Flame-retardant two-component polyurethane adhesive and preparation method thereof

A two-component polyurethane and adhesive technology, applied in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., to achieve long-lasting and stable flame retardancy, simple manufacturing process, and high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

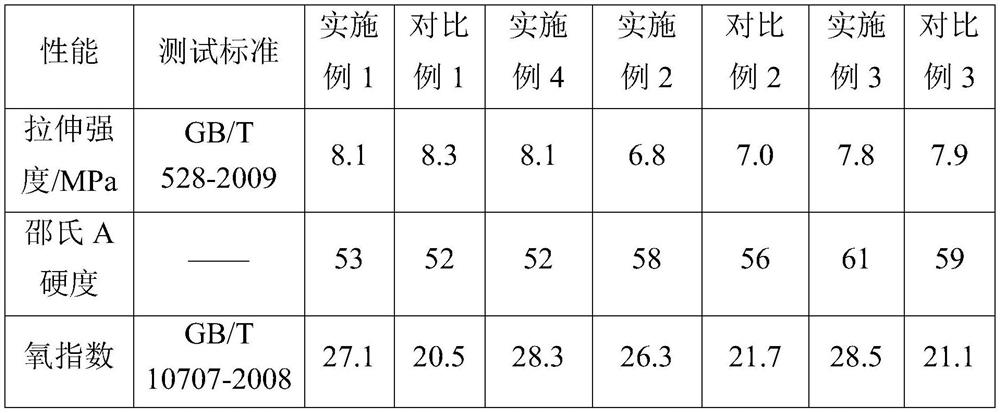

Examples

Embodiment 1

[0118] First, add 185.86kg of 1,2-dibromoethylene, 72.11kg of 3-buten-1-ol, 110.56kg of anhydrous methanol, and 111.00g of azobisisobutyronitrile into a reactor with a condenser, and start the agitator. Heat to the temperature of the reaction system at about 70°C, and maintain the reaction at this temperature; take a sample to measure the hydroxyl value of the prepolymer, and when the hydroxyl value is between 210.0 and 220.0 mgKOH / g, the reaction can be ended, and the temperature is lowered to 40~ 50°C, vacuum pumping and recovery of the solvent, and then the material can be discharged when the temperature is lowered to below 40°C to obtain a brominated polyol prepolymer for use.

[0119] Then, prepare the flame-retardant two-component polyurethane glue:

[0120]Preparation of component A (main agent): 35.00kg of the brominated polyol prepolymer prepared above, 10.00kg of polycastor oil adipate polyol, 5.00kg of polybutylene adipate diol, polybutylene adipate Add 9.00kg of c...

Embodiment 2

[0124] First, add 185.86kg of 1,2-dibromoethylene, 144.22kg of 3-buten-1-ol, 82.45kg of butyl acetate, and 206.12g of dibenzoyl peroxide into the reactor of the condenser, start the agitator, and heat The temperature of the reaction system is around 80°C, and the reaction is maintained at this temperature; the hydroxyl value of the prepolymer is measured by sampling. When the reaction reaches a hydroxyl value between 210.0 and 220.0 mgKOH / g, the reaction can be terminated, and the temperature is lowered to 40~ 50°C, vacuum pumping and recovery of the solvent, and then the material can be discharged when the temperature is lowered to below 40°C to obtain a brominated polyol prepolymer for use.

[0125] Then, prepare the flame-retardant two-component polyurethane glue:

[0126] Preparation of component A (main agent): 10.00kg of brominated polyol prepolymer prepared above, 15.00kg of polyethylene glycol 600, 10.00kg of polyoxypropylene glycol, 10.00kg of polyoxypropylene triol, ...

Embodiment 3

[0130] First, add 185.86kg of 1,2-dibromoethylene, 108.17kg of 3-buten-1-ol, 97.91kg of benzene, and 156.66g of tert-butyl peroxybenzoate into a reactor with a condenser, and start the agitator , heated to the temperature of the reaction system around 75°C, and maintained at this temperature for the reaction; take samples to measure the hydroxyl value of the prepolymer, and when the reaction reaches a hydroxyl value between 210.0 and 220.0 mgKOH / g, the reaction can be terminated, and the temperature can be lowered to 40-50°C, vacuum pumping and recovery of the solvent, and then the material can be discharged when the temperature is lowered to below 40°C, and the brominated polyol prepolymer is obtained for use.

[0131] Then, prepare the flame-retardant two-component polyurethane glue:

[0132] Preparation of component A (main agent): 20.00kg of brominated polyol prepolymer, 8.00kg of refined castor oil, 7.00kg of polyethylene adipate-propylene glycol ester diol, polyoxypropyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com