Flame retardant plastic shell for capacitor

A technology of flame-retardant plastics and capacitors, applied in the field of capacitors, can solve the problems of low flame retardancy, achieve good mechanical properties, increase thermal deformation temperature, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A flame-retardant plastic shell for capacitors, which is made of the following components in parts by weight: polybutylene terephthalate 70, ABS plastic 35, filler 6, color masterbatch 1, dimethyl trimethylsilyl phosphonate Ester 3, polyvinyl chloride resin 10, lubricant 6, flame retardant 0.2; the flame retardant is made of the following ingredients in parts by weight: bentonite 2, urea 4, triethyl phosphate 1, lauryl sulfuric acid Sodium2, modified starch4.

Embodiment 2

[0019] A flame-retardant plastic shell for a capacitor, made of the following components by weight: polybutylene terephthalate 90, ABS plastic 45, filler 10, color masterbatch 4, dimethyl trimethylsilyl phosphonate Ester 5, polyvinyl chloride resin 12, lubricant 10, flame retardant 0.4; the flame retardant is made of the following ingredients in parts by weight: bentonite 2, urea 4, triethyl phosphate 1, lauryl sulfuric acid Sodium2, modified starch4.

Embodiment 3

[0021] A flame-retardant plastic shell for capacitors, which is made of the following components by weight: polybutylene terephthalate 80, ABS plastic 40, filler 7, color masterbatch 2, trimethylsilylmethylphosphonic acid dimethyl Ester 4, polyvinyl chloride resin 11, lubricant 8, flame retardant 0.3; the flame retardant is made of the following ingredients in parts by weight: bentonite 2, urea 4, triethyl phosphate 1, lauryl sulfuric acid Sodium2, modified starch4.

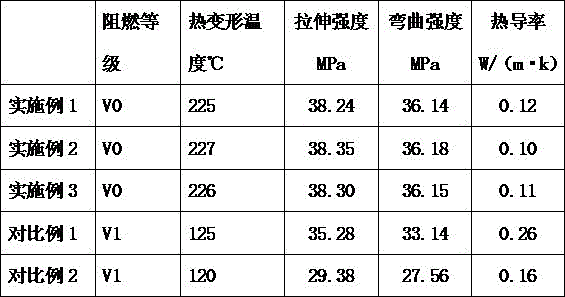

[0022] The performance of the flame-retardant plastic casing of the capacitor is compared by experiment:

[0023] Table 1

[0024]

[0025] Among them, Comparative Example 1 is: no modified starch is added when preparing the flame retardant in Example 2 of the present invention, and other ingredients remain unchanged;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com