Production process of fireproof fabric

A production process and technology for fireproof fabrics, applied in the field of textile fabrics, can solve the problems of uneven fireproof and heat insulation effects of fireproof fabrics, complex production processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A production process of a fireproof fabric, comprising the steps of:

[0021] S1. Preparation of base fabric: warp yarns are made of aramid fibers, and weft yarns are made of polyester fibers, which are spun into base fabrics by a textile machine;

[0022] S2. Anti-flame treatment: The selected fabric flame retardant is a mixture of liquid ammonium polyphosphate and colloid. The mass fraction ratio is: 75 parts of colloid and 75 parts of ammonium polyphosphate. ℃, the soaking time is 4 hours.

[0023] S3. Shaping: internal pressure: 0.8bar; external pressure: 1.2bar, temperature: bake the fabric for 1 minute at 130°C;

[0024] S4. Dyeing: put the fabric into the dyeing pool, dye at 80°C for 15 minutes, and then at 100°C for 30 minutes.

[0025] S5. Drying: place the fabric at room temperature, wash with water for 10 minutes, internal pressure: 0.8bar; external pressure: 1.2bar, temperature: 110°C for 2 minutes, to dry the fabric.

Embodiment 2

[0027] A production process of a fireproof fabric, comprising the steps of:

[0028] S1. Preparation of base fabric: warp yarns are made of aramid fibers, and weft yarns are made of polyester fibers, which are spun into base fabrics by a textile machine;

[0029] S2. Anti-flame treatment: The selected fabric flame retardant is a mixture of liquid ammonium polyphosphate and colloid. The mass fraction ratio is: 78 parts of colloid and 72 parts of ammonium polyphosphate. The base cloth is immersed in it, and the immersion temperature is 26 °C , The soaking time is 5 hours.

[0030] S3. Shaping: internal pressure: 0.8bar; external pressure: 1.2bar, temperature: bake the fabric for 1.5 minutes at 140°C;

[0031] S4. Dyeing: put the fabric into the dyeing pool, dye at 90°C for 16 minutes, and then at 110°C for 35 minutes.

[0032] S5. Drying: place the fabric at room temperature, wash with water for 10 minutes, internal pressure: 0.8bar; external pressure: 1.2bar, temperature: 120...

Embodiment 3

[0034] A production process of a fireproof fabric, comprising the steps of:

[0035] S1. Preparation of base fabric: warp yarns are made of aramid fibers, and weft yarns are made of polyester fibers, which are spun into base fabrics by a textile machine;

[0036] S2. Anti-flame treatment: the selected fabric flame retardant is a mixture of liquid ammonium polyphosphate and colloid, and its mass fraction ratio is: 80 parts of colloid and 70 parts of ammonium polyphosphate. °C, the immersion time is 6 hours.

[0037] S3. Shaping: internal pressure: 0.8bar; external pressure: 1.2bar, temperature: bake the fabric for 2 minutes at 150°C;

[0038] S4. Dyeing: put the fabric into the dyeing pool, dye at 100°C for 20 minutes, and then at 120°C for 40 minutes.

[0039] S5. Drying: place the fabric at room temperature, wash with water for 10 minutes, internal pressure: 0.8 bar; external pressure: 1.2 bar, temperature: 130°C for 4 minutes, to dry the fabric.

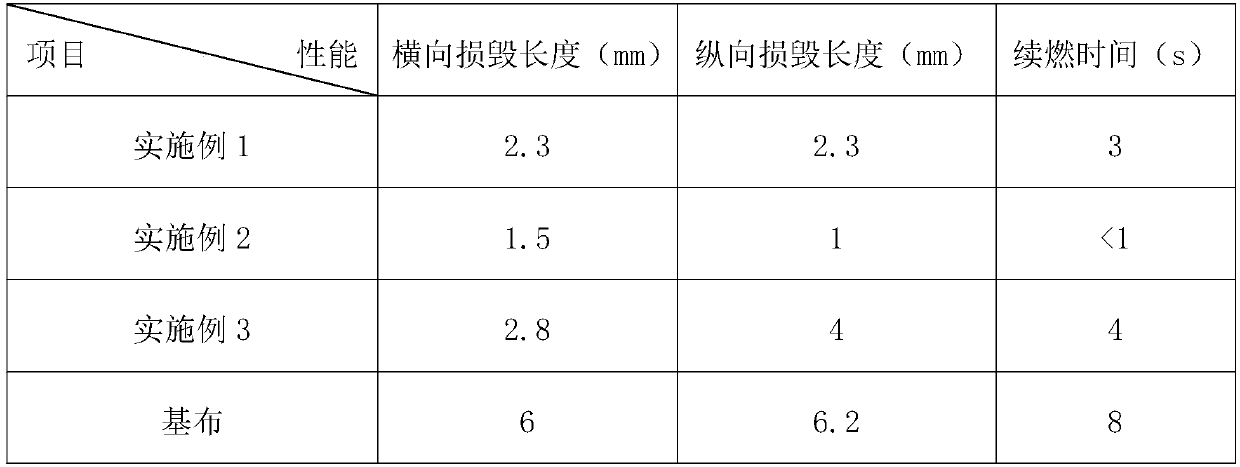

[0040] The base fabric i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com