Grouting material for low-temperature steel bar sleeve connection and preparation method and application thereof

A technology of sleeve connection and low-temperature steel bar, which is applied in the field of building materials, can solve the problems of unsatisfactory, high energy consumption, insufficient grouting material strength, fluidity and durability, etc., and achieve good fluidity, good strength and expansion rate, Excellent construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides the preparation method of the grouting material for low-temperature steel bar sleeve connection described in the above technical solution, comprising the following steps:

[0059] The gel material, aggregate, mineral admixture, water reducing agent, defoaming agent, early strength agent, retarder, plastic expansion agent and antifreeze agent are mixed to obtain the grouting material for low temperature steel bar sleeve connection.

[0060] In the present invention, the components in the preparation method are the same as the components in the grouting material for low-temperature steel bar sleeve connection described in the above technical solution, and will not be repeated here.

[0061] The present invention does not specifically limit the mixing, and the mixing well known to those skilled in the art can be used. In the present invention, the mixing device is preferably a mixer, more preferably a mechanical power grouting mixer or a...

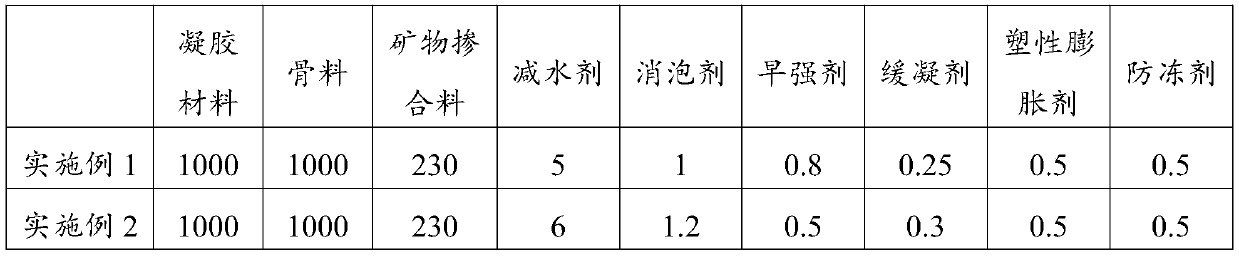

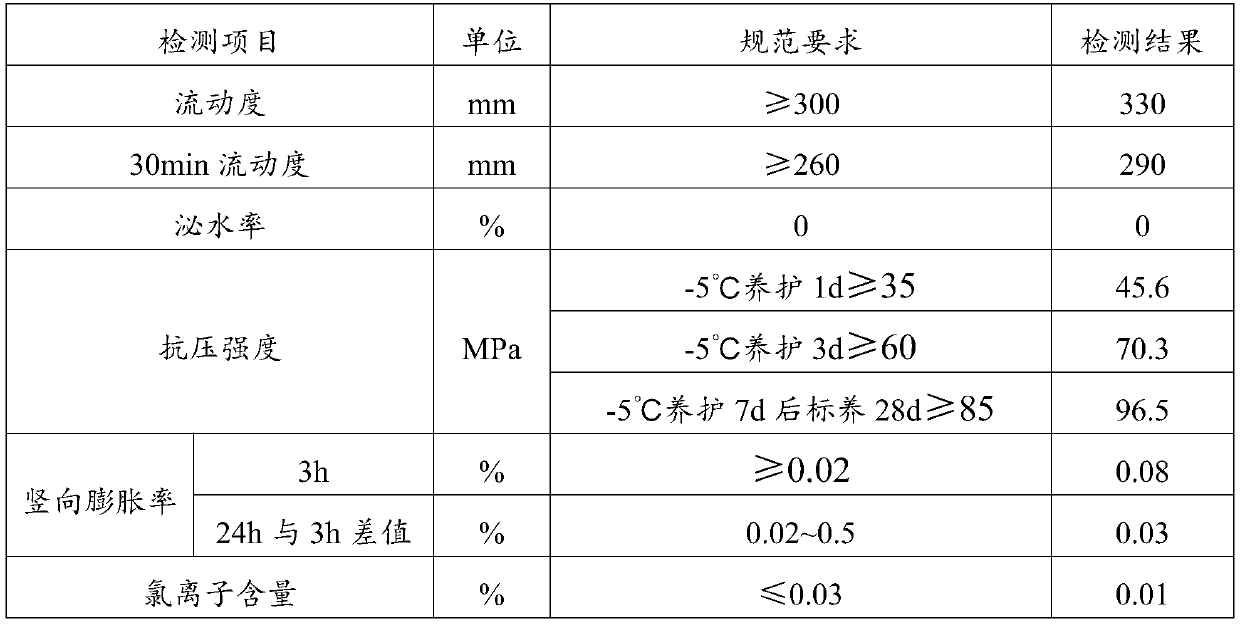

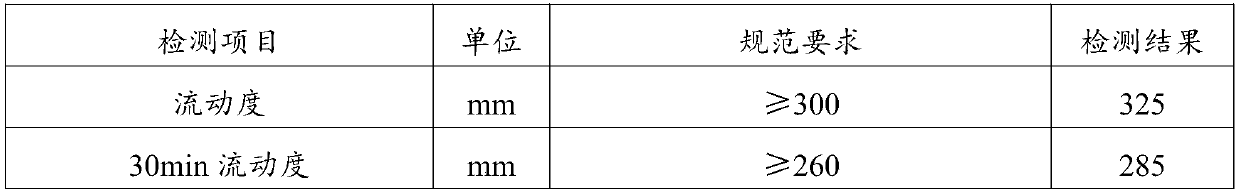

Embodiment 1~2

[0072] The reagents used in Examples 1-2 are all commercially available.

[0073] Mix gel material, aggregate, mineral admixture, water reducer, defoamer, early strength agent, retarder, plastic expansion agent and antifreeze at -5°C to obtain the low temperature steel sleeve The grouting material for connection, wherein the gel material is 52.5 grade Portland cement, sulfoaluminate cement and high belite cement mixed in a mass ratio of 1:1:1; the aggregate is river sand, and the The mass ratio of coarse river sand with particle size of 20-40 mesh and fine river sand with particle size larger than 40 mesh and less than or equal to 70 mesh is 3:1; Glass microbeads with a wall thickness of 1.2-1.8 μm are obtained by mixing according to a mass ratio of 1:1; the water reducing agent is a polycarboxylate water reducing agent; the defoaming agent is polyoxyethylene polyoxypropylene pentaerythritol; the early strength agent is calcium formate; antifreeze is sodium nitrate; retarder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com