Tin-based lead-free solder and preparing method thereof

A lead-free solder, tin-based technology, applied in the direction of welding equipment, welding/cutting media/materials, welding media, etc., can solve the problems of low wettability, increased cost, yellowing of solder joints, etc., to achieve a durable surface mirror, Cost savings and improved wetting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

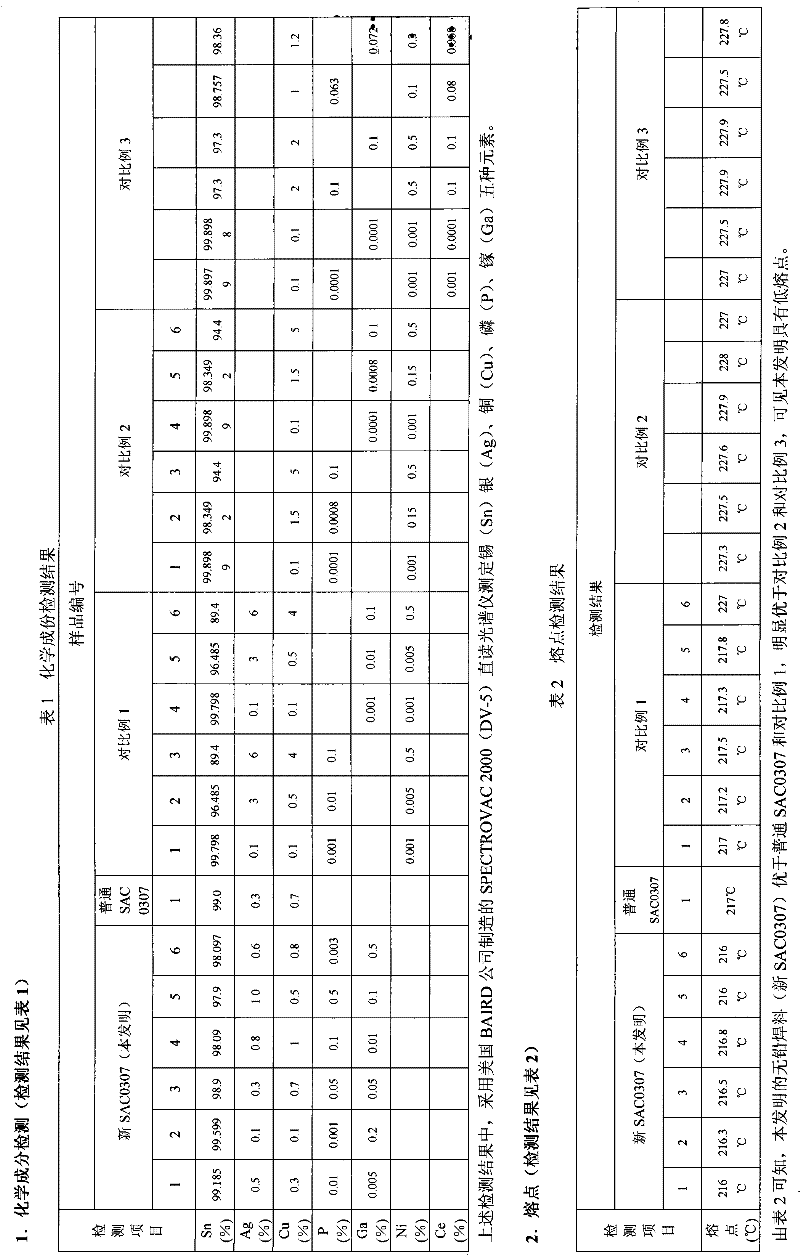

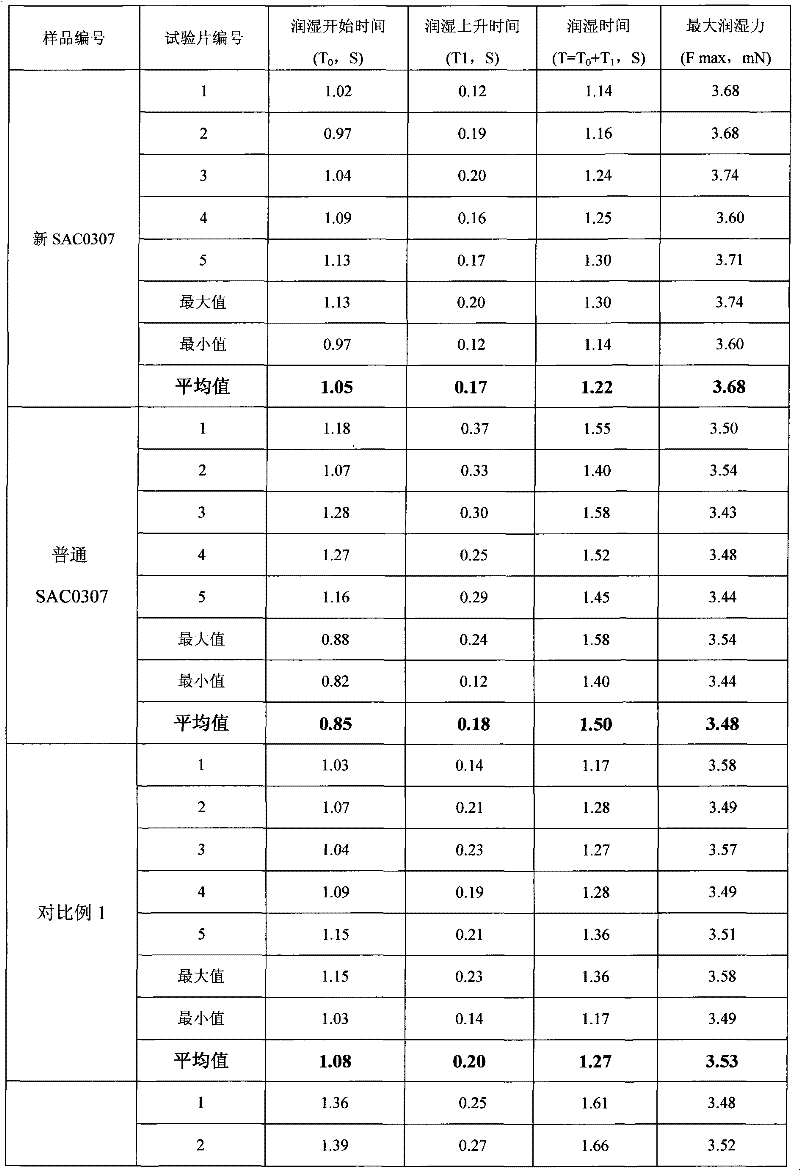

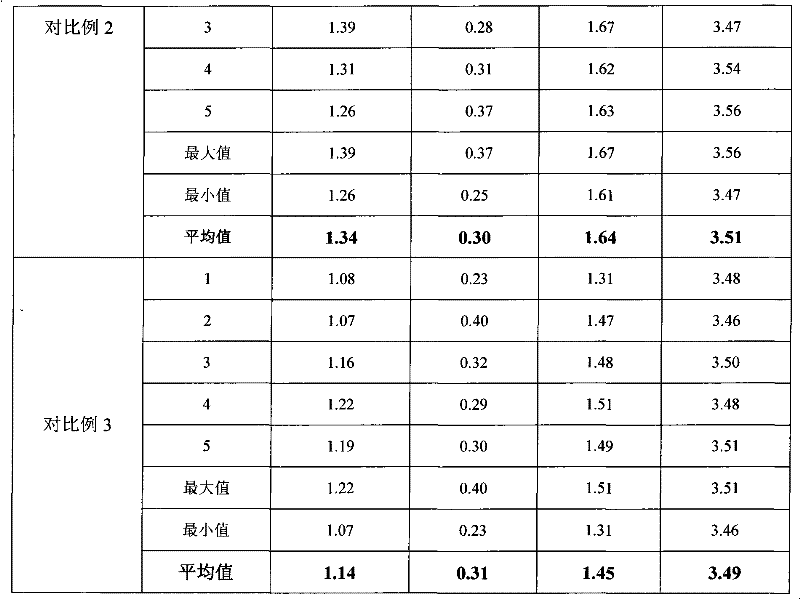

Examples

Embodiment 1

[0035] The formula of the solder in this example is 99.185% tin, 0.5% silver, 0.3% copper, 0.01% phosphorus, and 0.005% gallium.

[0036] The preparation method is:

[0037] Refined tin containing 99.95% of tin and metal gallium containing 99.99% of gallium are put into the crucible for melting at a weight ratio of 97:3, heated to 870°C, kept for 3.5 hours, stirred for 40 minutes, taken out of the furnace, cooled and cast into Gallium 3% tin-gallium master alloy ingot.

[0038] Refined tin containing 99.95% tin and silver powder containing 99.99% silver are put into the crucible for smelting according to the weight ratio of the two at 90:10, heated to 1000°C, kept for 3.5 hours, stirred for 40 minutes, taken out of the furnace, cooled and cast into silver-containing 10% tin-silver master alloy ingot.

[0039] Refined tin containing 99.95% tin and refined copper containing 99.95% copper are put into the crucible for melting at a weight ratio of 70:30, heated to 870°C, kept fo...

Embodiment 2

[0043]The formula of the solder in this example is 99.599% tin, 0.1% silver, 0.1% copper, 0.001% phosphorus, and 0.2% gallium.

[0044] The preparation method is:

[0045] Refined tin containing 99.95% of tin and metal gallium containing 99.99% of gallium are put into the crucible for melting at a weight ratio of 97:3, heated to 920°C, kept for 2.8 hours, stirred for 20 minutes, taken out of the furnace, cooled and cast into a Gallium 3% tin-gallium master alloy ingot.

[0046] Put 99.95% tin-containing refined tin and 99.99% silver-containing silver powder into the crucible for smelting according to the weight ratio of the two at 90:10, heat up to 1300°C, keep warm for 2.8 hours, stir for 20 minutes, take out of the furnace, cool and cast into silver-containing 10% tin-silver master alloy ingot.

[0047] Refined tin containing 99.95% tin and refined copper containing 99.95% copper are put into the crucible for melting at a weight ratio of 70:30, heated to 920°C, kept for 2....

Embodiment 3

[0051] The formula of the solder in this example is 98.9% tin, 0.3% silver, 0.7% copper, 0.05% phosphorus, and 0.05% gallium.

[0052] The preparation method is:

[0053] Refined tin containing 99.95% of tin and metal gallium containing 99.99% of gallium are put into the crucible for melting at a weight ratio of 97:3, heated to 900°C, kept for 3 hours, stirred for 30 minutes, taken out of the furnace, cooled and cast into a Gallium 3% tin-gallium master alloy ingot.

[0054] Refined tin containing 99.95% tin and silver powder containing 99.99% silver are put into the crucible for smelting according to the weight ratio of the two at 90:10, heated to 1200°C, kept for 3 hours, stirred for 30 minutes, taken out of the furnace, cooled and cast into silver-containing 10% tin-silver master alloy ingot.

[0055] Refined tin containing 99.95% tin and refined copper containing 99.95% copper are put into the crucible for melting at a weight ratio of 70:30, heated to 900°C, kept for 3 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com