Patents

Literature

35results about How to "Add flame retardant function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

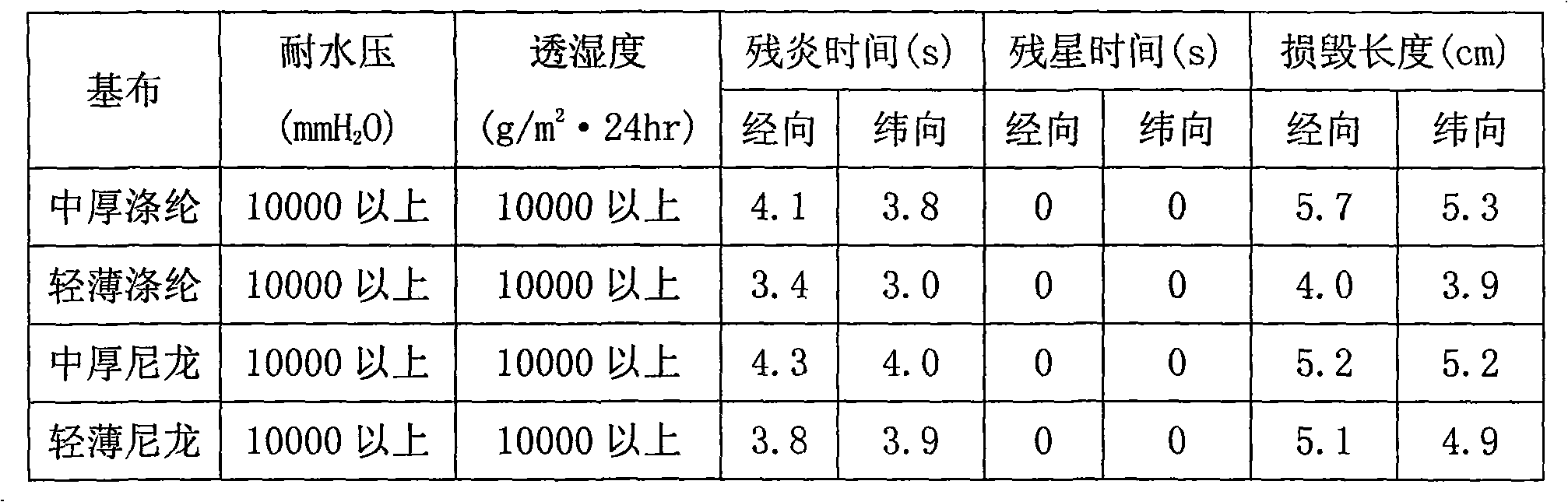

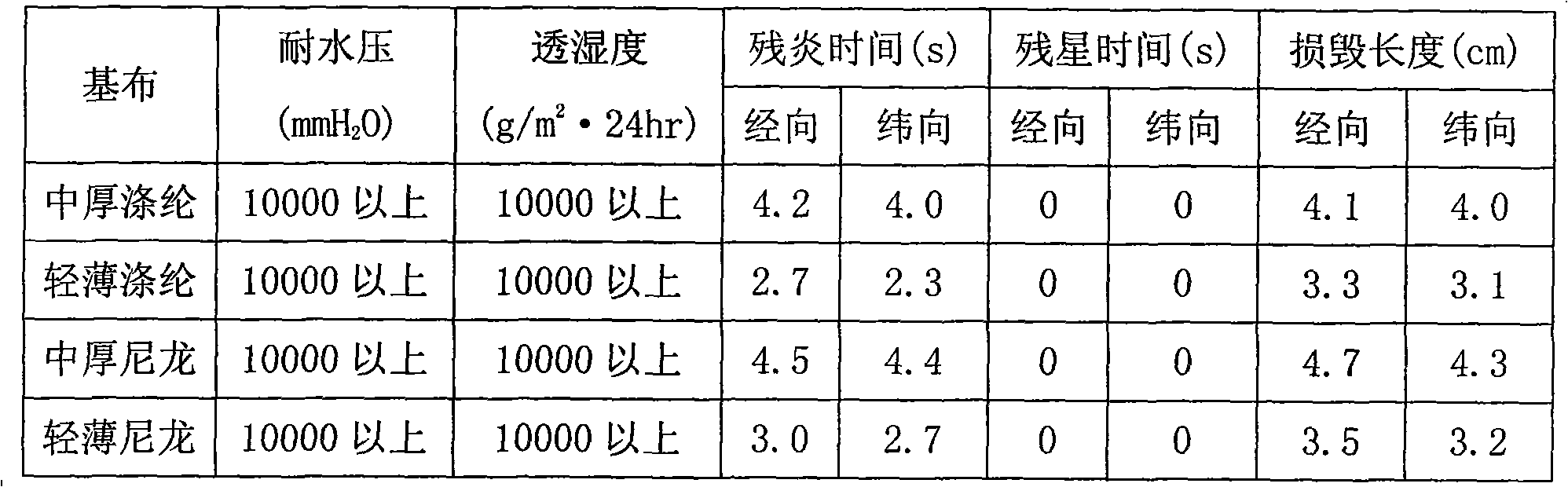

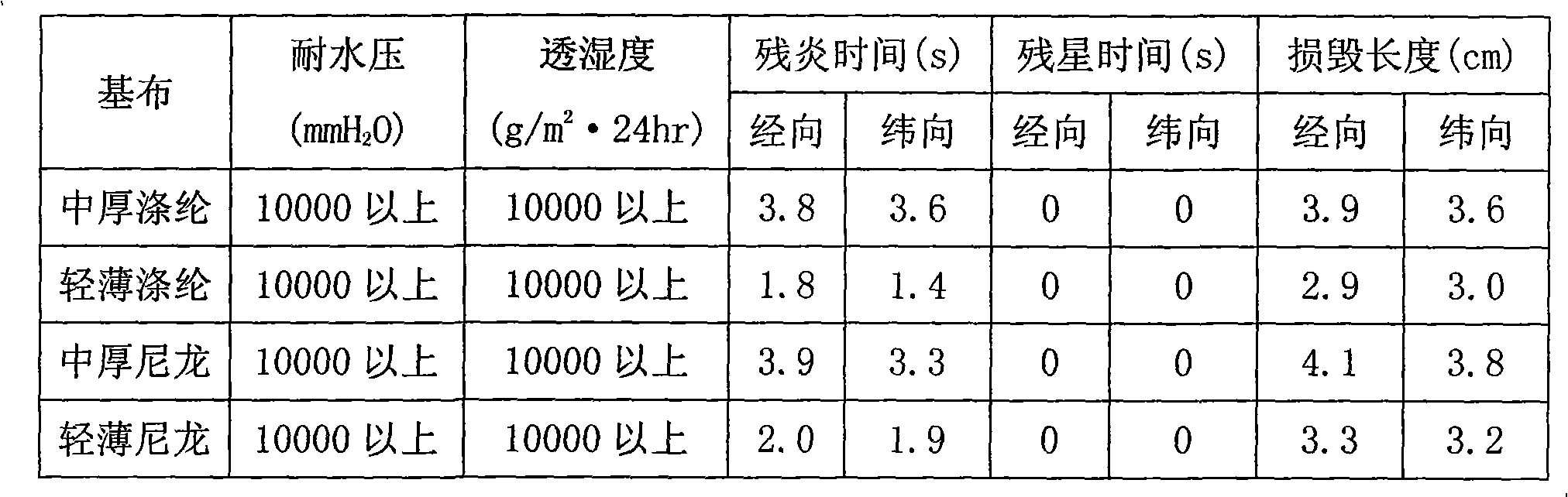

High-waterproof high-moisture-permeable flame-retardant coating fabric and production method thereof

InactiveCN101886340AExcellent waterproof and moisture permeabilityImprove flame retardancySynthetic resin layered productsTextiles and paperChemistryPetroleum

The invention discloses a high-waterproof high-moisture-permeable flame-retardant coating fabric and a production method thereof. The fabric comprises base cloth and a high-waterproof high-moisture-permeable flame-retardant coating, wherein high-waterproof high-moisture-permeable flame-retardant is a polyurethane non-porous layer, and the flame retardant used in the coating layer is a halogen free particle flame retardant. The production method comprises the following steps of: uniformly spreading fabric coating slurry which is prepared by mixing hydrophilic polyurethane resin, an organic solvent, an additive and the flame retardant on the base cloth; and drying the base cloth to obtain the high-waterproof high-moisture-permeable flame-retardant coating product with the hydrophilic polyurethane non-porous layer. The coating fabric of the invention has high waterproofness and moisture-permeability and extremely high flame resistance. The coating fabric is used on particular occasions when high requirements on waterproofness, and moisture-permeability and fire resistance are required, can be used for preparing protective garments and the fabrics of protective equipment of departments such as fire control, metallurgy, petroleum and national defense, the fabrics of tents and the like, and therefore has greater economic and social benefits.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

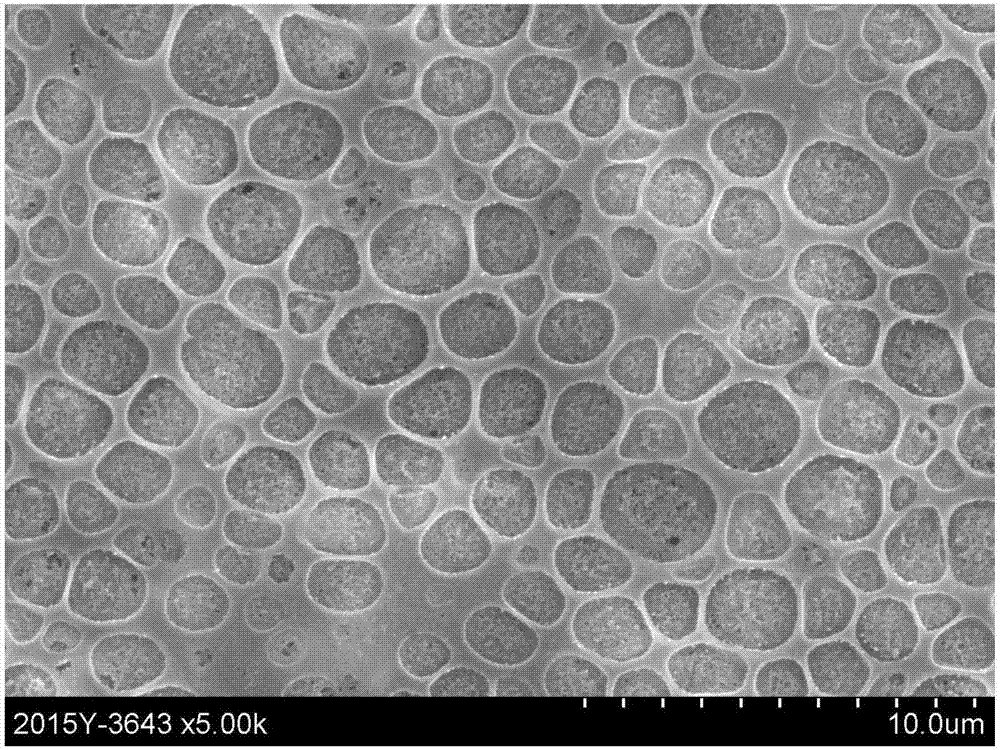

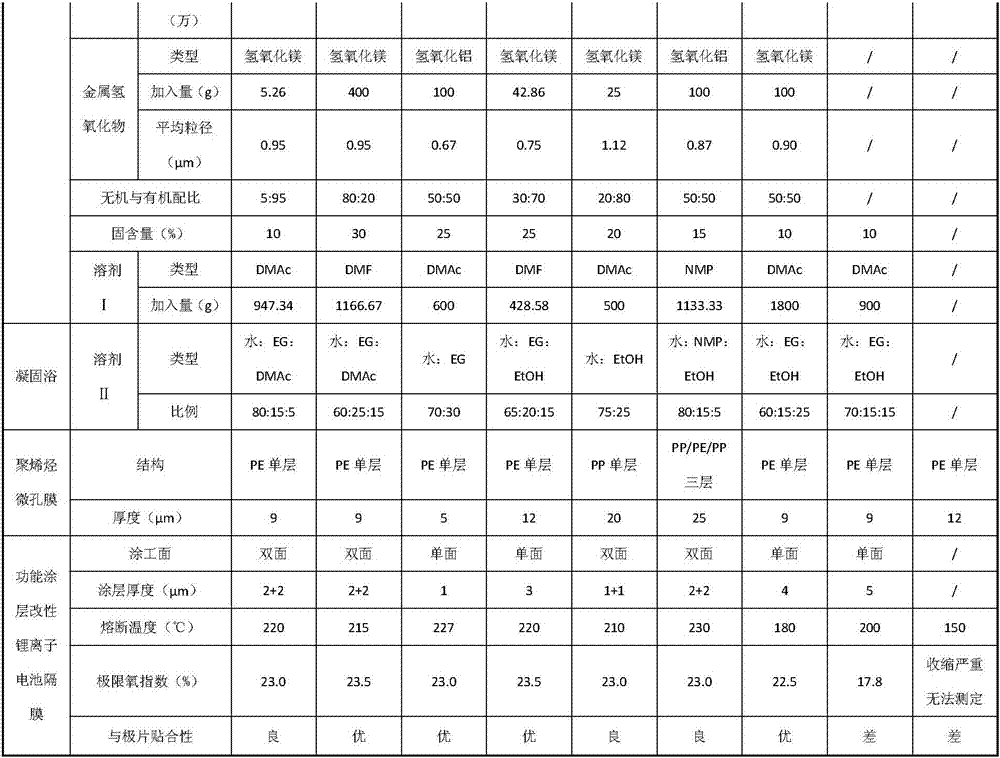

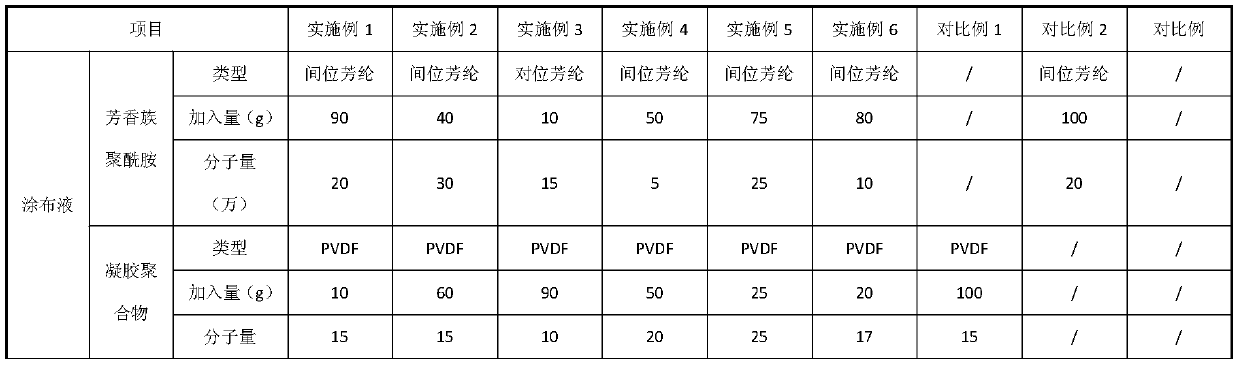

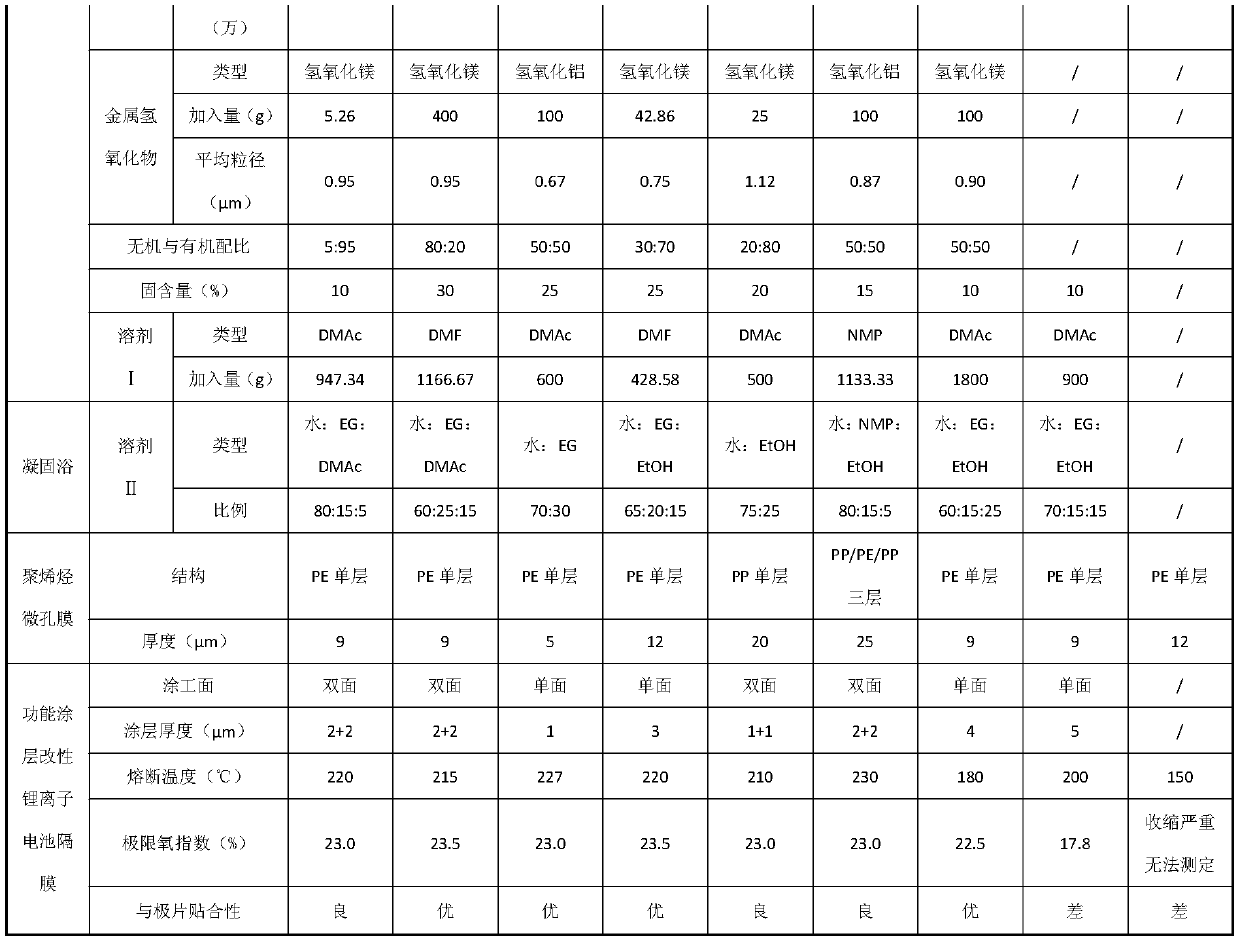

Lithium ion battery diaphragm and preparation method thereof

ActiveCN106898720AAdd flame retardant functionReduce surface temperatureCell component detailsSecondary cells servicing/maintenancePolyolefinPolyamide

The invention relates to a lithium ion battery diaphragm. The lithium ion battery diaphragm comprises a polyolefin microporous membrane and at least one functional coating applied to the polyolefin microporous membrane. Each functional coating is jointly composed of aromatic polyamide, gel polymers and metal oxides and has properties of high temperature resistance, flame retardation, easiness in fitting with battery pole pieces and the like. The lithium ion battery diaphragm is larger than or equal to 210 DEG C in fusing temperature and larger than or equal to 23% in limit oxygen index. In a battery hot-pressing process, the lithium ion battery diaphragm can well fit the battery pole pieces. The preparation method is convenient and simple in operation, and integral stability in use of batteries can be improved remarkably.

Owner:CHINA LUCKY FILM CORP +1

Preparation method of functional type engineered wood

ActiveCN105563586AWear-resistantWeather-resistantRadiation/waves wood treatmentWood treatment detailsStainingManufacturing technology

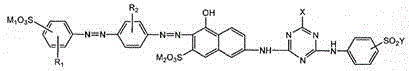

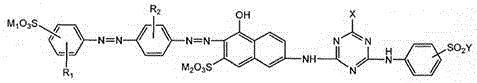

The invention relates to a furniture plate and in particular to a preparation method of a functional type engineered wood. The preparation method comprises the following steps: rotary cutting or slicing to prepare a blank veneer, and shearing the blank veneer into a needed size to obtain an A veneer; soaking the A veneer in a ternary compound solution prepared from a biomass nano cellulose solubilizer, a flame retardant and acid dyes, and carrying out treatments including toughening, flame retarding and dyeing to obtain a B veneer, wherein the ternary compound solution is prepared from the biomass nano cellulose solubilizer, the flame retardant and the acid dyes of a bis-azo compound according to the mass ratio to be 1:(25-40):(100-300) in a compounding manner; and adding a formaldehyde decomposition powder in a modified MUF adhesive, uniformly stirring, and carrying out dispensing, assembling, cold pressing and sawing on the B veneer to obtain a finished product. With the interface controlling design, the biomass nanotechnology and the synergistic compounding technology, the preparation method effectively solves the diversified matching problem of the flame retardant, a staining reagent and the adhesive, and realizes one material with multiple functions of the reconstituted decorative lumber manufacturing technology.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Recombined decorative material technical wood

ActiveCN105461873AWear-resistantWeather-resistantLaminationLamination apparatusManufacturing technologyDecomposition

The invention relates to a furniture board, particularly a recombined decorative material technical wood. The recombined decorative material technical wood is prepared by the following steps: carrying out rotary cutting or shaving to prepare a blank veneer, and cutting the blank veneer into the required size to obtain a veneer A; carrying out immersion toughening flame-retardant dyeing treatment on the veneer A in a three-element compound solution composed of a biomass nano cellulose solubilizer, a flame retardant and an acidic dye to obtain a veneer B; adding formaldehyde decomposition powder into a modified MUF adhesive, stirring uniformly, and coating on the veneer B to obtain a veneer C; and carrying out cold pressing treatment on the veneer C assembly to obtain a batten D, and sawing into the required pattern and size to obtain the finished product. The interface regulation design, biomass nano technique and synergetic compound technique are utilized to effectively solve the problem of diversified matching among the flame retardant, staining agent and adhesive, thereby implementing multiple functions of the one material in the recombined decorative material manufacturing technique.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

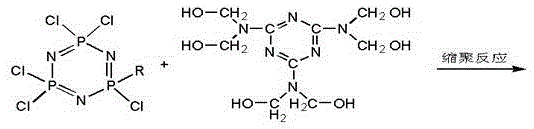

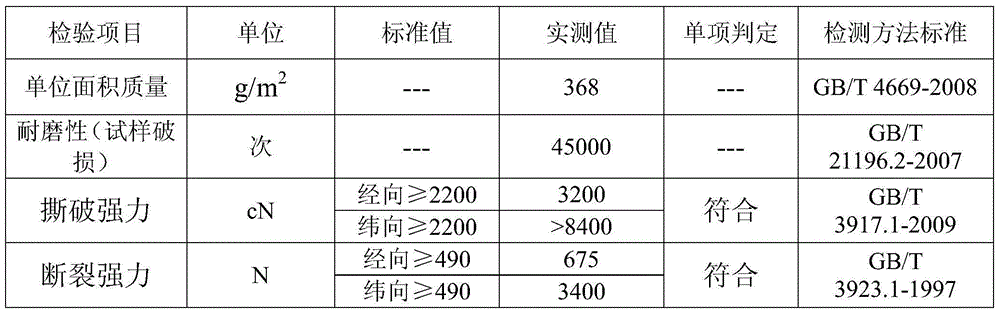

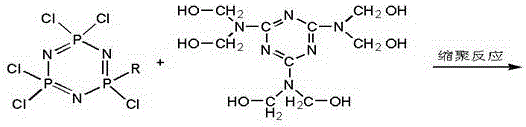

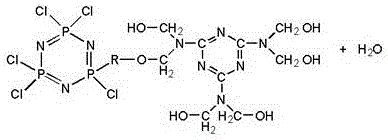

High-strength flame-retardant jean and production process and uses thereof

InactiveCN103603123AHigh strengthHigh modulusSucessive textile treatmentsWoven fabricsBreaking strengthWear resistant

The invention discloses high-strength flame-retardant jean and a production process and uses thereof. The high-strength flame-retardant jean comprises wefts of aramid fiber, and the aramid fiber has the good properties such as superhigh strength, high modulus, high temperature resistance, acid-base resistance, light weight, insulation, ageing resistance and long life. Through the use of the aramid fiber for the wefts of the jean, the jean can be higher in strength and wear resistance, the jean can be flame retardant, and the application range of the jean is widened. Warp-wise breaking strength of the high-strength flame-retardant jean is 1.4 times as high as that in common jean, and weft-wise breaking strength is up to 7 times as high as that in common jean; warp-wise tearing strength of the high-strength flame-retardant jean is 1.5 times as high as that of the common jean, and the weft-wise tearing strength is 4 times as high as that of the common jean; the high-strength flame-retardant jean is twice as wear resistant as the common jean; accordingly, the high-strength flame-retardant jean is available for both casual clothes and some industrial fields, and is also available for protective work suits used in places of electrowelding, automobile racing and the like. The jean can be still fashionable in various fields.

Owner:SHAOXING HENGRUI NONWOVEN TECH

Functional reconstituted lumber

ActiveCN105710939ALow formaldehyde and VOC emissionsGood penetrationOrganic chemistryWood treatment detailsIonChemistry

The invention relates to a furniture panel, particularly to functional reconstituted lumber. A manufacturing technology of the functional reconstituted lumber comprises the steps of preparing blank veneers through rotary cutting or slicing, and shearing the blank veneers into a required size, so as to obtain A veneers; soaking the A veneers in a ternary compound solution composed of a biomass nanocellulose solubilizer, a fire retardant and an acid dye for toughening, inflaming retarding and dyeing treatment, so as to obtain B veneers; adding a formaldehyde decomposition powder into a modified MUF adhesive, uniformly stirring, and dispensing on the B veneers, so as to obtain C veneers; assembling the C veneers, and carrying out cold pressing treatment, so as to obtain D square lumber; and carrying out compound hot pressing on the D square lumber with a transparent abrasion-resistant surface film adhesive paper layer, wherein the transparent abrasion-resistant surface film adhesive paper layer is a film adhesive paper layer formed through soaking transparent abrasion-resistant surface paper in an amino-formaldehyde resin adhesive solution containing tourmaline powder and Al2O3; the particle size of tourmaline negative ion powder is 500 meshes or above; and the count capacity of negative ions in the Giger. Miller zone is 3000 ions / cc or above. According to the functional reconstituted lumber, the effect that the lumber has multiple functions in a reconstituted decorative lumber manufacturing technology is achieved.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Flame-retardant ecological board and manufacturing method thereof

InactiveCN108656251AImprove pass rateIncrease productivityOther plywood/veneer working apparatusWood treatment detailsCrack resistanceSurface layer

The invention discloses a flame-retardant ecological board and a manufacturing method thereof. The flame-retardant ecological board comprises a board core, short cores, impregnated balance paper and surface layer decoration impregnated paper, the short cores are arranged on the two sides of the board core in a compounded mode, the short cores and the board core are integrally subjected to cold andhot laminating so as to form a substrate layer, the impregnated ecological paper is compounded on the upper surface and the lower surface of the substrate layer, the surface layer decoration impregnated paper is compounded on the upper surface and the lower surface of the impregnated ecological paper, and the substrate layer, the impregnated ecological paper and the surface layer decoration impregnated paper are subjected to double-sided compounding and hot-pressing integrated forming. The flame-retardant ecological board and the manufacturing method thereof have the beneficial effects that the short cores are subjected to impregnation treatment of an impregnant, so that the short cores achieves the inflame-retardant function, the substrate layer formed by bonding the short cores with theflame-retardant function and the board core also has the flame-retardant function, one board connected to a decoration layer is replaced by kraft paper or the balance paper which is impregnated withamino resin with certain flame-retardant function, and therefore the flame retardancy of the board can be improved, and meanwhile, the crack resistance of the surface of the ecological board can alsobe improved.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

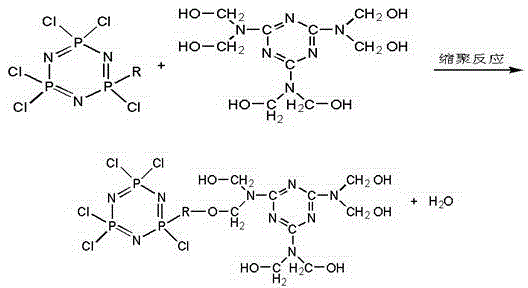

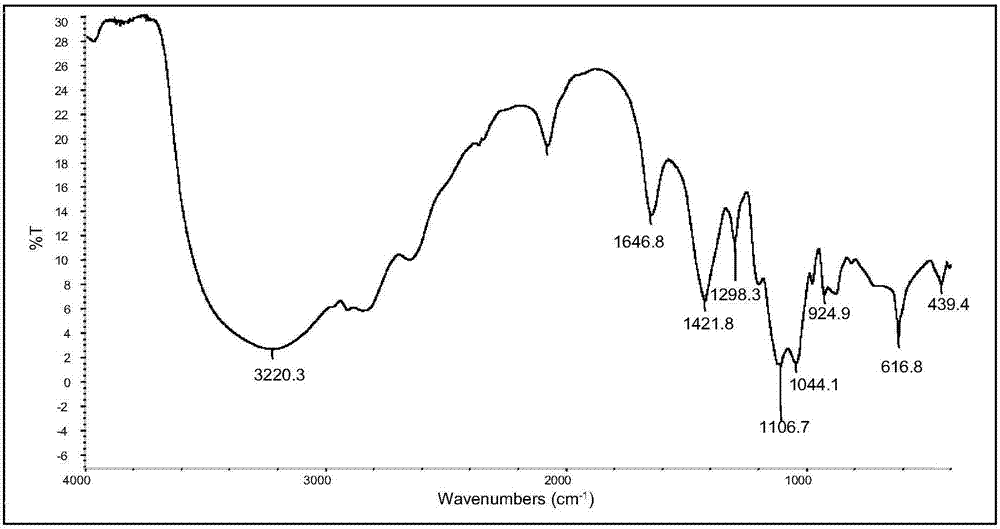

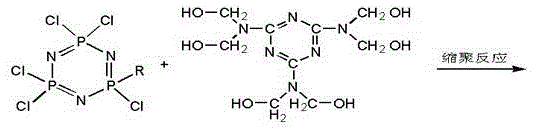

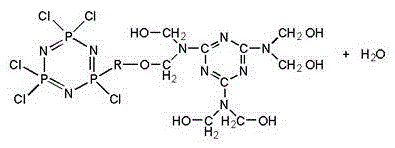

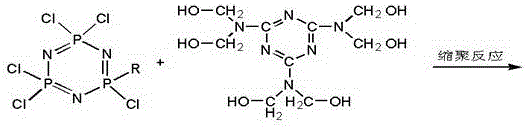

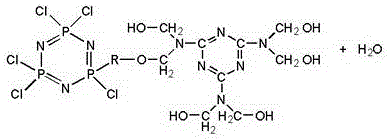

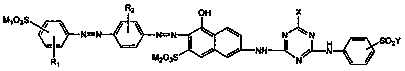

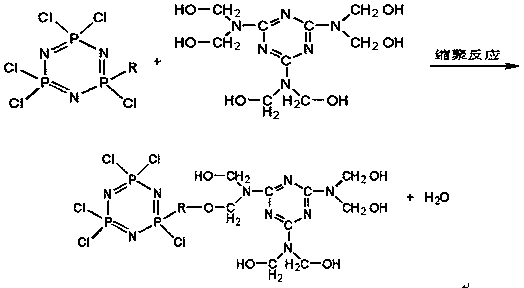

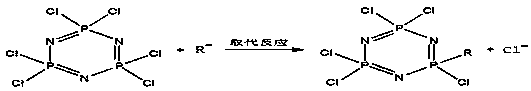

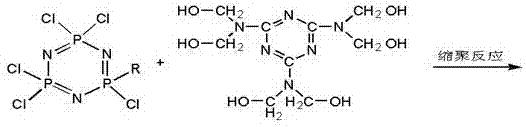

Chitosan tetramethylene phosphonium sulphate flame retardant, and preparation method and application thereof

The invention provides a preparation method for a chitosan tetramethylene phosphonium sulphate flame retardant. The preparation method comprises the following steps: performing electrostatic adsorption on tetrakis hydroxymethyl phosphonium sulphate and chitosan in water to obtain a tetrakis hydroxymethyl phosphonium sulphate / chitosan compound; performing dehydration covalent graft reaction on thetetrakis hydroxymethyl phosphonium sulphate / chitosan compound to obtain the chitosan tetramethylene phosphonium sulphate flame retardant. The chitosan tetramethylene phosphonium sulphate flame retardant prepared by the method provided by the invention does not contain halogen, has an antibacterial effect, and is non-toxic, degradable, green and environmentally friendly; the flame retardant is highin molecular weight, keeps linearity, does not have volatility, and has water washing resistance, migration resistance, good compatibility, high stability and good flame retarding effect.

Owner:JILIN INST OF CHEM TECH

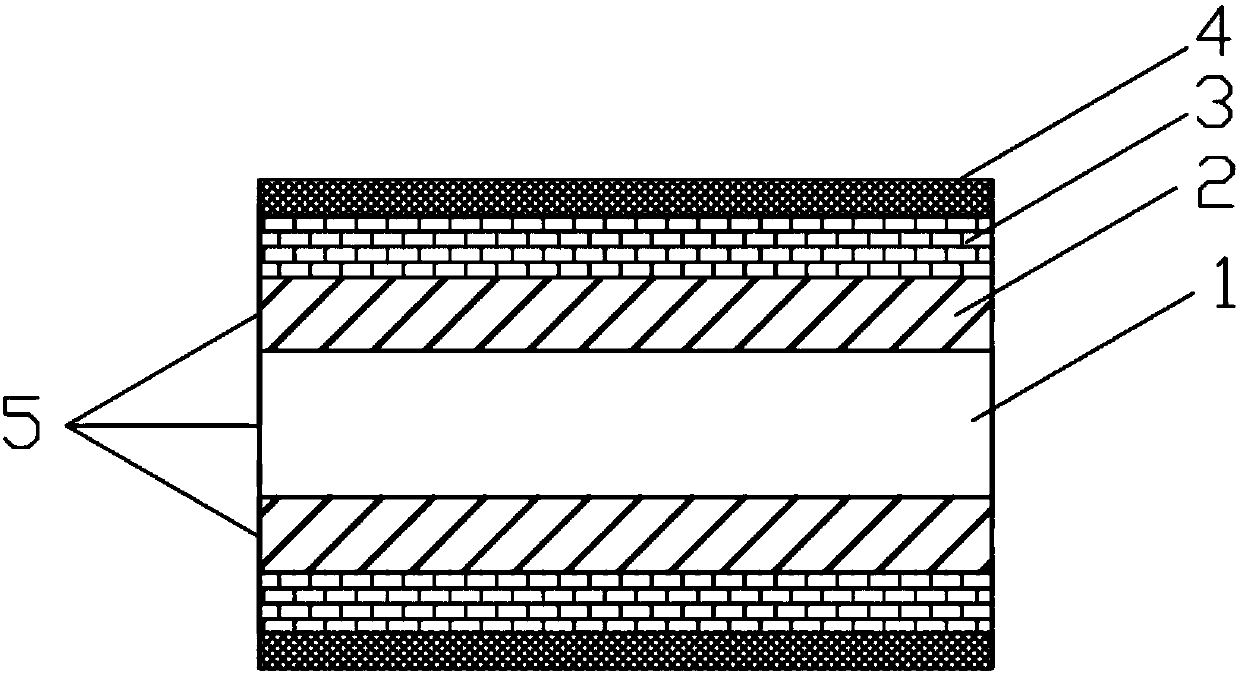

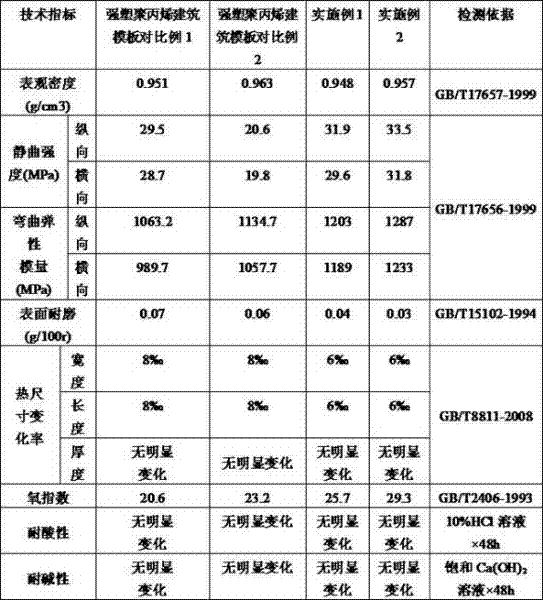

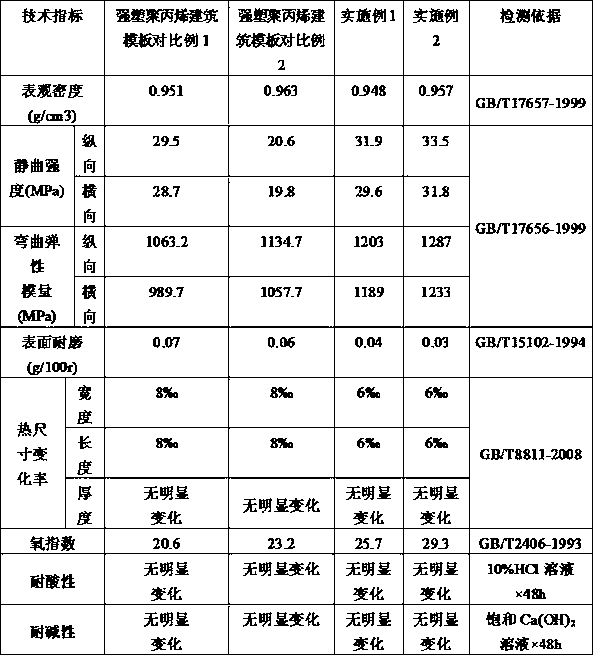

Novel environment-friendly composite reinforced polypropylene building template

InactiveCN102604205AImprove melt strengthDegree of crystallinityForming/stuttering elementsEnvironmental resistanceThermal expansion

The invention relates to a novel environment-friendly composite reinforced polypropylene building template, belonging to the technical field of building template preparation. By virtue of the interaction between fine powder of waste tires and polypropylene-styrene dibromide graft copolymer and aluminum hydroxide / polypropylene, the bonding force among the components is increased, the reinforced plastic polypropylene building template is subjected to physical blending and chemical modification, so that not only the overall properties of the reinforced plastic polypropylene building template areimproved and the flame retardant function of the reinforced plastic polypropylene building template is enhanced, but also a new field of recycling waste tires is opened. Through the composite reinforced polypropylene building template provided by the invention, the problems that the strength and rigidity of the existing composite plastic building template cannot meet the construction requirements, the thermal expansion and cold contraction coefficient is large and the electric welding dregs are likely to scald a face plate are solved, and a large amount of natural rubber and petroleum resources are saved. The composite reinforced polypropylene building template has the advantages of high strength, good flame retardant effect, easily-accessible raw materials and simplicity in production, and can be widely used as the construction template in construction engineering, hydroelectric structures, irregular design of bridges and tunnels and the like.

Owner:HUBEI XINLONG PLASTICS

Preparation method of engineered wood

InactiveCN105563570AGood penetrationSolving Diversity Matching ProblemsOther plywood/veneer working apparatusNon-macromolecular adhesive additivesManufacturing technologyStaining

The invention relates to a furniture plate and in particular to a preparation method of a engineered wood. The preparation method comprises the following steps: rotary cutting or slicing to prepare a blank veneer, and shearing the blank veneer into a needed size to obtain an A veneer; soaking the A veneer in a ternary compound solution prepared from a biomass nano cellulose solubilizer, a flame retardant and acid dyes of a bis-azo compound, and carrying out treatments including toughening, flame retarding and dyeing to obtain a B veneer; adding a formaldehyde decomposition powder in a modified MUF adhesive, uniformly stirring, and carrying out dispensing on the B veneer to obtain a C veneer; and carrying out cold pressing treatment on a C veneer assembly to prepare a D batten, and then sawing the D batten into the needed patterns and sizes to obtain a finished product. With the interface controlling design, the biomass nanotechnology and the synergistic compounding technology, the preparation method effectively solves the diversified matching problem of the flame retardant, a staining reagent and the adhesive, and realizes one material with multiple functions of the reconstituted decorative lumber manufacturing technology.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Flame-retardant contractile anti-corrosion packaging film and fabricating method thereof

InactiveCN103009745AWith flame retardant functionVersatilityFlexible coversWrappersBlow moldingMechanical equipment

A flame-retardant contractile anti-corrosion packaging film adopts a two-layer or three-layer structure, namely an inner layer containing a rust inhibitor which has an anti-corrosion and protection function for metal, and an intermediate layer and an outer layer respectively containing a fire retarding agent with a flame-retardant function, wherein each layer contains plastic particles which has thermal contractile property. The film is formed in a way that all raw materials are subjected to heating, co-extrusion and blow molding on two-layer / three-layer co-extrusion film blowing equipment under a certain thermal condition according to a certain thickness proportion after being mixed according to certain types and proportion, and is a novel multifunctional metal anti-corrosion and protection packaging material. The packaging film has the characteristics of thermal contractile property, good rust protection property, skin packaging, good air tightness, tightness, flame retardancy, and convenience in automatic operation, is economical and practical, and can be extensively applied to the anti-corrosion and protection packaging for such products in storage and delivery periods as automobile components, machinery equipment, hardware tools, metallurgy products, aerospace, electronic equipment and weapons. Therefore, the packaging film is a bran-new material in the filed of metal protection packaging.

Owner:沈阳防锈包装材料有限责任公司

Fire-retardant medium density fiberboard and preparation method thereof

ActiveCN105690536AReduce the impact of physical and chemical propertiesGuaranteed physical and chemical propertiesDomestic articlesFlat articlesFiberFiltration

The invention relates to medium density fiberboards, in particular to a fire-retardant medium density fiberboard and a preparation method thereof. The fire-retardant medium density fiberboard is prepared from, by mass, 100 parts of wood fibers, 8-15 parts of magnalium nanometer layered double hydroxide, 0.01-0.02 part of a coupling agent, 12-15 parts of a modified MUF adhesive and 1-2 parts of a waterproof agent. The preparation method comprises the steps that 1, the magnalium nanometer layered double hydroxide is firstly dried and finely ground to range from 20 micrometers to 50 micrometers, then the coupling agent with the mass percent concentration ranging from 20% to 30% is hydrolyzed for 25 min-35 min at room temperature and then added to a water solution with the temperature ranging from 80 DEG C to 90 DEG C of the finely-ground magnalium nanometer layered double hydroxide, and after reacting is carried out for 0.5 h-1.5 h, suction filtration, washing, drying and grinding are carried out; and 2, the modified MUF adhesive and modified Mg / Al-LDHs are added to the wood fibers, and the medium density fiberboard is obtained through pavement, pre-pressing forming, hot pressing and cooling. The provided medium density fiberboard is environment-friendly, non-toxic and free of obvious moisture absorption, and the oxygen index reaches up to 34%.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

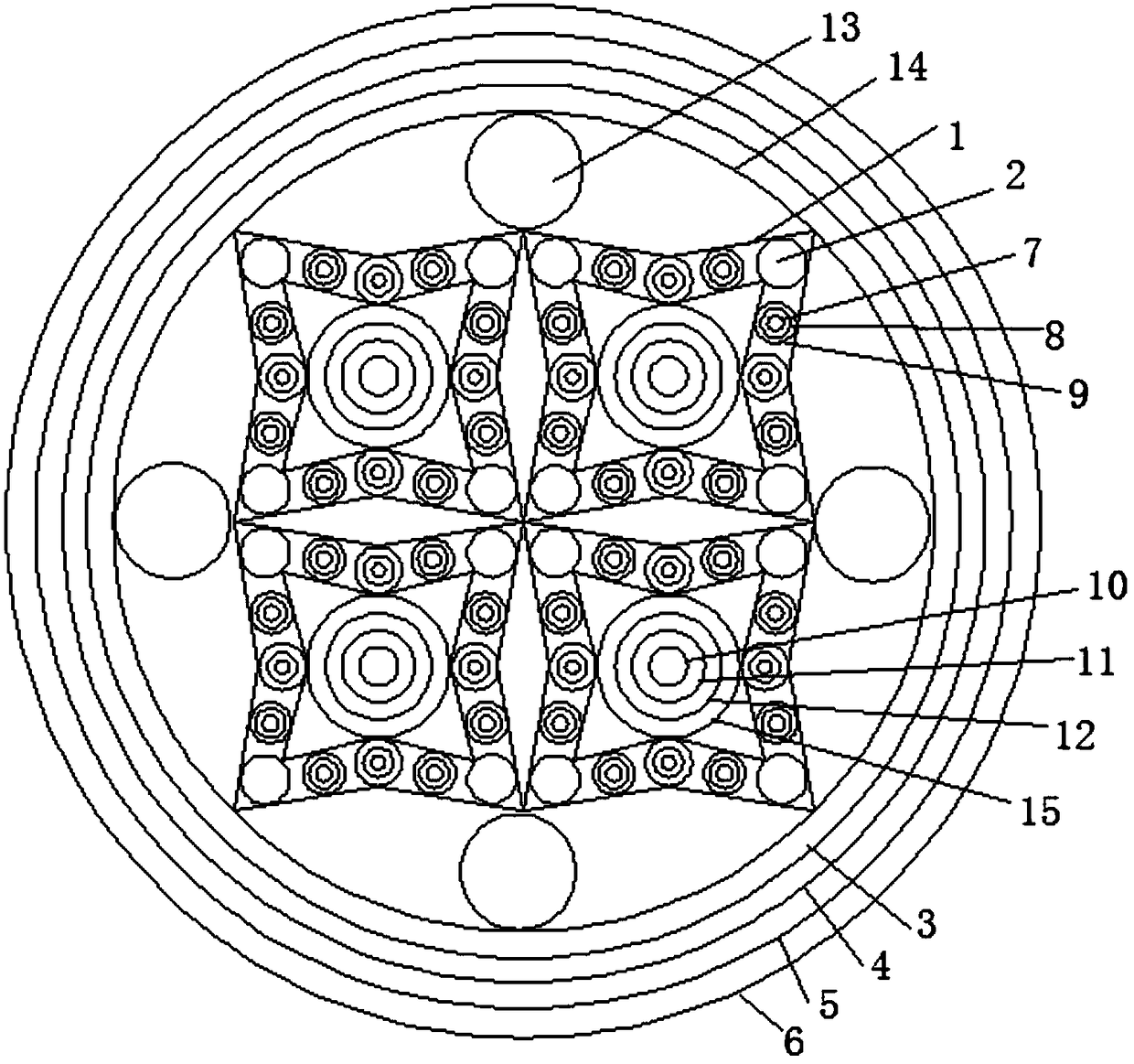

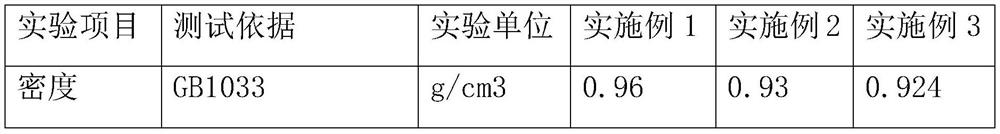

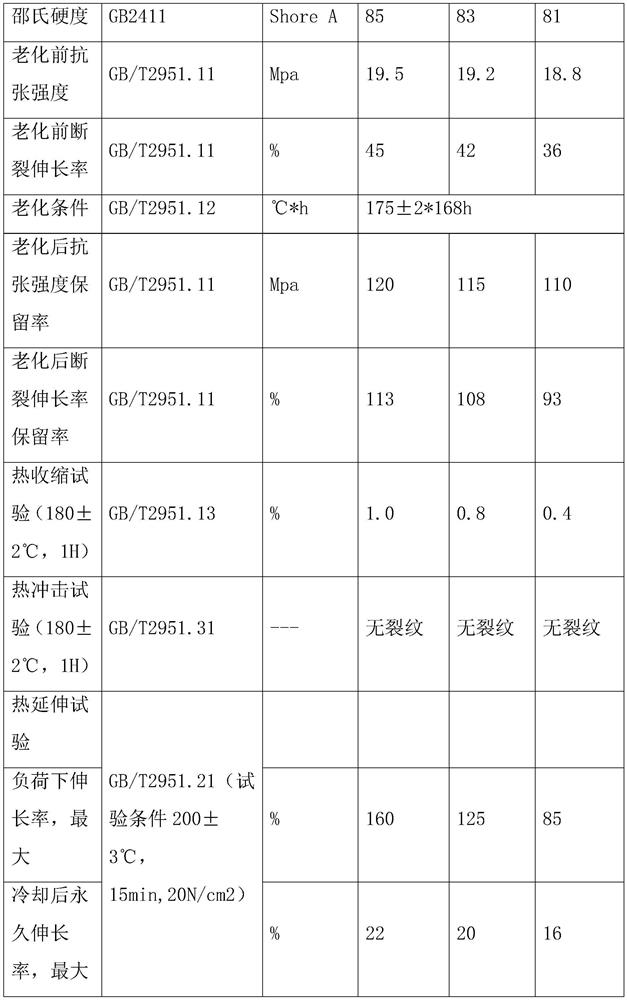

Power cable for new energy vehicle

InactiveCN108899118AGood flexibilityImprove waterproof functionPower cables with screens/conductive layersFlexible cablesFiberPolyolefin

The invention discloses a power cable for a new energy vehicle. The power cable for a new energy vehicle includes a cable core, wherein the cable core comprises four square rubber skeletons each of which has a square cross section; the each square rubber skeleton is double-layered, and a cavity is formed between the inner side and the outer layer; the centers of four surfaces of the each square rubber skeleton are bent inward; a plurality of cores 1 are arranged in the cavity of the each square rubber skeleton, and each corner in the cavity is provided with a polyurethane elastic rod; a core 2is arranged at the center of each square rubber skeleton; the four square rubber skeletons are spliced into a square cable core; and three layers of galvanized steel tape armor layer, a nano siliconwaterproof rubber filling layer, a Kevlar fiber braid layer and a halogen-free low smoke flame retardation polyolefin oversheath are sequentially coated on the outer side of the cable core. The powercable for a new energy vehicle combines four square skeletons, and each square skeleton has a double-layer structure, and the cores are arranged inside the skeletons to make the structure tidier, andthe cable can be compression resistant and tension resistant.

Owner:怀宁宜庆电线电缆有限公司

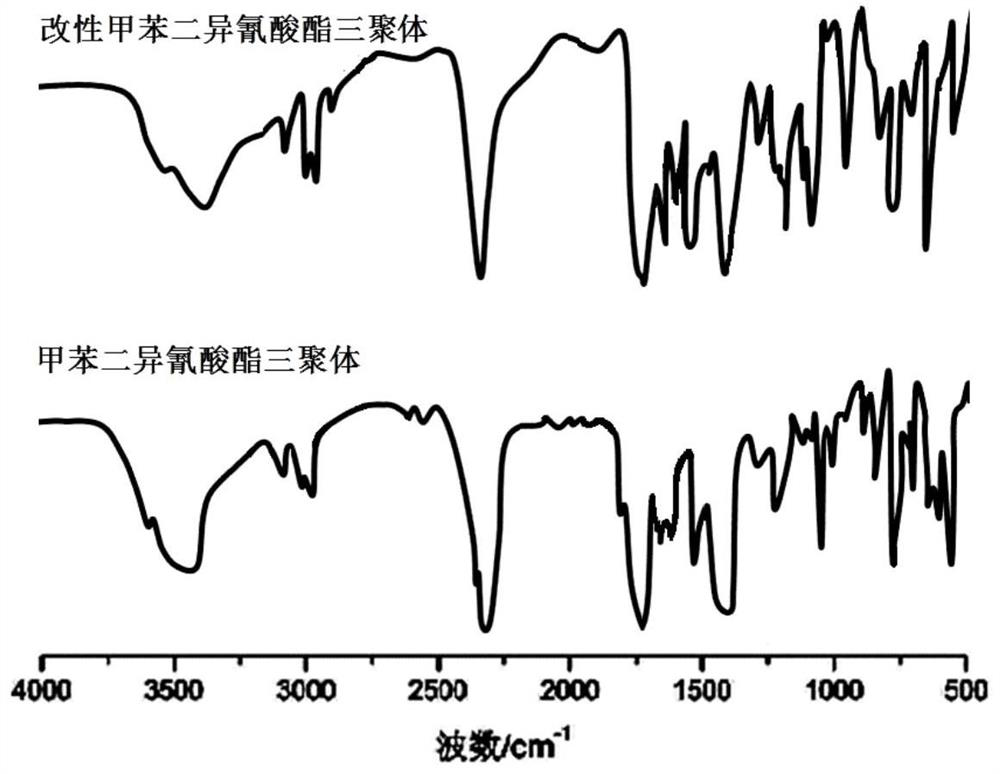

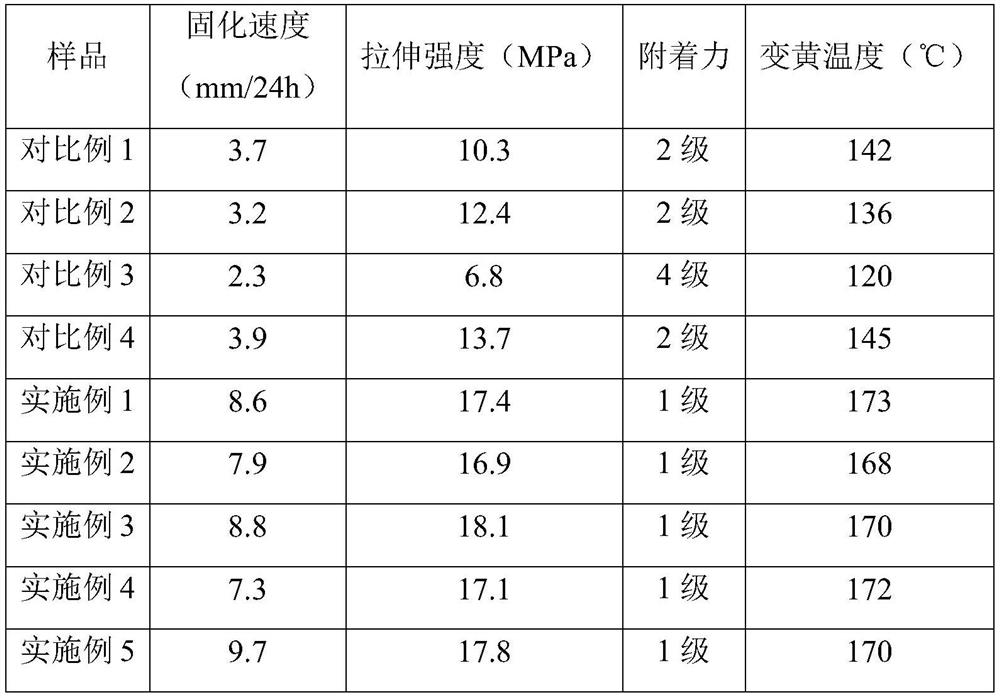

Insulating material for cable sealing and preparation method thereof

InactiveCN113046017AHigh bonding strengthHigh tensile strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPhosphoric Acid EstersAdhesive

The invention discloses an insulating material for cable sealing and a preparation method thereof, and relates to the technical field of adhesives. The preparation method of the insulation sealing material comprises the following steps: S1, mixing castor oil polyoxyethylene ether and polypropylene oxide glycol in parts by weight to obtain a product M; s2, uniformly mixing and stirring the product M and a component B to obtain a mixture N; S3, weighing micron-sized barium sulfate, oleylamine polyoxyethylene ether, nano-sized silicon dioxide, fibrous calcium carbonate whiskers, isophenylpropyl phenyl phosphate, antimony trioxide, triaryl phosphate, a silane coupling agent and epicatechin in parts by weight, and conducting mixing to obtain a mixture Q; and S4, uniformly mixing and stirring the mixture N and the mixture Q to obtain the insulating sealing material. The insulating material prepared by the preparation method disclosed by the invention has excellent insulating property, can keep good heat-conducting property, and is high in curing speed, outstanding in bonding strength, good in sealing property and excellent in flame-retardant effect; and the anti-aging capability is enhanced, and the service life is long.

Owner:ZHEJIANG DISIWEI ELECTRIC

Composite flame retardant and preparation method

InactiveCN109517219AImprove flame retardant performancePlay the role of heat and oxygen insulationCarbon layerPolyolefin

The invention relates to a composite flame retardant and a preparation method. The composite flame retardant is formed by coating graphene with aluminum hydroxide. Aluminum hydroxide is uniformly dispersed to the surface of graphene so as to form an aluminum hydroxide-graphene composite flame retardant with a relatively good coating layer, aluminum hydroxide is decomposed into water and aluminum oxide when a material is combusted, aluminum oxide generated by the decomposition of aluminum hydroxide uniformly covers the surface of graphene so as to form a compact structure, and aluminum oxide and a carbon layer cover the surface of a polyolefin material to generate synergetic flame retardance effect so as to realize thermal insulation and oxygen isolation, so that the flame retardance of thepolyolefin material is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Building reinforcing epoxy adhesive and preparation method thereof

InactiveCN112094609AStrongStrong toughnessNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesive cementFirming agent

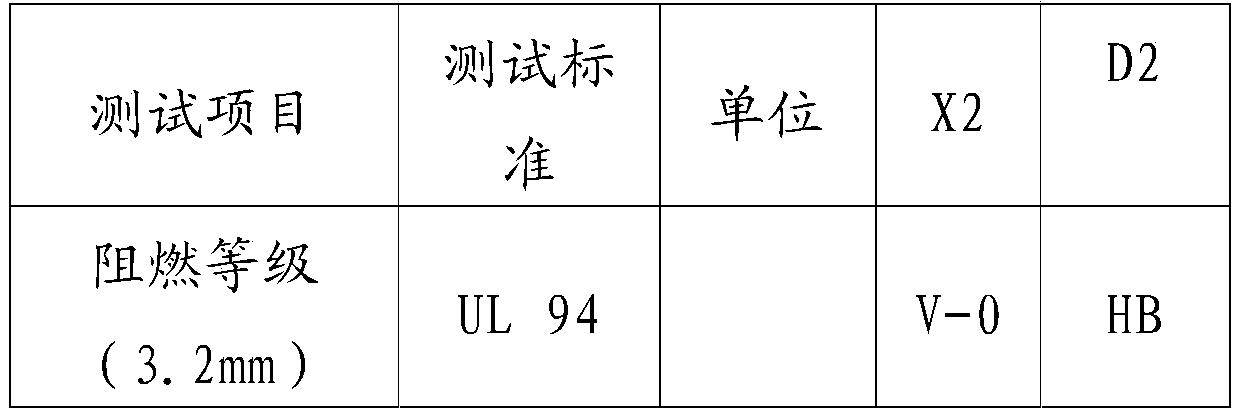

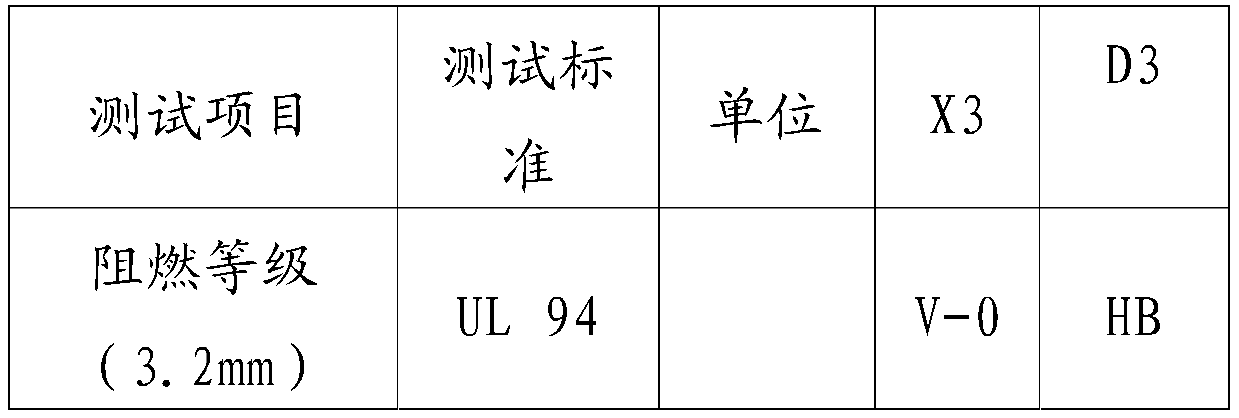

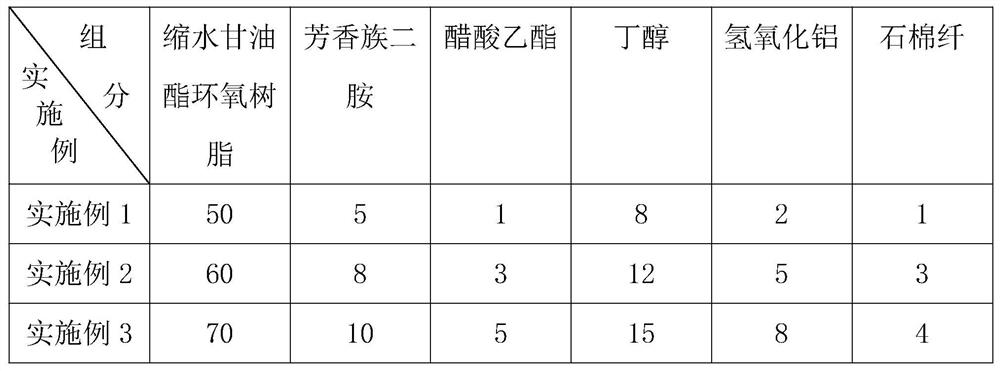

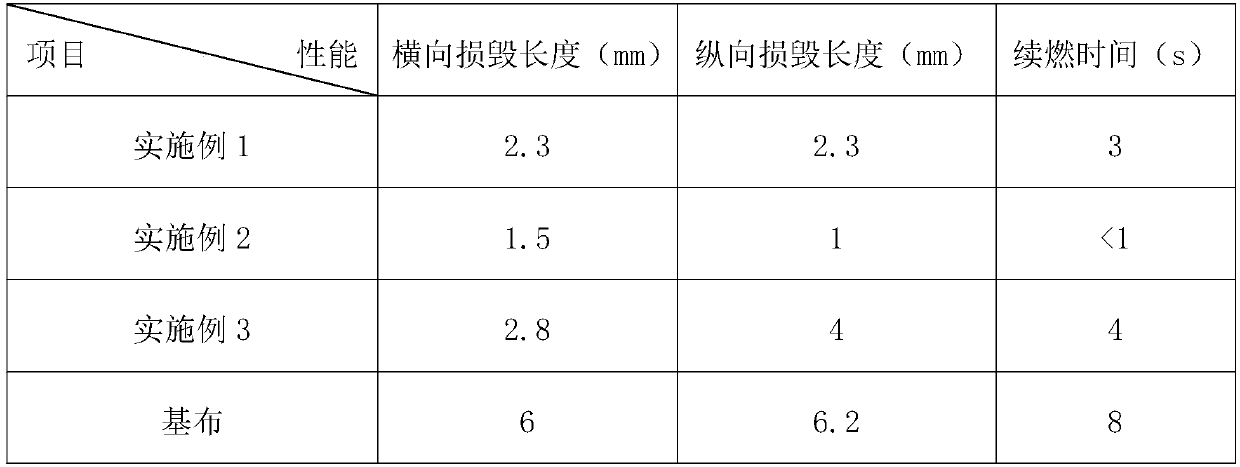

The invention discloses a building reinforcing epoxy adhesive and a preparation method thereof, and belongs to the field of building adhesives, and the building reinforcing epoxy adhesive comprises the following components by weight: 50-70 parts of epoxy resin; 5-10 parts of a curing agent; 1-5 parts of an accelerant; 8-15 parts of a diluent; 2-8 parts of aluminum hydroxide; 1-4 parts of filler. Aluminum hydroxide which is slow, durable and strong in acid resistance and has convergence and mucous membrane protection effects is added to be combined with other added raw materials, the prepared adhesive is high in strength and toughness, meanwhile, the flame-retardant function is added to the adhesive, the reaction of the adhesive can be promoted by adding ethyl acetate with solubility and quick-drying performance, and the adhesive has a good application prospect. According to the preparation method, the reaction speed of the adhesive is increased, and then the adhesive can be diluted byadding butanol which can be mixed and dissolved with various organic solvents, so that the concentration of the adhesive is reduced, the functions of the adhesive are increased, and the practicabilityof the adhesive is enhanced.

Owner:毓润(上海)生态科技有限公司

Production process of fireproof fabric

InactiveCN109610158AAdd flame retardant functionStrong flame retardant functionHeat resistant fibresDyeing processPolyesterInternal pressure

The invention provides a production process of a fireproof fabric. The production process comprises the following steps: S1, preparing a base fabric: weaving aramid fiber serving as warp yarns and polyester fiber serving as weft yarns through a weaving machine to form the base fabric; S2, performing fireproof treatment: immersing the base fabric in a flame retardant for fabric, which is a mixed agent of liquid ammonium polyphosphate and colloid at an immersion temperature of 25 to 28 DEG C for immersion time of 4 to 6 h, wherein the mass fractions are as follows: 75 to 80 parts of the colloidand 70 to 75 parts of the ammonium polyphosphate; S3, performing sizing: baking the fabric at an internal pressure of 0.8 bar, external pressure of 1.2 bar and temperature of 130 to 150 DEG C for 1 to2 min; S4, performing dyeing: putting the dye into a dyeing tank, dyeing the fabric at 80 to 100 DEG C for 15 to 20 min, and then dyeing the fabric at 100 to 120 DEG C for 30 to 40 min; S5, drying: placing the fabric at a room temperature, washing the fabric with clean water for 10 min, standing internal pressure of 0.8 bar, external pressure of 1.2 bar and temperature of 110 to 130 DEG C for 2 to 3 min, and drying the fabric. The process disclosed by the invention is simple and high in flame retarding and heat insulating performance.

Owner:江苏亨威实业集团有限公司

Wear-resistant and durable stone honeycomb aluminum plate

InactiveCN108044999AHigh strengthStrongConstructions elementsGlass/slag layered productsGlass fiberWear resistant

The invention discloses a wear-resistant and durable stone honeycomb aluminum plate. The stone honeycomb aluminum plate comprises a honeycomb aluminum layer, a soft buffer layer which is disposed at the bottom of the honeycomb aluminum layer, marble plates which are disposed on the upper surface of the honeycomb aluminum layer and an interlayer which is disposed between the honeycomb aluminum layer and the marble plates, wherein the honeycomb aluminum layer comprises honeycomb aluminum and copper plates disposed among the honeycomb aluminum, the copper plates comprise copper plate bodies, fixing strips which are disposed on upper ends of the copper plate bodies and bolts which are disposed in the copper plate bodies and run through the copper plate bodies. According to the stone honeycombaluminum plate, since the copper plates are arranged among the honeycomb aluminum, the strength of the honeycomb aluminum can be enhanced through the copper plates, and the marble plates can be separated, so that the marble plates can be stuck and fixed conveniently; in addition, the whole stone honeycomb aluminum plate can be installed and fixed conveniently through the copper plates, and high pressure and friction can be borne by combining a glass fiber board which is adopted as a buffer layer, so that the stone honeycomb aluminum plate has higher wear and pressure resistance, and the service life of the stone honeycomb aluminum plate is prolonged.

Owner:中海怡高建设集团股份有限公司

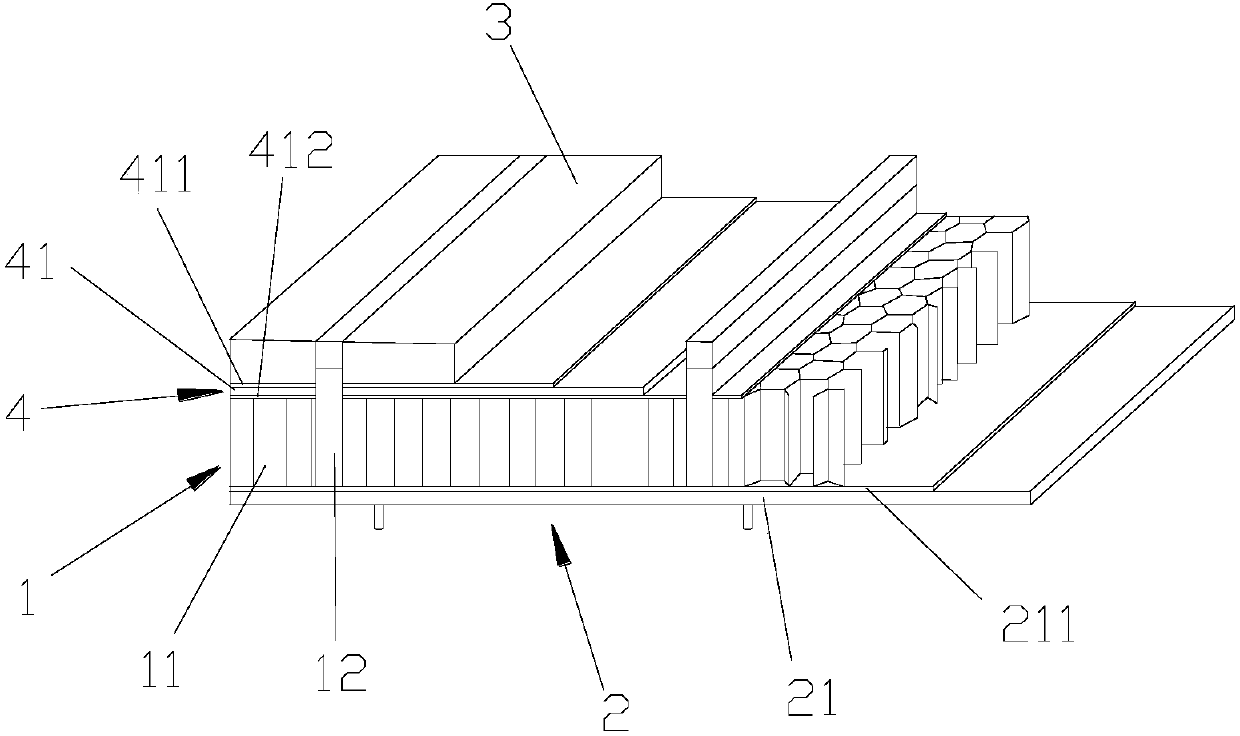

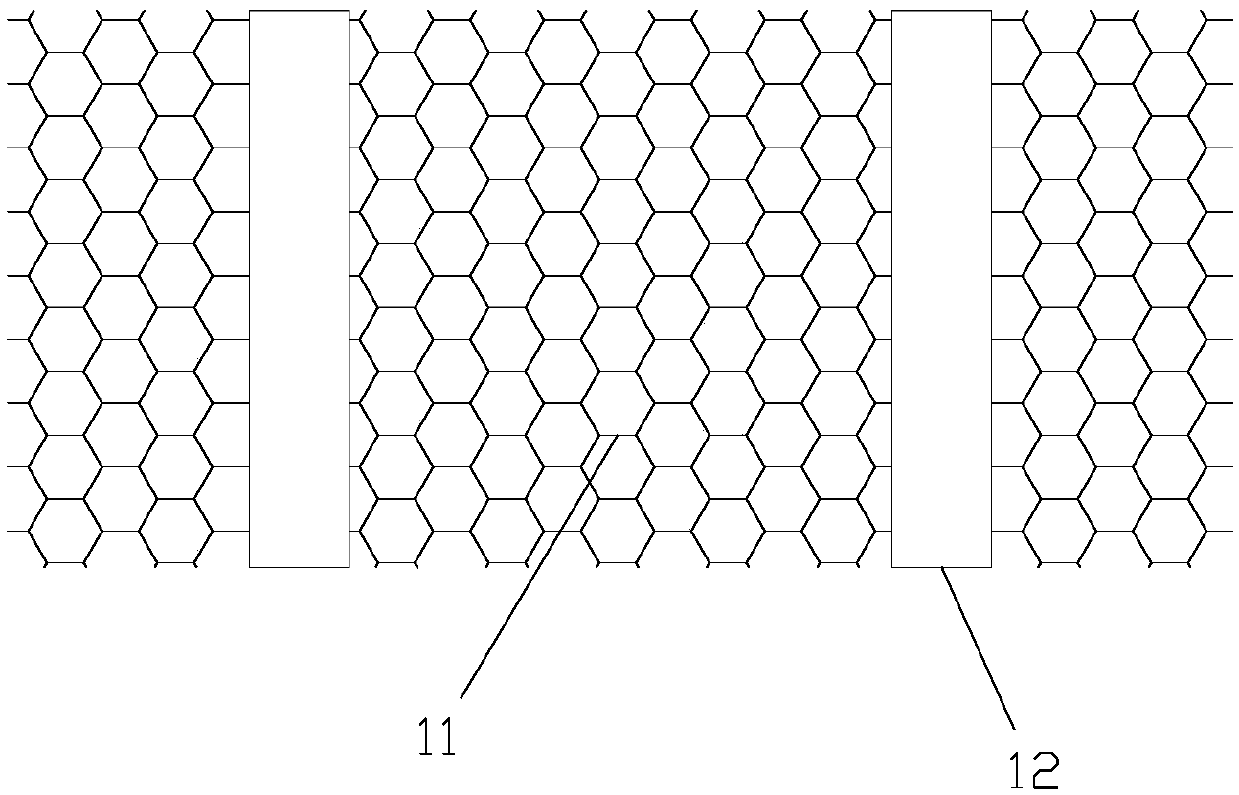

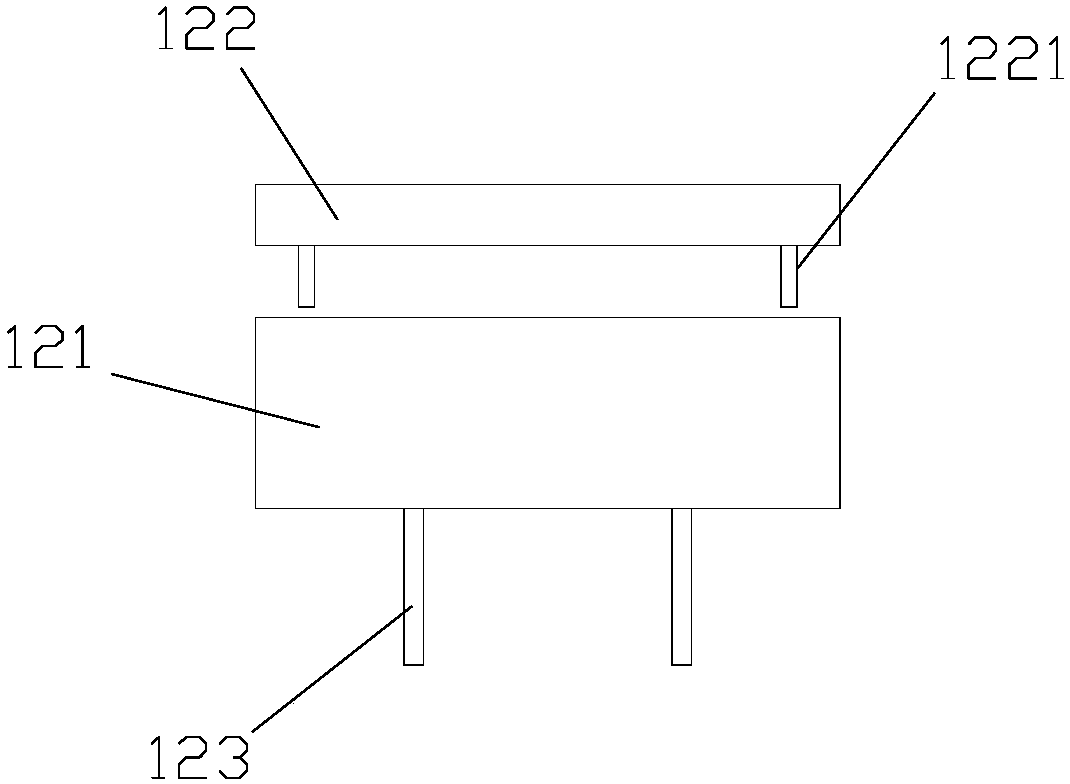

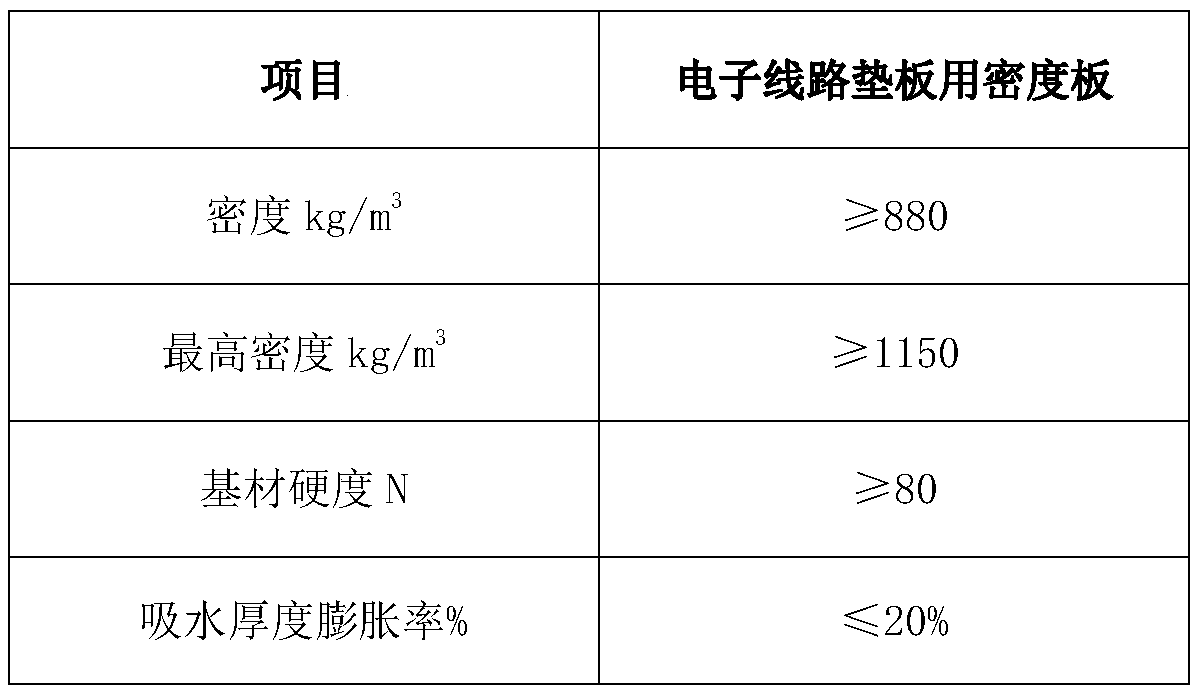

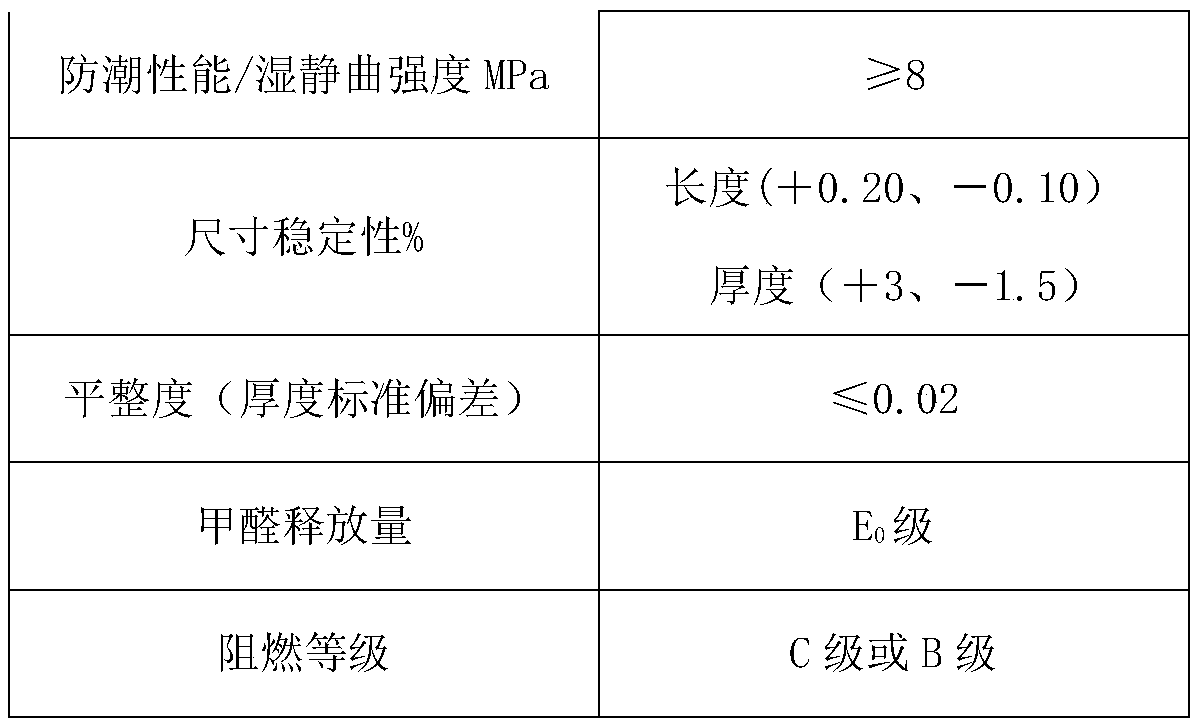

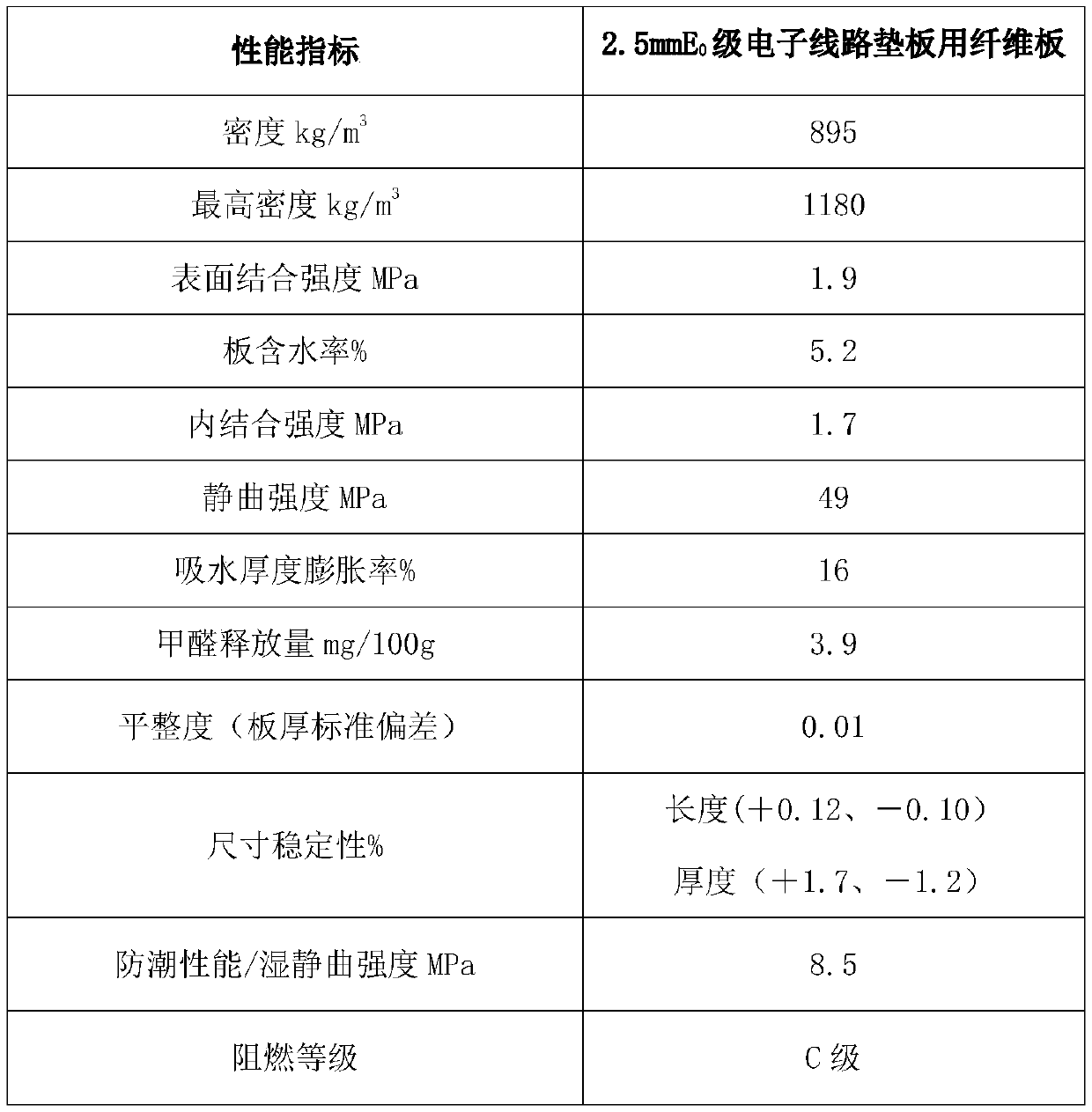

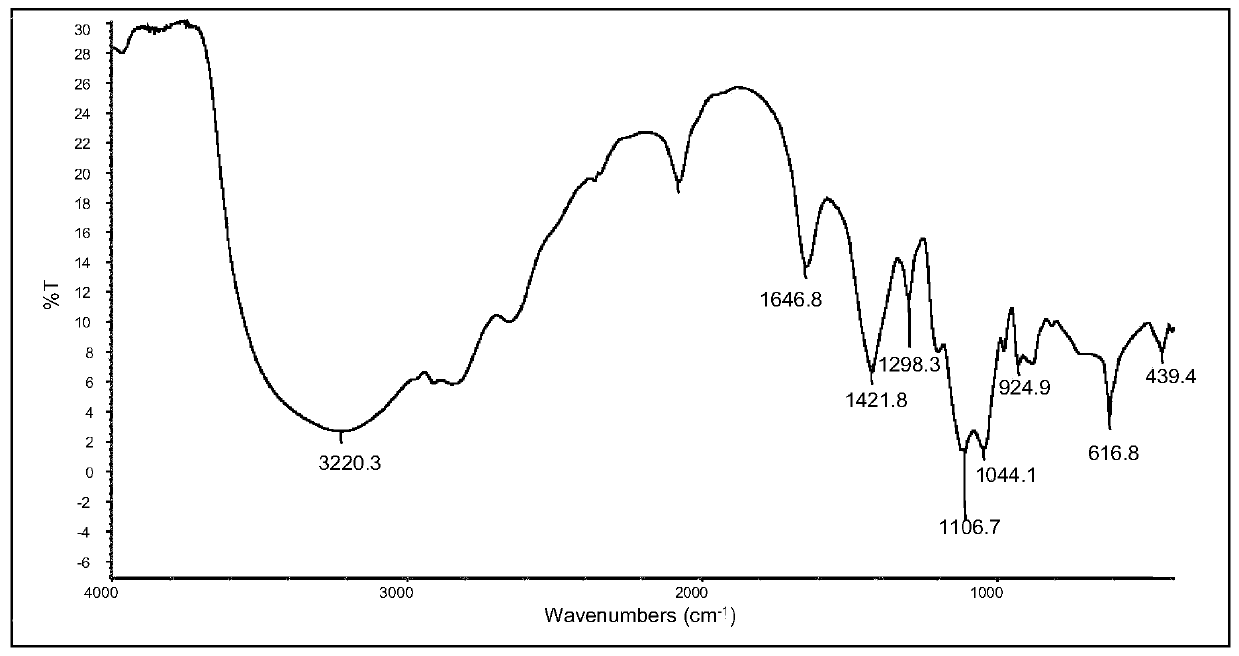

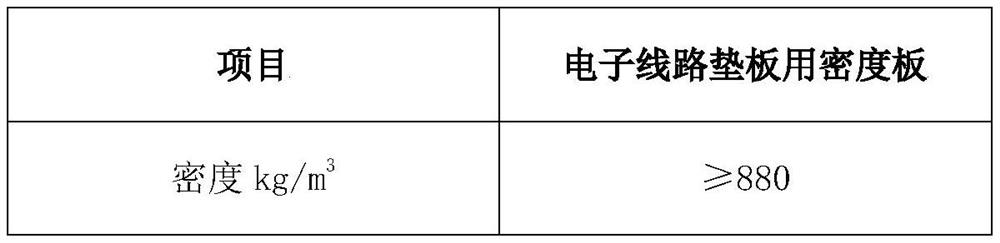

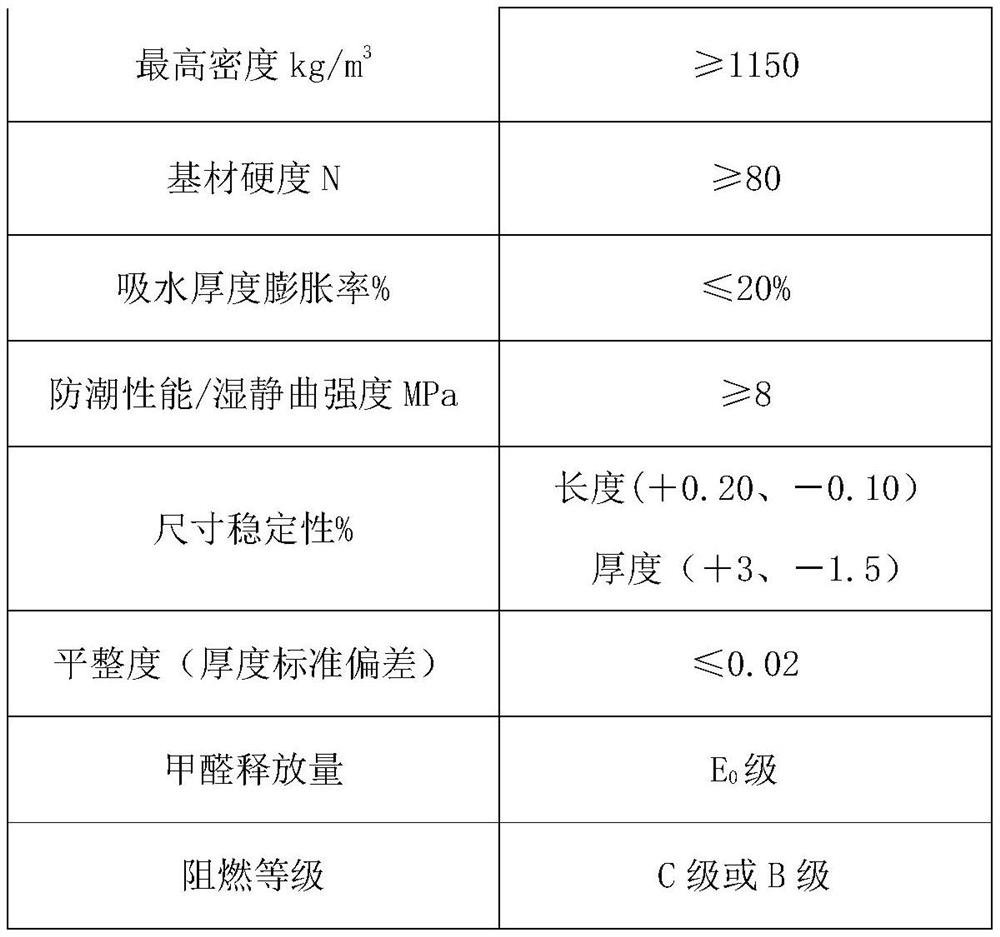

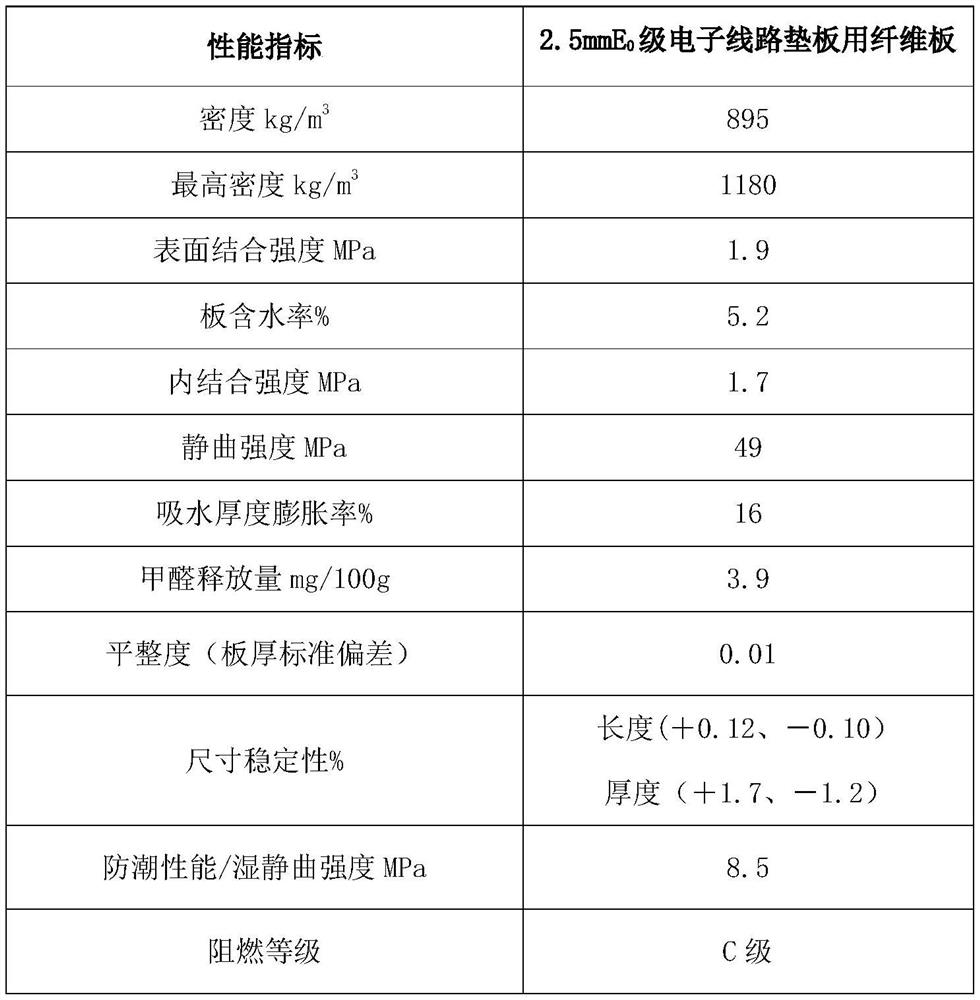

Manufacturing method of density fiberboard for E0-level electronic circuit base plate

ActiveCN110744670AImprove moisture resistanceImprove water resistanceAldehyde/ketone condensation polymer adhesivesFlat articlesProcess engineeringFire retardant

The invention belongs to the technical field of wood processing, and relates to a manufacturing method of a density fiberboard for an E0-level electronic circuit base plate. A secondary gluing technology is adopted, and the manufacturing method comprises the steps that wood peeling, chipping, wood chip screening, washing, pre-cooking, cooking and hot grinding are carried out; adding of waterproofagent and adjusting and applying of an E0-level damp-proof adhesive are carried out; and adding of an auxiliary, drying and sorting, adjusting and applying of an E0-level high-solid-content adhesive,adding of a fire retardant, paving and forming, pre-pressing, hot pressing, turning plate cooling, sanding, inspection and dividing and packaging and warehousing are carried out. The adhesive is addedtwice, so that the pre-curing influence is reduced, the adhesive bonding effect and full wrapping can be brought into full play, and meanwhile energy consumption of a heat energy center is reduced. The produced fiberboard for the E0-level electronic circuit base plate overcomes the defects that the fiberboard is prone to damp deformation and aging, and the hardness is not enough, the service cycle is prolonged, the fire retardant function is added, the combustion risk caused by too high local temperature in the electronic circuit base plate using process is effectively avoided, and the application field of the fiberboard is further expanded.

Owner:DARE WOOD BASED PANEL GRP

A kind of preparation method of functional technology wood

ActiveCN105563586BWear-resistantWeather-resistantRadiation/waves wood treatmentWood treatment detailsStainingManufacturing technology

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Novel environment-friendly composite reinforced polypropylene building template

InactiveCN102604205BImprove mechanical propertiesAdd flame retardant functionForming/stuttering elementsThermal expansionPolypropylene

Owner:HUBEI XINLONG PLASTICS

A kind of chitosan tetramethylene phosphine sulfate flame retardant and its preparation method and application

The invention provides a preparation method for a chitosan tetramethylene phosphonium sulphate flame retardant. The preparation method comprises the following steps: performing electrostatic adsorption on tetrakis hydroxymethyl phosphonium sulphate and chitosan in water to obtain a tetrakis hydroxymethyl phosphonium sulphate / chitosan compound; performing dehydration covalent graft reaction on thetetrakis hydroxymethyl phosphonium sulphate / chitosan compound to obtain the chitosan tetramethylene phosphonium sulphate flame retardant. The chitosan tetramethylene phosphonium sulphate flame retardant prepared by the method provided by the invention does not contain halogen, has an antibacterial effect, and is non-toxic, degradable, green and environmentally friendly; the flame retardant is highin molecular weight, keeps linearity, does not have volatility, and has water washing resistance, migration resistance, good compatibility, high stability and good flame retarding effect.

Owner:JILIN INST OF CHEM TECH

Manufacturing method of density fiberboard for e0 grade electronic circuit backing board

ActiveCN110744670BExtend the life cycleFunction increaseAldehyde/ketone condensation polymer adhesivesFlat articlesAdhesiveProcess engineering

The invention belongs to the technical field of wood processing and relates to an E 0 The manufacturing method of density fiberboard for grade electronic circuit backing board adopts the secondary sizing process, including wood peeling-shaving-wood chip screening-washing-precooking-steaming-hot grinding, adding waterproofing agent-adjustment E 0 Grade moisture-proof adhesive, add additives - dry sorting - blending E 0 High-grade high-solid content adhesives-adding flame retardants-pavement molding-pre-pressing-hot pressing-flap cooling-sanding-inspection and grading-packaging and storage. The adhesive of the present invention adopts the method of secondary addition, which reduces the influence of pre-curing, can give full play to the bonding effect of the adhesive and fully wraps it, and at the same time reduces the energy consumption of the heat energy center. produced E 0 High-grade fiberboard for electronic circuit backing boards solves defects such as moisture deformation, aging, and insufficient hardness, prolongs the service life, increases the flame retardant function, and effectively avoids the risk of burning caused by excessive local temperature during use of electronic circuit backing boards, and further expands Fields of application of fiberboard.

Owner:DARE WOOD BASED PANEL GRP

Antibacterial rat-proof and termite-proof magnetic polyethylene material and preparation method thereof

The invention discloses an antibacterial rat-proof and termite-proof magnetic polyethylene material and a preparation method thereof. The antibacterial rat-proof and termite-proof magnetic polyethylene material has the following advantages: 1, the material has a magnetic function, a conductive function, a rat-proof and termite-proof function and a signal interference shielding function, and achieves a multi-functional effect obtained by replacing a metal material with a high polymer material; 2, the material has a long-acting rat and termite prevention effect, can resist various viruses and bacteria, and is highly flame-retardant; 3, the raw materials are low in cost and wide in market source, and the purpose of reducing the purchase cost is achieved; and 4, the process is intelligent and simple, and manufacturing is more efficient.

Owner:3Q WIRE & CABLE

A kind of lithium-ion battery diaphragm and preparation method thereof

ActiveCN106898720BAdd flame retardant functionReduce surface temperatureCell component detailsSecondary cells servicing/maintenancePolymer sciencePolyolefin

Owner:CHINA LUCKY FILM CORP +1

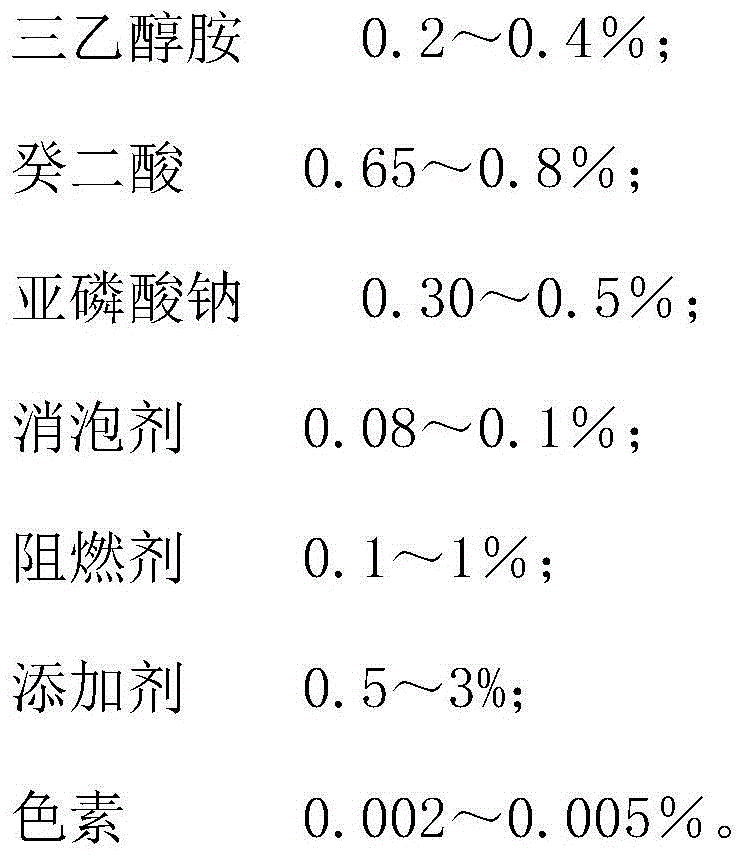

Automobile antifreeze and preparation method thereof

The invention relates to an antifreeze liquid for automobiles and a preparation method thereof. The basic raw materials of the antifreeze liquid for automobiles are dimethyl sulfoxide and deionized water, and the respective weight percentages are as follows: dimethyl sulfoxide 35% to 50%; water 50-70%; the antifreeze fluid for automobiles also includes some ingredients. Compared with the prior art, the present invention uses dimethyl sulfoxide instead of ethylene glycol to produce antifreeze, which has strong low temperature resistance; at the same time, due to the added flame retardant function, the antifreeze that is easy to catch fire is safer in use; A variety of high-efficiency corrosion inhibitors added can fully meet the requirements of antifreeze and anticorrosion, and have strong protection functions for various metals in the engine cooling system, which can greatly prolong the service life of the engine; moreover, the production process is simple.

Owner:西安昕罗新能源科技有限公司

Preparation method of nanometer magnesia coated kaolin composite material

The invention discloses a preparation method of a nanometer magnesia coated kaolin composite material. The preparation method comprises the following steps: (1), weighing the kaolin, grinding and screening, to obtain screened powders; (2), putting the powders into distilled water and putting sodium hexametaphosphate into the solution, carrying out ultrasonic dispersing, stirring and adding an MgCl2 solution, to form a uniform suspending solution; (3), heating the suspending solution to be 60-100 DEG C, stirring the suspending solution, and gradually dripping a CO(NH2)2 solution into the suspending solution until dripping off; (4), filtering the solution, washing filter residues by distilled water until no Cl<-> ion is existent in a washing liquid; and (5), drying the washed filter residues in a drying oven to obtain dry powders, and grinding the dry powders, so as to obtain the nanometer magnesia coated kaolin composite material. The composite material prepared by the preparation method has the advantages that the whiteness is as high as 90%, the index of refraction is high, and furthermore, the flame-retardant function of the composite material is enhanced.

Owner:广东科进应用技术研究有限公司

a medium density fiberboard

ActiveCN105563601BReduce the impact of physical and chemical propertiesGuaranteed physical and chemical propertiesAldehyde/ketone condensation polymer adhesivesFlat articlesFiberFiltration

The invention relates to a medium-density fiberboard. The medium-density fiberboard is prepared from, by mass, 100 parts of wood fibers, 8-15 parts of magnalium nanometer layered double hydroxide, 0.01-0.02 part of a coupling agent, 12-15 parts of a modified MUF adhesive and 1-2 parts of a waterproof agent. A preparation method comprises the steps that 1, magnalium layered double hydroxide is firstly dried and finely ground to be 20-50 micrometers, then the coupling agent with the mass percent concentration of 20%-30% is subjected to hydrolysis for 25-35 min at the room temperature, and after the coupling agent reacts for 0.5-1.5 h in an aqueous solution of 80-90 DEG C with the finely-ground magnalium layered double hydroxide added, suction filtration, washing, drying and grinding are carried out; and 2, the modified MUF adhesive and modified Mg / Al-LDHs are added to the wood fibers, 5-10 parts of a formaldehyde catching agent and 1-3 parts of a curing agent are added in the use process of the modified MUF adhesive, and the medium-density fiberboard is obtained through laying, pre-pressing forming, hot pressing and cooling. The medium-density fiberboard is environment friendly, non-toxic and free of obvious moisture absorption, and the oxygen index reaches up to 34%.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Method for preparing hybridized p-xylene

InactiveCN108341939AEasy to interpenetrateEasily intrusiveFlame-proof filament manufactureMonocomponent copolyesters artificial filamentPotassiumEthylamine

A method for preparing hybridized p-xylene comprises the steps of: mixing a fluorosulfonic acid solution and a fluorophosphoric acid solution with magnesium aluminate spinel, aluminum hydroxide whiskers and magnesium zinc spinel, performing a hydrothermal reaction, grinding, filtering, calcining, washing and drying to obtain a flame retardant hybridizer; mixing p-xylene, acetic acid, sodium hypophosphite, o-xylene, an ethylamine cosolvent, a potassium hydrogen phosphate dispersion, and the obtained flame retardant hybridizer, grinding, filtering and dispersing to obtain a hybridized p-xylene mother liquor; adding the obtained hybridized p-xylene mother liquor in a form of spraying into the p-xylene to prepare the hybridied p-xylene. The product prepared by the method has an excellent flameretardant function.

Owner:ZHEJIANG MODERN TEXTILE IND RES INST

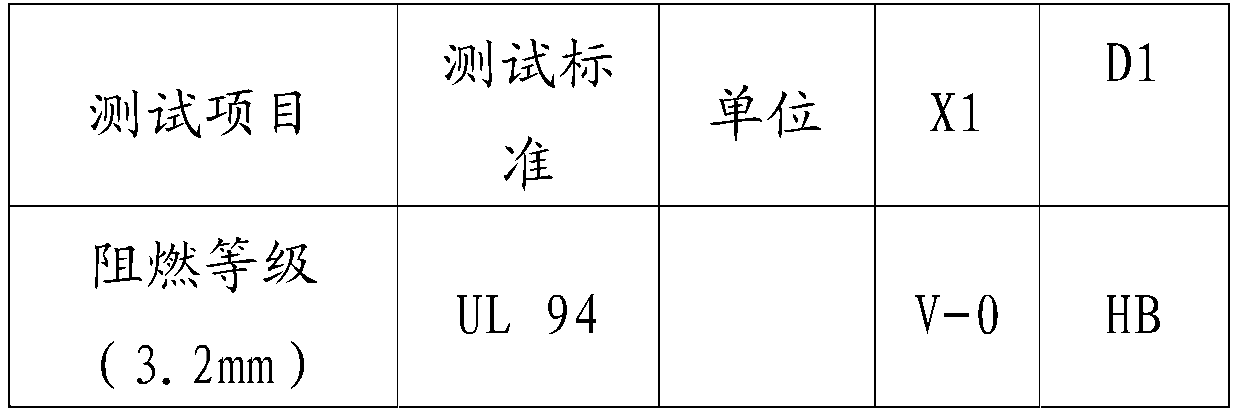

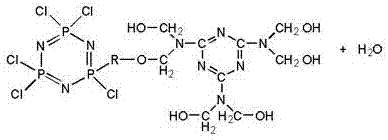

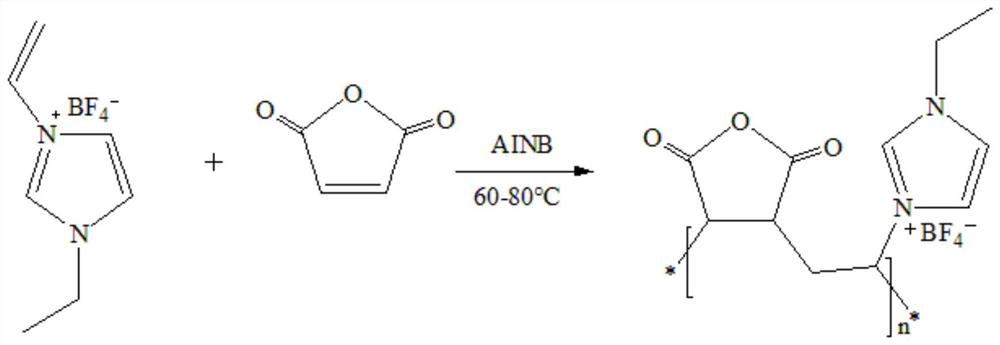

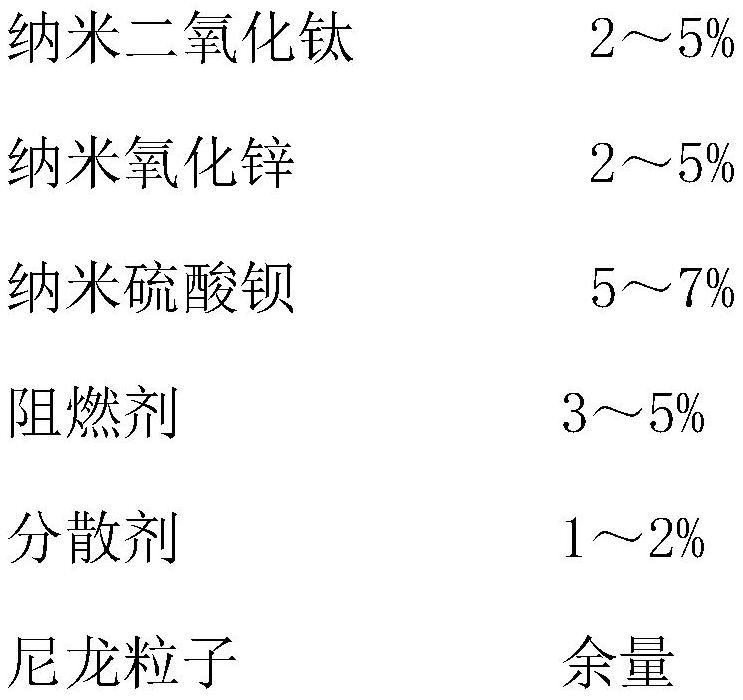

Chinlon monofilament with bending-resistance and wear-resistance composite function and preparation method of chinlon monofilament

ActiveCN111748865AAdd flame retardant functionImprove wear resistanceFlame-proof filament manufactureMonocomponent polyamides artificial filamentLimiting oxygen indexNano zinc oxide

The invention relates to a chinlon monofilament with a bending-resistance and wear-resistance composite function. The chinlon monofilament is characterized in that component raw materials of the chinlon monofilament comprise, by mass percent, 5%-10% of composite function master batches and the balance nylon particles; the number of times of bending resistance of the chinlon monofilament ranges from 50,000 to 90,000; and in the flame retardance performance of the chinlon monofilament, the limit oxygen index LOI ranges from 30% to 40%, and UL-94 is level V-0. Adding of nanometer titania and nano-zinc oxide is mainly used for overcoming the defects that the sunproof and light resistance performance of nylon wires is poor, and therefore light resistance is improved; adding of a fire retardantis mainly used for improving the fire retardant function of the nylon monofilament; and adding of nano barium sulfate is mainly used for improving wear resistance, and therefore wear resistance and bending resistance of a product are finally improved.

Owner:QUANZHOU ZHENGYING CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com