Photovoltaic pre-coating material, pre-coated solder strip and preparation methods thereof

A pre-coating, photovoltaic technology, applied in photovoltaic power generation, rosin coatings, coatings, etc., can solve problems such as environmental pollution, damage, regular cleaning of welding equipment parts, etc., to reduce manufacturing costs and increase solder wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Send the strip-shaped pure copper base material into a high-speed tinning machine for tinning to obtain a pure copper tinned base material;

[0030] (2) Put the photovoltaic pre-coating material into the coater, and keep the temperature of the coater at 100°C to prepare for the next step;

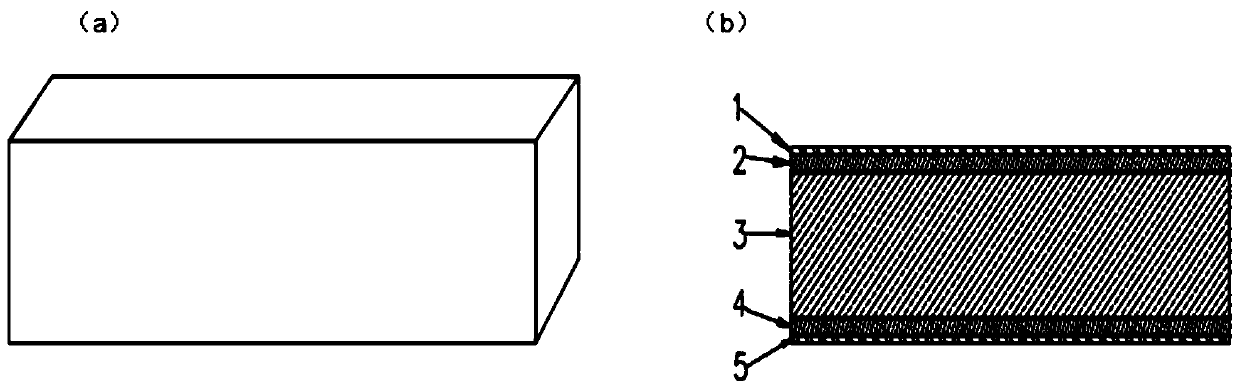

[0031] (3) Put the pure copper tinned base material obtained in step (1) into the coating machine described in step (2), carry out the coating of photovoltaic pre-coating material to the tinned base material, and slowly Bake until dry, and finally prepare a strip-shaped pre-coated welding strip. The cross-sectional view of the prepared ribbon is shown in figure 1 .

[0032] Among them, the preparation method of the photovoltaic pre-coating material is as follows: 41% of hydrogenated rosin and 30% of maleic rosin are mixed, heated and melted at a temperature of 100°C, then 10% of rosin resin is added and heated, melted and stirred, and then succinic acid 9 % and stir evenly, th...

Embodiment 2

[0034] (1) sending the triangular copper-silver alloy base material into a high-speed tinning machine for tinning to obtain a copper-silver tinned base material;

[0035] (2) Put the photovoltaic pre-coating material into the sprayer, and keep the temperature of the sprayer at 130°C to prepare for the next step;

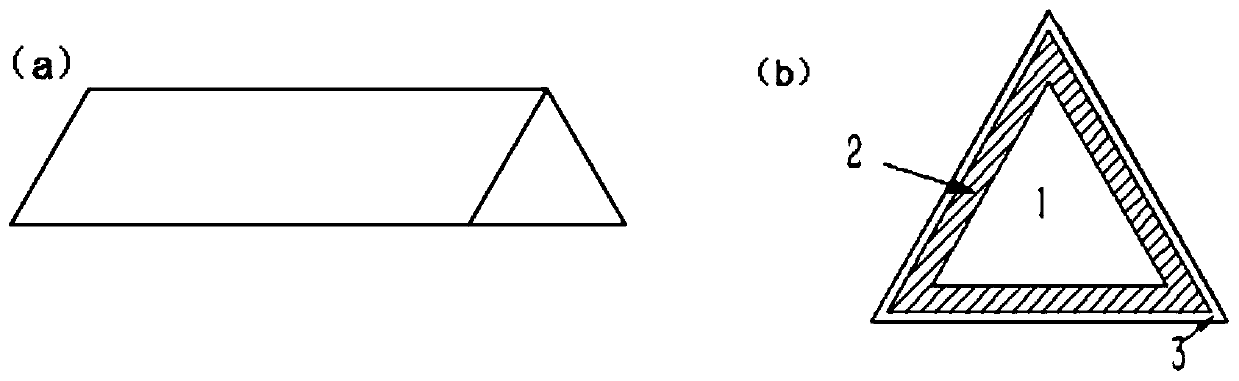

[0036] (3) Put the copper-silver tin-plated base material obtained in step (1) into the spraying machine described in step (2), carry out the wind knife blowing of photovoltaic pre-coating material to the tin-plated base material, and under 90 ℃ Slowly roast until dry, and finally prepare a triangular pre-coated welding strip. The cross-sectional view of the prepared ribbon is shown in figure 2 .

[0037] Among them, the preparation method of the photovoltaic pre-coating material is: mix 45% of hydrogenated rosin and 25% of maleic rosin, heat and melt, and the melting temperature is 125°C, then add 12% of rosin resin and heat, melt and stir, and then add succinic ...

Embodiment 3

[0039] (1) sending the round wire-shaped copper-nickel alloy base material into a high-speed tinning machine for tinning to obtain a copper-nickel tin-plated base material;

[0040] (2) Put the photovoltaic pre-coating material into the sprayer, and keep the temperature of the sprayer at 155°C to prepare for the next step;

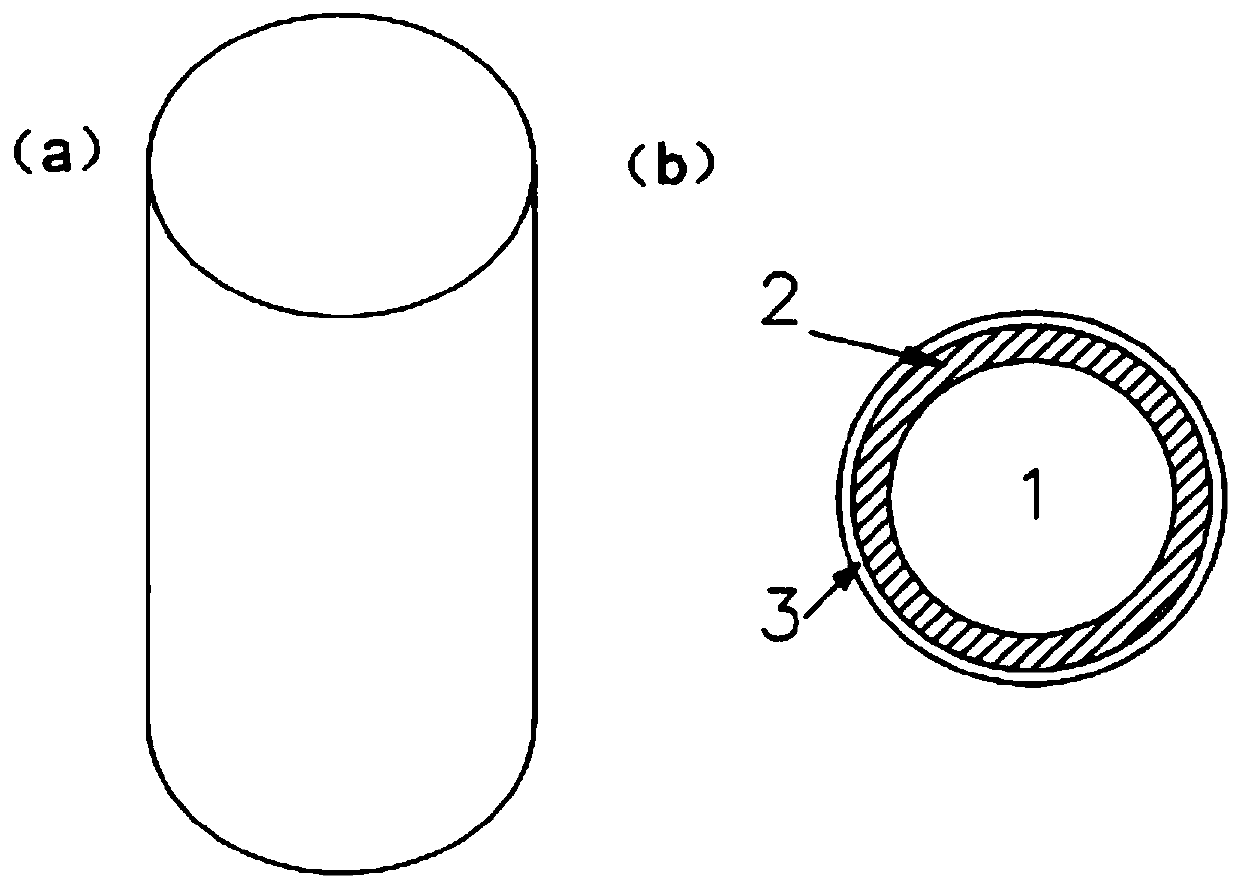

[0041] (3) Put the copper-nickel tin-plated base material gained in step (1) into the spraying machine described in step (2), carry out the wind knife blowing of photovoltaic pre-coating material to the copper-nickel tin-plated base material, and rapidly After cooling and drying, a round wire-shaped precoated welding strip is finally prepared. The cross-sectional view of the prepared ribbon is shown in image 3 .

[0042] Among them, the preparation method of the photovoltaic pre-coating material is as follows: 47% of hydrogenated rosin and 20% of maleic rosin are mixed, heated and melted, and the melting temperature is 150°C, then 15% of rosin resin is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com