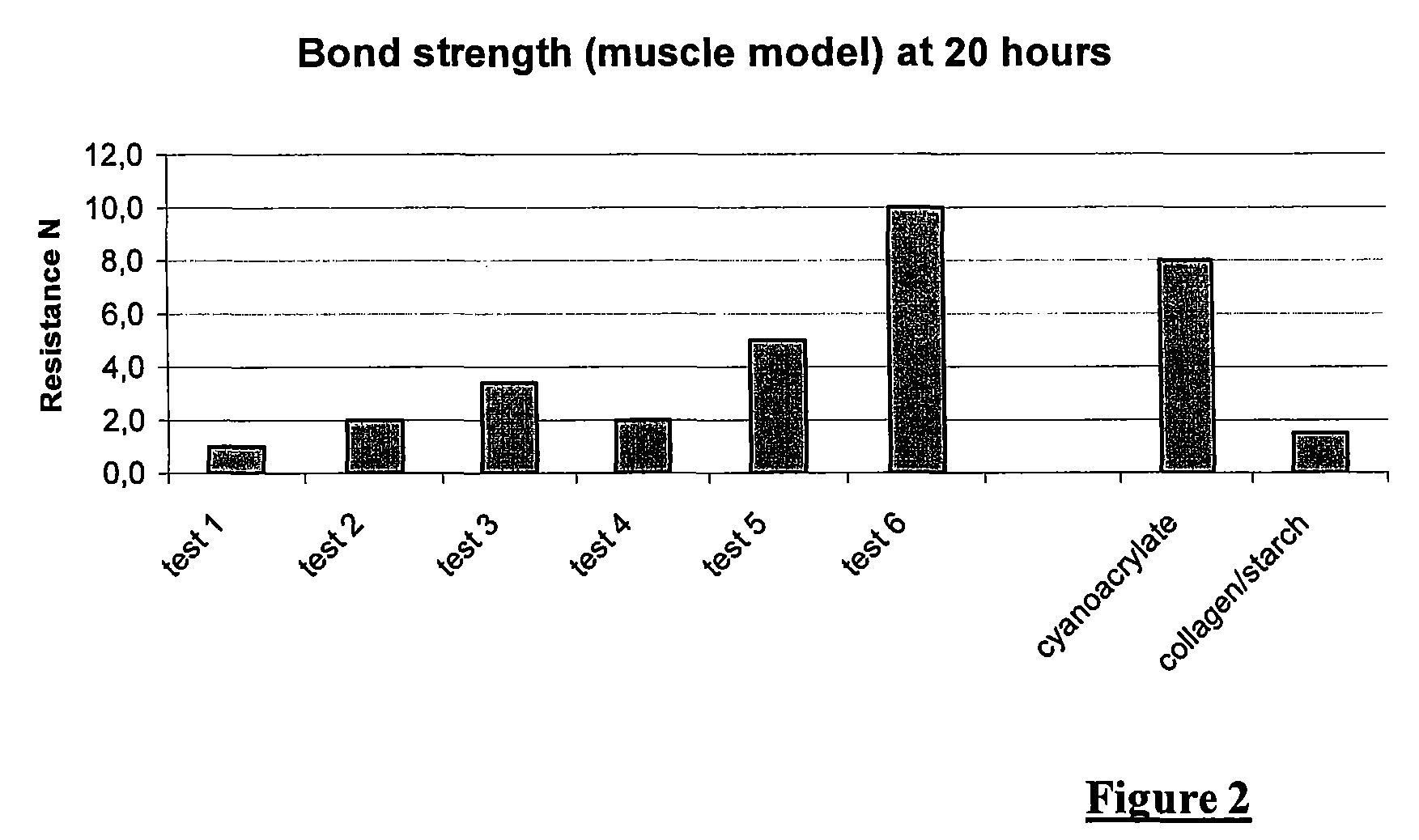

InactiveUS8137450B2Enhance wetting powerSufficient molecular weightSurgical adhesivesProtein waste adhesivesAdhesiveProsthesis

A lyophilized glue contains a collagen which is partially crosslinked with the aid of at least one type of aldehyde. A method for preparing the glue and the use thereof for producing an adhesive on anti-adhesive prosthesis are also provided.

Owner:SYMATESE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com