Paint and coating based on bridged dianhydride and POSS hybrid epoxy resin

A technology of epoxy resin and dianhydride, used in epoxy resin coatings, coatings, fire-retardant coatings, etc., can solve the problems of poor mutual solubility and high melting point, and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

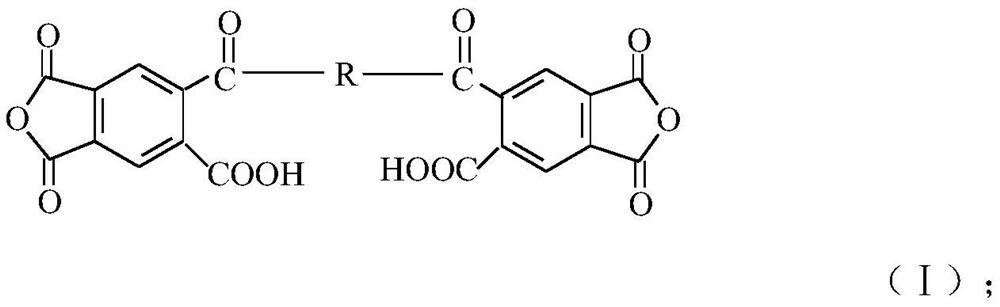

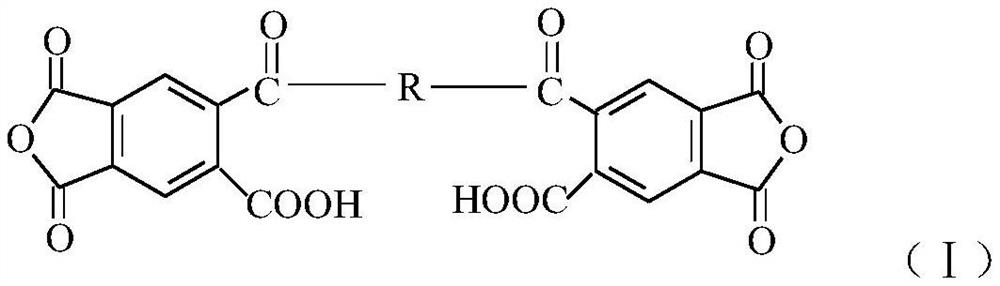

[0026] Preparation of Latent Bridged Dicarboxylic Anhydride CBA Curing Agent

[0027] In a three-necked flask equipped with a thermometer, a reflux condenser, and an agitator, add 0.2-0.22mol pyromellitic anhydride (PMDA) and the DMF solvent of 100% (about 43.62-47.99g) in PMDA mass fractions successively , heated to 100°C until PMDA dissolves into a transparent state, stirred, and then added dropwise about 0.1mol hydroxyl-terminated polyether diol (PEDO) within 30 minutes, controlling the PMDA:PEDO molar ratio to about 2-2.2:1, and then Continuous stirring reaction 4-10h again, reaction finishes, obtains light yellow transparent liquid, promptly structure is as shown in formula (I), R is the bridging diacid anhydride (CBA) solidifying agent of polyether group, the synthesis of CBA in each embodiment See Table 1 for the relevant performance indicators of raw materials, dosages and targets.

[0028] Table 1 prepares the raw material of latent CBA solidifying agent and consumpt...

Embodiment 1

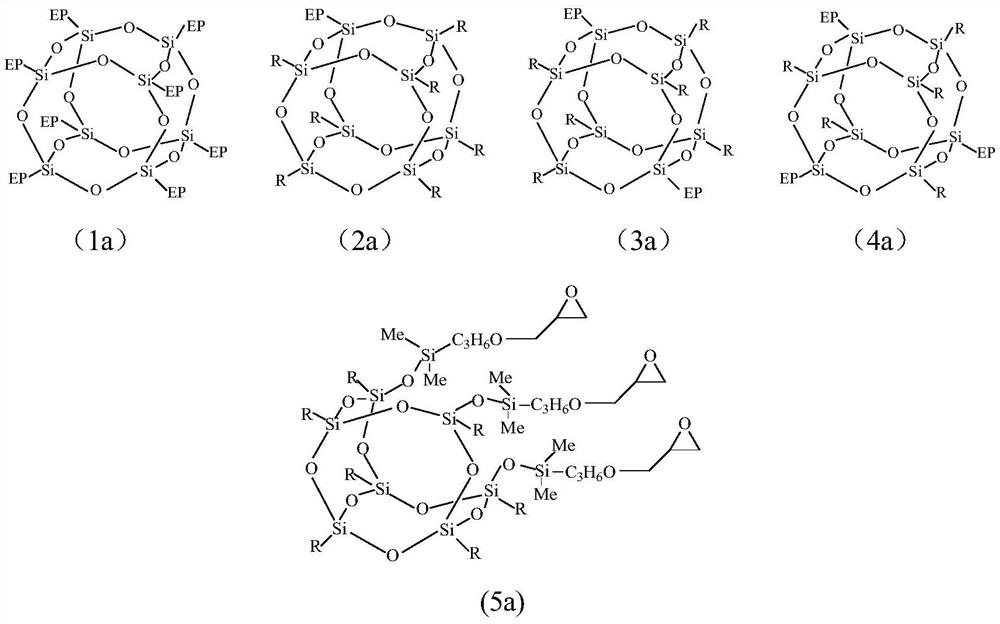

[0032] In parts by mass, weigh 100.0g of epoxy resin E-51 with an epoxy equivalent of about 0.51 and a viscosity of about 11000mPa.s, and 3.0g of epoxy resin E-51 whose structure is shown in formula (1a) Propoxypropyl) POSS, 10.0g butyl glycidyl ether, 1.0g BYK-ATU dispersant, 25.0g nano TiO 2 , after stirring and mixing, stir and disperse for 40min with a dispersing disc with a rotating speed of 1000r / min, and then press the epoxy group contained in the system: the molar ratio of (anhydride group+carboxyl group) contained in the latent CBA curing agent is 1:1 , then weighed 160.95g of tripropylene glycol bridged dianhydride (CBA-1) curing agent with a solid content of about 59.03%, an anhydride group content of about 0.3182%, and a carboxyl content of about 0.3182%, and stirred and mixed evenly. The resulting mixture is the coating prepared based on CBA-1 and POSS hybrid epoxy resin, etc., which is denoted as ECBA-1, diluted with BA to a solid content of about 60%, and set as...

Embodiment 2

[0035] By mass parts, take successively 166.67g epoxy equivalent to be about 0.20, solid content be 60% epoxy resin E-20 solution (containing solid resin 100.0g, Baotashan Paint Co., Ltd.), 5.0g structure such as formula ( 1a) cage-type octa(3,4-epoxycyclohexylethyl)POSS and 20.0g structure shown in formula (2a) cage-type mono(2,3-epoxypropoxypropyl)heptaisobutyl POSS, 20.0g C 12-14 Alkyl glycidyl ether AGE, 2.0g BYK-ATU dispersant, 50.0g nano CaCO 3 , stir and disperse for 60min with a dispersing disc with a rotating speed of 1000r / min, and then press the molar number of epoxy groups contained in the system: the molar number of (anhydride group+carboxyl) contained in the curing agent CBA is about 1:0.8. Weigh 69.11g of polyethylene glycol bridged dianhydride (CBA-2) curing agent with a solid content of about 65.20%, an anhydride group content of about 0.2564%, and a carboxyl content of about 0.2331%, stir and mix, and the resulting mixture is The coating prepared based on C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com