High-performance electromagnet

An electromagnet, high-performance technology, applied in the manufacture of inductors/transformers/magnets, circuits, magnetic cores, etc., can solve the problems of low saturation magnetic induction intensity of alloys, limited three-dimensional size of materials, and difficulty in meeting requirements, achieving magnetic Increased conductivity, improved insulation coating effect, and the effect of preventing powder from being oxidized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

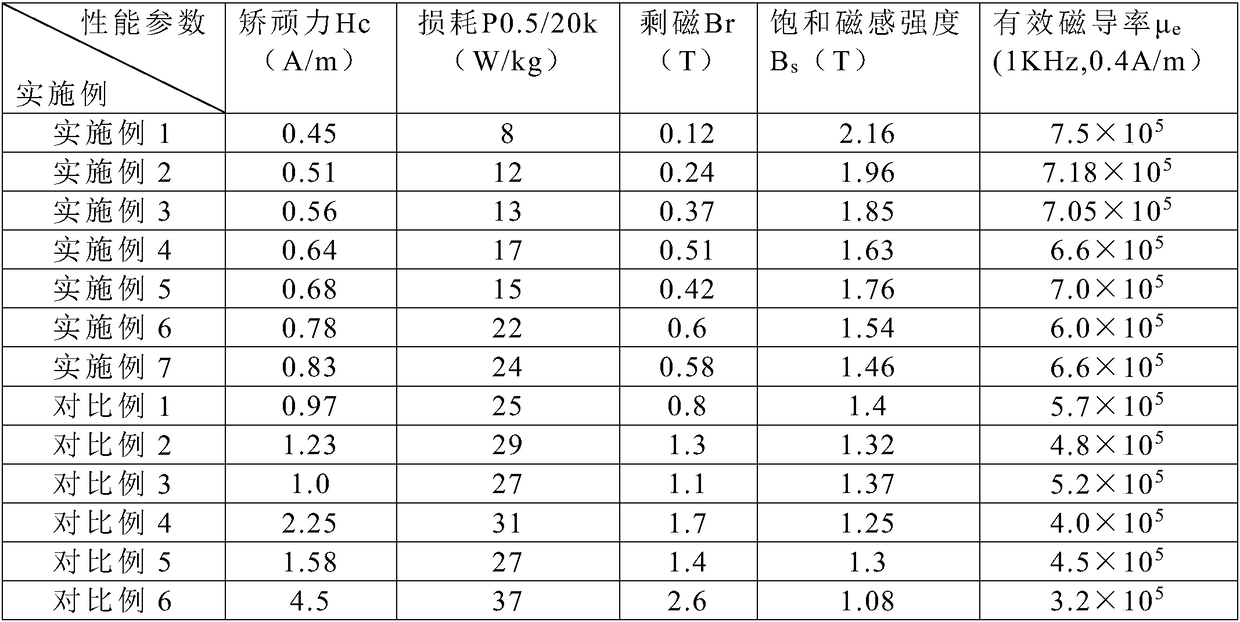

Examples

Embodiment 1

[0030] A high-performance electromagnet, the electromagnet is made up of a coil and a magnetic iron core, and the magnetic iron core is made by the following method:

[0031] According to raw material composition Fe 78 Nb 1.5 Cu 1 al 3 B 12 Ge 4.5 Weigh the ingredients, mix them uniformly and put them into a ball mill with a rotating speed of 270r / min for 35h to obtain nanocrystalline alloy powder, wherein the ball-to-material ratio is 12:1;

[0032] Add 6.5% tetraethyl orthosilicate, 2% silica sol, 17.5% alcohol, 6.5% deionized water, 0.01% nitric acid, 1.8% hard Fatty acid amide, stirred under 25Hz ultrasonic conditions for 15min, dried, ground, sieved, and then pressed into a green body under a pressure of 4GPa;

[0033] Under the mixed atmosphere of hydrogen and argon, the green body is heated up to 600°C at a heating rate of 25°C / min for annealing heat treatment, and then cooled in the furnace after holding for 2 hours;

[0034] Dip the annealed green body into the...

Embodiment 2

[0036] A high-performance electromagnet, the electromagnet is made up of a coil and a magnetic iron core, and the magnetic iron core is made by the following method:

[0037] According to raw material composition Fe 78 Nb 1.5 Cu 1 al 2 B 12 Ge 5.5 Weigh the ingredients, mix them uniformly and put them into a ball mill with a rotating speed of 260r / min for 32h to obtain nanocrystalline alloy powder, wherein the ball-to-material ratio is 11:1;

[0038] Add 6% tetraethyl orthosilicate, 1.5% silica sol, 16% alcohol, 6% deionized water, 0.008% nitric acid, 1% hard Fatty acid amide, stirred under 23Hz ultrasonic conditions for 13min, dried, ground, sieved, and then pressed into a green body under a pressure of 3.2GPa;

[0039] Under the mixed atmosphere of hydrogen and argon, the green body is heated up to 550°C at a heating rate of 23°C / min for annealing heat treatment, kept for 1.5h and then cooled with the furnace;

[0040] Dip the annealed green body into the cured emulsi...

Embodiment 3

[0042] A high-performance electromagnet, the electromagnet is made up of a coil and a magnetic iron core, and the magnetic iron core is made by the following method:

[0043] According to raw material composition Fe 78 Nb 1.5 Cu 1 al 4 B 12 Ge 3.5 (Mass percentage) Take the ingredients, mix them uniformly and put them into a ball mill with a rotating speed of 280r / min for 36h to get nanocrystalline alloy powder, wherein the ball-to-material ratio is 13:1;

[0044] Add orthosilicate ethyl ester, 2.2% silica sol, 17% alcohol, 6% deionized water, 0.014% nitric acid, 1.5% hard Fatty acid amide was stirred under 26Hz ultrasonic conditions for 16min, dried, ground, sieved, and then pressed into a green body under a pressure of 3.6GPa;

[0045] Heat the green body to 620°C at a heating rate of 26°C / min under an argon atmosphere for annealing heat treatment, keep it for 2 hours and then cool it in the furnace;

[0046] Dip the annealed green body into the cured emulsion at 130°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com