Halogen-free flame retarding polymer sheet material

A technology of flame retardant polymer and flame retardant polyester, which is applied in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of large amount of flame retardant, decreased tear resistance and folding resistance, and high water absorption rate of products. , to achieve the effect of high flame retardancy and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

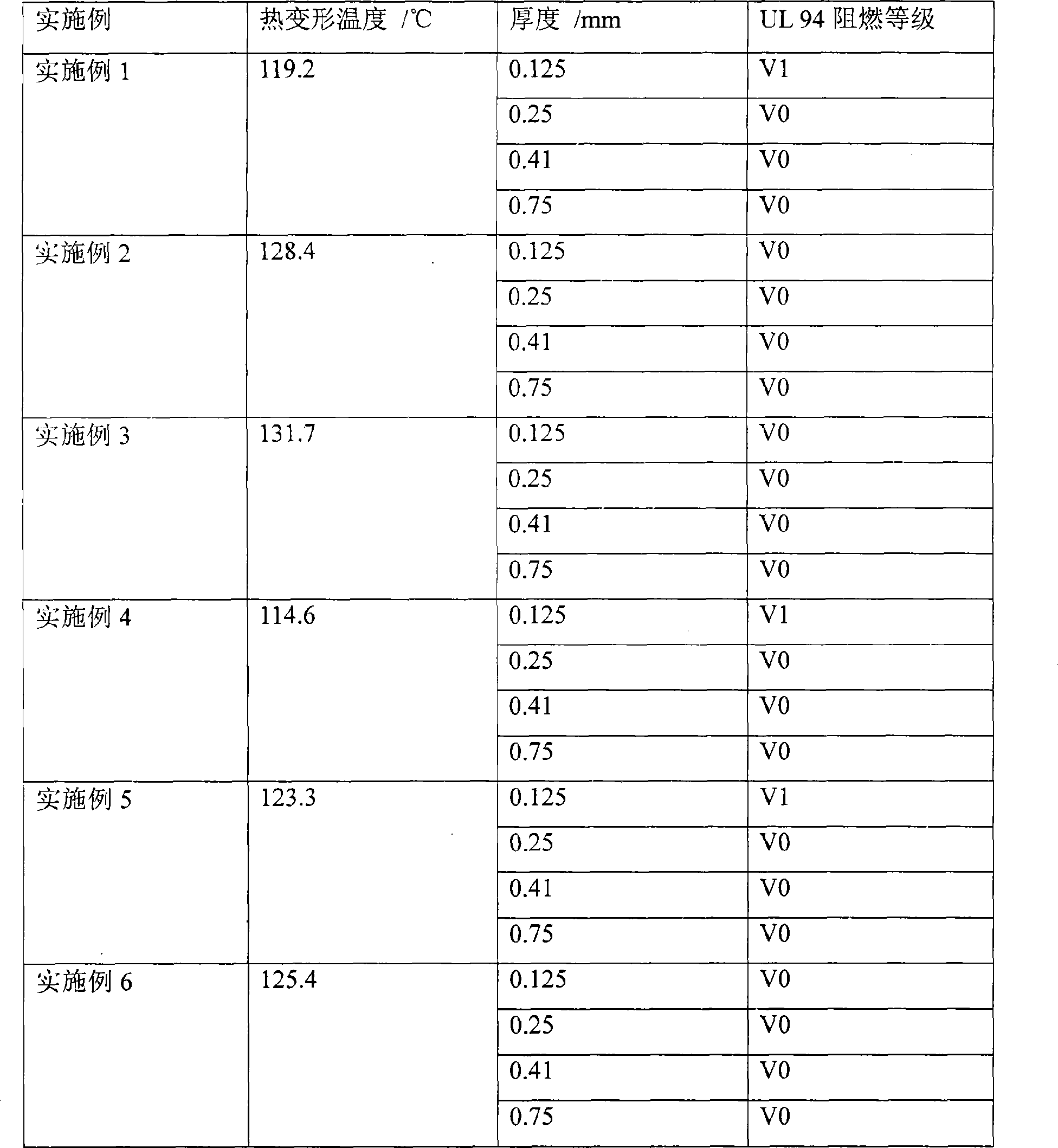

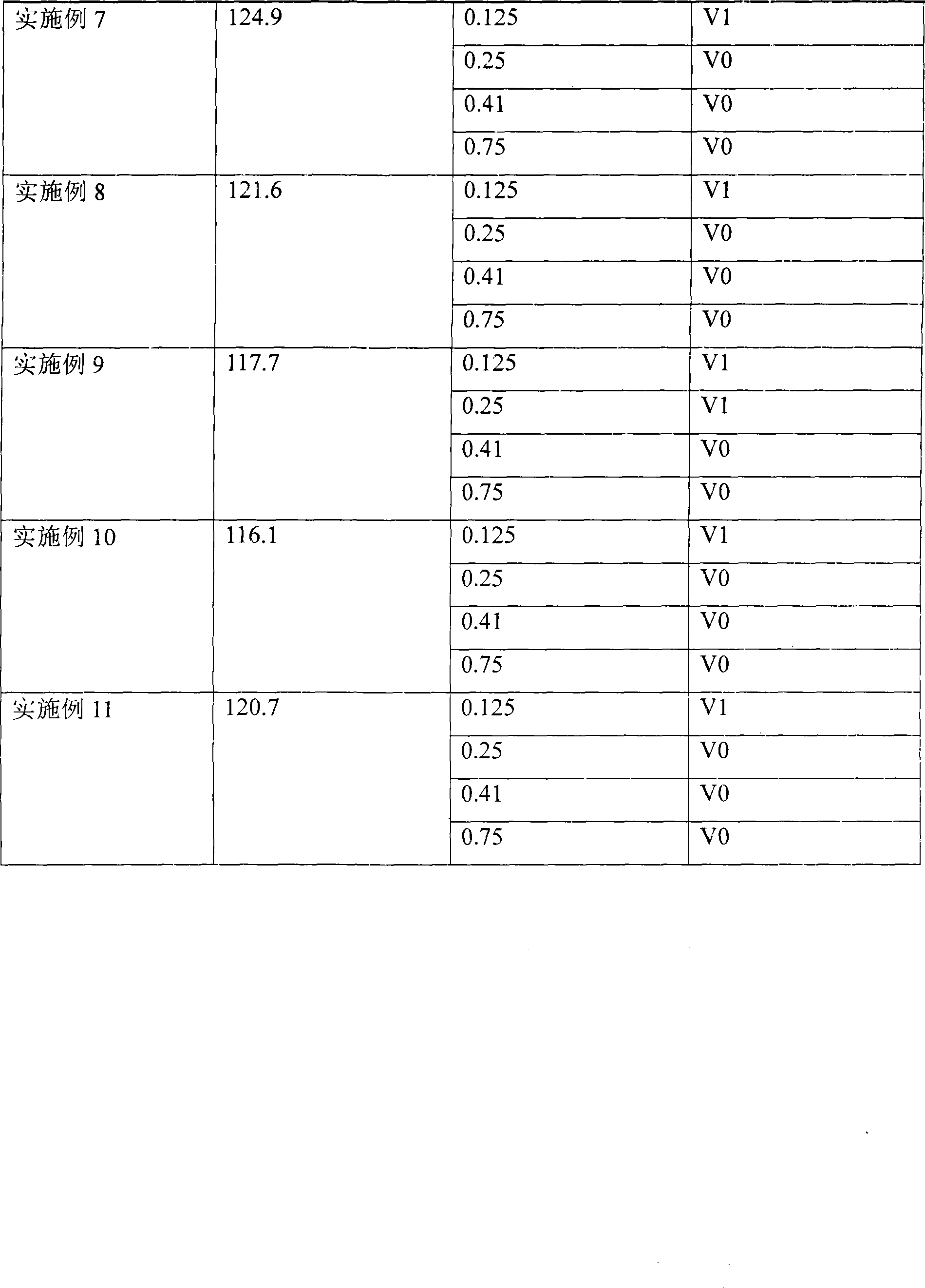

Embodiment 1

[0023] Prepare halogen-free flame-retardant polymer particles by step-by-step method. First, 10 kilograms of N-substituted alkoxy hindered amine Flamestab NOR 116FF of American Ciba Company, 0.3 kilogram of Ciba Antioxidant 1010 and 100 kilograms of German Basel Company The copolymerized polypropylene EP332K is extruded and granulated by a twin-screw extruder to obtain halogen-free flame-retardant polypropylene pellets. Then, 110.3 kg of halogen-free flame-retardant polypropylene pellets, 40 kg of U.S. DuPont's halogen-free flame-retardant polyethylene terephthalate RE19041 and 10 kg of French ARKEMA company's ethylene and glycidyl methacrylate AX8840 were passed through The halogen-free flame-retardant polymer particles of the present invention are obtained by extruding and granulating with a twin-screw extruder. Finally, the heat distortion temperature of the halogen-free flame-retardant polymer particles is measured according to the ASTM D648 standard, and then pressed into...

Embodiment 2

[0025] To prepare halogen-free flame-retardant polymer particles by direct method, 20 kg of red phosphorus RPM650 from Zhonglan Research Institute of Chemical Industry, 0.3 kg of Ciba Antioxidant 168 and 100 kg of copolymerized polypropylene EP332K from Basel, Germany, were passed through a twin-screw The feed port at the front of the extruder is fed into the extruder, and the material reaches the second feed port after preliminary melting, 80 kg of halogen-free flame-retardant polyethylene terephthalate RE19041 from DuPont of the United States and 25 kg of ethylene and Glycidyl methacrylate AX8840 is fed into the extruder by a forced feeding device, melted, extruded and granulated to obtain the halogen-free flame-retardant polymer particles of the present invention. Finally, the heat distortion temperature of the halogen-free flame-retardant polymer particles is measured according to the ASTM D648 standard, and then pressed into 0.125mm, 0.25mm, 0.41mm and 0.75mm thick sheets ...

Embodiment 3

[0027]Prepare halogen-free flame-retardant polymer particles by step-by-step method. First, 80 kg of ammonium polyphosphate-based composite flame retardant AP 750, 0.3 kg of Ciba Antioxidant 1010 and 100 kg of German Basel The company's copolymerized polypropylene EP332K is extruded and granulated by a twin-screw extruder to obtain halogen-free flame-retardant polypropylene pellets. Then, 180.3 kg of halogen-free flame-retardant polypropylene pellets, 100 kg of halogen-free flame-retardant polybutylene terephthalate PB40G10HU from Polyone Company of the United States, and 40 kg of ethylene and glycidyl methacrylate from French ARKEMA Company The ester AX8840 is extruded and granulated by a twin-screw extruder to obtain the halogen-free flame-retardant polymer particles of the present invention. Finally, the heat distortion temperature of the halogen-free flame-retardant polymer particles is measured according to the ASTM D648 standard, and then pressed into 0.125mm, 0.25mm, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com