Modified ammonium polyphosphate composite intumescent flame retardant and preparation method and application thereof

A technology of intumescent flame retardant and ammonium polyphosphate, which is applied in the field of modified ammonium polyphosphate composite intumescent flame retardant and its preparation, can solve the problems of complex production process, low flame retardant efficiency and high hygroscopicity, and achieve rich source of raw materials , Improve the flame retardant efficiency, improve the effect of hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

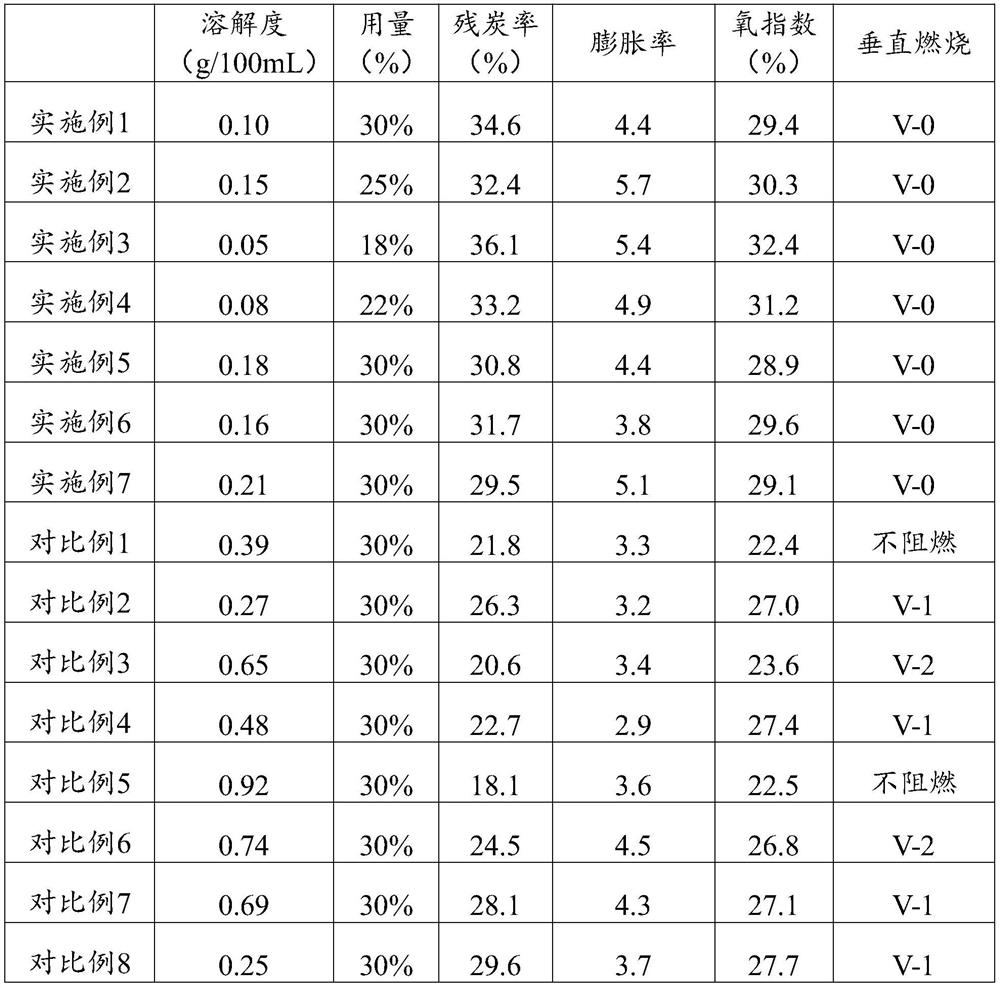

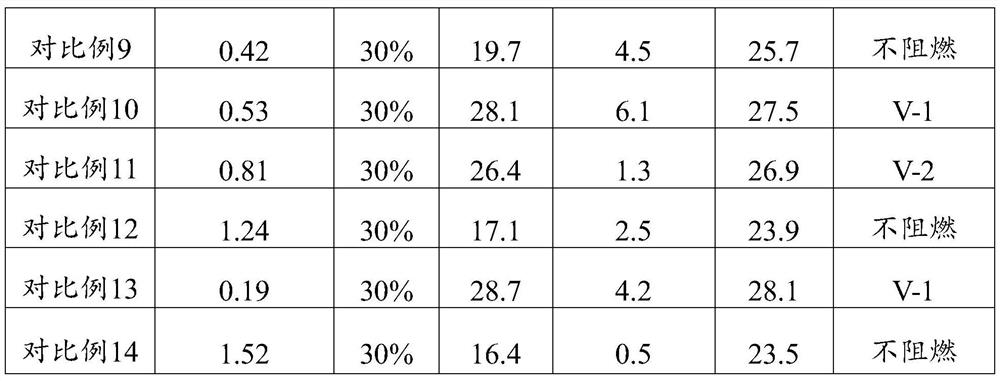

Examples

preparation example Construction

[0029] The preparation method of the modified ammonium polyphosphate composite expansion flame retardant described in the application specifically comprises the following steps:

[0030] Step 1. Disperse the ammonium polyphosphate powder with a degree of polymerization greater than 1000 in deionized water to obtain a dispersion A with a mass percent concentration of 10-40 wt%, stir the dispersion A at a constant temperature at a temperature of 25-45°C and gradually add Add the chitosan derivative aqueous solution dropwise to obtain the reaction solution A, continue to stir the reaction solution A at constant temperature for 15-120min, then wash and filter with deionized water;

[0031] Step 2. Disperse the powder product obtained after filtering in the step 1 in deionized water to obtain a dispersion B with a mass percent concentration of 10-40 wt%, stir the dispersion B at a constant temperature at a temperature of 25-45° C., and gradually add Add the phytic acid aqueous solu...

Embodiment 1

[0037] Step 1. Disperse 10 g of ammonium polyphosphate powder with a degree of polymerization greater than 1000 in 15 mL of deionized water to obtain a dispersion A with a mass percent concentration of 40 wt %. Stir the dispersion A at a temperature of 25° C. and gradually add the Molecular weight is 50kDa chitosan phosphate preparation pH value is 5.5, mass percent concentration is 62.5mL of chitosan derivative aqueous solution of 4wt%, obtains reaction solution A, and in described reaction solution A, ammonium polyphosphate powder and shell The mass ratio of polysaccharide derivatives is 4:1, continue to stir the reaction solution A30min at constant temperature, then wash and filter;

[0038]Step 2. Disperse the powder product obtained after filtering in step 1 in 15 mL of deionized water to obtain dispersion B. Stir dispersion B at a temperature of 25° C. and gradually add a pH value of 3.0 and a mass percentage concentration of 25mL of 8wt% phytic acid aqueous solution to ...

Embodiment 2

[0042] Step 1. Take 10 g of ammonium polyphosphate powder with a degree of polymerization greater than 1000 and disperse it in 30 mL of deionized water to obtain a dispersion A with a mass percent concentration of 25 wt%. Stir the dispersion A at a temperature of 25°C and gradually add it dropwise The chitosan derivative aqueous solution prepared by chitosan polyphosphate with a molecular weight of 150kDa has a pH value of 3.5 and a mass percentage concentration of 3wt% is 47.6mL to obtain a reaction solution A, and the ammonium polyphosphate powder in the reaction solution A is The mass ratio to chitosan derivatives is 7:1, continue to stir the reaction solution at constant temperature for 30min, then wash and filter;

[0043] Step 2. Disperse the powder product obtained after filtering in step 1 in 30 mL of deionized water to obtain dispersion B. Stir dispersion B at a temperature of 25° C. and gradually add a pH value of 4.0 and a mass percentage concentration of 6wt% phyti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com