Highly-waterproof and highly-moisture-permeable fabric coating and production technology thereof

A coating and moisture-permeable technology, which is applied in the direction of textiles and papermaking, can solve the problems of high operation requirements and products without flame-retardant properties, and achieve low economic cost, excellent water resistance and moisture permeability, and reasonable coating process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

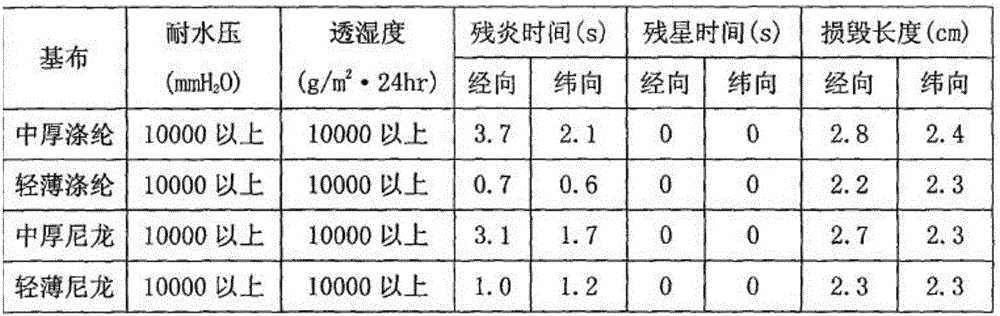

Image

Examples

Embodiment Construction

[0020] In order to facilitate understanding of the present invention, the present invention enumerates the following examples. Those skilled in the art should understand that the examples are only used to help understand the present invention, and should not be regarded as specific limitations on the present invention.

[0021] Unless otherwise specified, various raw materials of the present invention can be obtained commercially; or prepared according to conventional methods in the art. The experimental methods not indicating specific conditions in the following examples are usually measured according to national standards. If there is no corresponding national standard, proceed according to general international standards, conventional conditions, or the conditions suggested by the manufacturer.

[0022] A fabric coating process with high waterproof and high moisture permeability is characterized in that it is a secondary direct coating, comprising the following steps:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com