Photovoltaic welding strip detergent

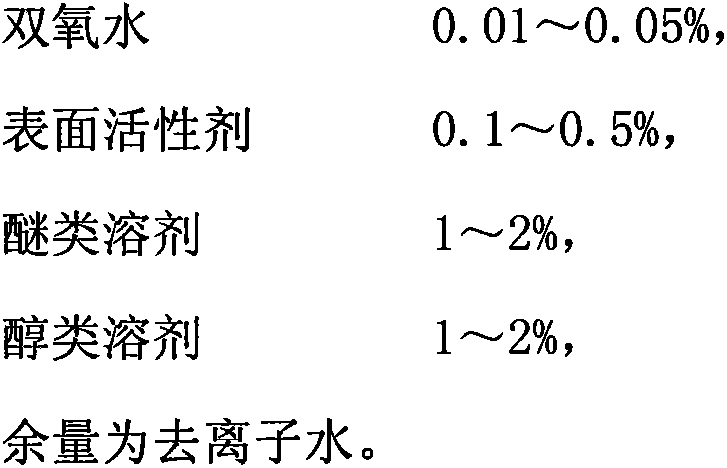

A technology for photovoltaic ribbons and cleaning agents, applied in the directions of detergent compositions, soap detergent compositions, surface active non-soap compounds and detergent compositions, etc. Wet force, reduce the residue of foreign matter, enhance the effect of decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The invention relates to a cleaning agent for photovoltaic ribbon, which is made of the following raw materials in percentage by weight: 0.01% hydrogen peroxide, 0.5% fatty acid glyceride, 2% ethylene glycol butyl ether, 1% ethanol, The balance is deionized water.

Embodiment 2

[0017] The invention relates to a cleaning agent for photovoltaic ribbon, which is made of the following raw materials in percentage by weight: 0.05% hydrogen peroxide, 0.1% fatty acid glyceride, 1% ethylene glycol butyl ether, 2% ethanol, The balance is deionized water.

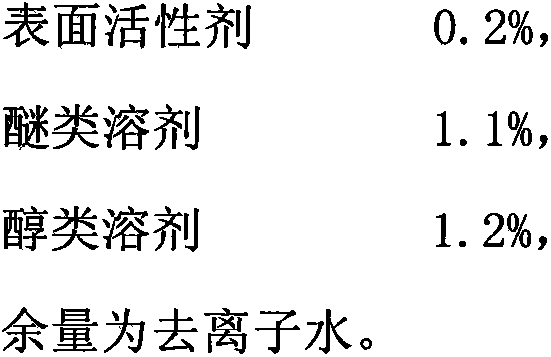

Embodiment 3

[0019] The invention relates to a cleaning agent for photovoltaic ribbon, which is made of the following raw materials in percentage by weight: 0.02% hydrogen peroxide, 0.2% fatty acid glyceride, 1.1% ethylene glycol butyl ether, 1.2% ethanol, The balance is deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com