Silicon carbide round pipe material and preparation method thereof

A technology of silicon carbide and round tubes, which is applied in the field of engineering ceramics, can solve the problems of low strength and density of silicon carbide round tubes, and achieve the effects of promoting lifting, saving costs, and improving lubricating and wetting forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

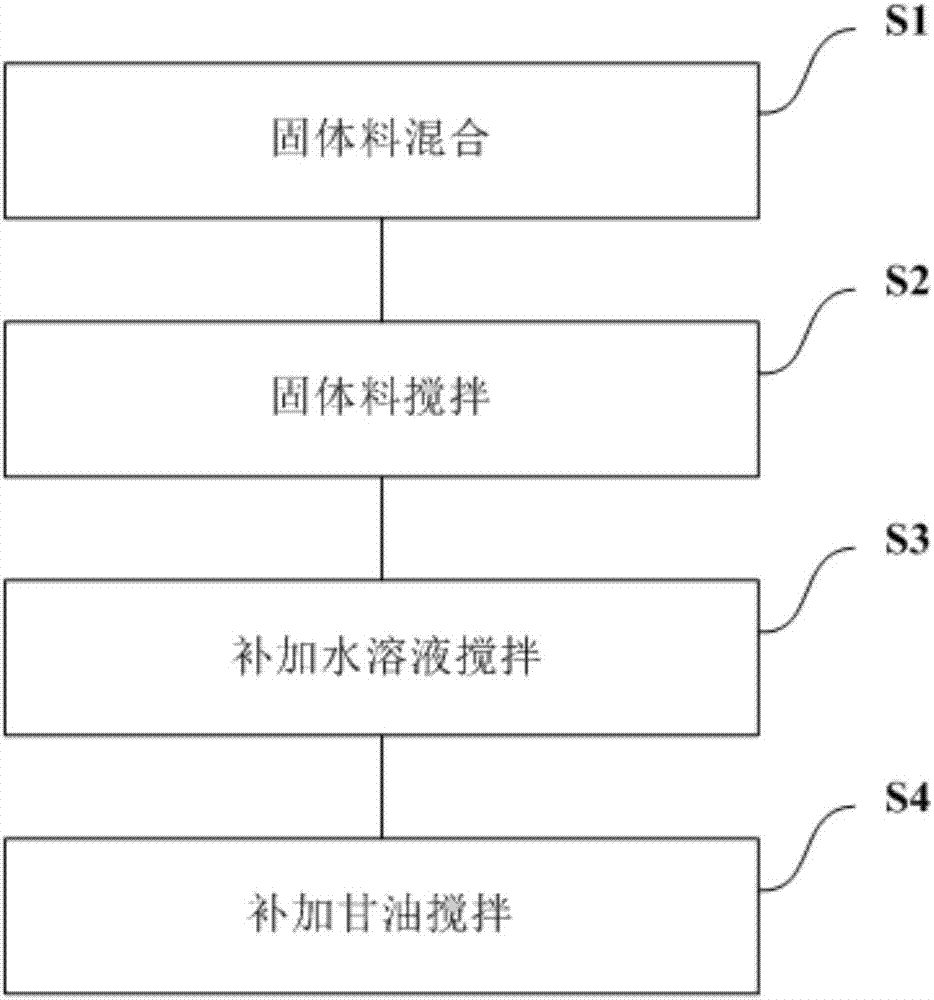

[0034] see figure 1 , is a flowchart of a method for preparing a silicon carbide round tube material provided in an embodiment of the present invention. The invention provides a method for preparing a silicon carbide circular tube material, the preparation method comprising:

[0035] S1: Mix the solid materials, put the silicon carbide coarse material, silicon carbide fine material, and cellulose into a 100-liter vertical mixer;

[0036] S2: Stir the solid material, start the 100-liter vertical mixer to stir, and the stirring time is 20-40 minutes, and obtain the solid material of the silicon carbide round tube material;

[0037] S3: add an aqueous solution and stir, add an aqueous solution to the solid material of the silicon carbide round tube material, and continue stirring until the temperature reaches 30° C., and the stirring time is 30 minutes to 60 minutes to obtain a silicon carbide round tube material slurry;

[0038] S4: adding glycerin and stirring, adding glyceri...

Embodiment 1

[0046] A kind of silicon carbide tube material, the silicon carbide tube material is made of the following raw materials in parts by weight:

[0047] 50 parts of silicon carbide coarse material, 30 parts of silicon carbide fine material, 1.5 parts of cellulose, 7 parts of aqueous solution, 0.2 part of glycerin.

[0048] S1: Mix the solid materials, put the silicon carbide coarse material, silicon carbide fine material, and cellulose into a 100-liter vertical mixer;

[0049] S2: Stir the solid material, start the 100-liter vertical mixer to stir, and the stirring time is 20 minutes, to obtain the solid material of the silicon carbide tube material;

[0050] S3: add an aqueous solution and stir, add an aqueous solution to the solid material of the silicon carbide round tube material, and continue stirring until the temperature reaches 30° C., and the stirring time is 30 minutes, to obtain a silicon carbide round tube material slurry;

[0051] S4: adding glycerin and stirring, a...

Embodiment 2

[0054] A kind of silicon carbide tube material, the silicon carbide tube material is made of the following raw materials in parts by weight:

[0055] 70 parts of silicon carbide coarse material, 50 parts of silicon carbide fine material, 3 parts of cellulose, 10 parts of aqueous solution, 0.5 part of glycerin.

[0056] S1: Mix the solid materials, put the silicon carbide coarse material, silicon carbide fine material, and cellulose into a 100-liter vertical mixer;

[0057] S2: Stir the solid material, start the 100-liter vertical mixer to stir, and the stirring time is 40 minutes, to obtain the solid material of the silicon carbide tube material;

[0058] S3: add an aqueous solution and stir, add an aqueous solution to the solid material of the silicon carbide round tube material, and continue stirring until the temperature reaches 30° C., and the stirring time is 60 minutes to obtain a silicon carbide round tube material slurry;

[0059] S4: adding glycerin and stirring, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com