Chinlon monofilament with bending-resistance and wear-resistance composite function and preparation method of chinlon monofilament

A composite function, nylon technology, applied in the field of nylon monofilament production, can solve the problems of unsuitable, nylon yarns with poor light fastness and light fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A nylon monofilament with folding and wear-resistant composite functions, the mass percentage of its component raw materials is: 5% composite functional masterbatch, 95% nylon particles; the bending resistance of nylon monofilament is 60,000; nylon monofilament The limiting oxygen index LOI of the flame retardant performance is 30%, and the UL-94 is V-0 level.

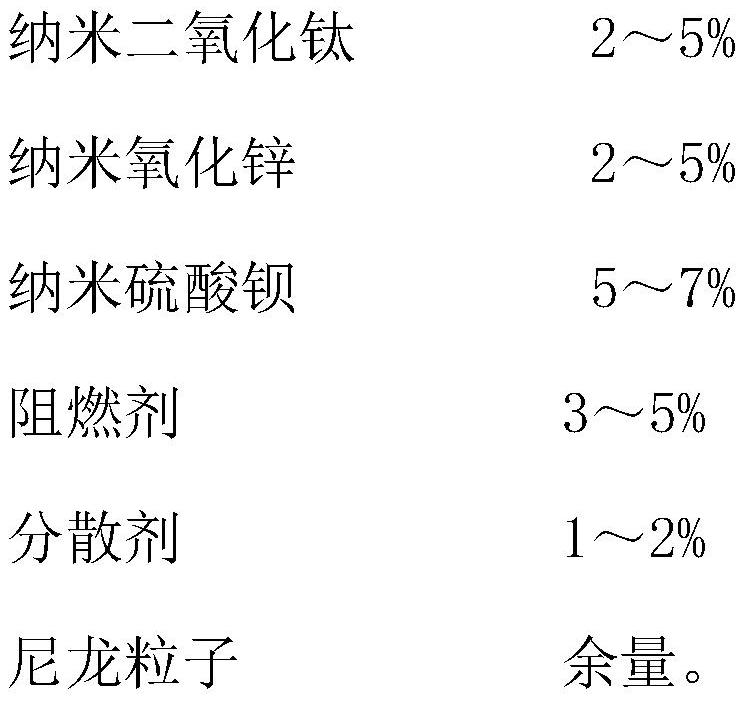

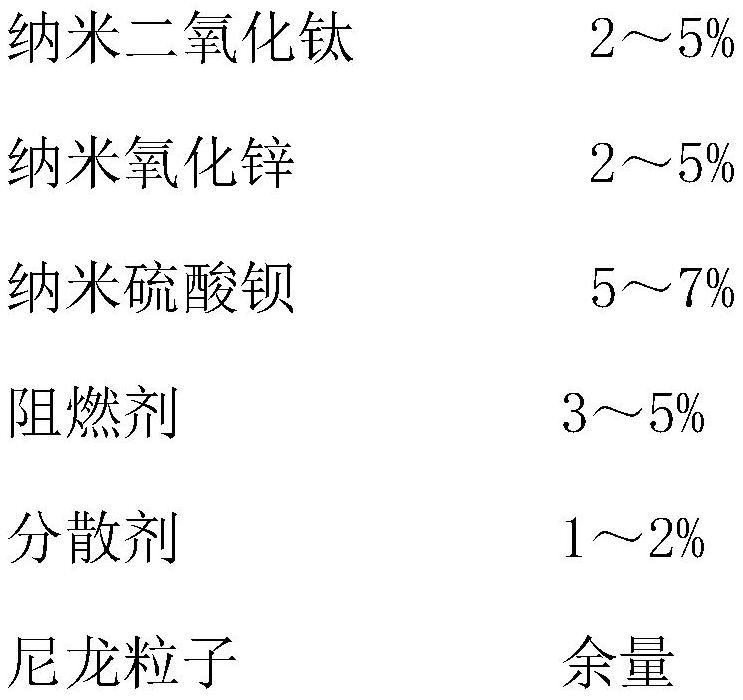

[0035] A kind of composite functional masterbatch, its raw material mass percentage is:

[0036]

[0037]

[0038] The invention discloses a preparation method of a composite functional masterbatch, which comprises mixing and blending the above-mentioned various raw materials to obtain a composite functional masterbatch.

[0039] A kind of preparation method of flame retardant, its concrete steps are:

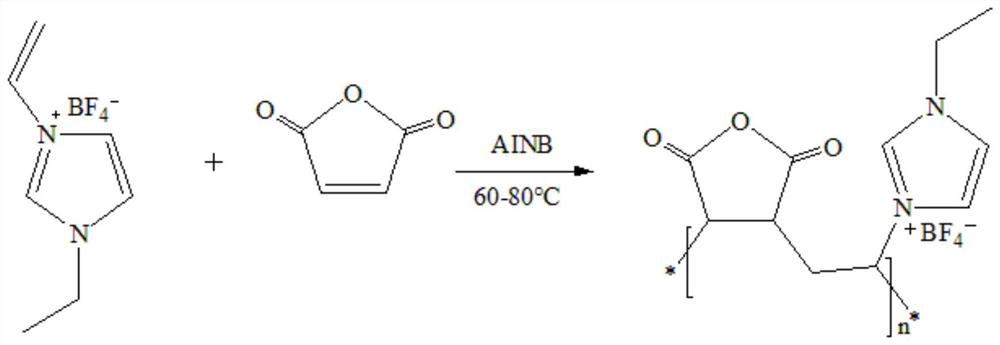

[0040] Use 1-vinyl-3-ethylimidazolium tetrafluoroborate and maleic anhydride as raw materials, azobisisobutyronitrile AIBN as the initiator, and mix the raw materials and the initiator at the reaction temp...

Embodiment 2

[0050] A nylon monofilament with folding and wear-resistant composite functions, the mass percentage of its component raw materials is: composite functional masterbatch is 5-10%, nylon particles are the balance; nylon monofilament has a bending resistance of 70,000 times; nylon The limiting oxygen index LOI in the flame retardant performance of monofilament is 38%, and UL-94 is V-0 level.

[0051] A kind of composite functional masterbatch, its raw material mass percentage is:

[0052]

[0053] The invention discloses a preparation method of a composite functional masterbatch, which comprises mixing and blending the above-mentioned various raw materials to obtain a composite functional masterbatch.

[0054] A kind of preparation method of flame retardant, its concrete steps are:

[0055] Use 1-vinyl-3-ethylimidazolium tetrafluoroborate and maleic anhydride as raw materials, azobisisobutyronitrile AIBN as the initiator, and mix the raw materials and the initiator at the rea...

Embodiment 3

[0062] A nylon monofilament with folding and wear-resistant composite functions, the mass percentage of its component raw materials is: 10% of composite functional masterbatch, 90% of nylon particles; the bending resistance of nylon monofilament is 40,000; The limiting oxygen index LOI of the flame retardant performance is 40%, and the UL-94 is V-0 level.

[0063] A kind of composite functional masterbatch, its raw material mass percentage is:

[0064]

[0065] The invention discloses a preparation method of a composite functional masterbatch, which comprises mixing and blending the above-mentioned various raw materials to obtain a composite functional masterbatch.

[0066] A kind of preparation method of flame retardant, its concrete steps are:

[0067] Use 1-vinyl-3-ethylimidazolium tetrafluoroborate and maleic anhydride as raw materials, azobisisobutyronitrile AIBN as the initiator, and mix the raw materials and the initiator at the reaction temperature of 60-80°C unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com