High-waterproof high-moisture-permeable flame-retardant coating fabric and production method thereof

A flame retardant coating and production method technology, applied in the field of high waterproof and high moisture permeability flame retardant coating fabrics, can solve the problems of low flame retardant performance, low economic benefits, cumbersome solvent recovery process, etc., and achieve high flame retardancy , Great economic and social benefits, excellent water resistance and moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

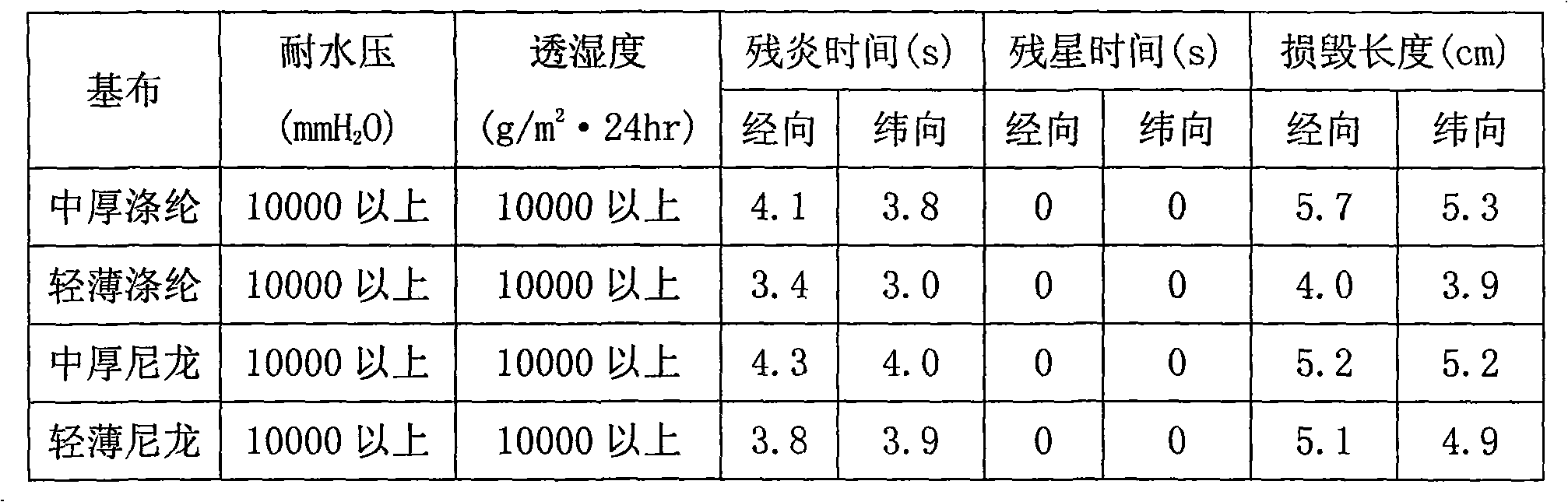

Embodiment 1

[0027] First, the following components by weight are uniformly mixed into a fabric coating slurry:

[0028] 100 parts of hydrophilic polyether polyurethane resin

[0029] 10 parts of halogen-free phosphorus-based particle flame retardant

[0030] 25 parts of non-polar solvent toluene

[0031] Non-polar solvent xylene 5 parts

[0032] Among them, the particle diameter of the halogen-free phosphorus-based particle-type flame retardant is less than 20 μm.

[0033] Secondly, the above-mentioned fabric coating slurry is evenly coated on the surface of the base fabric in a dry coating method to form a coating; finally, before the coating is dry, it is heated and dried. The heating and drying steps are divided into low-temperature pre-baking and high-temperature baking. The low-temperature pre-baking temperature is 50°C, and the pre-baking time is 4 minutes; the high-temperature baking temperature is 110°C, and the baking time is 4 minutes. After drying, a highly waterproof, high...

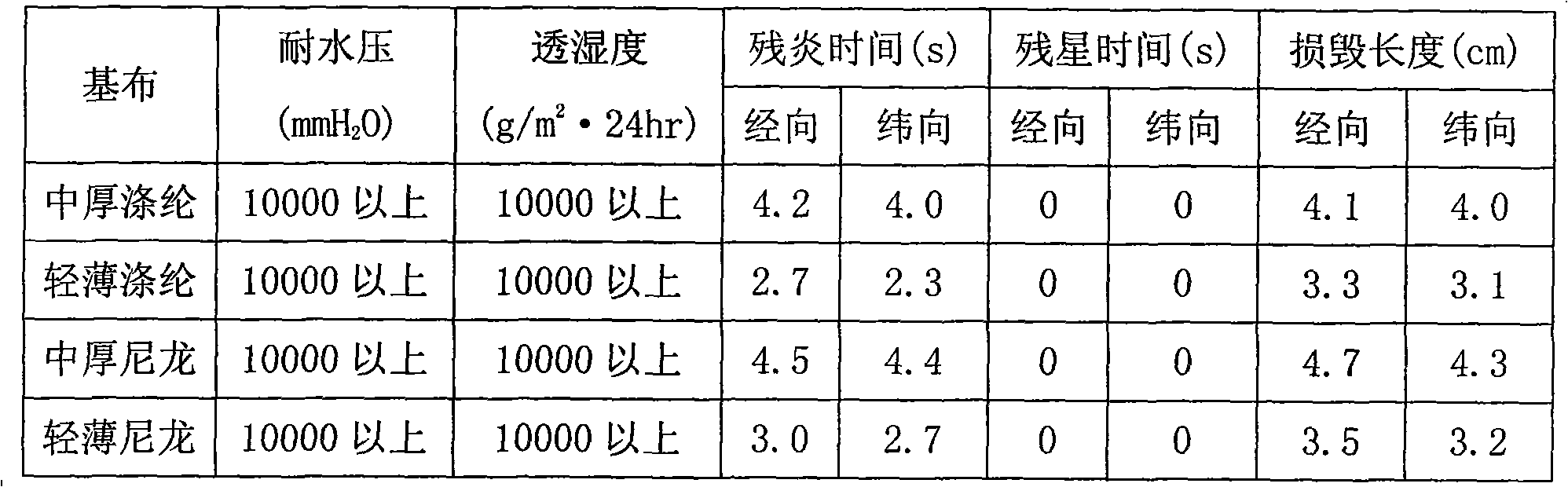

Embodiment 2

[0037] The weight part that is mixed into fabric coating slurry is:

[0038] Hydrophilic polyester polyurethane resin 100 parts

[0039] Halogen-free nitrogen particle type flame retardant 15 parts

[0040] Polar solvent butanone 40 parts

[0041] 10 parts non-polar solvent toluene

[0042] 4 parts white paint

[0043] Among them, the particle diameter of the halogen-free nitrogen-based particle-type flame retardant is less than 5 μm.

[0044] The low-temperature pre-baking temperature is 70°C, and the pre-baking time is 2 minutes; the high-temperature baking temperature is 120°C, and the baking time is 2 minutes. All the other are with embodiment 1. After drying, a highly waterproof, high moisture-permeable, flame-retardant coated fabric comprising a highly waterproof, high-moisture-permeable, flame-retardant coating layer is obtained.

[0045] The main indicators of the products obtained (see the table below):

[0046]

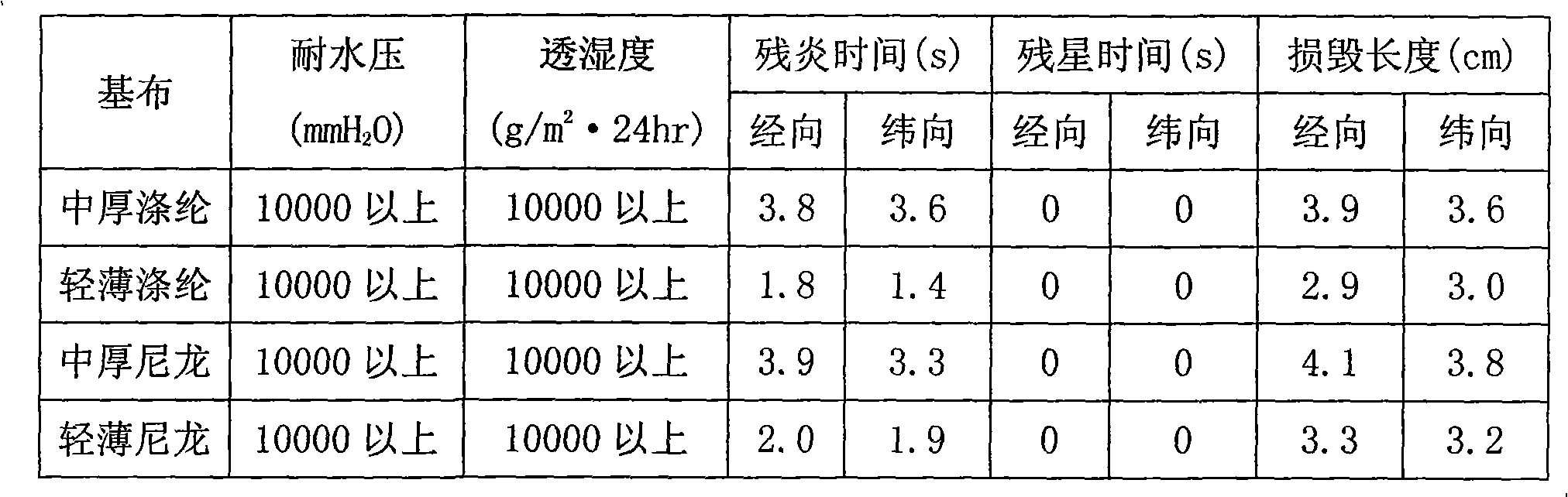

Embodiment 3

[0048] The weight part that is mixed into fabric coating slurry is:

[0049]Hydrophilic polyether-ester polyurethane resin 100 parts

[0050] Halogen-free phosphorus-nitrogen series particle type flame retardant 20 parts

[0051] Polar solvent butanone 40 parts

[0052] Polar solvent N,N-dimethylformamide 30 parts

[0053] 6 parts red paint

[0054] Among them, the particle diameter of the halogen-free phosphorus-nitrogen series particle-type flame retardant is less than 50 μm.

[0055] The low-temperature pre-baking temperature is 70°C, and the pre-baking time is 2min; the high-temperature baking temperature is 150°C, and the baking time is 1min. All the other are with embodiment 1. After drying, a highly waterproof, high moisture-permeable, flame-retardant coated fabric comprising a highly waterproof, high-moisture-permeable, flame-retardant coating layer is obtained.

[0056] The main indicators of the products obtained (see the table below):

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com