Lead-free solder alloy and preparation method thereof

A lead-free solder alloy and solder powder technology, applied in the field of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

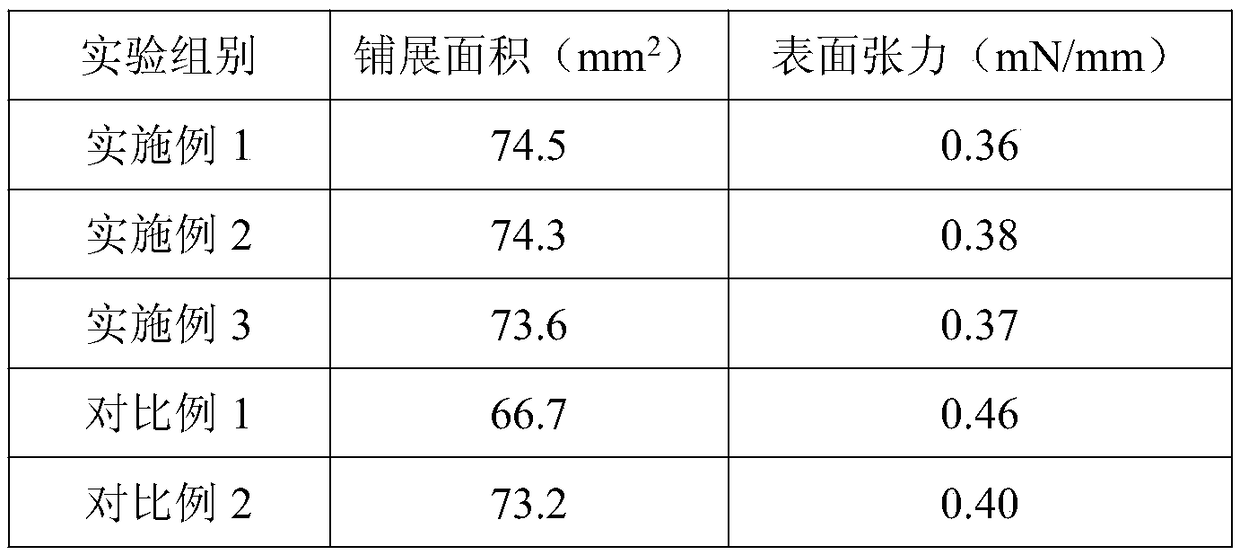

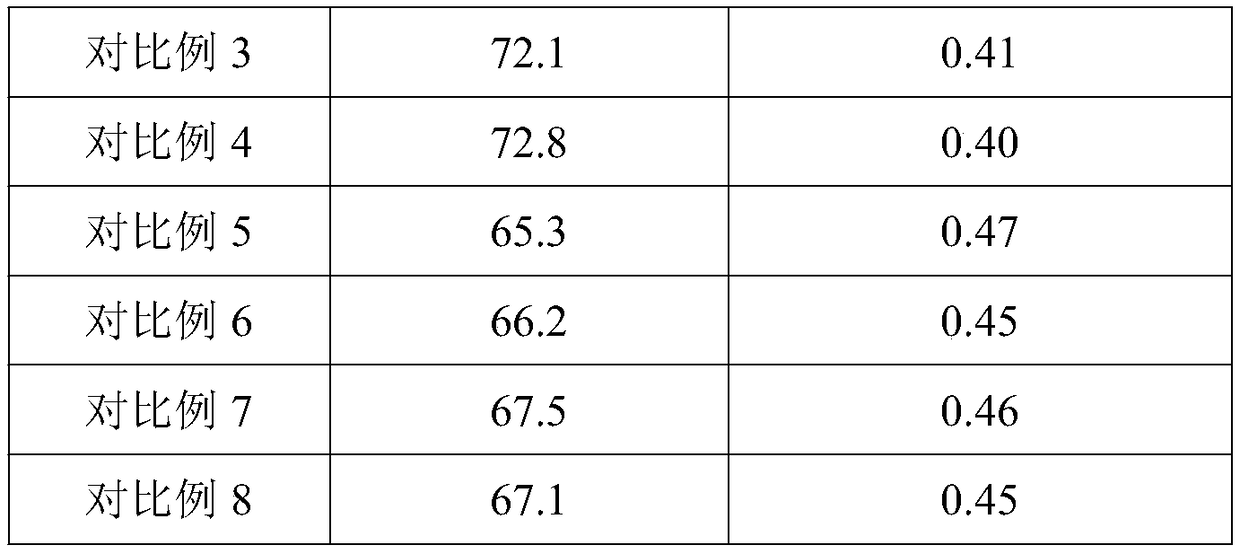

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of lead-free solder alloy, comprising the following steps:

[0030] S1: Put the proportionally weighed pure Sn ingot in the smelting furnace, and feed high-purity N 2 protective gas;

[0031] S2: The melting furnace is heated up to 460-500°C, after the pure Sn ingot is completely melted, add pure Zn, pure Bi and pure In, and keep it for 1h;

[0032] S3: adding pure Ti into the molten alloy liquid, raising the temperature to 680°C-720°C and stirring, keeping the temperature for 15-20min, the pure Ti is in the shape of a rod or a sheet;

[0033] S4: After the temperature of the solution drops to 260°C-300°C, add SnNi 4 、SnCe 1.8 , SnGe1 is continuously stirred to make it melt;

[0034] S5: After the smelting is uniform, the slag is removed, and the molten alloy is cast into a solder block or a solder bar, and finally processed into a welding wire, a solder foil or a solder powder.

Embodiment 1

[0036] The lead-free solder alloy includes raw materials in weight percentage: Zn5%, Bi1%, Ti0.5%, In0.003%, Ni0.03%, Ce0.04%, Ge0.05%, and the balance is Sn .

[0037] The present invention also provides a preparation method of lead-free solder alloy, comprising the following steps:

[0038] S1: Put the proportionally weighed pure Sn ingot in the smelting furnace, and feed high-purity N 2 protective gas;

[0039]S2: The melting furnace is heated up to 480°C, after the pure Sn ingot is completely melted, add pure Zn, pure Bi and pure In, and keep it warm for 1h;

[0040] S3: adding pure Ti into the molten alloy liquid, raising the temperature to 720° C. and stirring, and keeping the temperature for 15 minutes. The pure Ti is in the shape of a rod or a sheet;

[0041] S4: After the temperature of the solution drops to 260°C, add SnNi 4 、SnCe 1.8 , SnGe1 is continuously stirred to make it melt;

[0042] S5: After the smelting is uniform, the slag is removed, and the molten...

Embodiment 2

[0044] The lead-free solder alloy includes raw materials in weight percentage: Zn3%, Bi1.5%, Ti1%, In0.001%, Ni0.035%, Ce0.06%, Ge0.06%, and the balance is Sn .

[0045] The present invention also provides a preparation method of lead-free solder alloy, comprising the following steps:

[0046] S1: Put the proportionally weighed pure Sn ingot in the smelting furnace, and feed high-purity N 2 protective gas;

[0047] S2: The melting furnace is heated up to 500°C, after the pure Sn ingot is completely melted, add pure Zn, pure Bi and pure In, and keep it warm for 1 hour;

[0048] S3: adding pure Ti into the molten alloy liquid, raising the temperature to 700°C and stirring, and keeping it warm for 18 minutes, the pure Ti is in the shape of a rod or a sheet;

[0049] S4: After the solution temperature drops to 270°C, add SnNi 4 、SnCe 1.8 , SnGe1 is continuously stirred to make it melt;

[0050] S5: After the smelting is uniform, the slag is removed, and the molten alloy is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com