Preparation method for flame-retardant and antistatic pipeline with high strength

A flame-retardant, anti-static, high-strength technology, applied in chemical instruments and methods, tubular objects, applications, etc., can solve problems such as poor anti-static performance, affecting production, and easy damage, and achieve high interface bonding and reduce resistance rate, improve the effect of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

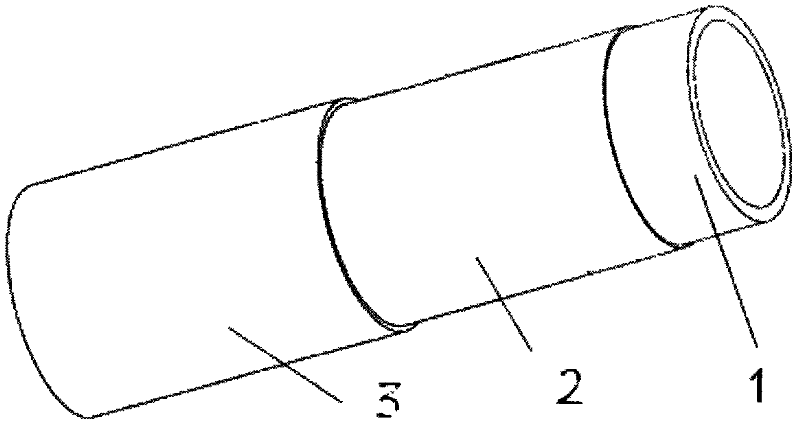

[0019] see figure 1 , The high-strength flame-retardant and antistatic tube prepared by the preparation method of the present invention is divided into three layers, the outer layer of plastic 3, the bonding layer 2, and the inner layer of plastic 1. The bonding layer 2 is located between the outer plastic 3 and the inner plastic 1 .

[0020] Wherein the inner layer comprises the following components: 600 parts by weight of high-density polyethylene, 5 parts by weight of glass fiber, 1 part by weight of wollastonite, 1 part by weight of EPDM rubber, and 4 parts by weight of nitrile Glue, 3 parts by weight of styrene-butadiene-styrene terpolymer copolymer, 9 parts by weight of carbon nanotubes, 10 parts by weight of polypropylene grafted maleic anhydride, 15 parts by weight of decabromodiphenyl Ethane, the conductive carbon black of 13 parts by weight; The outer layer comprises the component of following ratio: the medium density polyethylene of 300 parts by weight, the decabr...

Embodiment 2

[0037] Wherein the inner layer comprises the following components: 600 parts by weight of high-density polyethylene, 5 parts by weight of glass fiber, 1 part by weight of wollastonite, 1 part by weight of EPDM rubber, and 4 parts by weight of nitrile Glue, 3 parts by weight of styrene-butadiene-styrene terpolymer copolymer, 9 parts by weight of carbon nanotubes, 10 parts by weight of polypropylene grafted maleic anhydride, 15 parts by weight of decabromodiphenyl Ethane, the conductive carbon black of 13 parts by weight; The outer layer comprises the component of following ratio: the medium density polyethylene of 300 parts by weight, the decabromodiphenylethane of 12 parts by weight, the conductive carbon black of 9 parts by weight; Combine The main component of the layer is hot melt adhesive.

[0038] a. According to the above component distribution ratio, prepare the material of the inner layer 1 of the pipeline;

[0039] b. The prepared inner layer material is extruded int...

Embodiment 3

[0048] Wherein the inner layer comprises the following components: 600 parts by weight of high-density polyethylene, 5 parts by weight of glass fiber, 1 part by weight of wollastonite, 1 part by weight of EPDM rubber, and 4 parts by weight of nitrile Glue, 3 parts by weight of styrene-butadiene-styrene terpolymer copolymer, 9 parts by weight of carbon nanotubes, 10 parts by weight of polypropylene grafted maleic anhydride, 15 parts by weight of decabromodiphenyl Ethane, the conductive carbon black of 13 parts by weight; The outer layer comprises the component of following ratio: the medium density polyethylene of 300 parts by weight, the decabromodiphenylethane of 12 parts by weight, the conductive carbon black of 9 parts by weight; Combine The main component of the layer is hot melt adhesive.

[0049]a. According to the above component distribution ratio, prepare the material of the inner layer 1 of the pipeline;

[0050] b. The prepared inner layer material is extruded into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com