a medium density fiberboard

A fiberboard, medium density technology, applied in the field of flame retardant medium density fiberboard and its preparation, can solve the problems of flame retardant performance and environmental protection performance to be improved, fiberboard is easy to absorb moisture, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Preparation method 1 of modified MUF adhesive:

[0056] A. 100 parts of formaldehyde aqueous solution, 0.1 part and 0.3 part of amino-terminated hyperbranched polymer PAMAM whose mass concentration is 36.5wt% are 100 parts by weight, and 0.3 part of amino-terminated hyperbranched polymer PAMAM is put into the reactor, and the stirring is started; The active substance is sodium hydroxide, potassium hydroxide, calcium hydroxide, barium hydroxide or ammonia water;

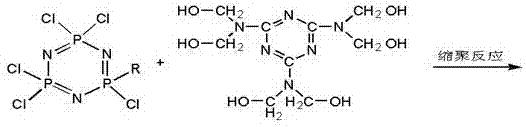

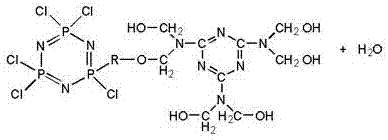

[0057] B. Add 1 part of hexachlorocyclotriphosphazene, heat up to 50°C, and when the temperature rises to 75°C by itself, add 35 parts of melamine, continue to heat up to 90°C, and react to obtain a preliminary polycondensate;

[0058] C. Add 40 parts of melamine to the above-mentioned preliminary polycondensate, and add 0.6 part of p-toluenesulfonamide to obtain the second polycondensate;

[0059] D. Add 20 parts of urea when the temperature of the second polycondensation product is lowered to 70°C, continue ...

Embodiment 1

[0071] 12 parts of the modified MUF adhesive prepared by the modified MUF adhesive preparation method 1, 0.12 parts of ammonium chloride, 1.2 parts of paraffin emulsion (concentration 40%), Mg / Al-LDHs prepared by the flame retardant formula 1 (0.01 part of silane coupling agent modified) 12 parts, sprayed evenly on the surface of poplar fiber with spray gun and sieve in turn, after spraying, the fiber was paved, pre-pressed (pre-pressed pressure 3MPa), hot-pressed ( The three-stage curve of hot pressing pressure is 4.0MPa, 2.5MPa, 1.0MPa respectively, the hot pressing time is 60s / mm, and the temperature is 180°C). After cooling, the flame-retardant medium density fiberboard can be obtained, and the measured oxygen index is 34.2%.

Embodiment 2

[0073] 14 parts of modified MUF adhesive prepared by preparation method 2 of modified MUF adhesive, 0.14 part of ammonium chloride, 1.2 parts of paraffin emulsion (concentration 40%), Mg / Al-LDHs15 prepared by flame retardant formula 2 parts (modified by 0.01 part of silane coupling agent) are evenly sprayed on the surface of poplar fiber with a spray gun and a sieve in sequence. Pressure three-stage curve, respectively 4.0MPa, 2.5MPa, 1.0MPa, hot pressing time 60s / mm, temperature 190 ℃), cooling to obtain a flame-retardant medium density fiberboard, the measured oxygen index is 34.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com