Water system high-voltage window anti-freezing electrolyte and application thereof

A technology of voltage window and electrolyte, applied in hybrid capacitor electrolytes, circuits, electrical components, etc., can solve problems such as hindering ion transmission, reducing solubility, limiting the application of high-concentration electrolytes, etc., to achieve cost reduction, good electrochemical performance, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method provided by the invention is simple and convenient to operate and easy for large-scale production.

[0044] The present invention provides the application of the water system high-voltage window antifreeze electrolyte in the supercapacitor or battery described in the above scheme. The present invention has no special requirements on the positive electrode, negative electrode and diaphragm of the supercapacitor or battery; the present invention has no special requirements on the assembly method of the supercapacitor or battery, and the assembly method known to those skilled in the art can be used.

[0045] In a specific embodiment of the present invention, activated carbon is used as the positive electrode and the negative electrode respectively, and glass fiber is used as the diaphragm to assemble a button supercapacitor; activated carbon is used as the positive electrode, and sodium titanium phosphate is used as the negative electrode to assemble ...

Embodiment 1

[0049] NaClO 4 - Preparation of acetonitrile electrolyte:

[0050] 1.7mol NaClO 4 Add to 6mol water, stir and mix to obtain NaClO with a mass molar concentration of 15.74mol / kg 4 aqueous solution; then 2 mol of acetonitrile was added to NaClO 4 In the aqueous solution, stirring and mixing to obtain NaClO with a mass molar concentration of 8.94mol / kg 4 base electrolyte.

[0051] To the NaClO that embodiment 1 obtains 4 Electrochemical performance tests were performed on the base electrolyte, as follows:

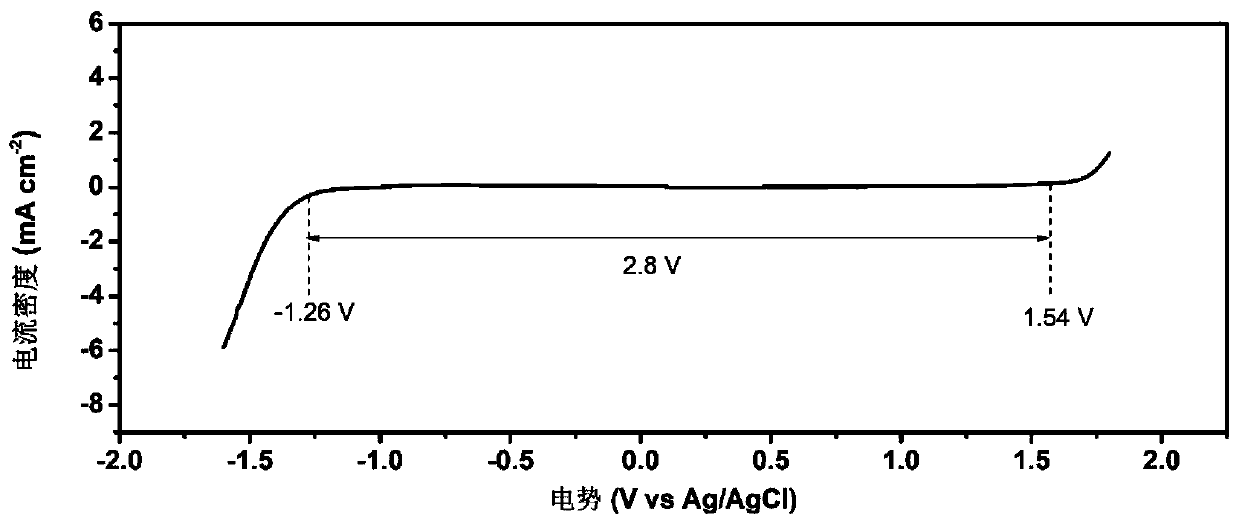

[0052] (1) the NaClO that test embodiment 1 obtains 4 The voltage window of the base electrolyte: with the stainless steel column as the working electrode and the counter electrode, Ag / AgCl as the reference electrode to form a three-electrode system, the electrolyte of Example 1 is tested for the voltage window, and the test results are as follows figure 1 shown. From figure 1 It can be seen that the electrolyte solution of Example 1 has a stable voltage window of 2.8...

Embodiment 2

[0063] NaClO 4 - Preparation of Methanol Electrolyte:

[0064] 1.7mol NaClO 4 Add to 6mol water, stir and mix to obtain NaClO with a mass molar concentration of 15.74mol / kg 4 aqueous solution; then 2 mol methanol was added to NaClO 4 In the aqueous solution, stirring and mixing to obtain NaClO with a mass molar concentration of 9.88mol / kg 4 base electrolyte.

[0065] Test the NaClO that embodiment 2 obtains according to the method for embodiment 1 4 The voltage window and conductivity of the base electrolyte, the electrolyte of Example 2 was measured to have a stable voltage window of 2.8V, and the conductivity was 140.61mS / cm.

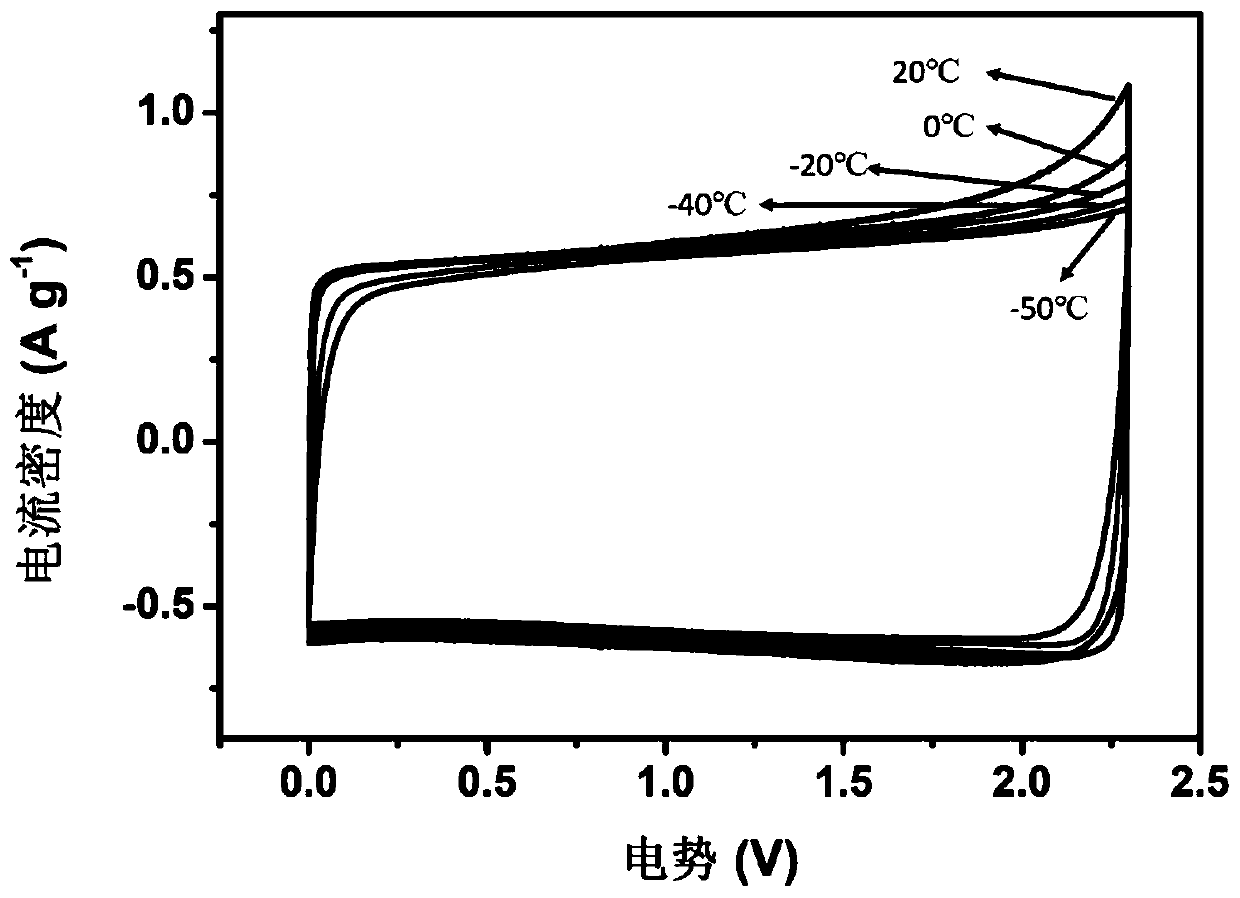

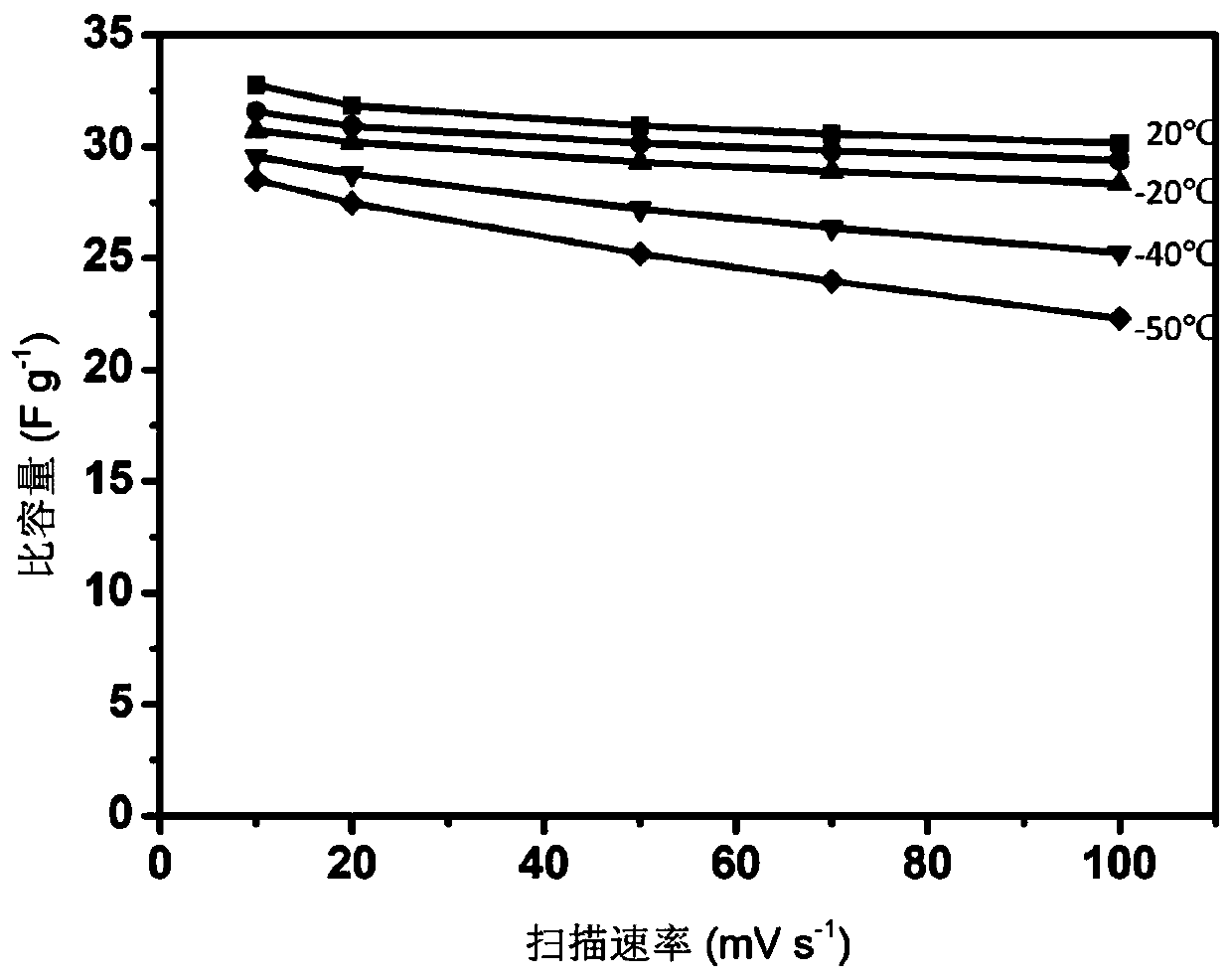

[0066] According to the method for embodiment 1, embodiment 2 is obtained NaClO 4 -Methanol electrolyte is used in supercapacitors, and cyclic voltammetry tests are carried out on supercapacitors at room temperature, 0°C, -20°C, -40°C and -60°C, and the test results are as follows Figure 6 shown. From Figure 6 It can be seen that the supercap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com