B2-grade flame-retardant cable as well as preparation method and application thereof

A flame-retardant cable and cable technology, applied in the direction of cable/conductor manufacturing, conductor/cable insulation, insulated cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

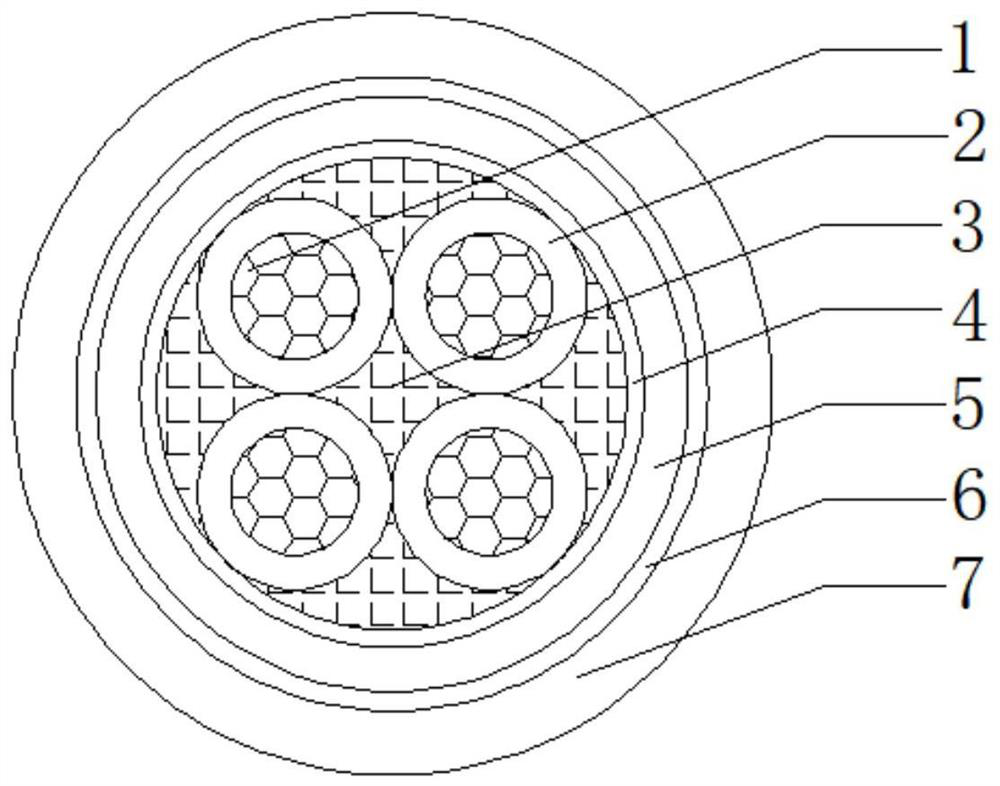

[0070] This embodiment provides a B 2 Class flame retardant cable, the structure diagram is as follows figure 1 As shown, the cable includes four cable cores, the cable cores are distributed in an array, and flame-retardant fillers 3 are arranged in the pores of the cable cores, and flame-retardant tapes 4, inner Lining 5, galvanized steel strip 6 and protective layer 7;

[0071] The cable core includes a conductor 1 and an insulating layer 2 covering the surface of the conductor;

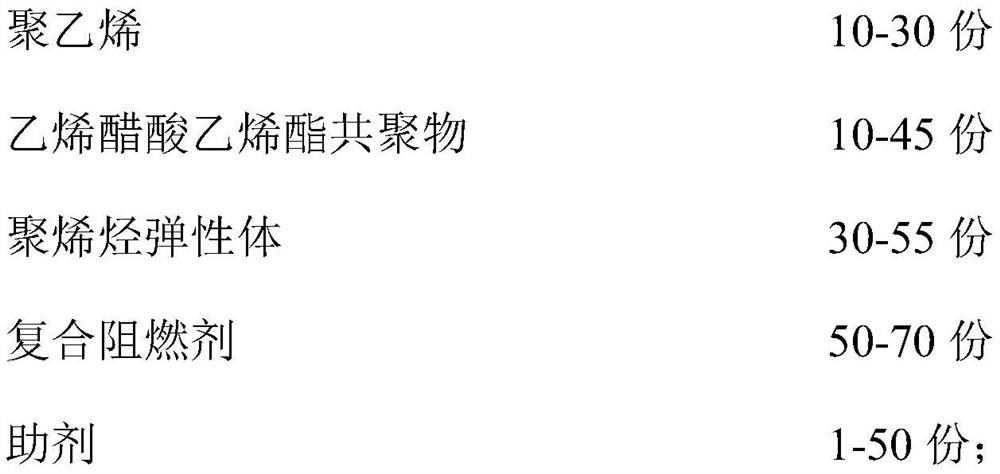

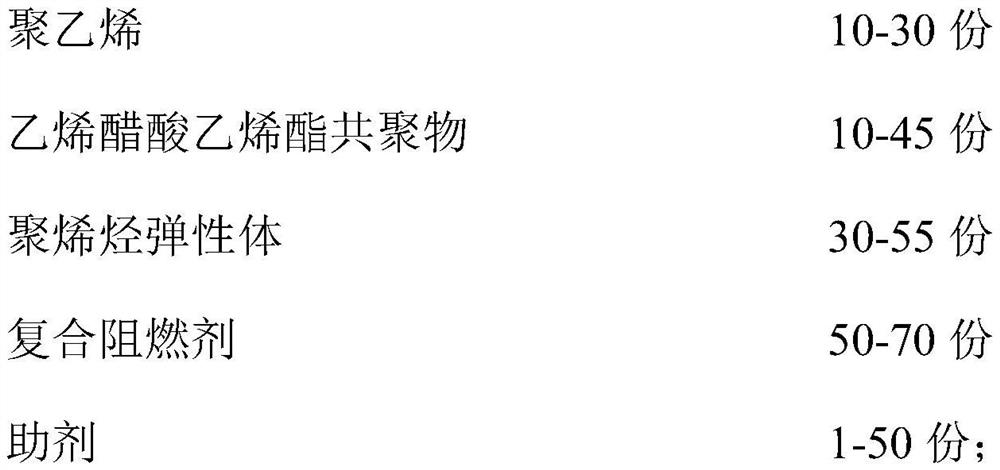

[0072] The raw materials for the preparation of the protective layer are composed of the following components in parts by weight: 20 parts of polyethylene, 30 parts of ethylene vinyl acetate copolymer, 45 parts of polyolefin elastomer, 8 parts of compatibilizer, 20 parts of reinforcing agent, 20 parts of zinc borate, 60 parts of composite flame retardant, 4 parts of antioxidant, 6 parts of lubricant;

[0073] The above-mentioned raw materials are specifically:

[0074] Polyethylene was purchase...

Embodiment 2

[0087] This embodiment provides a B 2 Class flame retardant cable, the cable includes four cable cores, the cable cores are distributed in an array, and flame retardant fillers are arranged in the pores of the cable cores, and the outer parts of the four cable cores are sequentially provided with flame retardant tapes, inner Lining, galvanized steel strip and protective layer;

[0088] The cable core includes a conductor and an insulating layer covering the surface of the conductor;

[0089] The preparation raw materials of the protective layer are composed of the following components in parts by weight: 10 parts of polyethylene, 10 parts of ethylene vinyl acetate copolymer, 30 parts of polyolefin elastomer, 5 parts of compatibilizer, 15 parts of reinforcing agent, 15 parts of zinc borate, 50 parts of composite flame retardant, 2 parts of antioxidant, 9 parts of lubricant;

[0090] The above-mentioned raw materials are specifically:

[0091] Polyethylene was purchased from ...

Embodiment 3

[0104] This embodiment provides a B 2 Class flame retardant cable, the cable includes four cable cores, the cable cores are distributed in an array, and flame retardant fillers are arranged in the pores of the cable cores, and the outer parts of the four cable cores are sequentially provided with flame retardant tapes, inner Lining, galvanized steel strip and protective layer;

[0105] The cable core includes a conductor and an insulating layer covering the surface of the conductor;

[0106] The raw materials for the preparation of the protective layer are composed of the following components in parts by weight: 30 parts of polyethylene, 45 parts of ethylene vinyl acetate copolymer, 55 parts of polyolefin elastomer, 10 parts of compatibilizer, 25 parts of reinforcing agent, 25 parts of zinc borate, 70 parts of composite flame retardant, 6 parts of antioxidant, 3 parts of lubricant;

[0107] The above-mentioned raw materials are specifically:

[0108] Polyethylene was purchase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com