A kind of polymer electrolyte and its preparation method and application

A polymer and electrolyte technology, applied in the direction of non-aqueous electrolyte, solid electrolyte, non-aqueous electrolyte battery, etc., can solve the problem that it is difficult to reduce the risk of thermal runaway of high-energy lithium batteries, can not meet the safety of high-specific energy lithium batteries, polymer electrolytes are not It has secondary cross-linking and other problems to achieve the effect of rapidly reducing battery temperature, avoiding battery thermal runaway, and preventing battery thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The raw materials used to prepare the polymer electrolyte are listed in Table 1, and the LiTFSI / EMC solution was prepared in an argon-filled glove box. Will Add acrylonitrile and acrylonitrile to the above solution, and add the initiator AIBN. After complete dissolution, inject the solution into a lithium ion battery containing positive and negative electrode materials, and place it at 60 °C for in-situ polymerization. After 8 hours, the required Polymer Electrolyte Batteries.

[0065] Table 1:

[0066]

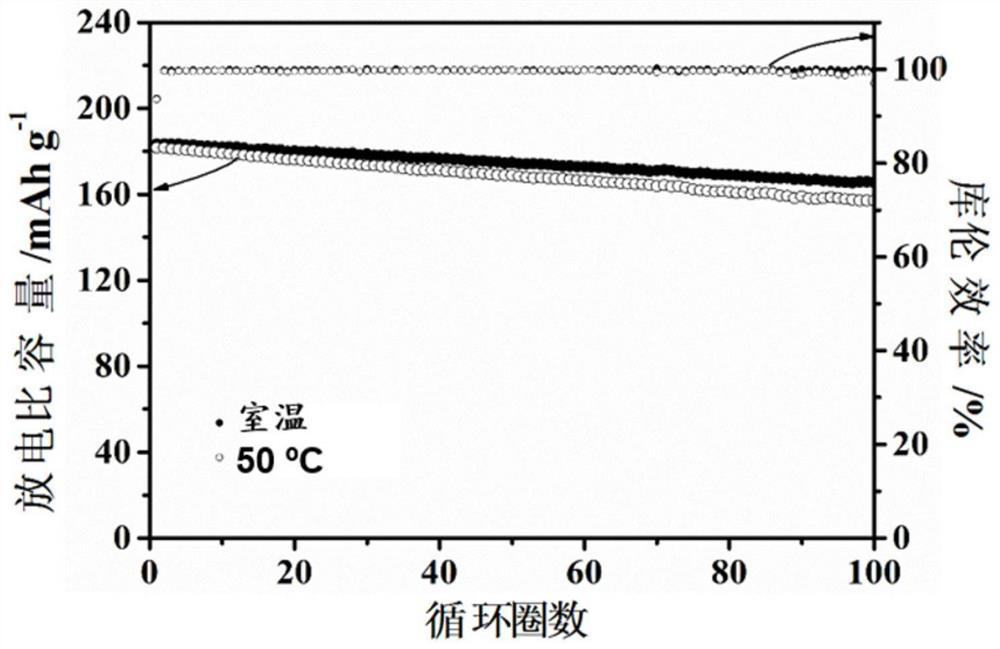

[0067] The electrolyte obtained from Example 1 above has high ionic conductivity, wide electrochemical window, and high tensile strength (Table 1). The NCM622 / Li metal full battery was assembled with the electrolyte obtained above, and the capacity retention rates were 90% and 87% after 100 cycles at room temperature and 50 °C at operating voltages of 2.5–4.4 V and 0.1 C, respectively (e.g. figure 1 shown), it can be seen that the obtained polymer electrolyte ha...

Embodiment 2

[0070] Table 2 shows the proportions of raw materials used to prepare the polymer electrolyte. The urethane acrylate prepared in advance according to the monomer ratio shown in Table 2 was dissolved in NMP, mixed uniformly and then scraped onto PET, and dried to obtain a polymer film. After punching the polymer film, The solution is fully swollen to obtain a polymer electrolyte membrane. A lithium battery is assembled with the electrolyte membrane and the corresponding positive and negative electrode materials.

[0071] Table 2:

[0072]

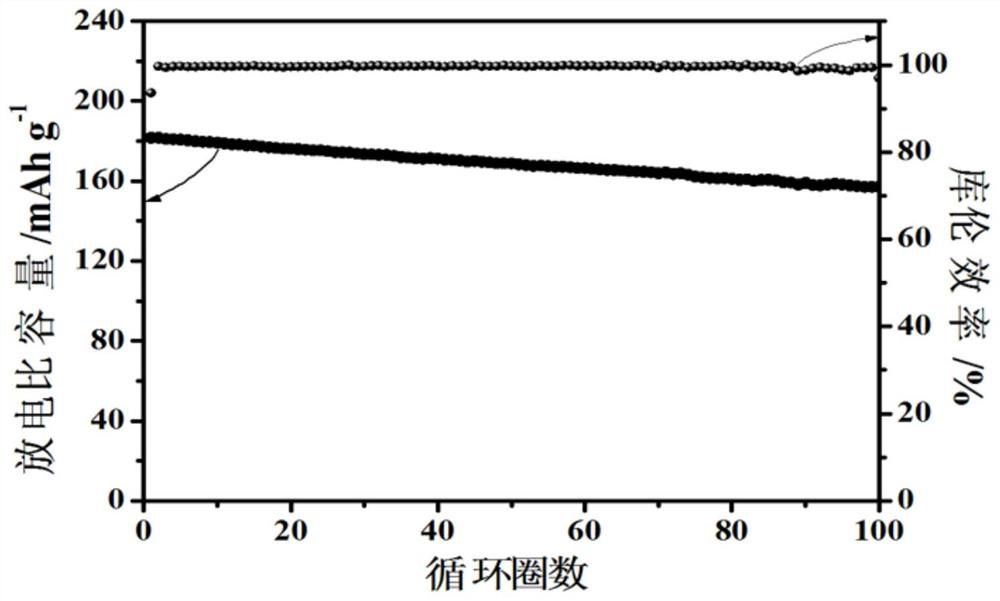

[0073] The electrolyte obtained from Example 2 above has high ionic conductivity, wide electrochemical window, and high tensile strength (Table 2). The NCM811 / lithium metal full battery was assembled with the above electrolyte, and the capacity retention rate was 89% after 100 cycles at an operating voltage of 2.5 to 4.3 V and 2.0 C (e.g. image 3 shown), it can be seen that the obtained polymer electrolyte has excellent electrochemi...

Embodiment 3

[0076] The raw material ratio for preparing the polymer electrolyte is shown in Table 3. In an argon-filled glove box, the Vinylene carbonate and LiDFOB were mixed together to prepare a solution, and the initiator BPO was added. After complete dissolution, the solution was injected into a lithium ion battery containing positive and negative materials, and placed at 80 °C for in-situ polymerization. After 6 hours The desired polymer electrolyte battery is obtained.

[0077] table 3:

[0078]

[0079]

[0080] The electrolyte obtained from Example 3 above has high ionic conductivity, wide electrochemical window, and high tensile strength (Table 3). The lithium cobalt oxide / graphite full battery was assembled with the above electrolyte, and the capacity retention rate was 91% after 200 cycles at 50°C at an operating voltage of 2.5-4.4V and 0.5C (eg Figure 5 shown), it can be seen that the obtained polymer electrolyte has excellent electrochemical performance.

[0081] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com