Soldering flux for solder wires for robotic automatic welding and preparation method thereof

A technology of automatic welding and solder wire, applied in welding equipment, welding medium, welding/cutting medium/material, etc., which can solve the problems of high viscosity, poor fluidity and unevenness of flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention also provides a preparation method for the flux used for the automatic welding of the above-mentioned robot solder wire, the steps of which are as follows:

[0023] First add the above-mentioned high-temperature solvent and rosin resin in the weight percentage into the container, heat to 155-165°C, and stir at a speed of 30-40 rpm until completely melted, then add the above-mentioned weight percentage of the linear polymer, active agent and Surfactant, continue to stir at the speed of 30-40 rpm at the aforementioned temperature for 30-45 minutes, stop stirring after the materials are melted and mixed evenly, and then the flux for robot automatic welding solder wire can be obtained. Pour the flux prepared above into an extruder, and extrude it into the solder wire at a temperature of 120-130°C and an air pressure of 0.18-0.22Mpa. The flux accounts for 2.8-3.2% by weight of the solder alloy. Solder wires of different specifications are drawn through ...

Embodiment 1

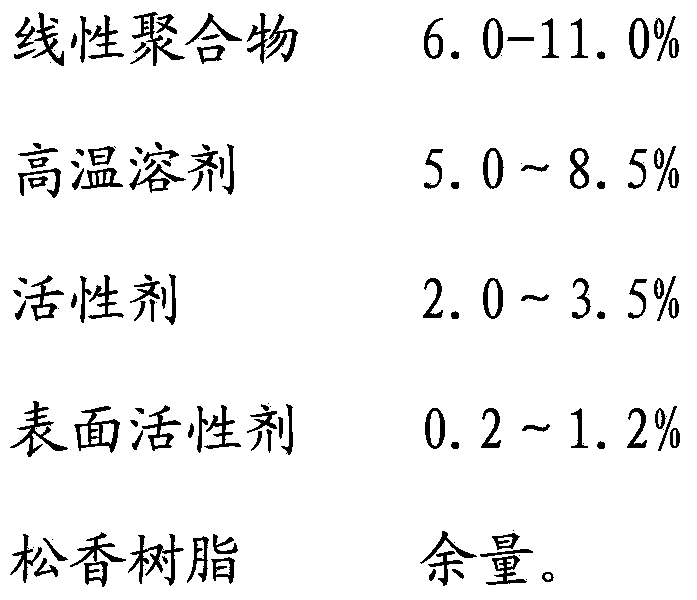

[0026] This embodiment provides a kind of flux that robot automatic soldering tin wire is used, is made up of the component of following weight:

[0027]

[0028]

[0029] The above-mentioned polystyrene is highly linear polystyrene (HDPS 1300J, Mitsui Corporation of Japan); FC-4430 is produced by 3M Company of the United States.

[0030] First add 55g propylene glycol butyl ether, 600g hydrogenated rosin and 247g polymerized rosin into the container, heat to 160°C while stirring at a speed of 35 rpm until completely melted, then add 70g polystyrene, 16g suberic acid, 8g Diethylamine hydrobromide and 4g FC-4430 were stirred for 40 minutes at a speed of 35 rpm, and the stirring was stopped after the materials were melted and mixed uniformly to obtain the flux for robot automatic welding solder wire. Pour the flux prepared above into the extruder, and extrude it into the solder alloy (alloy composition is Sn96.5Ag3.0Cu0.5) wire at a temperature of 125°C and an air pressure...

Embodiment 2

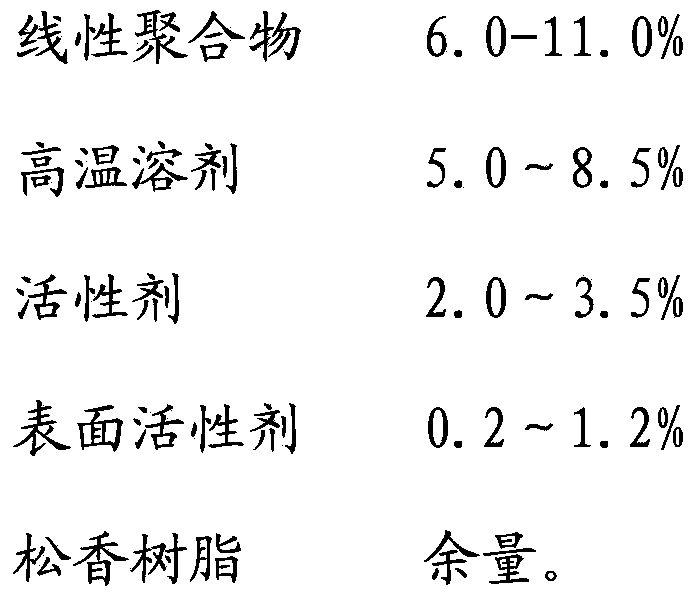

[0033] This embodiment provides a kind of flux that robot automatic soldering tin wire is used, is made up of the following components by weight percentage:

[0034]

[0035] The above polystyrene is highly linear polystyrene (HDPSP 5000G Korea LG Company), and the above FC-4430 is produced by 3M Company of the United States.

[0036] First add 80g propylene glycol butyl ether, 600g hydrogenated rosin and 187g polymerized rosin into the container, heat to 160°C and stir at a speed of 35 rpm until completely melted, then add 105g polystyrene propylene, 16g suberic acid, 8g Diethylamine hydrochloride and 4g FC-4430 were stirred for 40 minutes at a speed of 35 rpm, and the stirring was stopped after the materials were melted and mixed uniformly to obtain the flux for robot automatic welding solder wire. Pour the flux prepared above into the extruder, and extrude it into the solder alloy (alloy composition is Sn96.5Ag3.0Cu0.5) wire at a temperature of 125°C and an air pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com