Modified polypropylene composite material

A composite material and polypropylene technology, applied in the field of modified polypropylene composite materials, can solve the problems of poor weather resistance and high price, and achieve the effects of long service life, improved compatibility, and improved impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

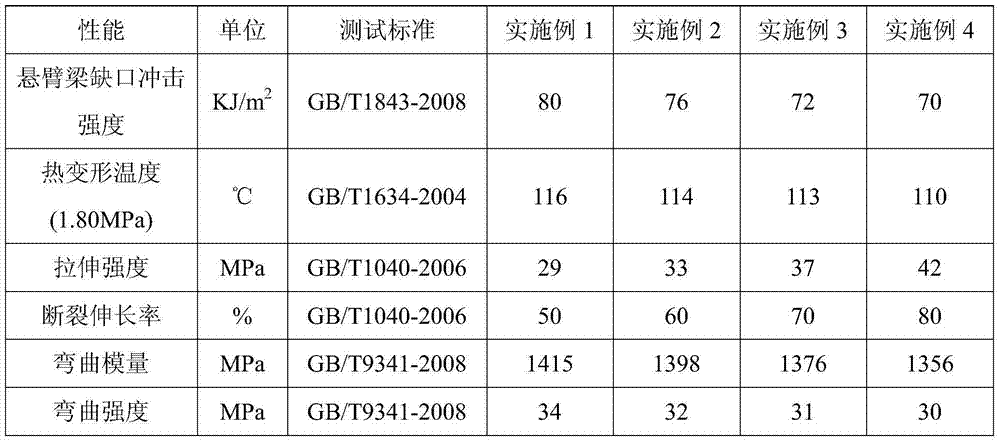

Examples

Embodiment 1

[0021] The weight percent formula of the modified polypropylene composite material in Example 1 is: 65% of copolymerized polypropylene, 6% of polyolefin elastomer, 6% of maleic anhydride grafted polypropylene, γ-methacryloxypropyl trimethyl 0.5% oxysilane, 10% ammonium polyphosphate, 5% melamine, 5% pentaerythritol, 1% organic montmorillonite, 0.5% light stabilizer with CAS No. 82451-48-7, 1% stearic acid, the above The raw materials were mixed and stirred, extruded by a twin-screw extruder, cooled, and pelletized to obtain the modified polypropylene composite pellets of Example 1.

Embodiment 2

[0022] The weight percent formula of the modified polypropylene composite material in Example 2 is: 60% of copolymerized polypropylene, 4% of polyolefin elastomer, 5% of maleic anhydride grafted polypropylene, γ-methacryloxypropyl trimethyl Oxysilane 0.3%, ammonium polyphosphate 14%, melamine 7.5%, pentaerythritol 6.5%, organic montmorillonite 1.3%, CAS No. 82451-48-7 light stabilizer 0.2%, stearic acid 1.2%, the above The raw materials were mixed and stirred, extruded by a twin-screw extruder, cooled, and pelletized to obtain the modified polypropylene composite pellets of Example 2.

Embodiment 3

[0023] The weight percentage formula of the modified polypropylene composite material of embodiment 3 is: copolymerized polypropylene 70%, polyolefin elastomer 8%, maleic anhydride grafted polypropylene 8%, γ-methacryloxypropyl trimethyl Oxysilane 1.0%, ammonium polyphosphate 4.5%, melamine 2.7%, pentaerythritol 2.3%, organic montmorillonite 0.3%, light stabilizer with CAS No. 82451-48-7 1.5%, stearic acid 1.7%, the above The raw materials were mixed and stirred, extruded by a twin-screw extruder, cooled, and pelletized to obtain the modified polypropylene composite pellets of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com