Patents

Literature

118results about How to "Improve flame retardancy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PVC resin composition and products made of the same

InactiveUS20100292379A1Improve flame retardancyHigh flame retardancyImpression capsDentistry preparationsChemistryCombustion

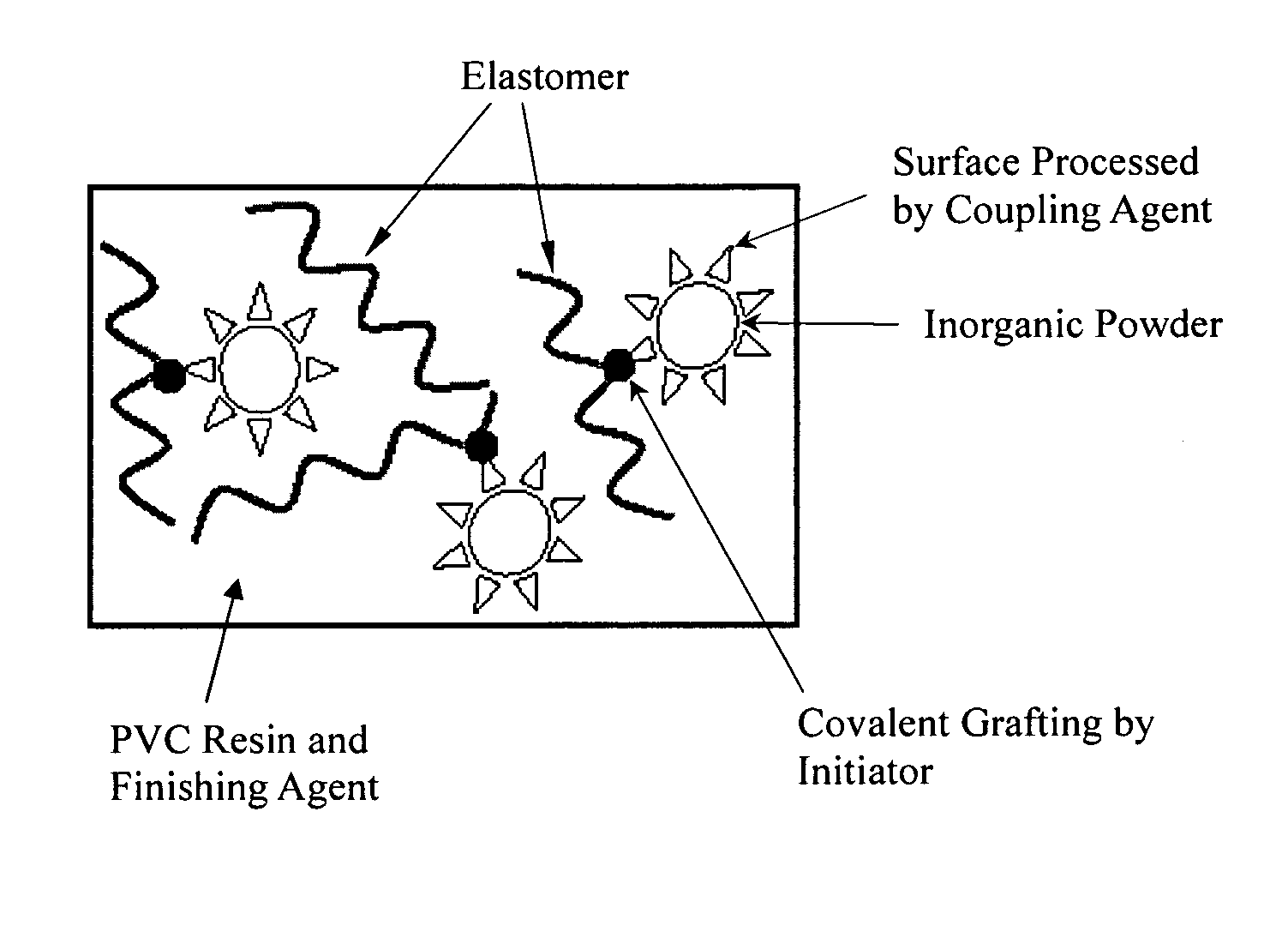

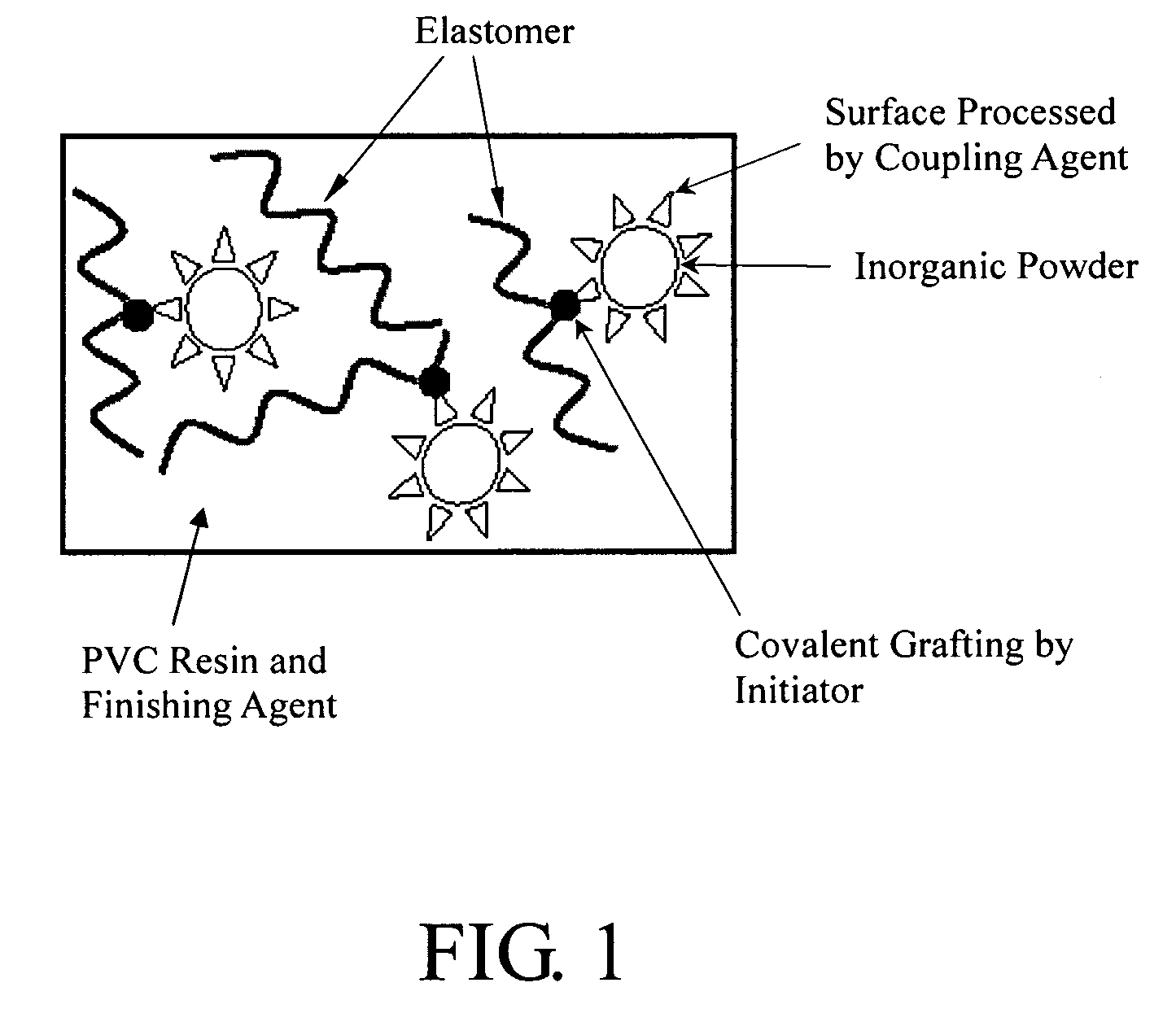

A PVC resin composition having high flame retardancy and low smoke generation comprises a formula including a PVC resin, inorganic powders, a additive, a toughening agent, a coupling agent and an initiator mixed by proportion, wherein the initiator cooperates with the coupling agent to improve a binding effect of the inorganic powders inside the PVC resin composition to endow a PVC product if made of the composition to provide with excellent tensile strength and elongation and enable the product to perform high flame retardancy and low smoke generation during combustion.

Owner:NANYA PLASTICS CORP

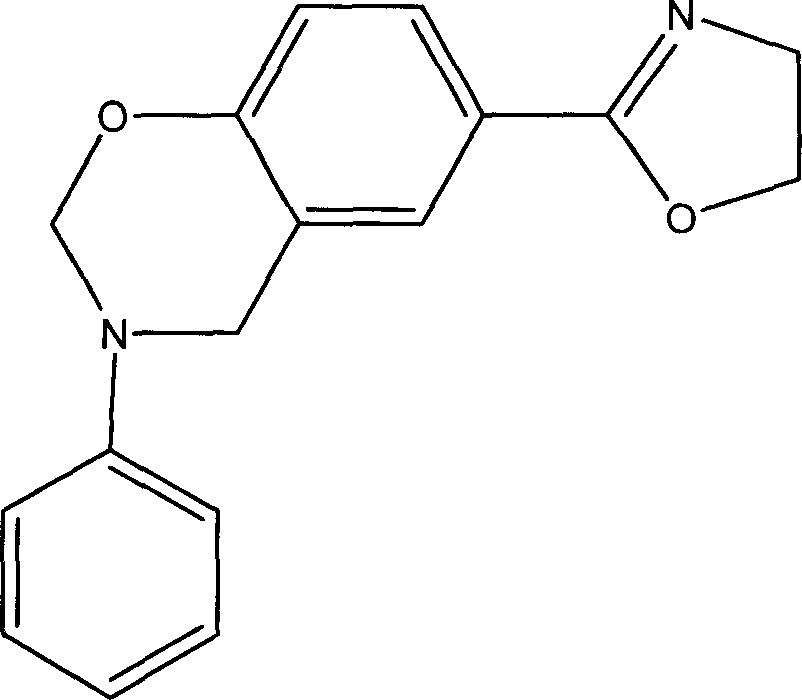

2-oxazolinyl-benzo oxazinyl compound and its composition and preparing method

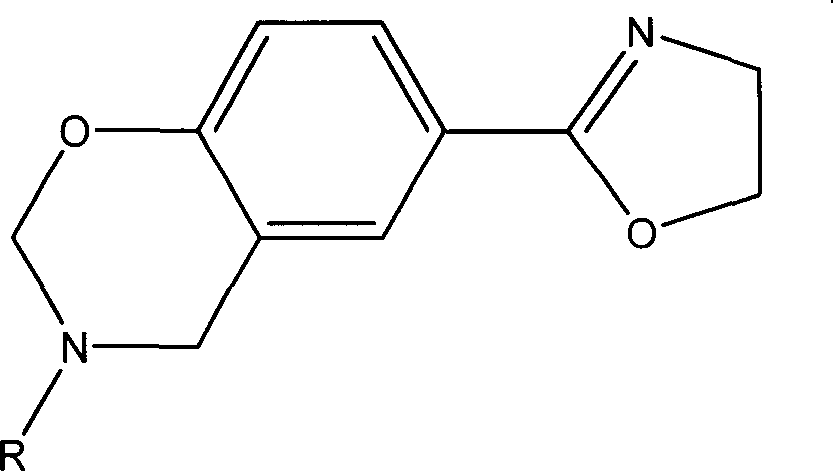

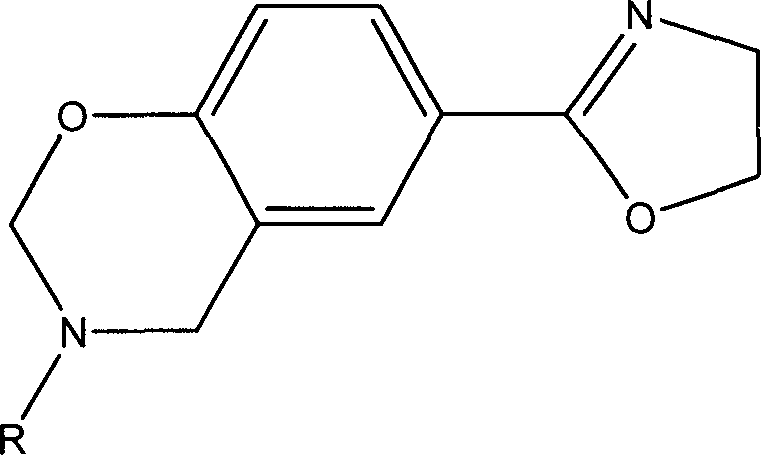

The present invention relates to one kind of benzo oxazine intermediate containing 2-oxazolinyl radical and its composition and their preparation process. The intermediate, 2-oxazolinyl- benzo oxazine, is prepared with 2-(p-hydroxy phenyl)-2-oxazoline, primary amine and formaldehyde or paraformaldehyde. The composition is prepared with 2-oxazolinyl- benzo oxazine, and thermosetting resin monomer or filler and through mechanical mixing or in-situ polymerization. The intermediate and its composition has excellent comprehensive performance.

Owner:BEIJING UNIV OF CHEM TECH

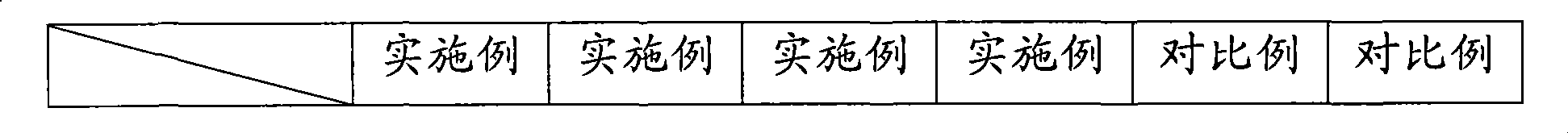

PC/PBT alloy and method for producing the same

The invention discloses a PC / PBT alloy and a preparation method thereof. The PC / PBT alloy comprises the components with the weight percentage as follows: 65-87 percent of polycarbonate, 5-20 percent of polyethylene glycol terephthalate, 3-10 percent of flame retardant, 1-3 percent of toughening compatilizer, 0.2-0.6 percent of antioxidant and 0.1-2.5 percent of other promoter. In the PC / PBT alloy prepared by the invention, halogen-free environmental protective flame retardant is used, thereby improving the flame retardant resistance and keeping high toughness and good optical performance at the same time. The PC / PBT alloy provided by the invention has simple preparation technology and low cost.

Owner:SHENZHEN KEJU NEW MATERIAL

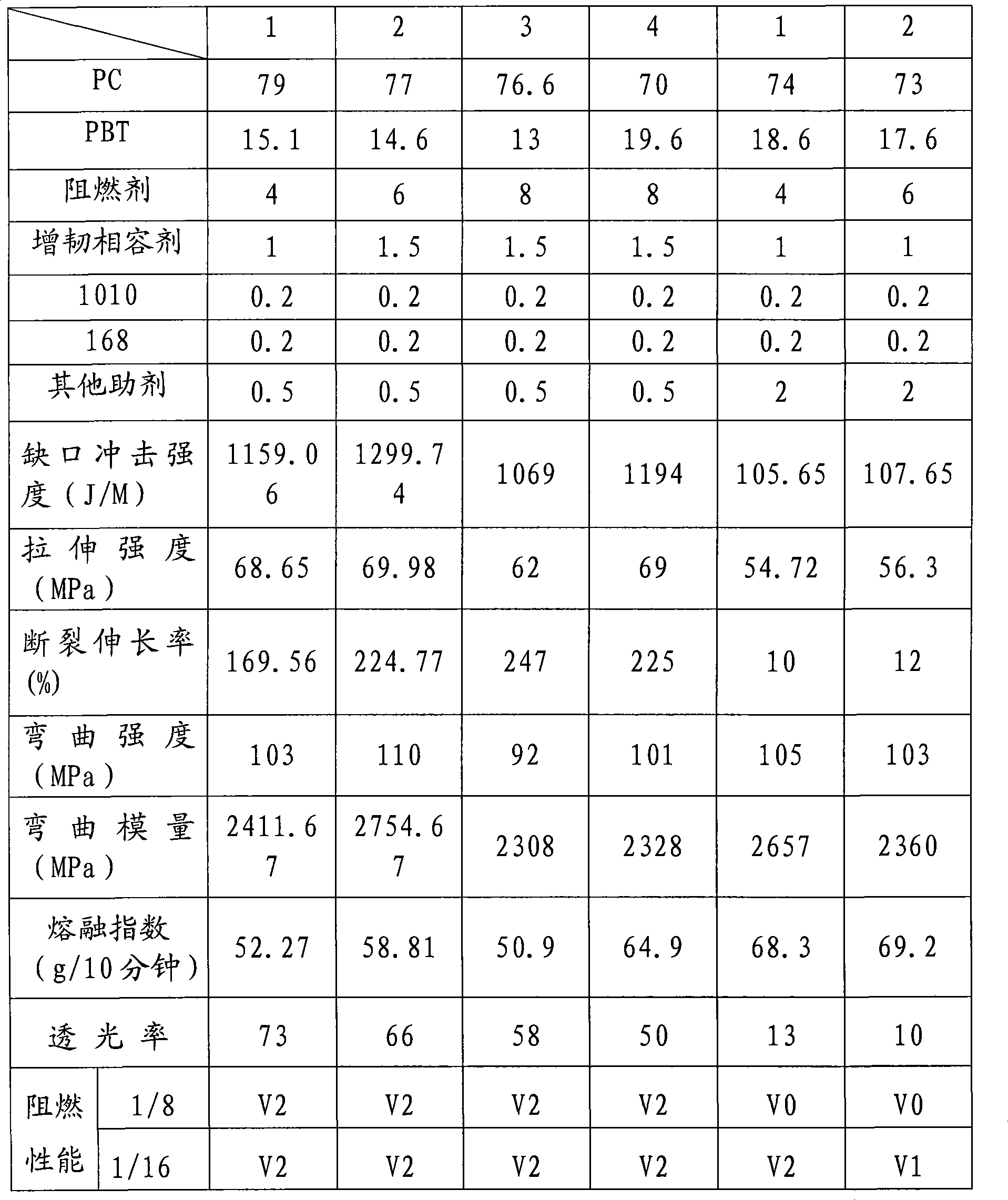

Flame-retardant coiled material and preparation method thereof

ActiveCN105694665AImprove flame retardancyGood flame retardant performanceFireproof paintsEpoxy resin coatingsChemistryMagnesium

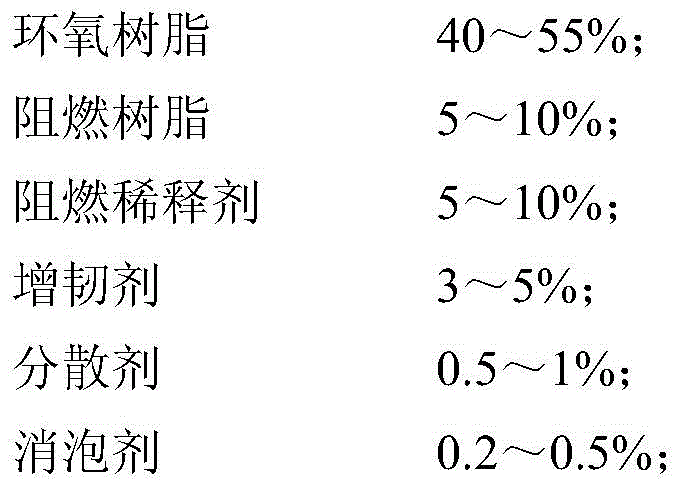

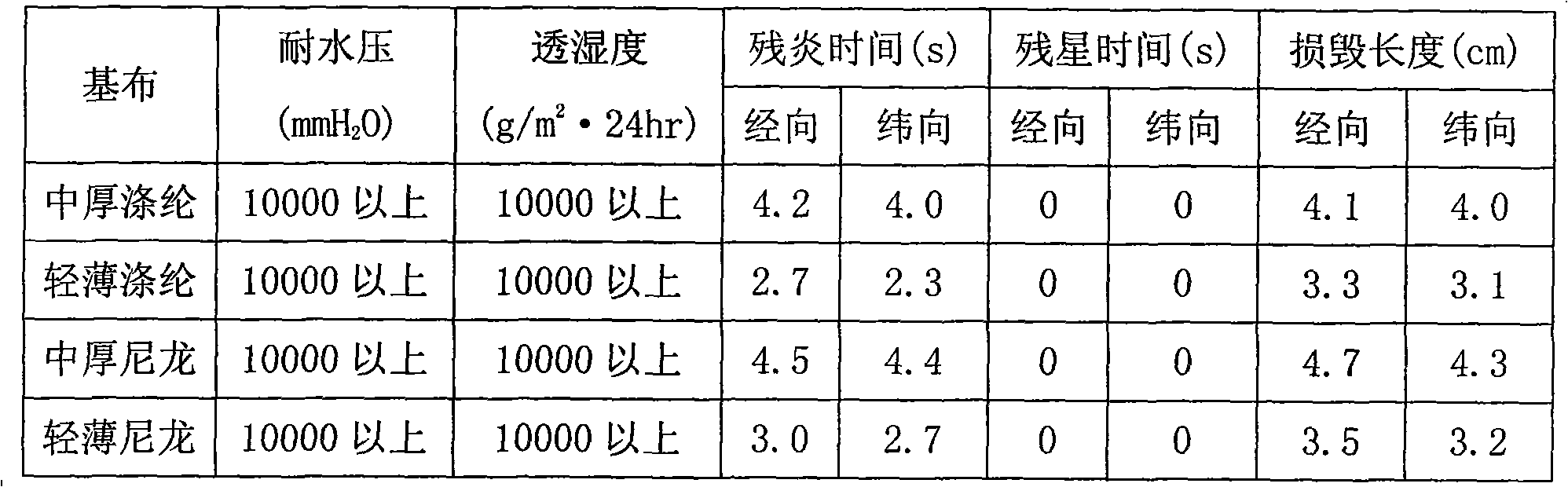

The invention discloses a flame-retardant coiled material and a preparation method thereof. The flame-retardant coiled material is a laminated structure which is formed by bonding a flame-retardant surface layer and a chopped fiber layer by a flame-retardant paint and carrying out curing. The flame-retardant paint is composed of a component A and a component B in a weight ratio of 10:(2-5). The component A comprises the following ingredients in percentage by mass: an epoxy resin, a flame-retardant resin, a flame-retardant diluter, a toughener, a dispersing agent, a defoaming agent, a leveling agent, a flame-retardant additive, a color paste and the balance of inorganic filler. The component B comprises a curing agent and the balance of curing accelerator. The flame-retardant additive comprises at least one of antimony trioxide, aluminum hydroxide, magnesium hydroxide, melamine cyanurate, chlorinated paraffin, tri(2-chloropropyl) phosphate and dimethyl methylphosphate. The epoxy resin, flame-retardant resin, flame-retardant diluter and flame-retardant additive are utilized to form the compound system, thereby fully displaying the synergistic effects of the components, and greatly enhancing the flame retardancy of the flame-retardant paint.

Owner:浙江港流高分子科技股份有限公司

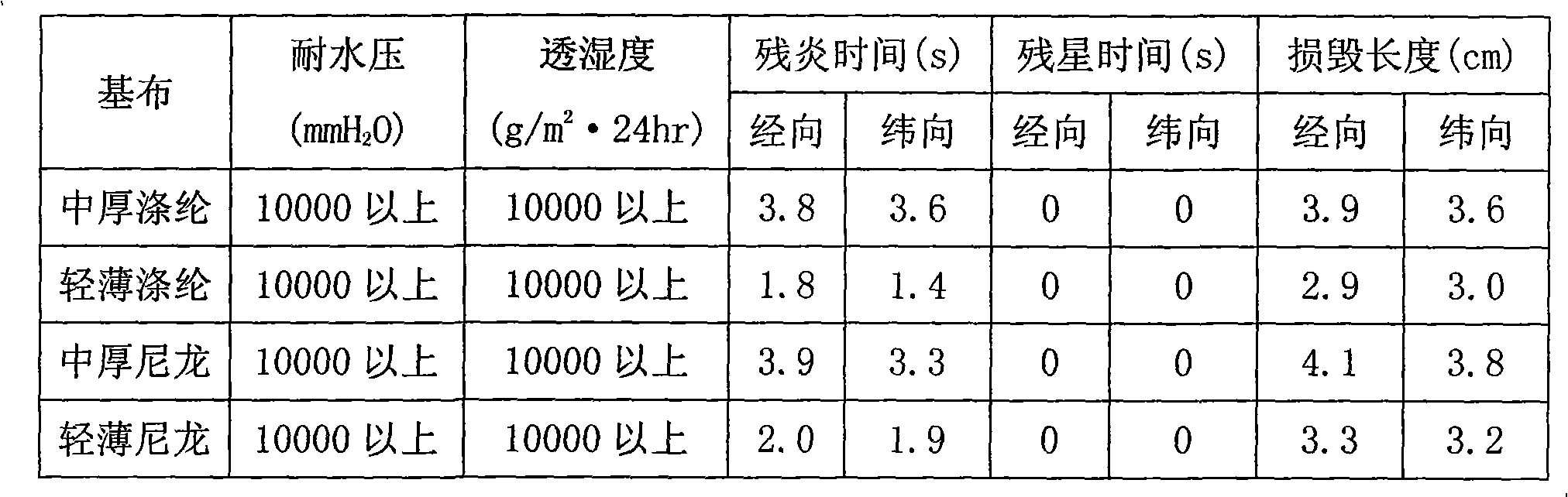

High-waterproof high-moisture-permeable flame-retardant coating fabric and production method thereof

InactiveCN101886340AExcellent waterproof and moisture permeabilityImprove flame retardancySynthetic resin layered productsTextiles and paperChemistryPetroleum

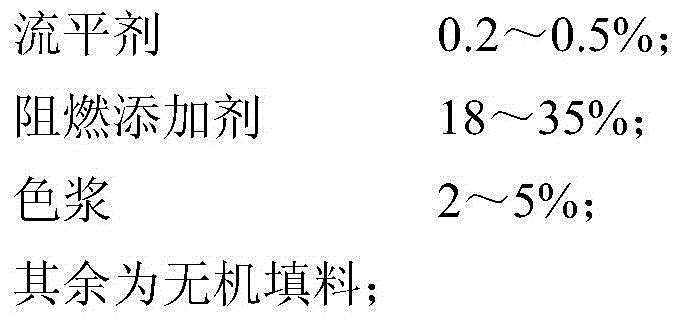

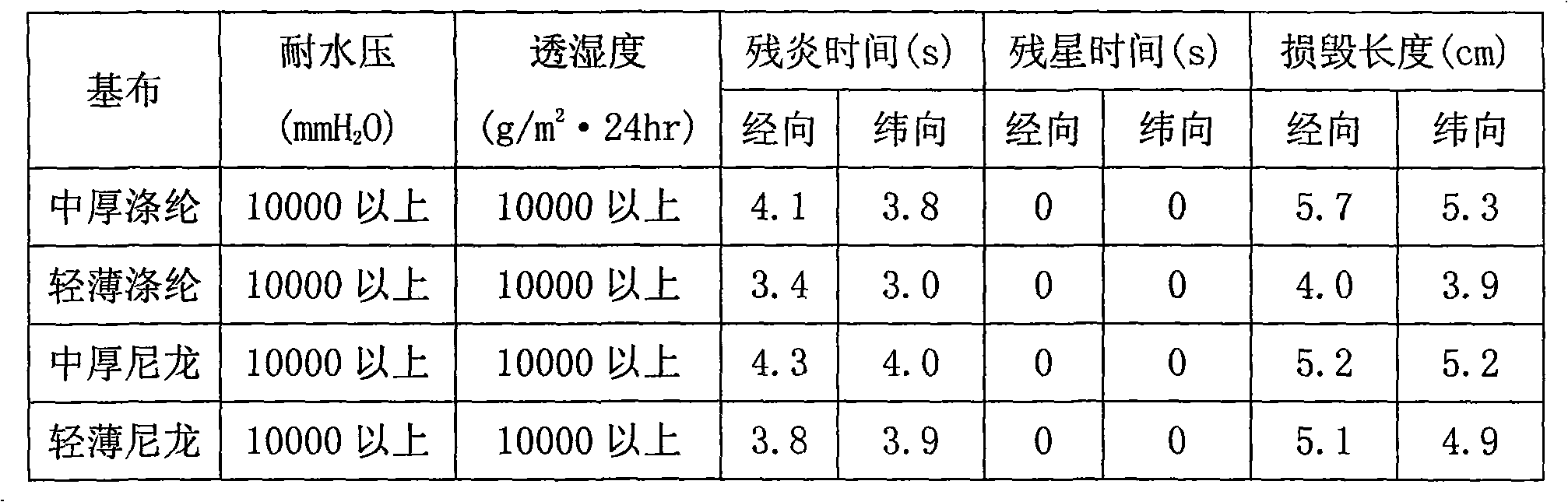

The invention discloses a high-waterproof high-moisture-permeable flame-retardant coating fabric and a production method thereof. The fabric comprises base cloth and a high-waterproof high-moisture-permeable flame-retardant coating, wherein high-waterproof high-moisture-permeable flame-retardant is a polyurethane non-porous layer, and the flame retardant used in the coating layer is a halogen free particle flame retardant. The production method comprises the following steps of: uniformly spreading fabric coating slurry which is prepared by mixing hydrophilic polyurethane resin, an organic solvent, an additive and the flame retardant on the base cloth; and drying the base cloth to obtain the high-waterproof high-moisture-permeable flame-retardant coating product with the hydrophilic polyurethane non-porous layer. The coating fabric of the invention has high waterproofness and moisture-permeability and extremely high flame resistance. The coating fabric is used on particular occasions when high requirements on waterproofness, and moisture-permeability and fire resistance are required, can be used for preparing protective garments and the fabrics of protective equipment of departments such as fire control, metallurgy, petroleum and national defense, the fabrics of tents and the like, and therefore has greater economic and social benefits.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

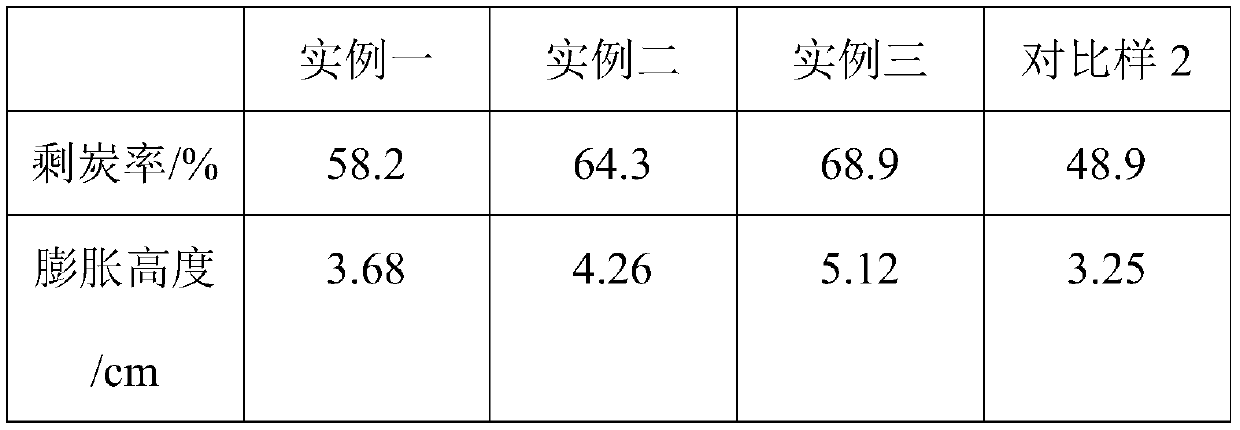

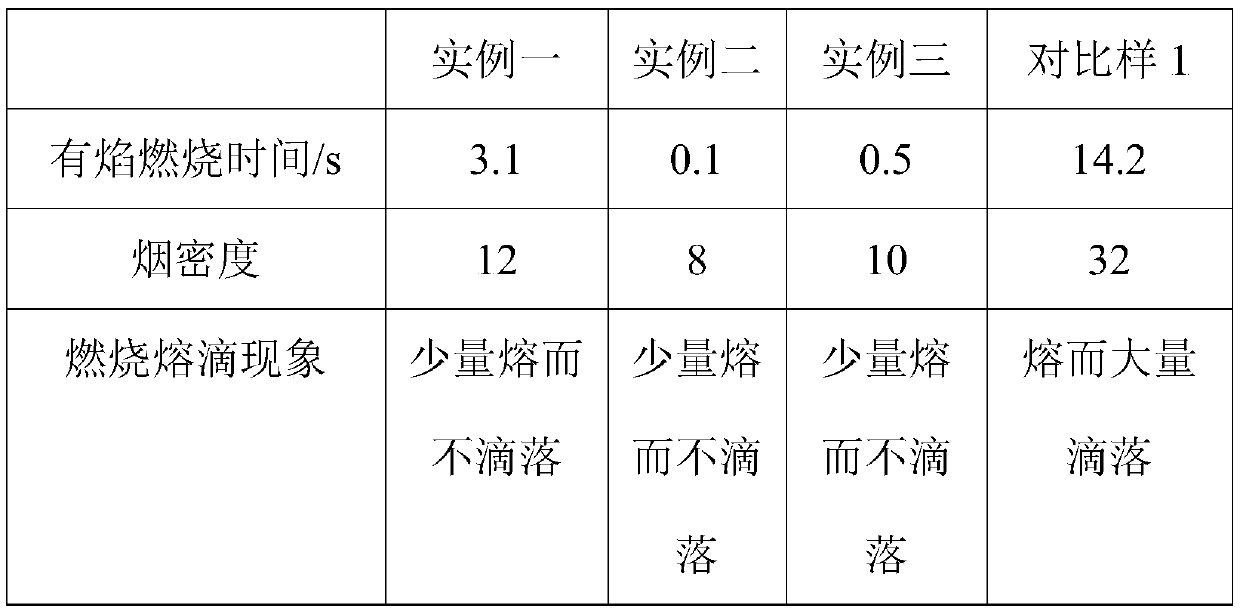

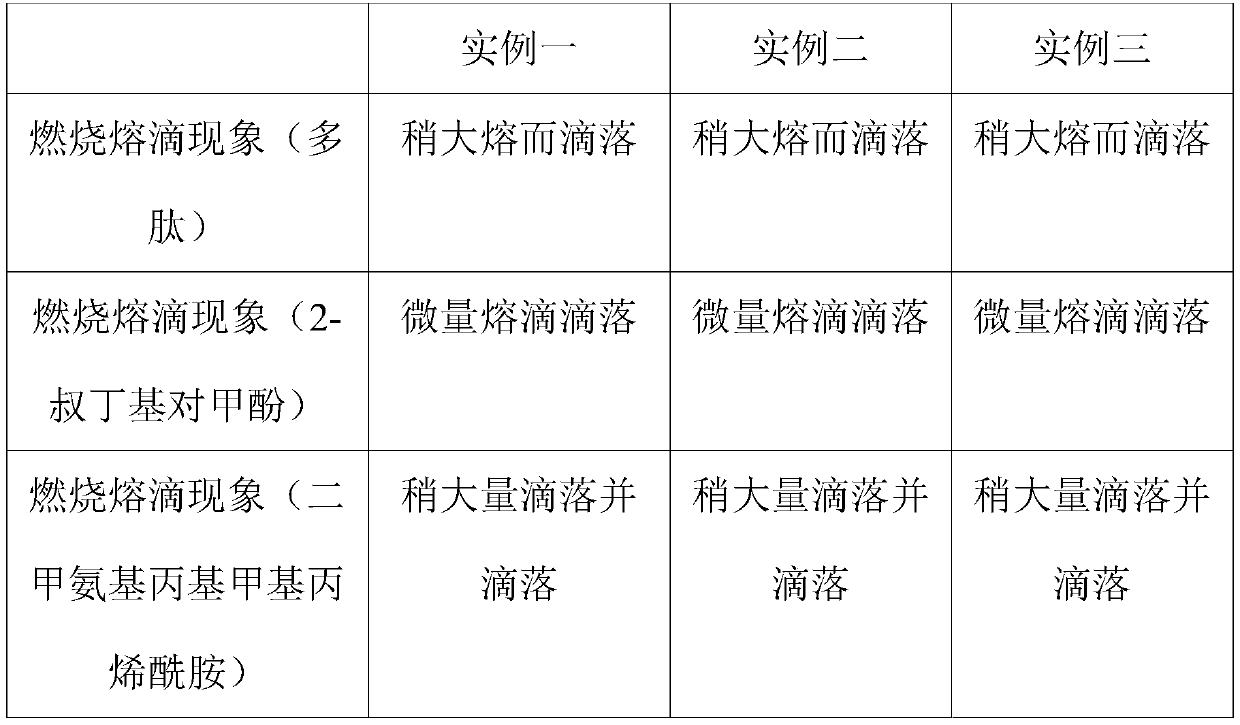

Nitrogen-phosphorus expanded type flame retardant and preparation method for application in aqueous polyurethane coating

ActiveCN110343413AImprove flame retardancyKeep the original natureFireproof paintsGroup 5/15 element organic compoundsChemistrySodium methoxide

The invention relates to preparation of a nitrogen-phosphorus expanded type flame retardant and a method for application in preparing an aqueous polyurethane coating. The method comprises the following steps: mixing dimethyl phosphate, and alkali catalysts, namely sodium methoxide and acrylamide, performing a reaction so as to obtain an intermediate, adding a charcoal formation agent and a substance A, keeping the pH value of the solution to 6.5-7.0 in the stirring process, further adding a substance B and a substance C, performing a continuous stirring reaction, and performing concentration so as to obtain the nitrogen-phosphorus expanded type flame retardant; and preparing the aqueous polyurethane coating from the nitrogen-phosphorus expanded type flame retardant. By adopting the flame retardant provided by the invention, flame can be rapidly choked, and the flame retardancy of the nitrogen-phosphorus expanded type flame retardant can be improved by releasing smoke, controlling flamecombustion time and controlling densities of charcoal layers. In addition, the nitrogen-phosphorus expanded type flame retardant is grafted with polyurethane, so that the flame retardancy of the polyurethane can be further improved.

Owner:YANTAI UNIV

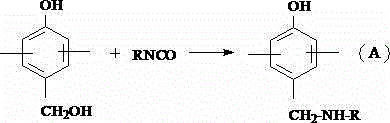

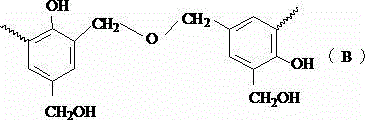

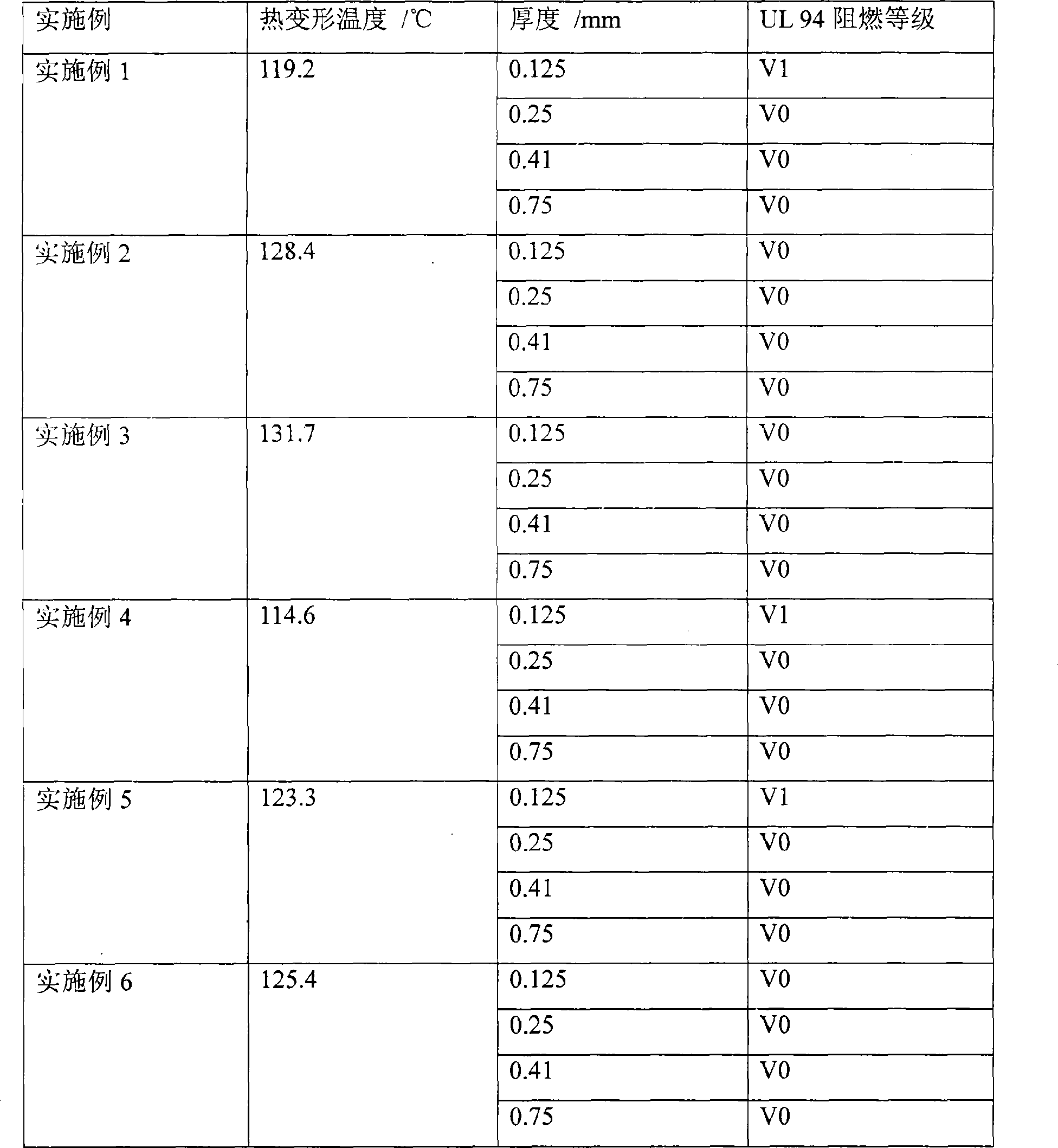

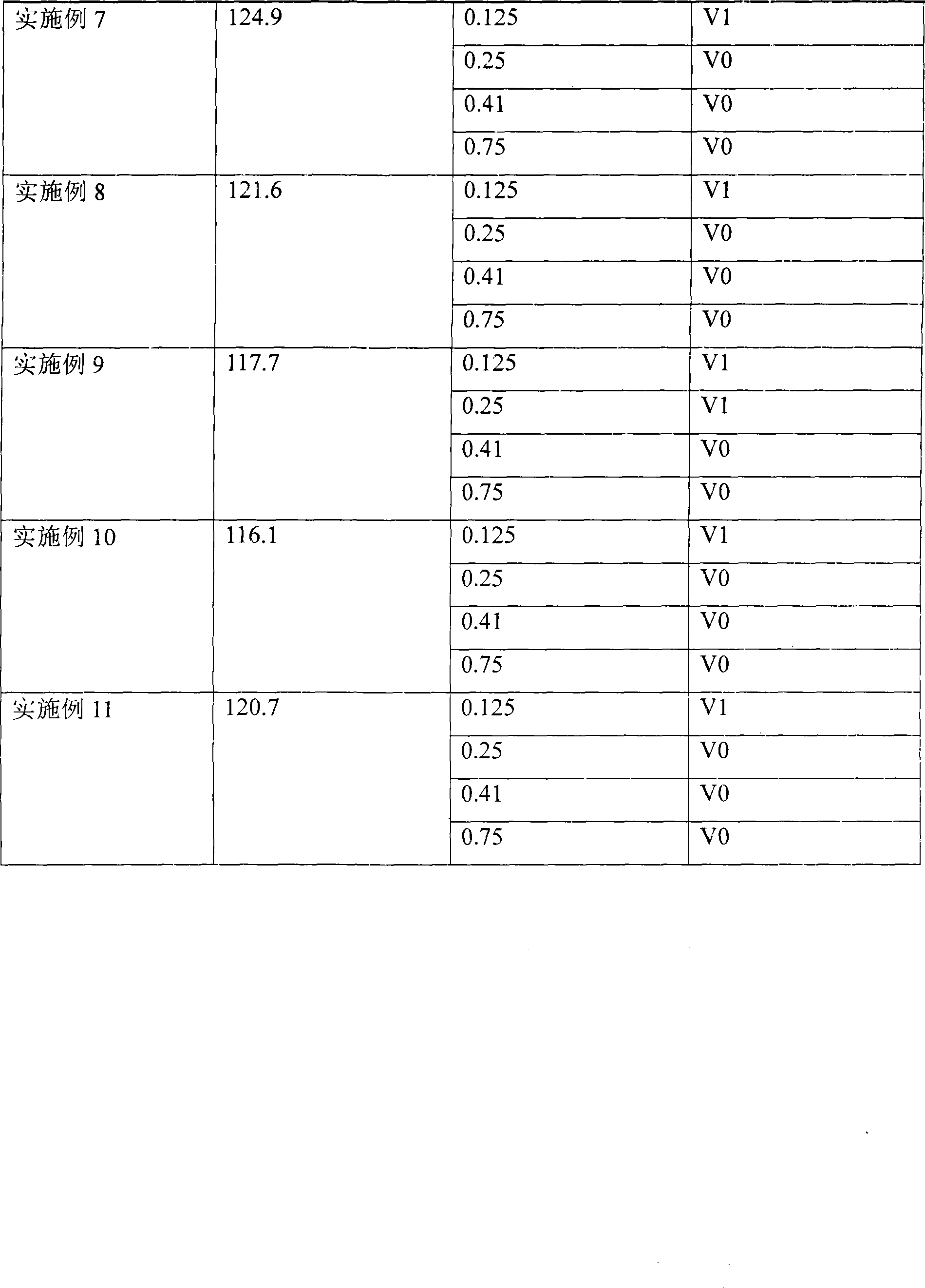

Phenol-formaldehyde-resin-modified rigid polyurethane foam and preparation method thereof

The invention relates to phenol-formaldehyde-resin-modified rigid polyurethane foam and a preparation method thereof. The phenol-formaldehyde-resin-modified rigid polyurethane foam is prepared by the following steps: (1) synthesizing phenol formaldehyde resin, namely, stirring phenol and formaldehyde solution in a reactor, heating while adding an alkaline catalyst, performing the reaction at the reaction temperature of 80 to 95 DEG C, cooling a reaction solution after the reaction is ended, adjusting the pH value of the system to 6 to 7 by adding an acid solution, and dehydrating to obtain the phenol formaldehyde resin; (2) preparing a rigid polyurethane foam material which comprises the following substances: (A) isocyanate; (B) the phenol formaldehyde resin; (c) polyhydric alcohols; (D) a foam stabilizer; (E) a catalyst; (F) a flame retardant; (G) a foaming agent. The phenol formaldehyde resin is introduced into the polyurethane foam, and a flame retardant structure is generated by virtue of chemical reaction of the phenol formaldehyde resin and isocyanate. Compared with the conventional polyurethane foam, the foam provided by the invention has the advantages that the flame resistance is obviously improved, the smoke density is reduced, and the stability is relatively good.

Owner:SHANDONG HAIGUAN CHEM TECH

Halogen-free flame retarding polymer sheet material

InactiveCN101434727AImprove flame retardancyImprove heat resistancePlastic/resin/waxes insulatorsPolypropyleneChemistry

The invention discloses a halogen-free fire-retardant polymer sheet and pertains to the field of insulation material. The halogen-free fire-retardant polymer sheet is characterized by mainly being prepared by the following components according to the weight portions: 100 portions of polypropylene, 10 portions to 80 portions of halogen-free polypropylene fire retardant, 20 portions to 100 portions of halogen-free fire-retardant polyester and 5 portions to 40 portions of compatilizer, wherein, the compatilizer refers to as functionalized macromolecule capable of realizing compatibilization effect between the polypropylene and the halogen-free fire-retardant polyester. The method disperses one or more halogen-free polyesters with lower combustibility into thin halogen-free fire-retardant polypropylene sheet by a melt blending method, solves the technological difficulty that the existing halogen-free fire-retardant system is very hard to lead thin polypropylene sheet to reach a higher fire-retardant degree at the mentioned thickness. The fire-retardant polypropylene sheet has the properties of environmental protection, high fire-retardancy and high heat resistance, and is mainly used for insulation in live components in the electrical and electronic industries.

Owner:JINAN UNIVERSITY

Flame retardant resin composition without halogen

To provide a nonhalogen flame retardant resin composition which exhibits high flame retardance and excels in tensile strength, does not generate a halogen gas on combustion, and excels in safety for the environment. The nonhalogen flame retardant composition comprises (A) 100 pts. mass one or more carboxylic anhydride group-free thermoplastic resins, (B) 0.1-30 pts. mass carboxylic anhydride group-containing resin, (C) 40-300 pts. mass inorganic flame retardant, and (D) 0.1-100 pts. mass organopolysiloxane.

Owner:SHIN ETSU CHEM CO LTD +1

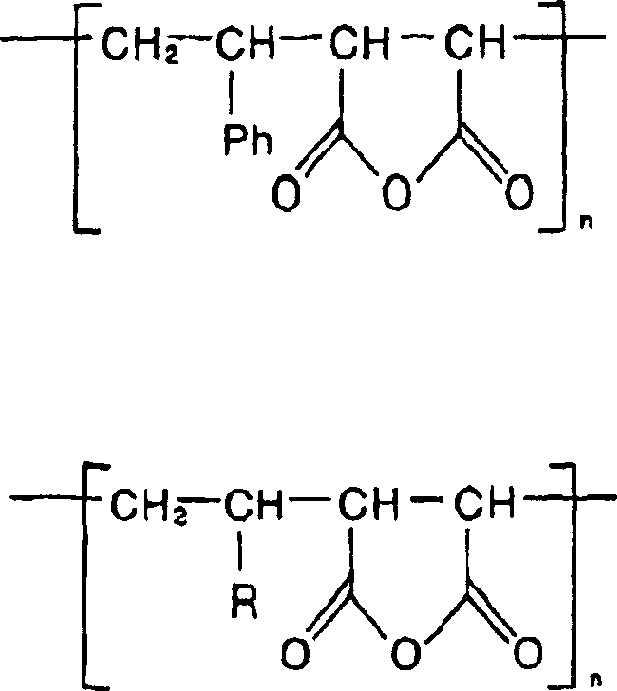

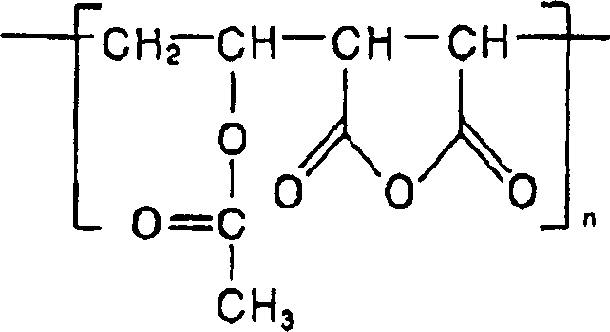

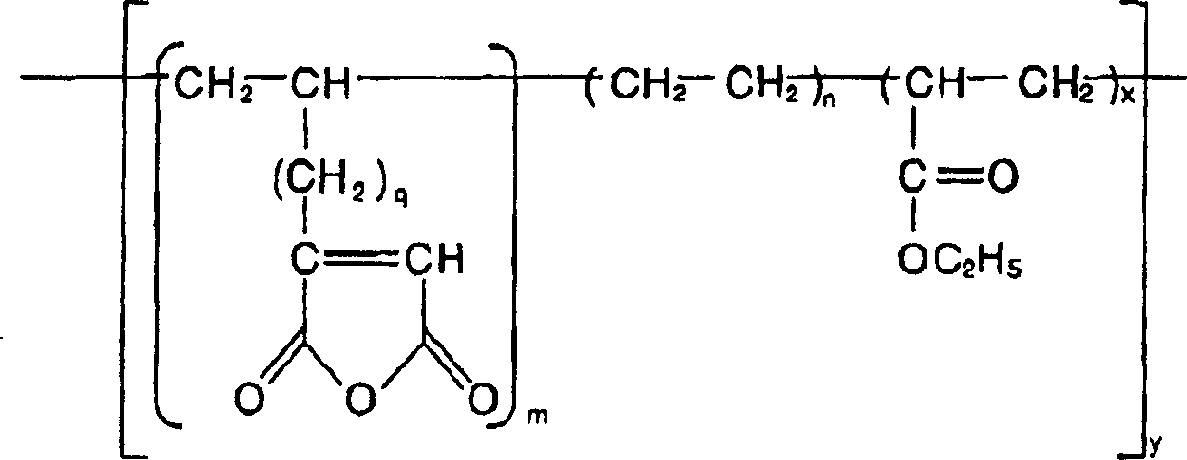

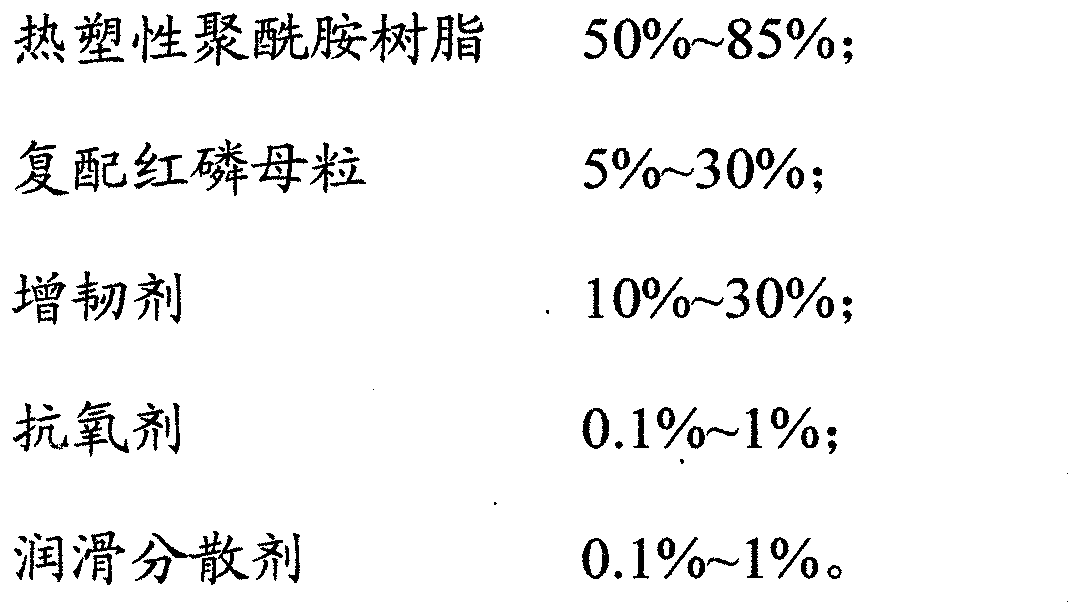

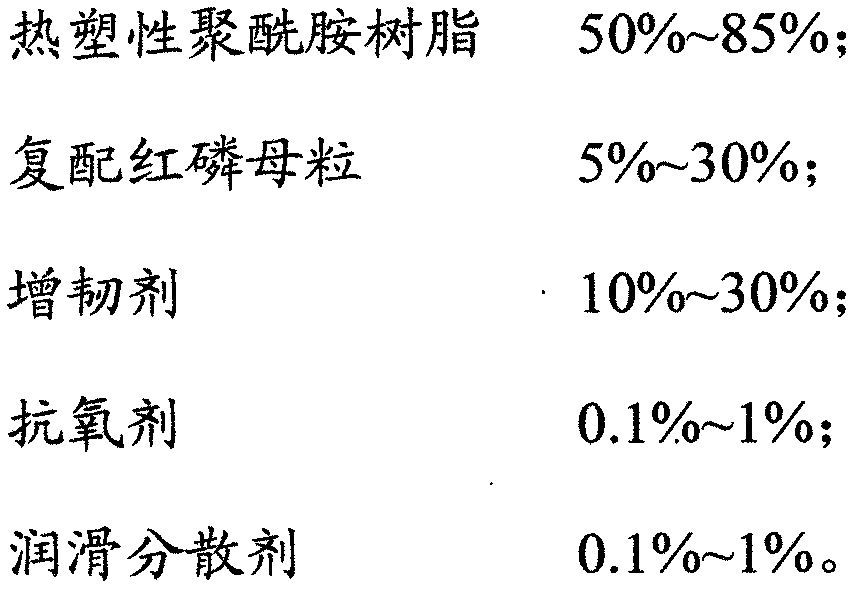

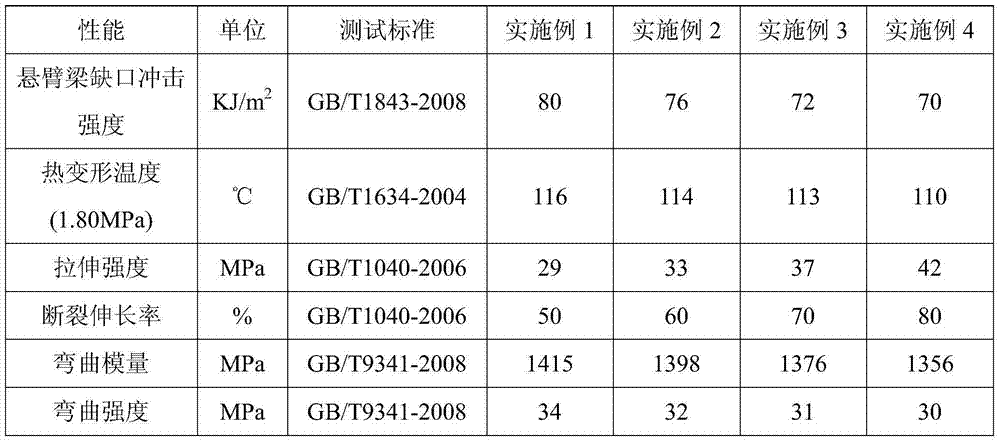

Halogen-free red phosphorus flame retardant nylon with high toughness and preparation method of nylon

The invention relates to halogen-free red phosphorus flame retardant nylon with high toughness for manufacturing explosion-proof equipment and a preparation method of the nylon. The nylon comprises 50-85% of thermoplastic polyamide resin, 5-30% of compound red phosphorus masterbatch, 10-30% of a flexibilizer, 0.1-1% of an antioxidant and 0.1-1% of a lubricating dispersant. The preparation method comprises the following steps: firstly, putting the components in parts by weight in a high mixer to be mixed for 2-5 minutes; then, putting the mixed materials from a main feed inlet of a twin-screw extruder to the extruder; carrying melt extrusion and prilling; and then preparing the red phosphorus flame retardant nylon with high toughness, wherein the temperatures of the regions of the twin-screw extruder are controlled in a range of 220-280 DEG C and the screw speed is controlled at 300-400RPM. By replacing common red phosphorus masterbatch with the compound red phosphorus masterbatch and adding the flexibilizer, the nylon material prepared satisfies the demand of high flame retardance, high toughness, no halogen and environment friendliness, and is more suitable for manufacturing explosion-proof equipment.

Owner:温州科力塑业有限公司

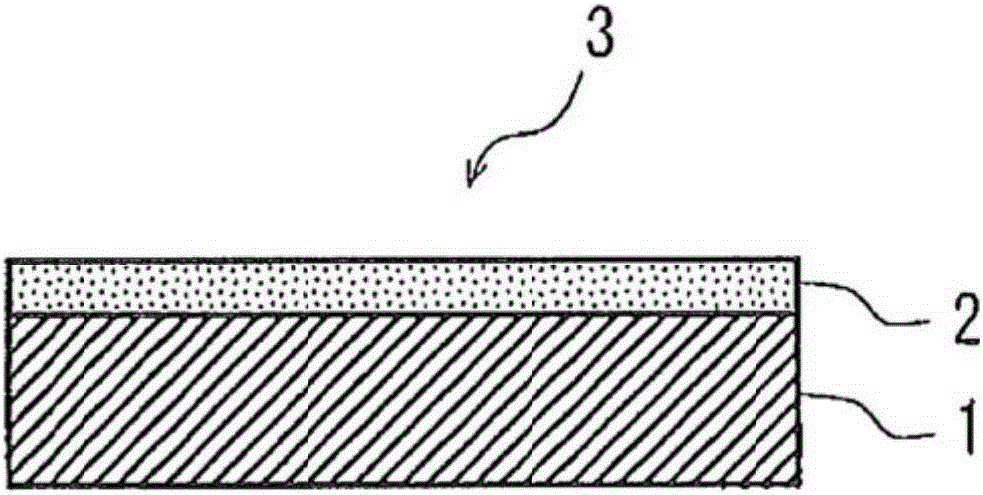

Flame-retardant sheet and formed article therefrom

InactiveCN1849422AImprove flame retardancyImprove flame retardant performanceFibre treatmentSynthetic resin layered productsFiberGraphite

An object of the present invention is to provide a fiber sheet excellent in flame retardancy and a molded article thereof. Provided is a flame-retardant fiber sheet containing expanded graphite in fibers. The expanded graphite expands when exposed to high temperatures, thereby imparting self-extinguishing properties to the fibrous sheet. The molded product of the flame-retardant fiber sheet has high flame retardancy and is harmless to humans and animals, so it can be used, for example, as interior materials for automobiles and buildings.

Owner:NAGOYA OIL CHEM CO LTD

High-gloss scraping-resistant filling PP resin and preparation method thereof

ActiveCN102477181AImproves scratch resistance and surface glossImprove flame retardancyChemistryMagnesium

A high-gloss scraping-resistant filling PP resin comprises the following components: 35-80 parts by weight of PP resins; 20-60 parts by weight of ultrafine magnesium hydroxide; 3-7 parts by weight of compatilizers; and 0.1-2 parts by weight of anti-oxidants. When the invention is compared with the prior art, ultrafine magnesium hydroxide is added into PP resins, which not only maintains original excellent performance of PP resins, but also increases the scraping-resistance and surface gloss of PP resins, and improves the flame retardancy; and the PP resin of the invention has a series of outstanding advantages of high gloss, environmental protection, scraping-resistance, and the like.

Owner:滁州格美特科技有限公司

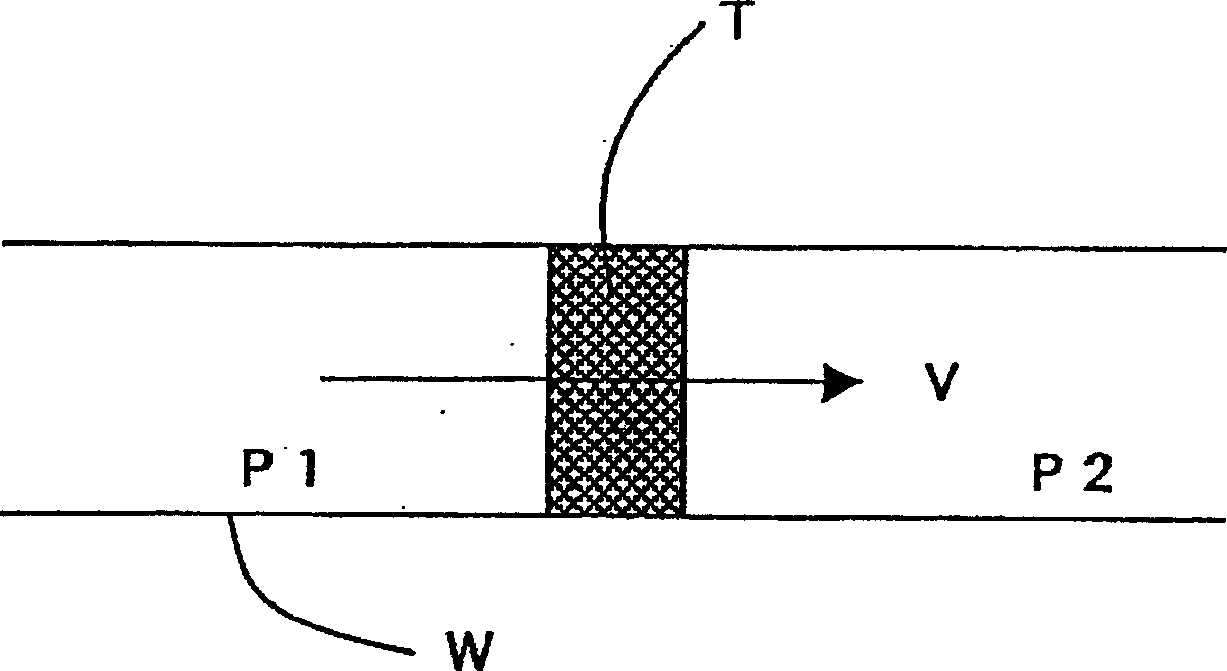

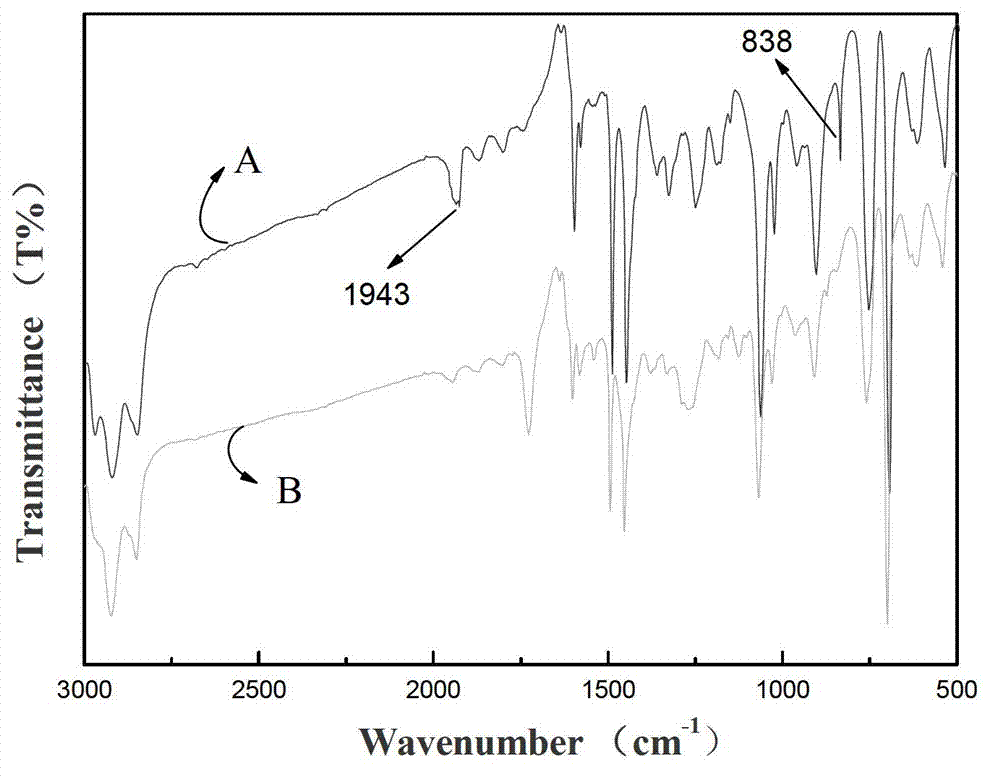

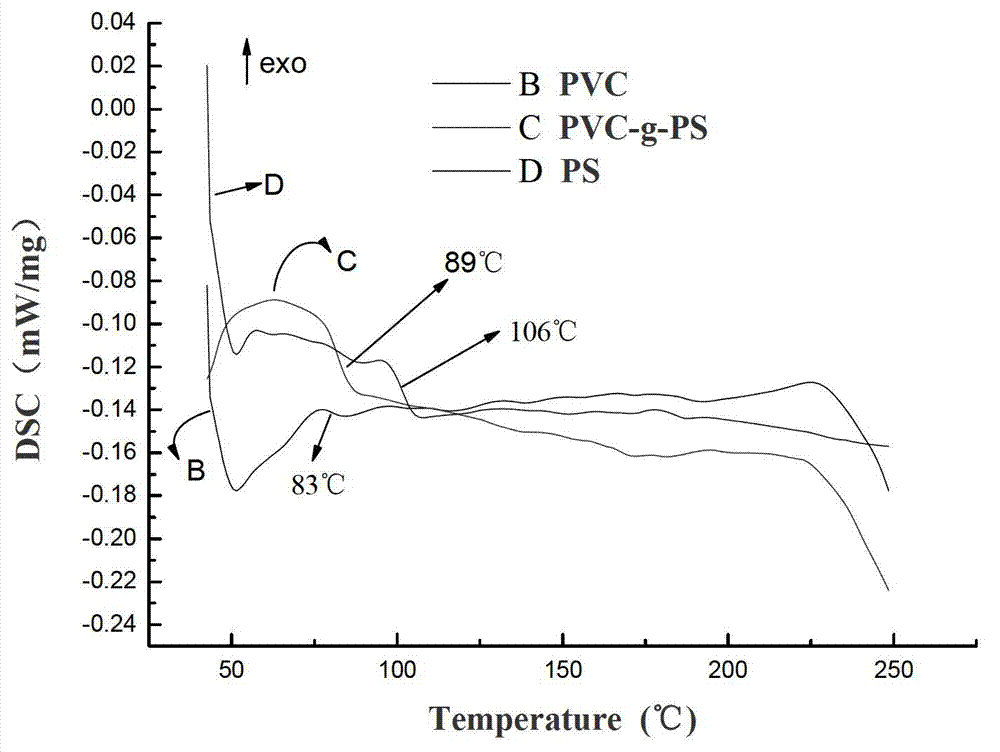

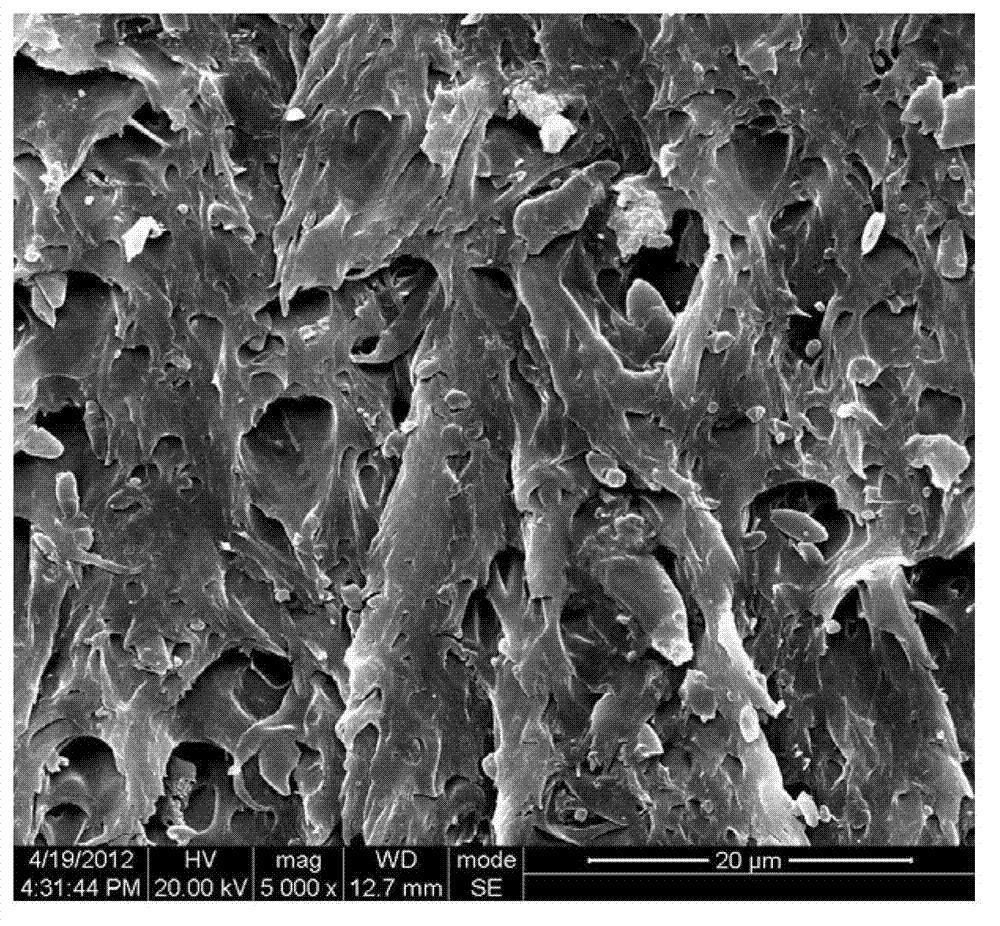

PVC (polyvinyl chloride)/styrene polymer alloy and preparation method thereof

ActiveCN102731936AAlloying is simpleImprove flame retardancyAluminum chloride anhydrousCompatibilization

The invention discloses a PVC (polyvinyl chloride) / styrene polymer alloy. The alloy is characterized by being prepared from the following raw materials in percentage by weight: 50-95% of PVC resin, 3-30% of styrene polymer, 0.2-6% of catalyst, 0-10% of addition agent and 1.5-4% of heat stabilizer. Besides, the invention also discloses a preparation method of the PVC / styrene polymer alloy. The PVC / styrene polymer alloy material has the following advantages: not only are the defects of the existing extra compatilizer overcome, but also the alloying of PVC and styrene polymer is simpler and more convenient; anhydrous aluminium chloride, anhydrous ferric chloride or anhydrous stannic tetrachloride is taken as the catalyst; the reaction mixing / extrusion in-situ compatibilization technology is adopted, thus realizing the blending of PVC and styrene polymer; and the polymer alloy material can improve the flame retardance of the styrene polymer while reinforcing and toughening the PVC, and has industrial application prospects.

Owner:XIAN UNIV OF SCI & TECH

Modified polypropylene composite material

ActiveCN103483690AImprove impact toughnessImprove flame retardancyMaleic anhydrideWeather resistance

The invention discloses a modified polypropylene composite material which comprises the following components in percentage by weight: 60-80% of polypropylene copolymer, 2-10% of toughener, 1-10% of maleic anhydride grafted polypropylene, 0.1-2% of coupling agent, 5-30% of halogen-free flame retardant, 0.2-2% of photostabilizer and 1-2% of stearic acid. The modified polypropylene composite material has the advantages of favorable weather resistance and long service life; the 3000-hour color difference is less than 1, and thus, the modified polypropylene composite material satisfies the requirement of no color fading after outdoor use for 8-10 years; the flame retardancy is favorable, the flame-retardant grade reaches V0 Grade, and the environmental protection property satisfies the RoHS standard requirement; and besides, the modified polypropylene composite material has excellent toughness, rigidity and scratch resistance. The modified polypropylene composite material can be used for blow molding, is suitable for producing various automobile parts, electric appliance parts and the like, and is especially suitable for producing outdoor bleacher chairs.

Owner:SHANTOU TENGYE PLASTIC IND

Low temperature-resistant halogen-free flame-retardant polycarbonate composition and use thereof

The invention provides a low temperature-resistant halogen-free flame-retardant polycarbonate composition. The composition comprises, by weight, 20 to 30 parts of polycarbonate, 0.3 to 1 part of a polysiloxane-polycarbonate random copolymer, and 8 to 15 parts of an acrylonitrile / butadiene / styrene terpolymer. A mass ratio of polycarbonate to polysiloxane-polycarbonate random copolymer is 20: 0.3 to 1. The polysiloxane-polycarbonate random copolymer comprises 5-20% by weight of the polysiloxane block. The polycarbonate composition has the advantages of simple preparation processes, low cost and high flame retardancy.

Owner:广东新通彩材料科技有限公司 +1

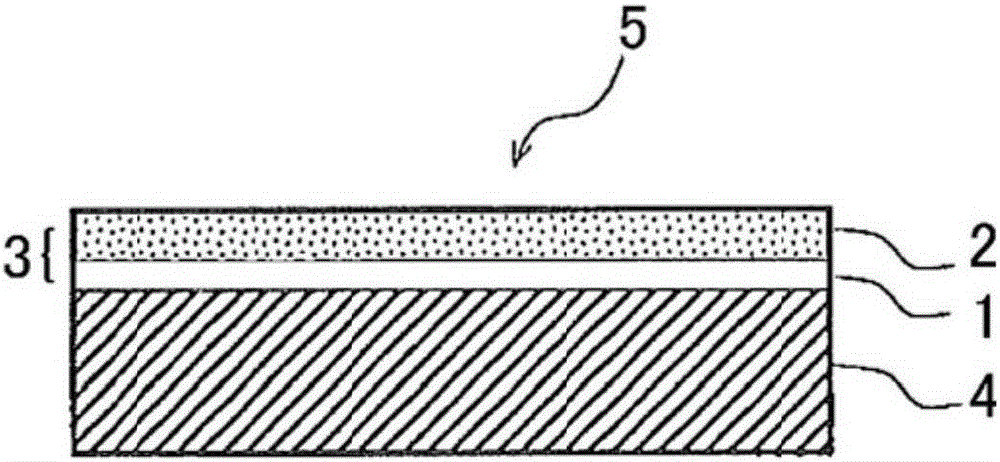

Flame-retardant sheet and flame-retardant composite member

ActiveCN105307857AGood flame retardancyImprove flame retardancyFireproof paintsRailway lightingSilicone resinFlame resistance

Provided are: a flame-retardant sheet having extremely high flame retardance; and a flame-retardant composite member using said flame-retardant sheet and exhibiting extremely high flame retardance even when having a flammable base material. This flame-retardant sheet has: a coating formed from a silicone resin composition (C) including at least an inorganic oxide particle-containing condensation-reactive silicone resin; and a glue layer or an adhesive layer. This flame-retardant composite member has this flame-retardant sheet on at least one surface side of a base material, and has the glue layer or adhesive layer between the base material and the coating.

Owner:NITTO DENKO CORP

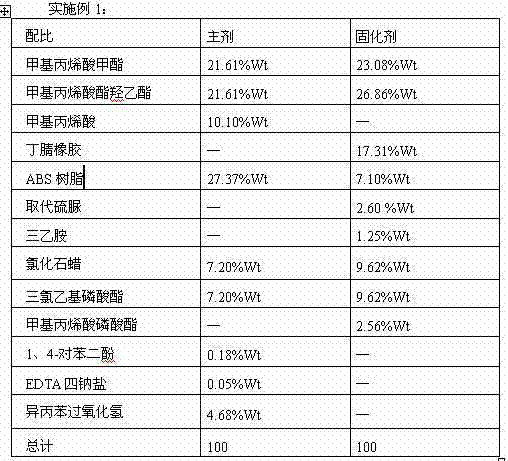

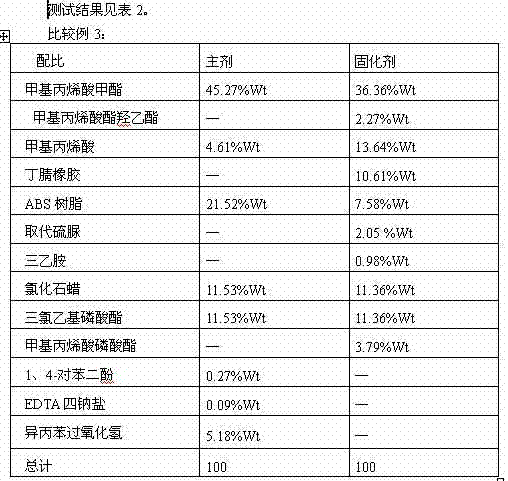

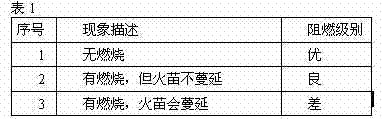

Acrylate adhesive for spot welding process

ActiveCN102533131AImprove flame retardancyNot easy to catch fireOrganic non-macromolecular adhesiveFire retardantAdhesive

The invention relates to an acrylate adhesive for a spot welding process and belongs to the technical field of a double-component acrylate structural adhesive, and is mainly used for solving the problems that the existing acrylate adhesive is extremely easy to ignite and burn when in spot welding. The acrylate adhesive is characterized by mainly comprising a main agent component and a solidifyingagent component, wherein (1) the main agent component comprises the following raw materials by weight percent: 42%-85% of acrylate monomer containing at least one vinyl group, 0%-12% of methacrylic acid, 0%-30% of elastomer, 0.01%-1% of stabilizing agent, 0%-30% of toughening resin, 0%-20% of fire retardant and 0.5%-8% of peroxide; (2) the solidifying agent component comprises the following raw materials by weight percent: 40%-90% of acrylate monomer containing at least one vinyl group, 0%-23% of elastomer, 0%-20% of methacrylic acid, 1%-10% of accelerating agent, 0%-30% of toughening resin and 0%-20% of fire retardant; and (3) at least one component in the main agent and the solidifying agent contains 10%-30% of elastomer. The acrylate adhesive disclosed by the invention has the characteristic that the adhesive can be used for the spot welding process and can be widely applied to the fields of machinery manufacturing and maintenance.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

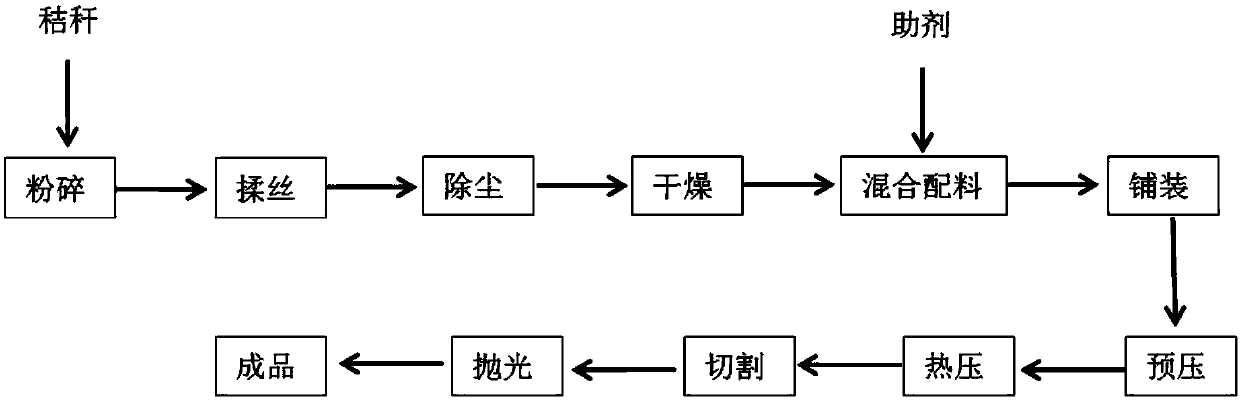

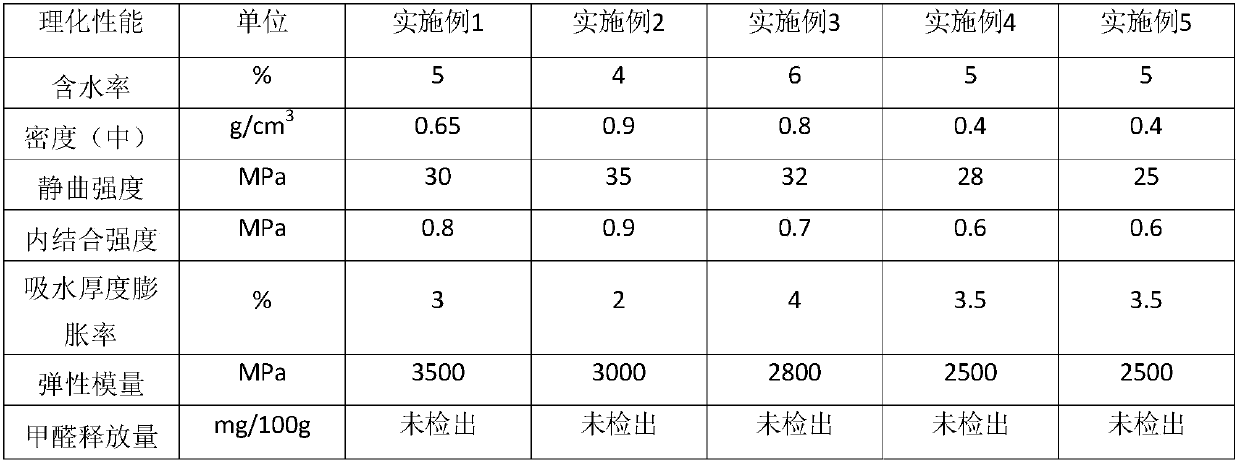

Auxiliary agent for straw artificial board and preparation method for straw artificial board

InactiveCN109571703AImprove flame retardancyHigh elastic modulusNon-macromolecular adhesive additivesWood working apparatusOrganic chemicalsPhenols

Owner:天津缔木博科技有限公司

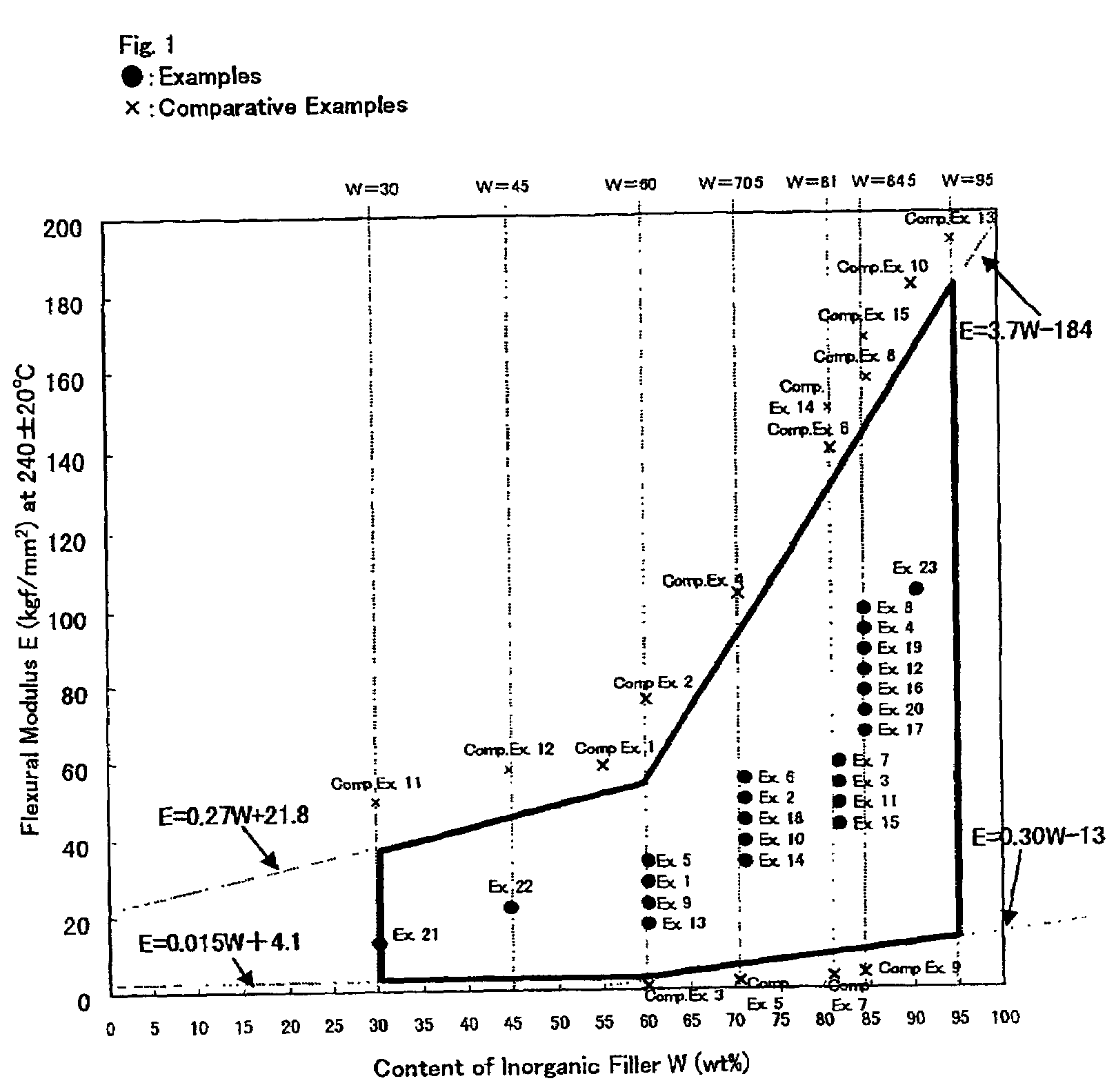

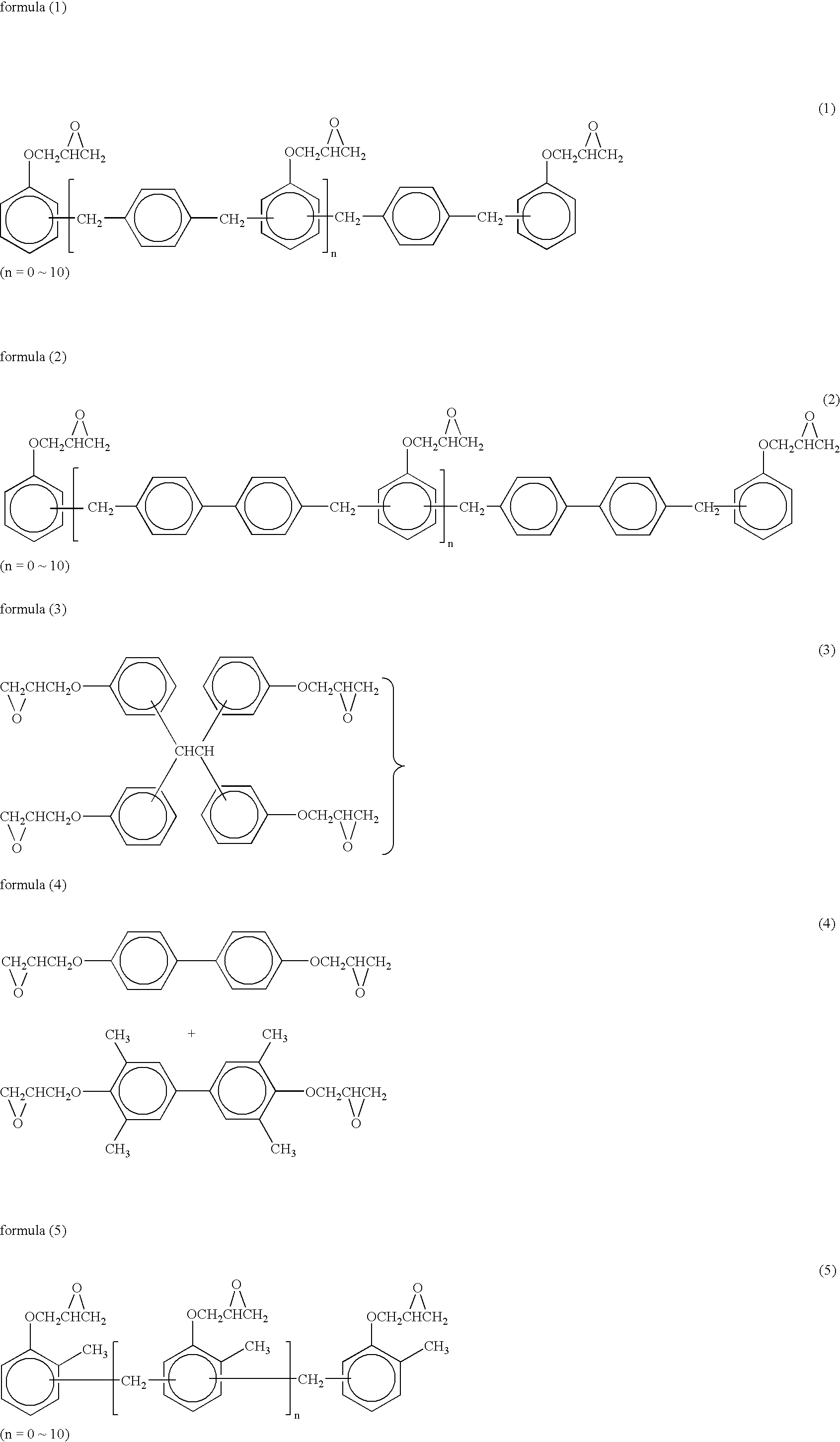

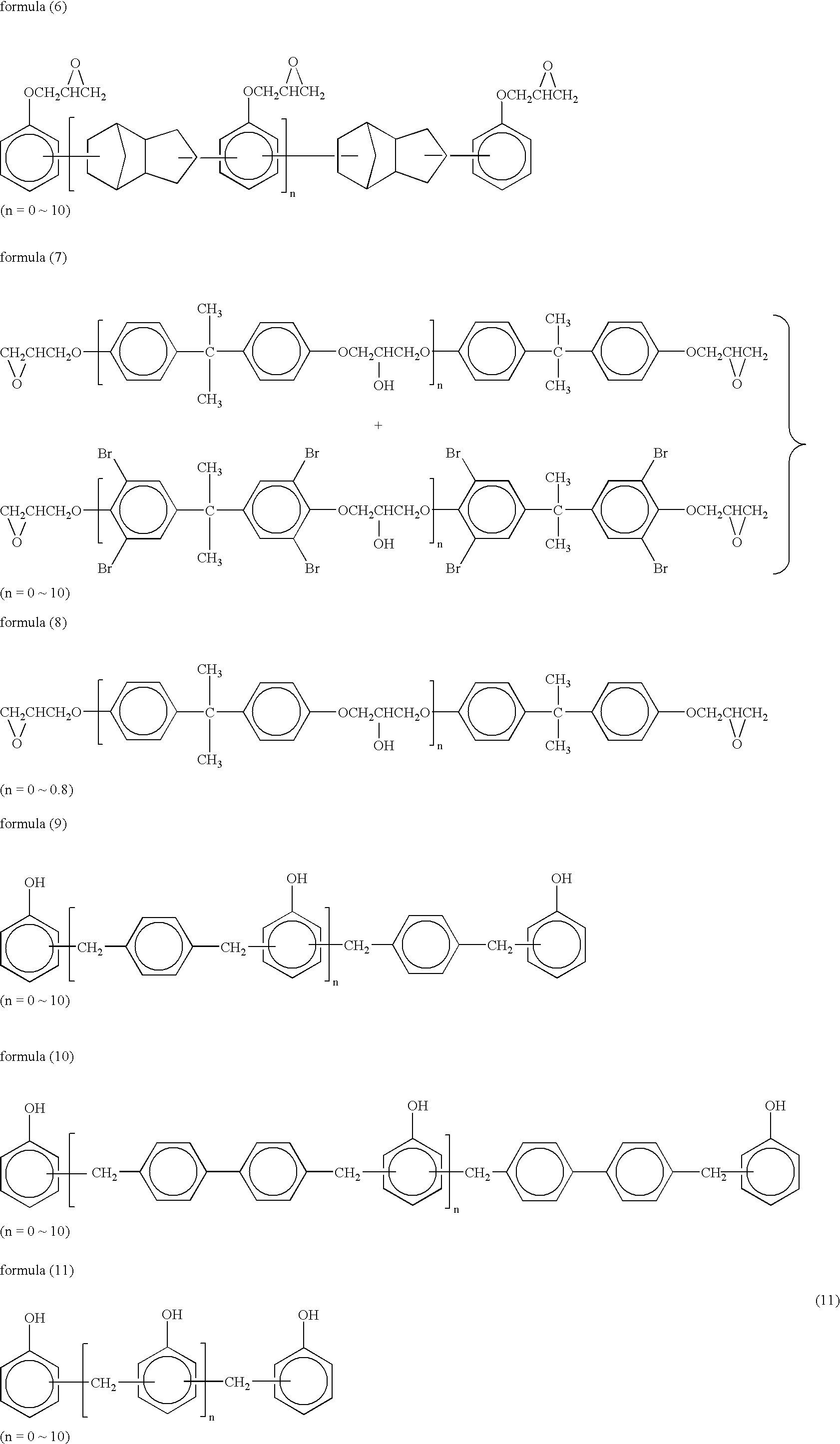

Flame-retardant epoxy resin composition and semiconductor device made using the same

InactiveUS7098276B1Improve flame retardancyGood reliabilitySemiconductor/solid-state device detailsSolid-state devicesChemistryPhenol formaldehyde resin

An epoxy resin composition which can be used as a semiconductor encapsulating resin and in which the improvement of flame retardancy can be attained by suitably adapting a crosslinked structure itself of a cured article without using any flame retardant material and without particularly highly filling an inorganic filler. The epoxy resin composition includes an epoxy resin (A), a phenolic resin (B), an inorganic filler (C) and a curing accelerator (D), wherein a flexural modulus E (kgf / mm2) at 240±20% C of a cured article obtained by curing the composition is a value satisfying 0.015 W+4.1≦E≦0.27 W+21.8 in the case of 30≦W<60, or a value satisfying 0.30 W−13≦E≦3.7 W−184 in the case of 60≦W≦95 wherein W (wt %) is a content of the inorganic filler (C) in the cured article. The cured article of this composition forms a foamed layer during thermal decomposition or at ignition to exert flame retardancy.

Owner:NEC CORP +1

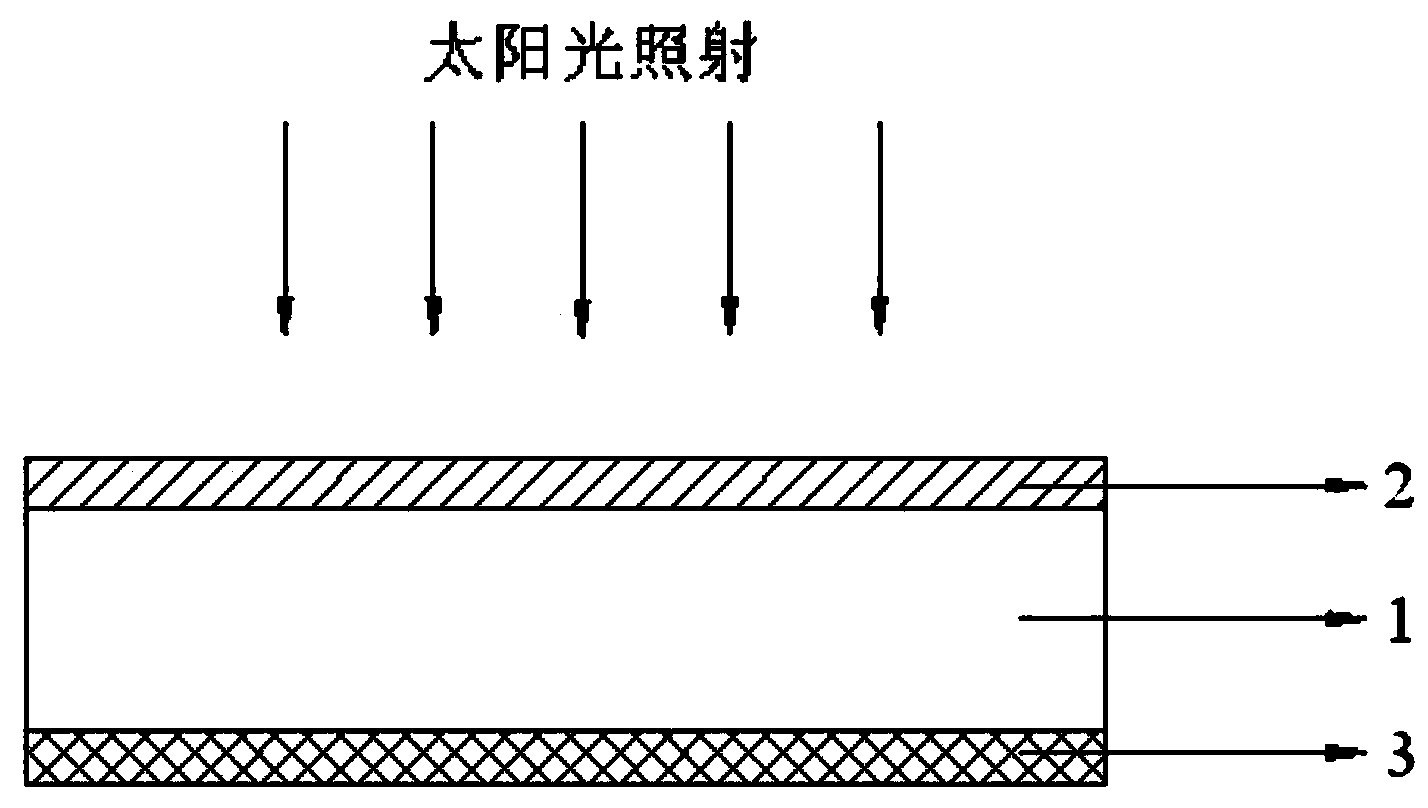

Preparation method of flame-retardant insulation board for building exterior wall

ActiveCN103553543APrevent heat transferImprove flame retardancyCeramicwareBuilding materialRadiation

The invention discloses a preparation method of a flame-retardant insulation board for a building exterior wall, and relates to a building material prepared from a composition of natural mineral materials. The method comprises the following steps: preparing an inorganic mineral nano fiber powder panel matrix with an internal porous structure; preparing a coating material for forming a heat reflecting layer on the upper surface of the panel matrix; preparing a coating material for forming a heat radiation layer on the lower surface of the panel matrix; respectively coating the coating material of the heat reflecting layer and the coating material of the heat radiation layer on the upper surface and the lower surface of the inorganic mineral nano fiber powder panel matrix to form the heat reflecting layer and the heat radiation layer respectively, and then naturally airing, so as to prepare the flame-retardant insulation board product for the building exterior wall. The defects that the existing insulation board for the building exterior wall is poor in thermal insulating property, and easy to burn, so as to form a potential safety hazard, and the preparation technology and the required conditions are complicated are overcome.

Owner:HEBEI UNIV OF TECH

Coloring pigment of wood product and making method thereof

The invention discloses a wood product coloring pigment and a preparation method thereof. The wood product coloring pigment is made of the following raw materials in parts by weight: 1-1.4 parts of tree lacquer, 6-10 parts of tung oil, 6-10 parts of linseed oil, 25-35 parts of amino resin, 10-10 parts of rosin resin 20 parts, 2-3 parts of beeswax, 2-3 parts of insect wax, 1-2 parts of vegetable wax, 15-25 parts of vegetable pigment, 35-40 parts of natural diluent, 0.5-1 part of drier, glass powder 6-8 parts, 1-3 parts of composite nano-bactericidal powder, 2-4 parts of molybdenum oxide. The invention has the following beneficial effects: the pigment of the invention is environmentally friendly, low-smoke and flame-retardant, has better spraying effect, better moisture resistance, aging resistance and wear resistance, and prolongs the service life of the material.

Owner:周建涛

Flame retardant bio-based polymer blends

InactiveUS20120296020A1Improve flame retardancyImprove flame retardant performanceGroup 5/15 element organic compoundsPolycarbonatePolymer blend

Polycarbonate compositions having flame retardant properties and improved impact resistance are disclosed, together with methods for preparing the same.

Owner:SABIC GLOBAL TECH BV

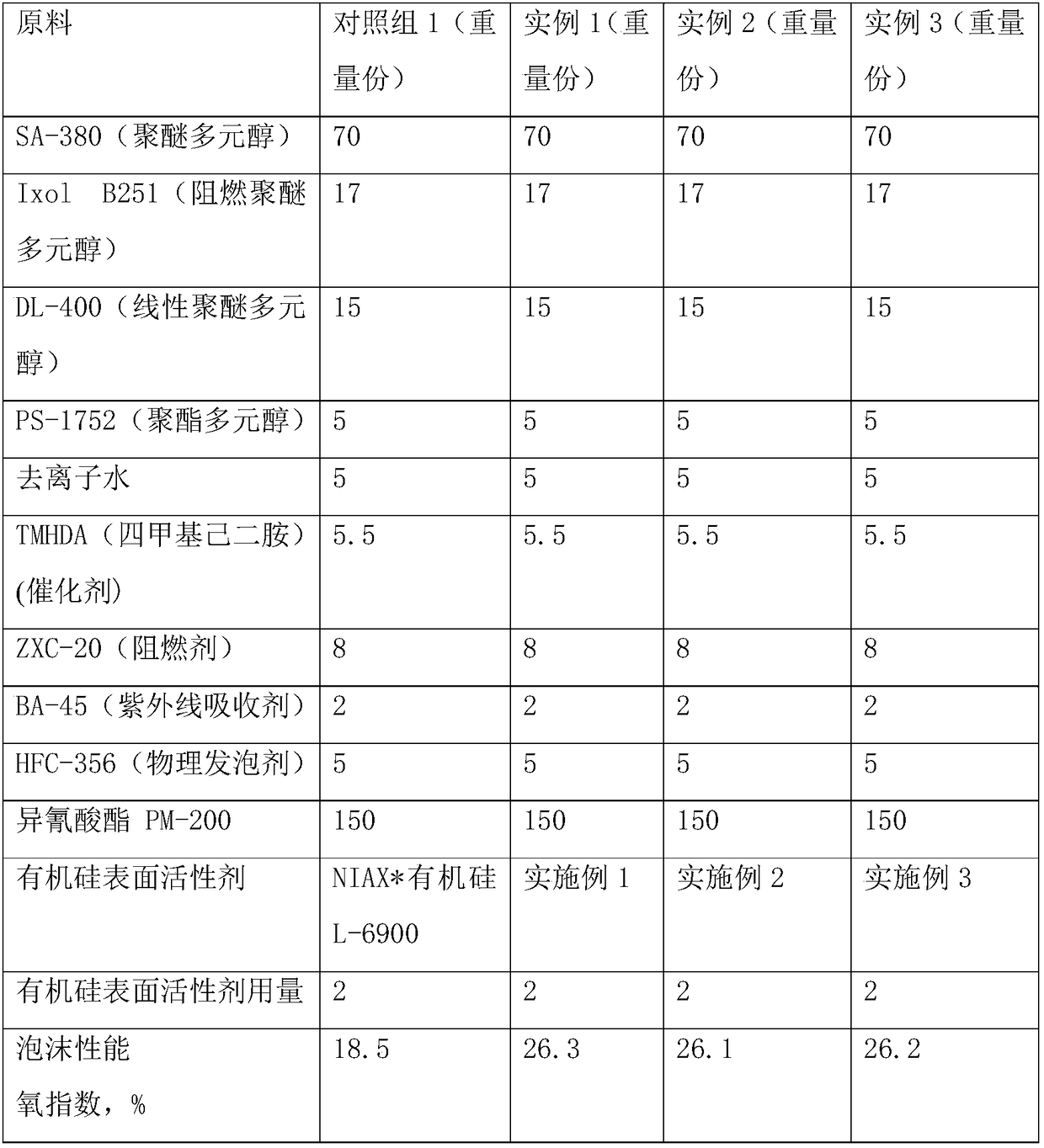

Flame-retardant organic silicon surfactant and application thereof

The invention provides a flame-retardant organic silicon surfactant and application thereof to preparation of flame-retardant polyurethane rigid foam. A general formula of the flame-retardant organicsilicon surfactant is MDxD'yM, wherein M is selected from any one of (CH3)3SiO1 / 2 and (CH3)2RSiO1 / 2; D refers to (CH3)3SiO2 / 2; D' refers to (CH3)2(R)SiO2 / 2; x+y refers to 5-50, y refers to 3-13; R isselected from at least one of unblocked polyether portions and at least one radicals containing benzene rings. The organic silicon surfactant is capable of improving flame retardation of polyurethanerigid foam; especially in application to solar water heaters, high flame retardation of polyurethane foam plastic can be achieved without adding of flame retardants. In addition, the flame-retardant organic silicon surfactant has advantages of high fluidity and high storage stability in combined materials.

Owner:JIANGXI MENHOVER CHEM TECH CO LTD

Casting process of corrosion-resistant pipeline valve

InactiveCN107876707AImprove dispersibility and compatibilityImprove flame retardancyFoundry mouldsFurnace typesCorrosion resistantMetallurgy

The invention discloses a casting process of a corrosion-resistant pipeline valve. The valve comprises a valve body and a protecting layer coating the valve body. The casting process of the valve specifically includes the following steps of manufacturing of a casting mold, melting, pouring, grinding, heat treatment and coating of the protecting layer. The casting process is simple and easy to implement, and low in casting cost, the cast valve has good corrosion resistance, and the service life is prolonged.

Owner:郑媛媛

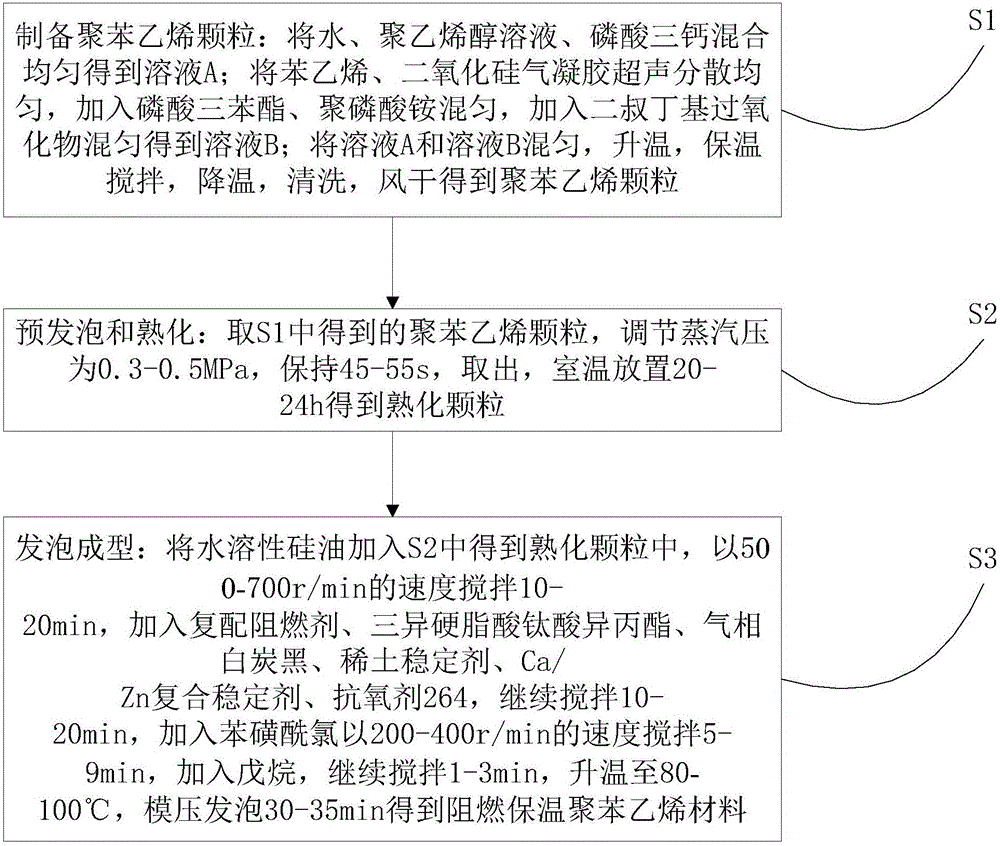

Flame retardant thermal insulation polystyrene material and preparation method thereof

InactiveCN105906965AImprove flame retardancyGood thermal insulation performanceAmmonium polyphosphateChemistry

The invention discloses a flame retardant thermal insulation polystyrene material. The raw materials include, by weight, 80-120 parts of styrene, 200-400 parts of water, 80-120 parts of a polyvinyl alcohol solution, 3-5 parts of tricalcium phosphate, 1-1.5 parts of triphenyl phosphate, 2.5-4.5 parts of ammonium polyphosphate, 2-5 parts of silica aerogel, 1-3 parts of di-tert-butyl peroxide, 2-4 parts of water soluble silicone oil, 10-18 parts of pentane, 80-100 parts of a compound flame retardant, 3-6 parts of benzenesulfonyl chloride, 4-6 parts of isopropyl titanate triisostearate, 20-30 parts of fumed silica, 2-3 parts of a rare earth stabilizer, 2-3 parts of a Ca / Zn composite stabilizer, and 3-5 parts of an antioxidant 264. The invention also discloses a preparation method of the flame retardant thermal insulation polystyrene material. The flame retardant thermal insulation polystyrene material provided by the invention has the advantages of simple operation, convenient industrial production, high flame retardance and good thermal insulation performance.

Owner:望江县精美欣钢构有限公司

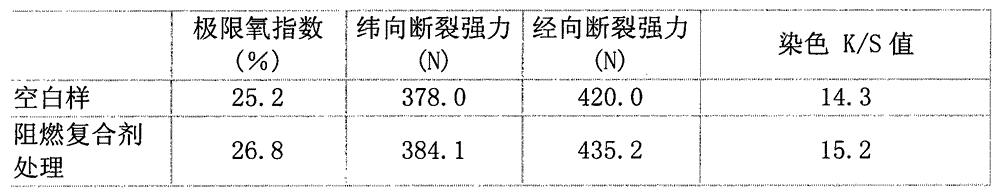

Yarn fire retardant and processing technology of fire-retardant yarn

InactiveCN104862977AImprove flame retardancyGood economic and social benefitsBiochemical fibre treatmentVegetal fibresPhosphoric acidWool

The invention provides a biological enzyme and adsorption coupled method to improve the flame retardancy of wool, and in particular provides a function finishing method for wool by using fire retardant complexing agent. The fire retardant complexing agent includes a transfer TGase (MTG), a fire retardant, a penetrating agent, a softener, industrial phosphoric acid, formic acid, citric acid, a buffer, and the balance of water. The prepared fire-retardant yarn can effectively prevent yarn from combustion.

Owner:BAODING JINGWEI TEXTILE CO LTD

High-concentration flame-retardant masterbatch applicable to polycarbonate and preparation method thereof

The invention discloses a high-concentration flame-retardant masterbatch applicable to polycarbonate and a preparation method thereof. The masterbatch comprises the following components by weight percentage (%): 15-45% of polycarbonate (PC), 50-80% of bromo-triazine, 4% of diphenyl phosphate, 0.8% of antioxidant and 0.2% of lubricant. The high-concentration flame-retardant masterbatch provided by the invention has the advantages of low dosage, high flame retardancy, low influence on the mechanical properties of the polycarbonate and the like. The flame-retardant masterbatch is used only by direct mixing and injection molding with the PC, without modification and grain pumping, thus reducing intermediate processes and saving a lot of time and intermediate cost.

Owner:SHENZHEN KEJU NEW MATERIAL

Flame retardant plastic shell for capacitor

ActiveCN106366586AGood mechanical propertiesImprove flame retardancyPolytetramethylene terephthalateChemistry

The invention discloses a flame retardant plastic shell for a capacitor. The flame retardant plastic shell is prepared from, by weight, polybutylene terephthalate, ABS plastic, a filling agent, color master batch, dimethyl trimethylsilylmethylphophonate, polyvinyl chloride resin, a lubricant and a flame retardant. The prepared plastic shell for the capacitor is good in mechanical performance, high in flame retardance, good in processability and low in cost and melt viscosity.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

Low-smoke nontoxic electrical insulating material

InactiveCN105585832AHigh Dielectric Strength and Insulation ResistanceImprove flame retardancyWaxTritolyl Phosphates

The invention discloses a low-smoke nontoxic electrical insulating material, belonging to the technical field of power industry. The low-smoke nontoxic electrical insulating material overcomes the defects of high smoke density and high tendency to generate toxic gas in the existing electrical insulating material combustion process. The low-smoke nontoxic electrical insulating material is composed of the following raw materials in parts by weight: 200-300 parts of polycarbonate resin, 50-100 parts of glass fiber, 10-20 parts of acrylate elastomer, 30-40 parts of ethylene-vinyl acetate copolymer, 3-8 parts of dicumyl peroxide, 4-10 parts of polyethylene wax, 5-10 parts of tritolyl phosphate, 1-3 parts of molybdenum trioxide, 10-20 parts of aluminum hydroxide, 5-10 parts of calcined argil, 10-20 parts of ground calcium carbonate and 1-2 parts of 50-80% AS-coated PTFE (polytetrafluoroethylene) micropowder. The low-smoke nontoxic electrical insulating material can be widely used as a cable material, an insulating sleeve and a watt-hour meter casing material.

Owner:国网山东省电力公司临沭县供电公司 +1

High-performance organic fireproof plugging material

InactiveCN105176091AImprove flame retardancyExcellent mechanical properties and impact resistanceEthanediolsParaffin oils

The invention discloses a high-performance organic fireproof plugging material, belongs to the technical field of macromolecular materials, and solves the problems of low fire resistance, low sealing property and low impact resistance of the existing fireproof plugging material. The high-performance organic fireproof plugging material consists of the following raw materials in parts by weight: 10 parts of chlorinated paraffin, 20 parts of kaoline, 8 parts of phenolic resin, 7 parts of butyl rubber, 25 parts of silicon oil, 15 parts of attapulgite, 20 parts of aluminum hydroxide, 5 parts of zinc borate, 1 part of dioctyl phthalate and 3 parts of ethanediol. The high-performance organic fireproof plugging material disclosed by the invention is high in combustion resistance, excellent in mechanical performance and high in impact resistance, and soft in texture and can realize random plugging.

Owner:国网山东沂水县供电公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com