Preparation method of polyimide profiled fiber

A special-shaped fiber and polyimide technology, which is applied in fiber processing, fiber chemical characteristics, dry spinning, etc., can solve problems such as cost increase, lack of description of fiber irregularity, and fiber performance degradation, and achieve high production efficiency. Good thermal dimensional stability and convenient solvent volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

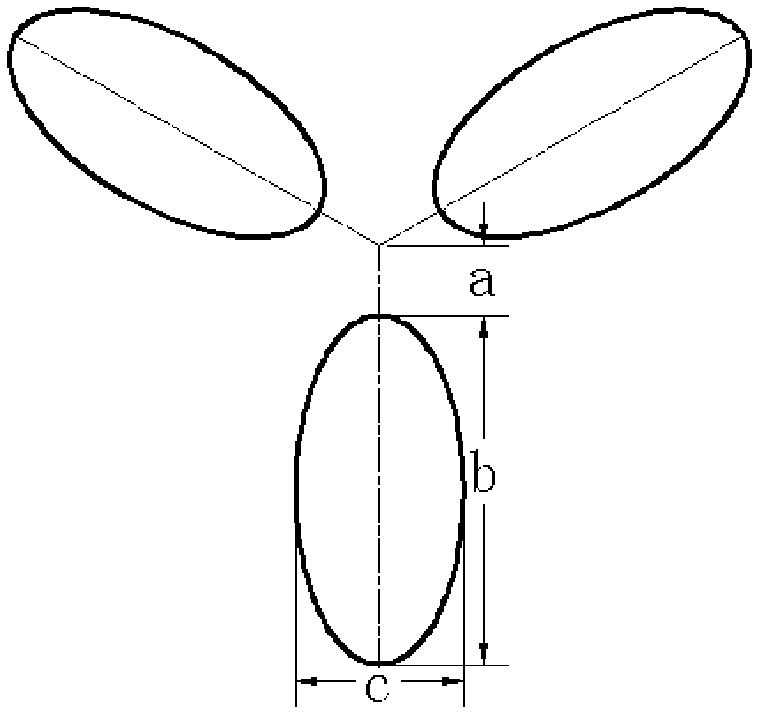

[0037] Put 10kg (49.938mol) of 4,4-diaminodiphenyl ether and 83kg of N,N-dimethylformamide into the polymerization kettle, stir at room temperature until it is completely dissolved, and pass the refrigerant to reduce the temperature of the solution to -5℃ , Then add 10.893kg (49.938mol) of pyromellitic anhydride and continue to pass the refrigerant. After 24h, a polyamic acid solution with a concentration of 20wt% is obtained. After the solution is degassed, spinning can be carried out. The cross-section of the spinning solution passing through the capillary is elliptical trilobal (center distance a is 0.03mm, leaf width b is 0.2mm, leaf length c is 0.12mm) ( figure 1 The spinneret of) enters the hot-air spinning tunnel, the spinning tunnel is 10m long, the hot-air temperature is 205°C, the winding speed is 100m / min, and the thin stream solidifies into fibers to obtain the nascent fiber with irregular cross-section. The nascent fiber enters a heating box for cyclization at a te...

Embodiment 2

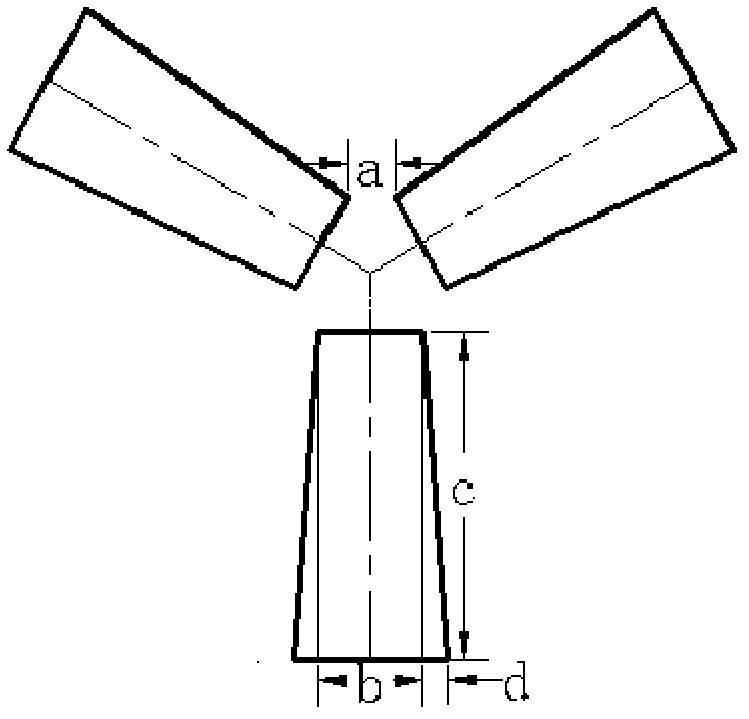

[0039] Put 2.5kg (23.122kmol) of p-phenylenediamine, 2.5kg (23.122kmol) of m-phenylenediamine and 86.3kg of N,N-dimethylacetamide and N-methylpyrrolidone mixture into the polymerizer and stir To completely dissolve, let the temperature of the solution drop to -5°C through refrigerant, then add 16.566kg (46.244mol) of 3,3',4,4'-benzophenone sulfone tetracarboxylic dianhydride, continue to stir through the refrigerant, after 24h A polyamic acid solution with a concentration of 18 wt% is obtained, and spinning can be performed after the solution is defoamed. The cross section of the spinning solution passing through the capillary is elliptical four-leaf (center distance a is 0.05mm, leaf width b is 0.2mm, leaf length c is 0.12mm) (such as Figure 5 The spinneret of) enters the hot-air spinning tunnel, the spinning tunnel is 10m long, the hot-air temperature is 270℃, the winding speed is 400m / min, and the thin stream solidifies into fibers to obtain the irregular cross-sectional spu...

Embodiment 3

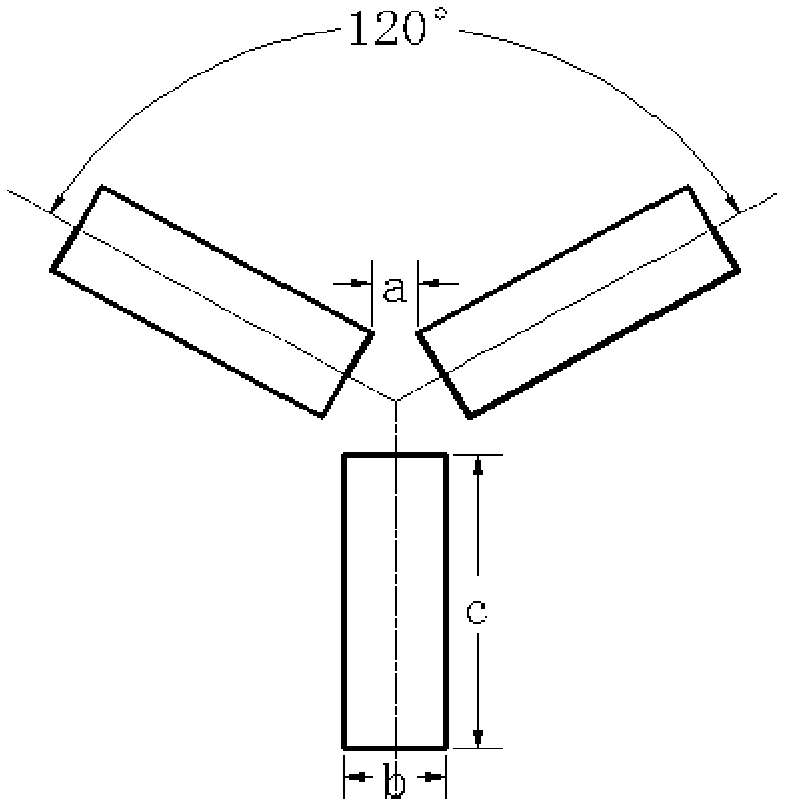

[0041] Put 4kg (19.976mol) of 4,4-diaminodiphenyl ether, 3.960kg (19.976mol) of 4,4-diaminodiphenylmethane and 83.4kg N,N-dimethylformamide into the polymerizer, Stir at room temperature until it is completely dissolved, pass the refrigerant to reduce the temperature of the solution to -5°C, then add 12.873kg (39.952mol) of 3,3,4,4-benzophenonetetracarboxylic dianhydride, 28h to obtain a concentration of 30wt% Polyamic acid solution. Spinning can be performed after the solution is defoamed. The cross section of the spinning solution passing through the capillary is elliptical five-lobed (center distance a is 0.08mm, leaf width b is 0.2mm, leaf length c is 0.12mm) (e.g. Image 6 The spinneret of) enters the hot-air spinning tunnel, the spinning tunnel is 12m long, the hot-air temperature is 210°C, the winding speed is 800m / min, and the thin stream solidifies into fibers to obtain nascent fibers with irregular cross-sections. The nascent fiber enters the hot box to complete the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com