Biaxial orientation type polyphenylene sulfide composite membrane

A composite film and polyphenylene sulfide technology, applied in the field of biaxially oriented polyphenylene sulfide composite film and its preparation, can solve problems such as low toughness and elongation at break, and achieve improved heat resistance, stable and uniform surface properties , the effect of improving the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

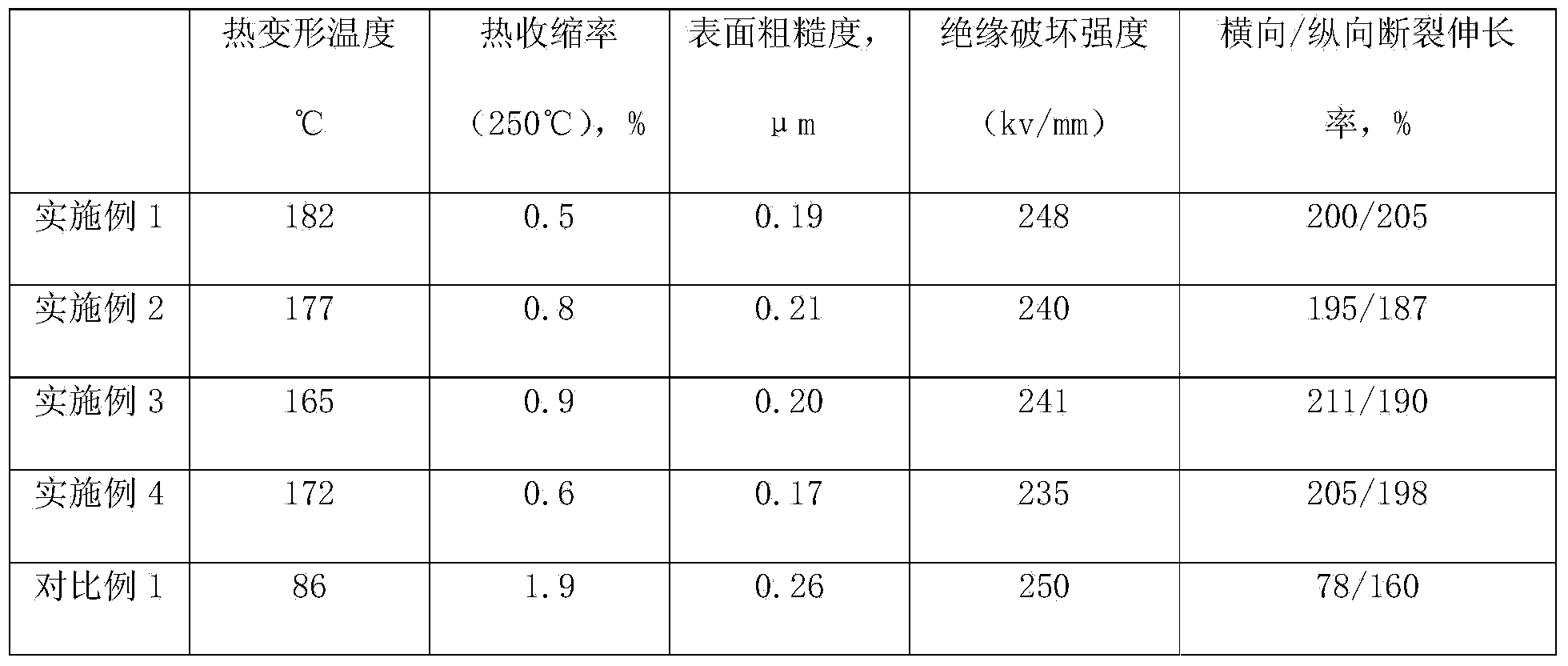

Examples

Embodiment 1

[0024] A preparation method of biaxially oriented polyphenylene sulfide composite film, the preparation method has the following steps:

[0025] (1) Prepare materials

[0026] Prepare film-grade polyphenylene sulfide resin, polypropylene, and silicon dioxide, wherein the film-grade polyphenylene sulfide resin includes film-grade polyphenylene sulfide resin for masterbatch and film-grade polyphenylene sulfide resin for casting, according to the quality In terms of ratio, the ratio of film-grade polyphenylene sulfide resin for masterbatch to polypropylene is 85:15, and the ratio of the sum of the total amount of film-grade polyphenylene sulfide resin and polypropylene for masterbatch to silicon dioxide is 100:0.4; the ratio of the sum of the total amount of film-grade polyphenylene sulfide resin for masterbatch, polypropylene, and silicon dioxide to film-grade polyphenylene sulfide resin for casting is 2:8;

[0027] (2) Masterbatch preparation

[0028] The above materials are ...

Embodiment 2

[0037] A preparation method of biaxially oriented polyphenylene sulfide composite film, the preparation method has the following steps:

[0038] (1) Prepare materials

[0039] Prepare film-grade polyphenylene sulfide resin, polypropylene, and calcium carbonate, wherein the film-grade polyphenylene sulfide resin includes film-grade polyphenylene sulfide resin for masterbatch and film-grade polyphenylene sulfide resin for casting, according to the mass ratio Calculated, the ratio of film-grade polyphenylene sulfide resin and polypropylene for masterbatch is 90:10, and the ratio of the total amount of film-grade polyphenylene sulfide resin and polypropylene for masterbatch to calcium carbonate is 100: 0.2; the ratio of the sum of the total amount of film-grade polyphenylene sulfide resin, polypropylene, and calcium carbonate for the masterbatch to the film-grade polyphenylene sulfide resin for casting is 1:9;

[0040] All the other steps are the same as in Embodiment 1.

Embodiment 3

[0042] A preparation method of biaxially oriented polyphenylene sulfide composite film, the preparation method has the following steps:

[0043] (1) Prepare materials

[0044] Prepare film-grade polyphenylene sulfide resin, polycarbonate, and silicon dioxide, wherein the film-grade polyphenylene sulfide resin includes film-grade polyphenylene sulfide resin for masterbatch and film-grade polyphenylene sulfide resin for casting, according to In terms of mass ratio, the ratio of film-grade polyphenylene sulfide resin and polycarbonate for masterbatch is 95:5, and the sum of the total amount of film-grade polyphenylene sulfide resin and polycarbonate for masterbatch and the amount of silicon dioxide The ratio is 100:0.6; the ratio of the sum of the total amount of film-grade polyphenylene sulfide resin, polycarbonate, and silicon dioxide for the masterbatch to the film-grade polyphenylene sulfide resin for casting is 3:7;

[0045] All the other steps are the same as in Embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com