High-temperature resistant fire-retardant co-axial cable

A coaxial cable, high temperature resistance technology, applied in the direction of coaxial cable/analog cable, climate change adaptation, etc. Good physical properties, good weather resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

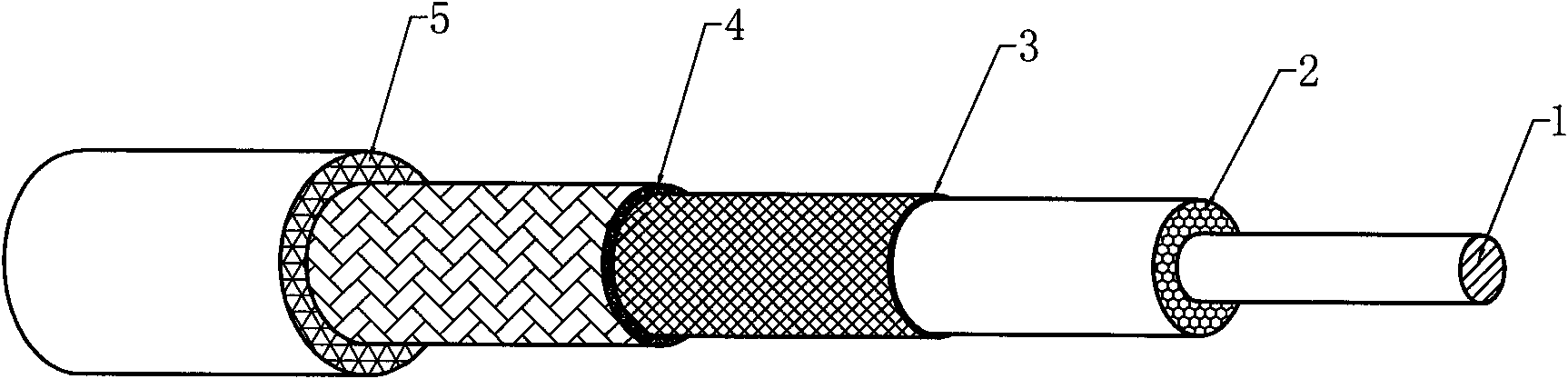

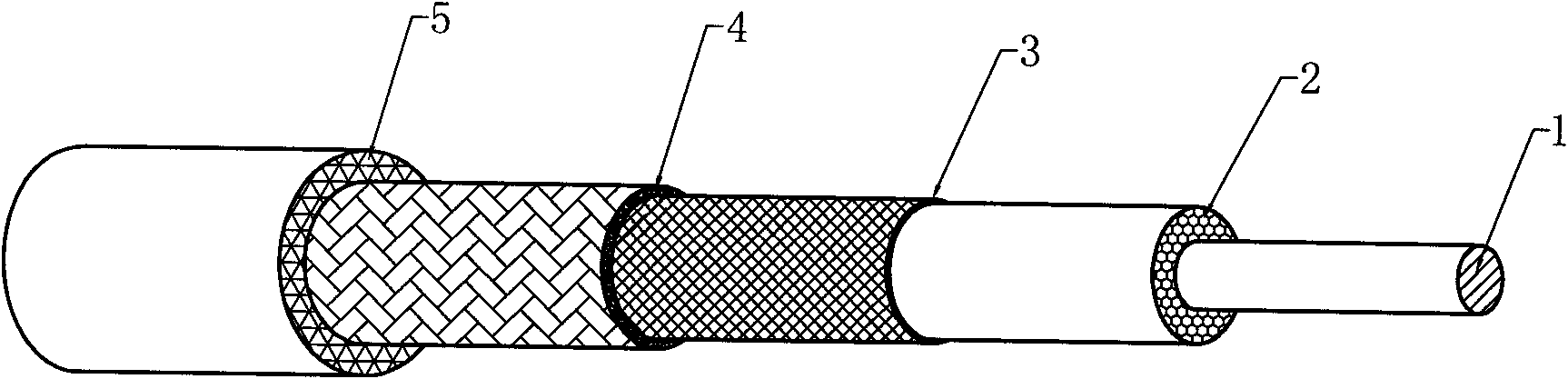

[0017] refer to figure 1 , a high-temperature-resistant flame-retardant coaxial cable (taking a 50Ω coaxial cable as an example), including a central conductor 1 arranged sequentially from the inside to the outside; an irradiation cross-linked foamed flame-retardant polyethylene insulating layer 2; copper Foil shielding layer 3; copper wire braided outer conductor layer 4; outer sheath layer 5, the processing steps include:

[0018] 1. The central conductor 1 is made of pure copper core wire with a diameter of φ0.94mm;

[0019] 2. Making insulated core wire:

[0020] A) Ingredients, the weight ratio of materials is: 50kg of PE base material with brand 6944; 50kg of PE base material with brand 1253; 10kg of polyethylene series flame retardant masterbatch; 1.8kg of HD101 nucleating agent;

[0021] B) mixing the above materials;

[0022] C) The above-mentioned central conductor and materials are foamed and extruded on a physical foaming machine to extrude an insulated core wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com