Livestock and poultry breeding biogas slurry treatment and resource utilization method

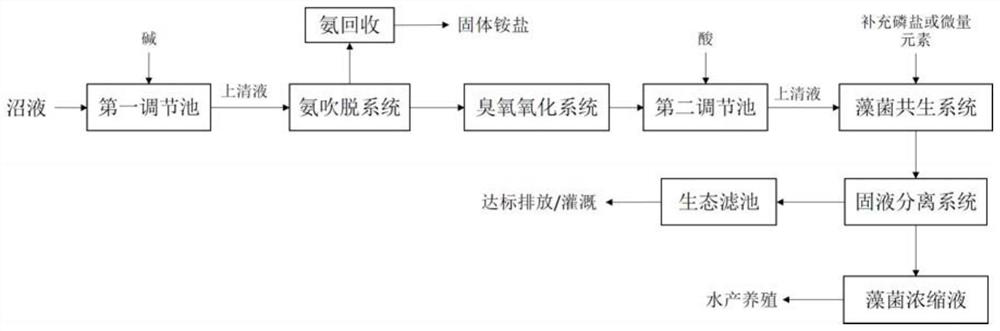

A biogas slurry treatment, livestock and poultry breeding technology, applied in chemical instruments and methods, animal husbandry wastewater treatment, biological water/sewage treatment, etc., can solve the problems of COD not being effectively removed, treatment capacity and reaction volume increasing, reaching No problems such as simultaneous removal of carbon, nitrogen and phosphorus, so as to avoid high energy consumption process and high processing cost, less sludge output, and high removal rate of carbon, nitrogen and phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

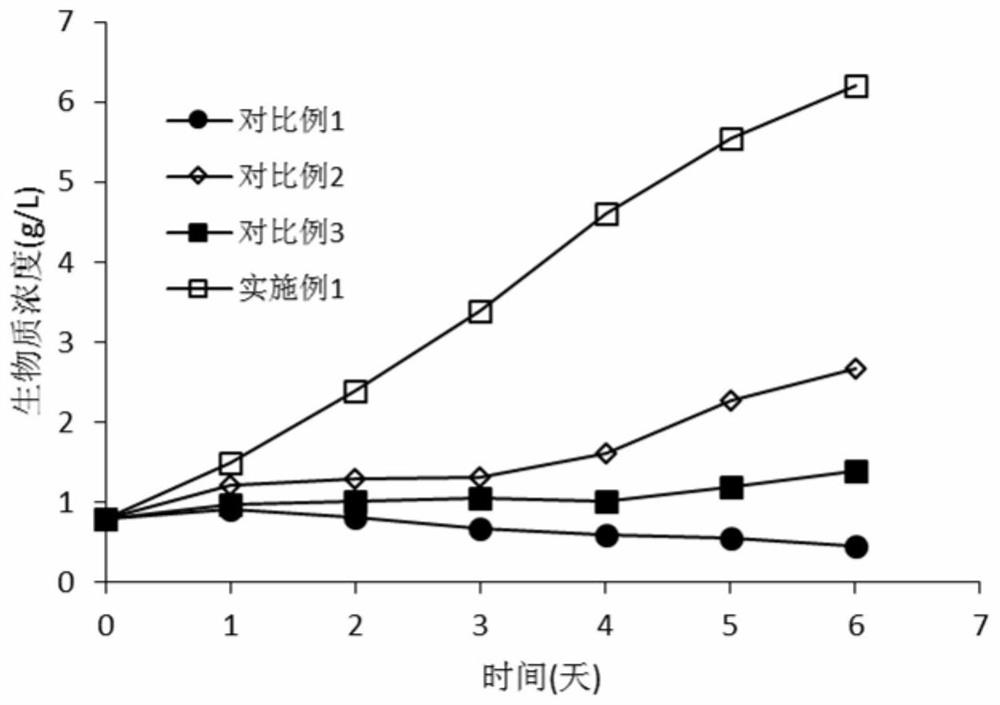

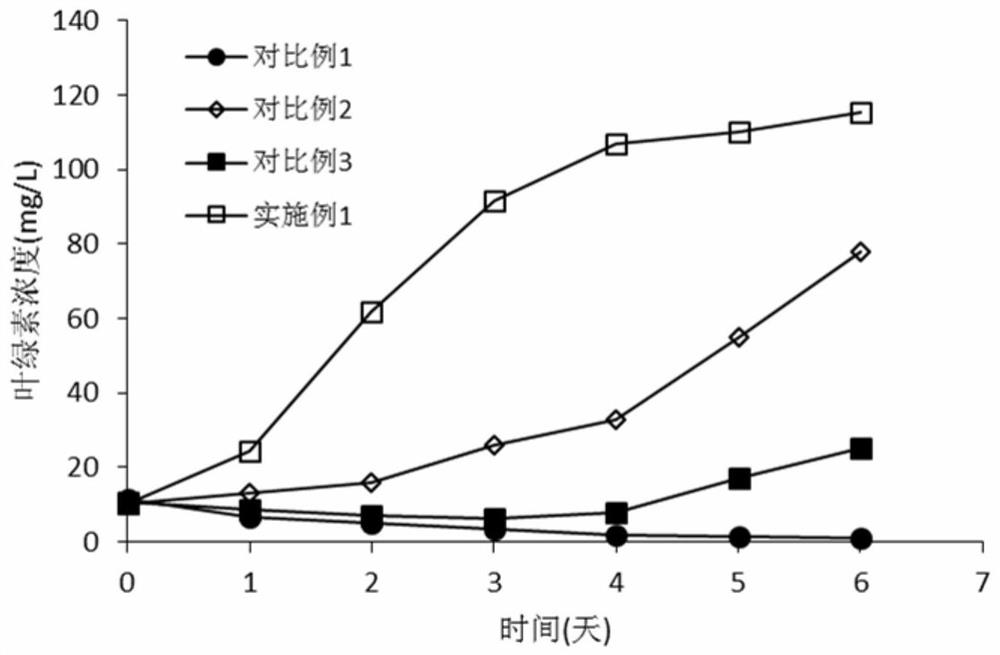

[0047] Taking biogas slurry from a cattle farm as an example, the raw water quality is 1880mg / L COD, 660mg / L ammonia nitrogen, 710mg / L total nitrogen, 40mg / L phosphate, and pH 7.6. Biogas slurry raw water through 1mol / L Ca(OH) 2 Adjust the pH of the solution to 10. After stirring and settling, the supernatant enters the ammonia stripping tower with a gas-liquid ratio of 3000. The ammonia stripping is carried out at room temperature. The concentration of ammonia nitrogen in the effluent of the ammonia stripping tower drops to 205mg / L, and the recovery rate of ammonia nitrogen up to 65%. The effluent treated by the ammonia stripping tower enters the ozone oxidation reaction tank, the ozone concentration is 50mg / min, the oxidation treatment time is 30min, and the biodegradability is increased by 1.5 times.

[0048] After the effluent of the ozone oxidation reaction tank is adjusted to pH 7.5 by 1mol / L HCl solution, the supernatant after adjusting the pH value is introduced into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com