Preparation method of flame-proof sea silk new material

A technology of seaweed fiber and new material, applied in fiber processing, wet spinning, alginate man-made filament and other directions, can solve the problems of seaweed fiber elasticity, strength and color are not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

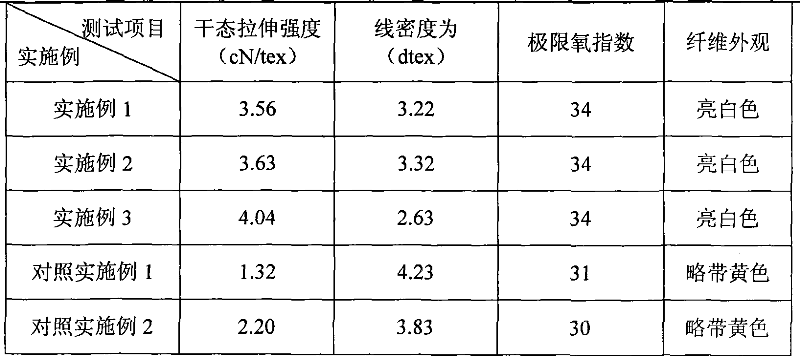

Embodiment 1

[0014] Add 10 kg of 200-mesh high-viscosity potassium alginate into a dissolving kettle filled with 190 liters of deionized water, stir and dissolve at a high speed at 70°C, wherein the ratio of the G segment to the M segment of the raw material potassium alginate is 1:1 , and use hydrogen peroxide to adjust the viscosity of the solution to 12000mPa·S, and make spinning solution after filtration and vacuum defoaming.

[0015] Utilize a spinneret with 4000 holes of 0.075 microns to carry out wet spinning, the spinning speed is 30 m / min, the temperature of the spinning solution is 55 °C, the coagulation bath is 3% calcium chloride aqueous solution, and the coagulation bath temperature is 40 °C . After passing through the coagulation bath, the primary seaweed fibers are drawn, heat-set and oiled after passing through the pre-heating bath and the drawing bath, wherein the temperatures of the pre-heating bath, the drawing bath and the drawing-setting temperature are 60°C, 100°C, an...

Embodiment 2

[0017] Add 8 kg of 200-mesh high-viscosity potassium alginate and 2 kg of 200-mesh sodium alginate into a dissolving kettle filled with 190 liters of deionized water, stir and dissolve at a high speed at 65°C, wherein the raw material potassium alginate G segment and M The ratio of chain segments is 3:1, and the viscosity of the solution is adjusted to 10000mPa·S by using sodium hypochlorite, and the spinning solution is made after filtration and vacuum defoaming.

[0018] Utilize the spinneret of 4000 holes 0.075 micron to carry out wet spinning, the spinning speed is 30 m / min, the temperature of the spinning solution is 55°C, the coagulation bath is 3.5% calcium chloride aqueous solution, and the coagulation bath temperature is 40°C . After passing through the coagulation bath, the primary seaweed fibers are drawn, heat-set and oiled after passing through the pre-heating bath and the drawing bath, wherein the temperatures of the pre-heating bath, the drawing bath and the dra...

Embodiment 3

[0020] Add 10 kg of 200-mesh high-viscosity potassium alginate into a dissolving kettle filled with 190 liters of deionized water, stir and dissolve at a high speed at 70°C, wherein the ratio of the G segment to the M segment of the raw material potassium alginate is 2:1 , and use hydrogen peroxide to adjust the viscosity of the solution to 5000mPa·S, and make spinning solution after filtration and vacuum defoaming.

[0021] Utilize a spinneret with 4000 holes of 0.060 microns to carry out wet spinning, the spinning speed is 30 m / min, the temperature of the spinning solution is 55°C, the coagulation bath is 3% calcium chloride aqueous solution, and the coagulation bath temperature is 40°C . After passing through the coagulation bath, the primary seaweed fiber is subjected to drawing heat setting and oiling treatment after the preheating bath and drawing bath, wherein the temperatures of the preheating bath, drawing bath and drawing setting temperature are 70°C, 100°C, and 130°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com