Patents

Literature

86results about How to "Guaranteed physical and chemical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neutral boron silicate glass used for medicinal mold-formed bottle and manufacturing method thereof

InactiveCN101186437AImprove performanceSmall coefficient of thermal expansionElectric furnaceGlass productionSilicate glassHeat stability

Neutral borosilicate glass used for moulding medicinal bottles is provided, which pertains to the technology filed of glass containing aluminum, boron, 40 percent to 90 percent (by weight) of silicon dioxide and provides neutral borosilicate glass meeting the standard of medical packaging container (material) YBB00292002, YBB00322002. The glass contains 8-12 percent of B2O3 with expansion coefficient of 4.0-5.0 multiplied by 10<-6> / K, as well as a series of excellent physical and chemical properties such as good heat stability, strong acid-resistance, alkali-resistance, water-resistance and erosion-resistance. The invention adopts cold furnace top and deep bed, recycles volatiles of boron during the course of melting, thus effectively reducing boron volatilization, preventing unfavorable phenomenon from taking place, for example, the combined material layer from incrustation and reversing, and obtaining comparatively good economic benefit and quality benefit.

Owner:SHANDONG PHARMA GLASS

Filling masterbatch used in biodegradable plastic, and preparation method thereof

InactiveCN102516723AGuaranteed DispersionAvoid reunionArtifical filament manufactureMasterbatchPolymer science

The invention discloses a filling masterbatch used in biodegradable plastic. The masterbatch is composed of components of, by mass: (A) 20.0-80.0% of biodegradable polyester, (B) 1.0-80.0% of a filling material, (C) 0.1-10.0% of a lubricating agent, (D) 0.1-5.0% of a high-temperature-resistant agent, and (E) 0.1-5.0% of a hydrolysis-resisting agent. The masterbatch is advantaged in that: (1) compatibility of the carrier is consistent with that of the biodegradable plastic, such that the filling masterbatch has excellent dispersity in the biodegradable plastic; (2) the obtained filling masterbatch satisfies an application requirement of biodegradable plastic En13432; when the filling masterbatch is mixed with biodegradable plastic, the biodegradation performance of the original material is completely maintained; (3) high temperature and hydrolysis resistances of the filling masterbatch are good, and the filling masterbatch has high physical mechanical properties; (4) with the filling masterbatch, while the cost of biodegradable plastic is reduced, physical chemical properties especially the biodegradation performance of the filled material are maintained.

Owner:KINGFA SCI & TECH CO LTD +2

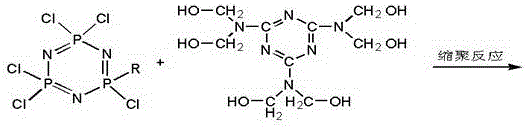

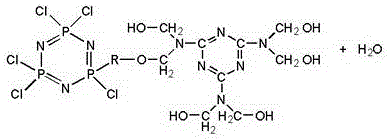

Prepn process of hydrophilic paint for superthin air conditioner aluminium foil heat exchanger

InactiveCN101020798ADoes not affect heat exchange performanceIncrease contentCoatingsSpecial surfacesCross-linkPolymer science

The present invention discloses preparation process of hydrophilic paint for heat exchanger aluminum foil of air conditioner. The paint consists of one kind of base paint, and one kind of top paint. The base paint consists of hydroxyl emulsion 15.0-20.0 wt%, amino resin 1.5-3.0 wt%, cross-linking assistant 0.05-0.5 wt%, color paste 1.5-2.5 wt%, and mixed solvent for the rest. The top paint includes two components, component A and component B, in the weight ratio of 9.0-11.0 to 1, the component A consists of hydrophilic polymer 25.0-35.0 wt%, hydrophilic reinforcer 5.0-10.0 wt%, surfactant 0.5-3.5 wt%, and mixed solvent for the rest; and the component B consists of curing agent 60.0-65.0 wt% and deionized water 35.0-40.0 wt%. The paint of the present invention has high adhesion, high hydrophilicity, and capacity of forming very thin coating to ensure the heat exchange performance of the heat exchanger.

Owner:SHANGHAI JIAO TONG UNIV

Mushroom casing soil using grain stillage biogas residues as raw material and preparation method thereof

InactiveCN101225001AAchieve reuseProtect resourcesBio-organic fraction processingWaste based fuelAlcoholVinasse

The invention relates to a mushroom cover material prepared by using vinasse biogas residues as materials and a preparation method. Thanks to an organic combination of the biogas residues and common soil material, the common soil particle generates more millipores, the permeability, the hydroscopic property, the moisture retention, the organic matter and other nutrient substance are greatly improved, the mushroom culture yield is steadily increased, and synchronously the reuse of the biogas residues is realized and the original turfy soil resources are protected; the preparation method for the mushroom cover material is especially suitable for preparing mushroom cover material with the biogas residues which is the production of a distillery, an alcohol distillery and a large-scale biogas project using vinasse as materials.

Owner:孙效峰

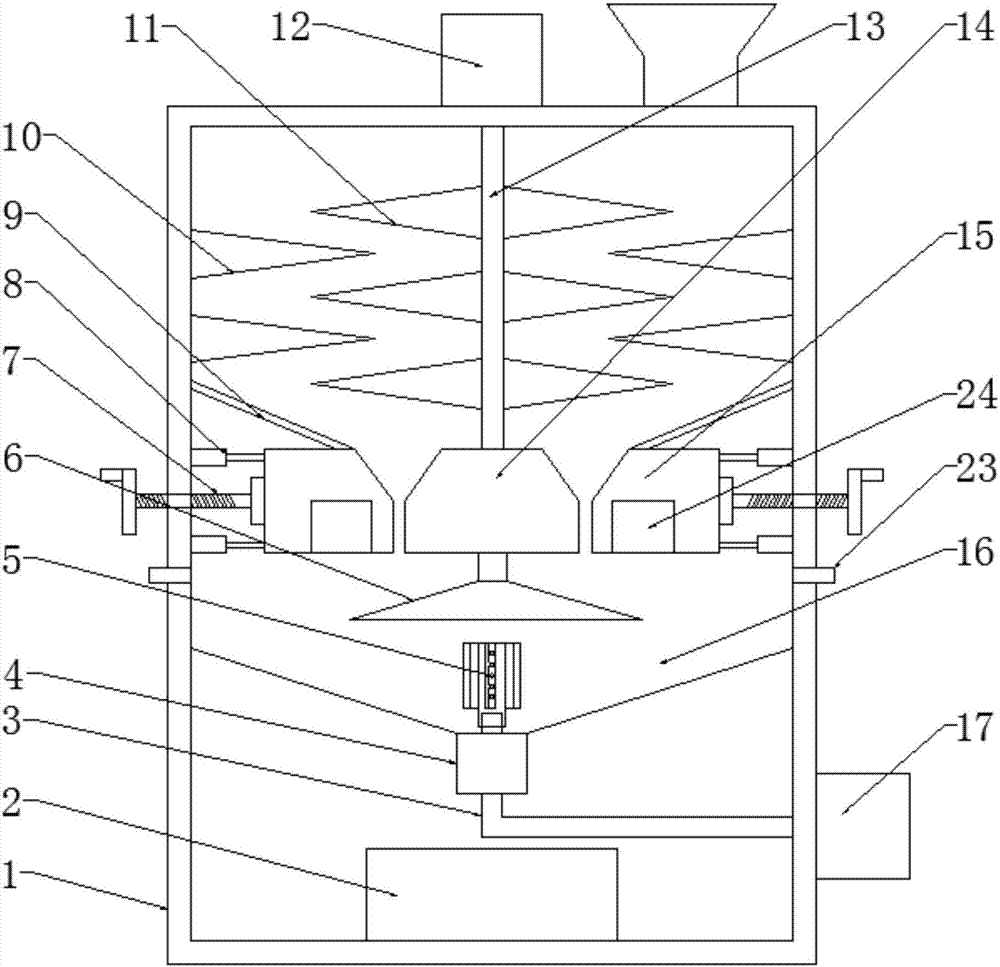

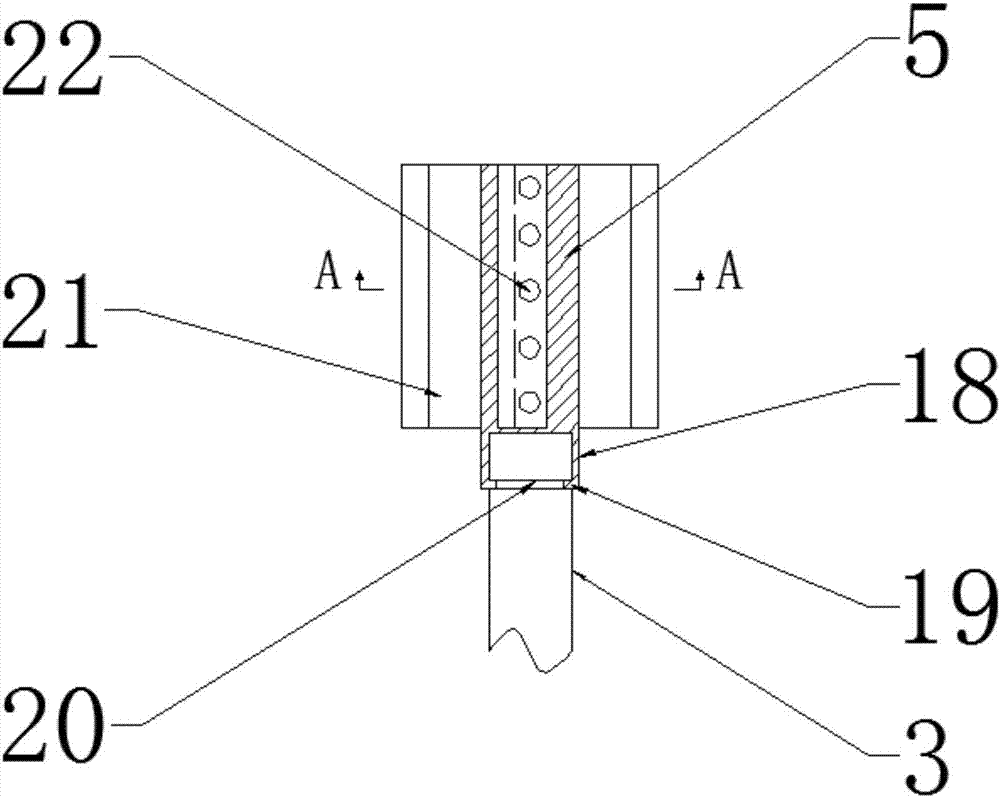

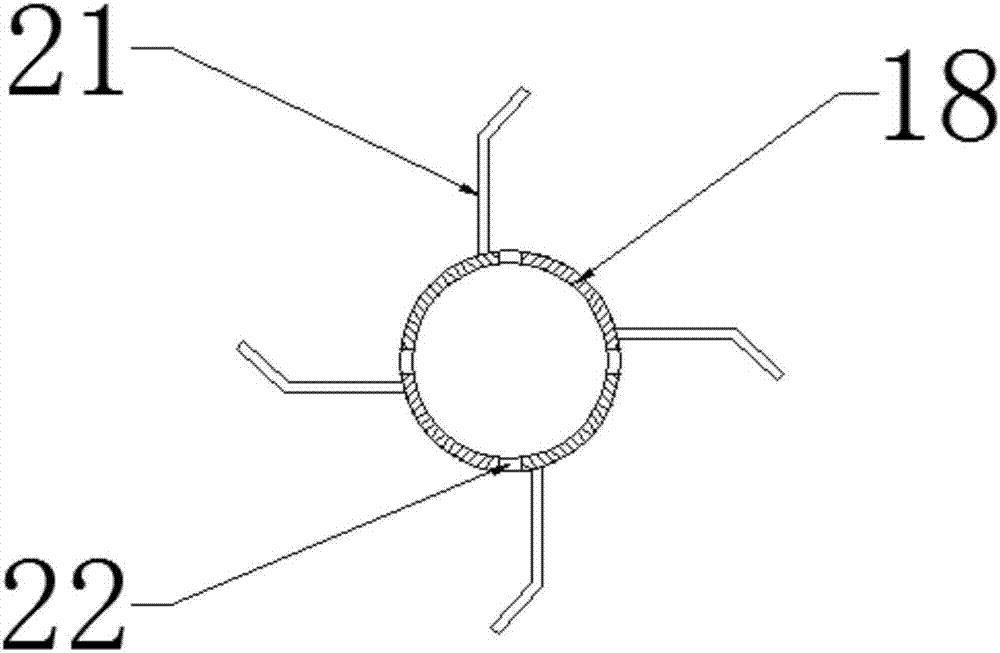

High-efficiency grinding and drying integral device for traditional Chinese medicine

InactiveCN107537645AEvenly dispersedGood dispersionDrying solid materials with heatDrying gas arrangementsEngineeringThreaded rod

The invention discloses a high-efficiency grinding and drying integral device for traditional Chinese medicine. The high-efficiency grinding and drying integral device comprises a box body, first cutting blades, second cutting blades, a grinding body and a drying device, wherein a motor is arranged in the middle part of the top part of the box body, and is in driving connection with a rotary shaft; the first cutting blades are fixedly arranged at the surface of the rotary shaft; the second cutting blades are arranged at the inner walls of both sides of the upper part of the box body; the grinding body is arranged at the bottom end of the rotary shaft; a grinding sleeve is arranged at the outer side of the grinding body; the middle part of the outside wall of the grinding sleeve is rotationally connected with a threaded rod; a medicine splitting cone is fixedly arranged in the middle part of the bottom part of the grinding body; a drying device is arranged just under the medicine splitting cone. The high-efficiency grinding and drying integral device has the advantages that by arranging the first cutting blades and the second cutting blades, the traditional Chinese medicine is primarily crushed, so as to facilitate the subsequent refining and grinding; by arranging the grinding body, the grinding sleeve and the threaded rod, the traditional Chinese medicine can be ground, and the grinding fineness of the traditional Chinese medicine can be adjusted, so as to meet different requirements; by arranging the drying device, the high-efficiency grinding and drying integral device can automatically rotate and uniformly spray hot air, so that the drying efficiency is improved.

Owner:陈木镇

Method for preparing concentrated cheese powder by accelerated fermentation

ActiveCN101326937AShorten the production cycleReduce cost inputCheese manufactureFlavorRoom temperature

The invention relates to a method for preparing condensed cheese powder by rapid fermentation. The preparation steps include that (1) milk powder is taken as the raw material, and cooled to room temperature after sterilization; (2) microbiological culture is put into the milk powder; (3) enzyme preparation and supplementary materials are added; (4) the zymolyte product is embedded by embedding materials and emulsifier; (5) the embedded product is dried to make flour, thereby, the condensed cheese powder is achieved. The invention has the advantages of reasonable production process and easy operation; the production process is simplified and the production cycle is shortened, the flavor of cheese powder is enhanced, and high quality is ensured. The invention is a production method applicable to the modern large-scale production of novel cheese powder products.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

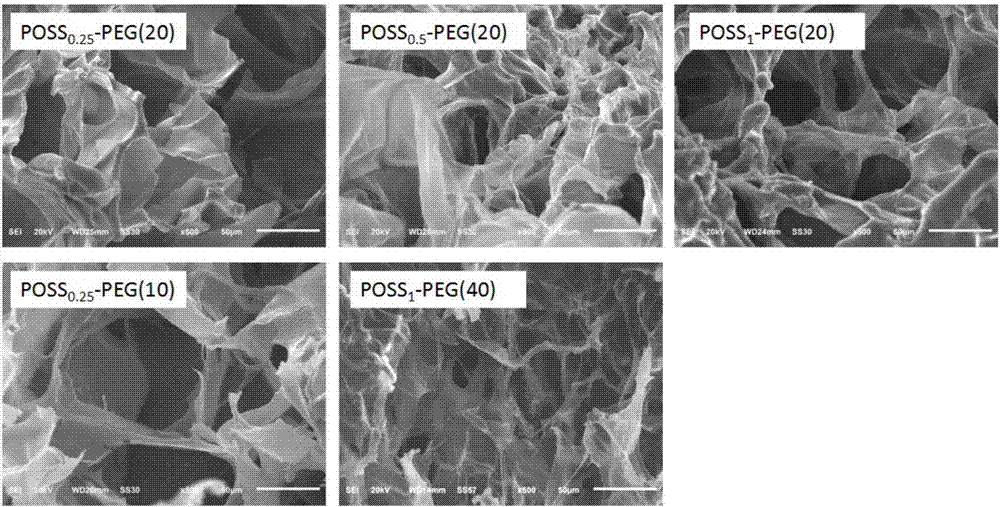

POSS-PEG (Polyhedral Oligomeric Silsesquioxane-Polyethylene Glycol) hybrid hydrogel as well as preparation method and application thereof

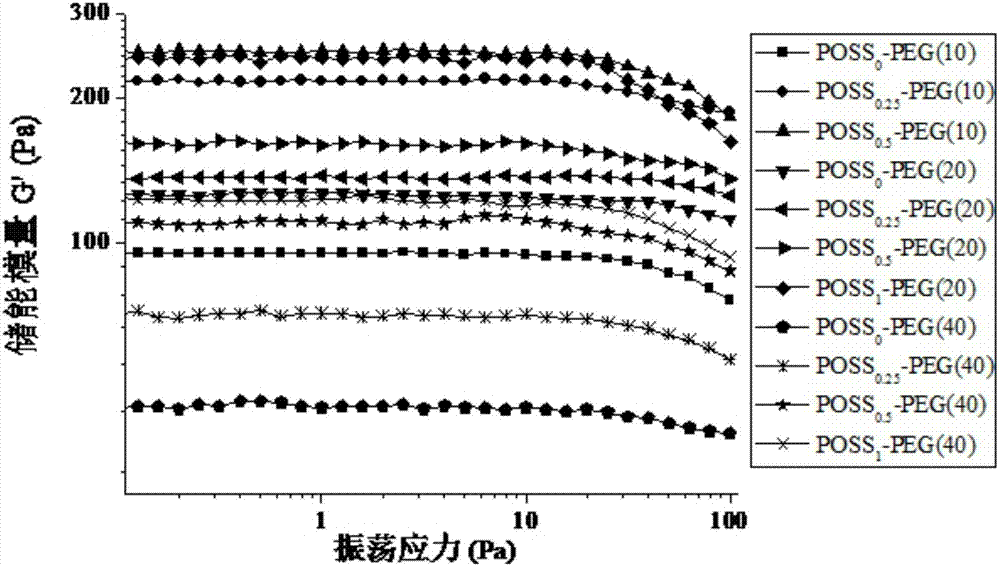

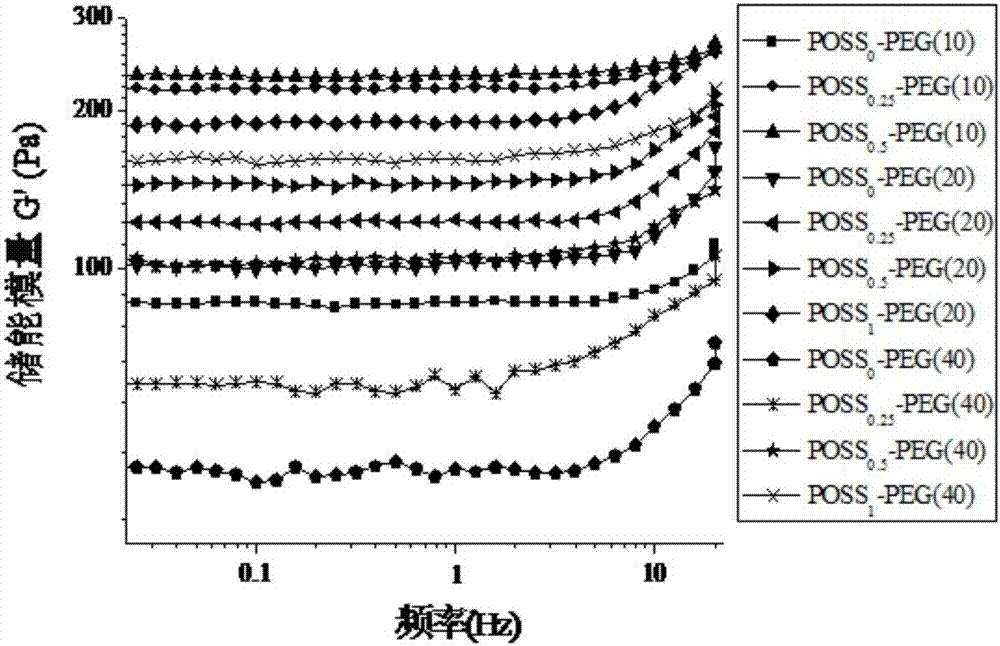

ActiveCN107118373AGood mechanical strengthGelation time is shortProsthesisPeptidePolyethylene glycol

The invention relates to a preparation method of POSS-PEG (Polyhedral Oligomeric Silsesquioxane-Polyethylene Glycol) hybrid hydrogel. The preparation method comprises the following steps: carrying out Michael addition reaction on 4-arm-PEG-MAL and POSS-SH to obtain a POSS-PEG pre-polymer; taking a matrix metalloproteinase substrate peptide as a cross-linking agent, carrying out the Michael addition reaction on the matrix metalloproteinase substrate peptide and the POSS-PEG pre-polymer and crossly linking to form gel, so as to obtain the POSS-PEG hybrid hydrogel. The POSS-PEG hybrid hydrogel provided by the invention has good mechanical strength and the mechanical strength of the POSS-PEG hybrid hydrogel can be finely regulated and controlled through changing the molecular weight of the 4-arm-PEG-MAL and the mol ratio of the POSS-SH to the 4-arm-PEG-MAL; meanwhile, the POSS-PEG hybrid hydrogel can be prepared in a triethanolamine with low concentration and gel formation time is short; the damages or loss on seed cells or medicines loaded on the POSS-PEG hybrid hydrogel can be reduced as much as possible under the condition that basic physicochemical properties are ensured.

Owner:HUBEI UNIV +1

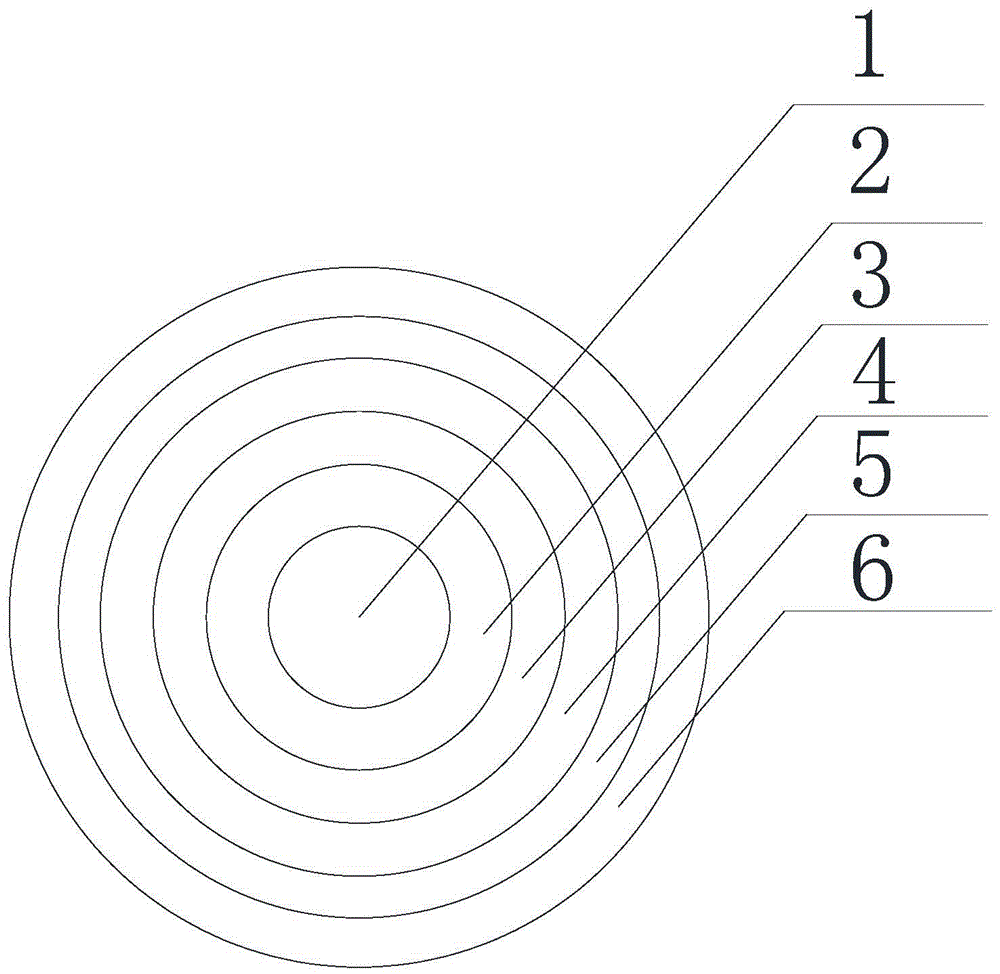

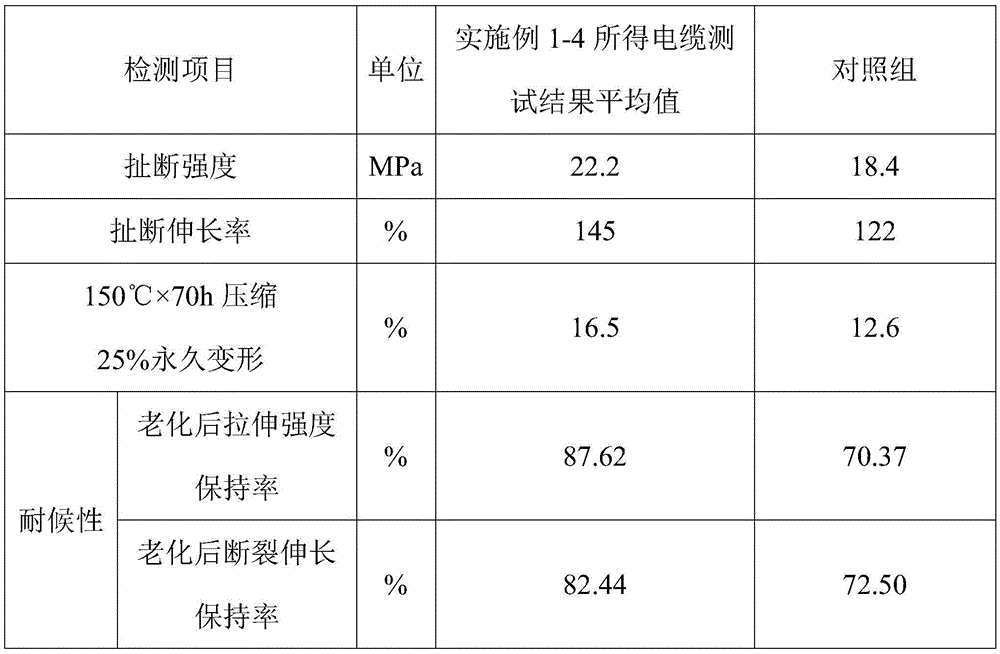

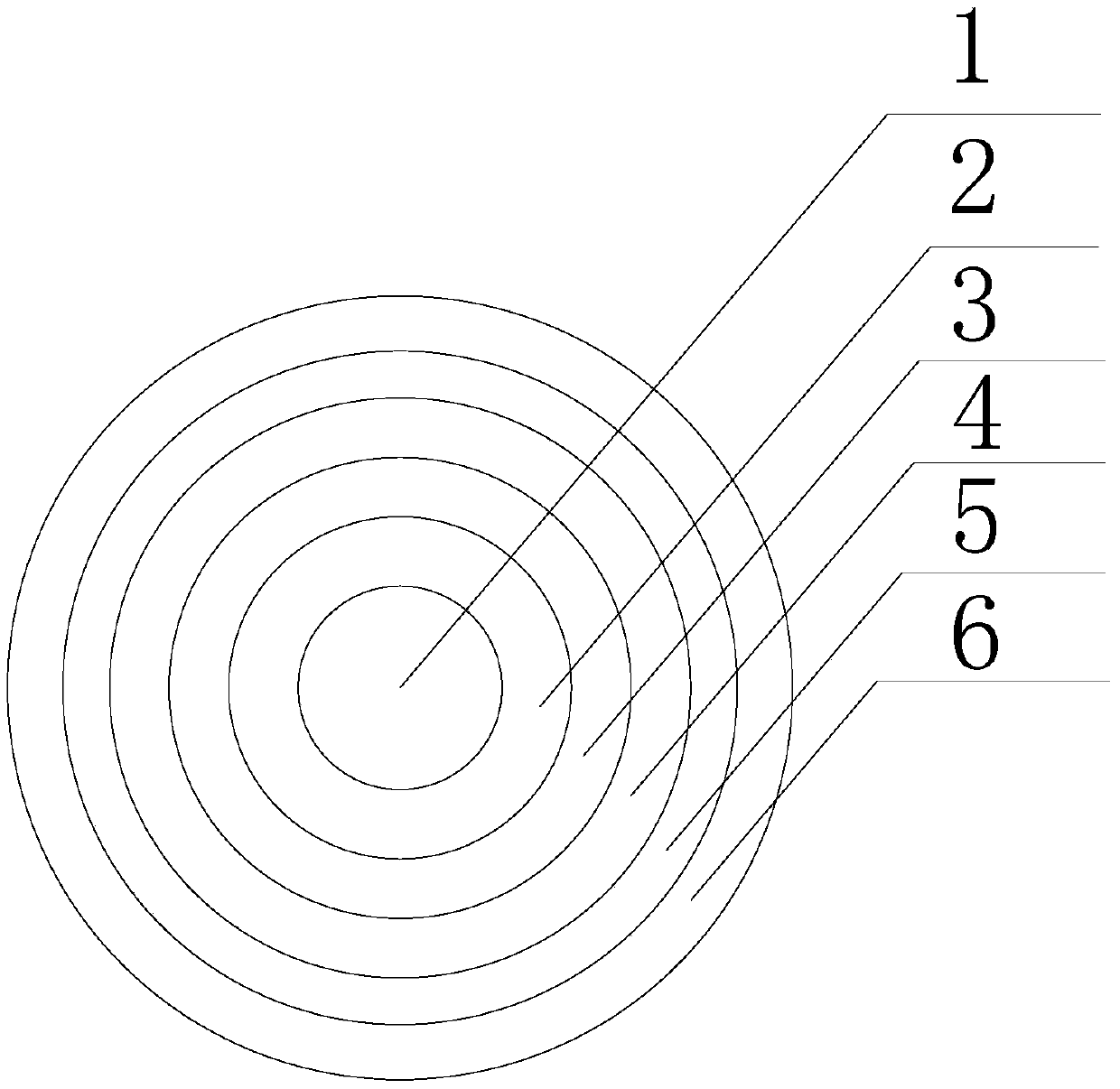

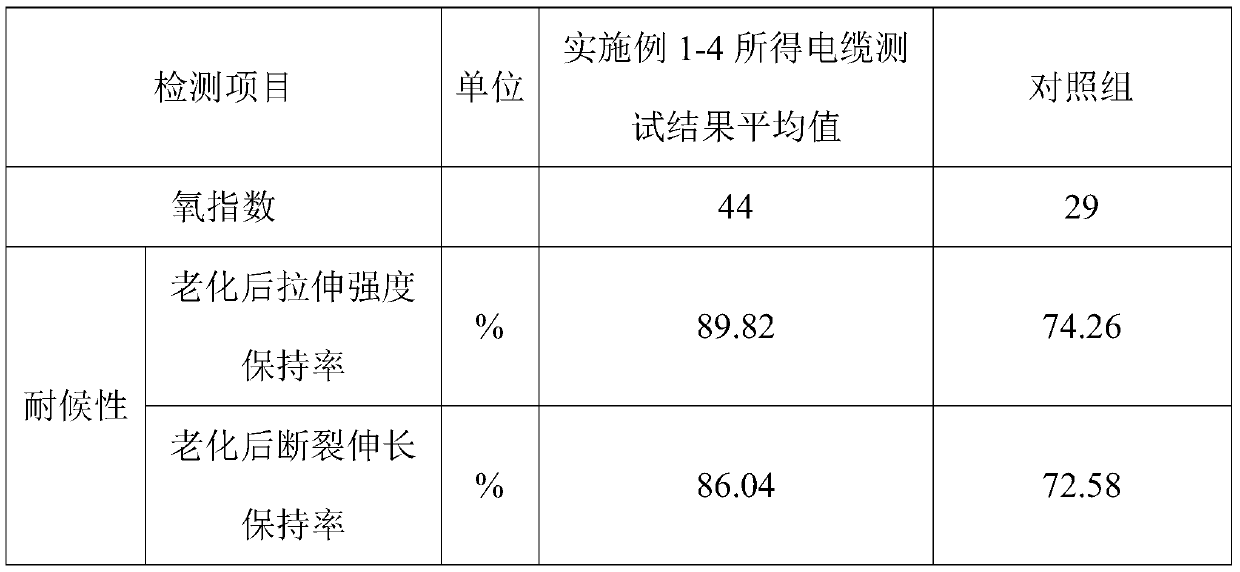

Shock-resistant tearing-resistant high-weather-resistant cable

InactiveCN105462002ASuitable temperatureGuaranteed physical and chemical propertiesInsulated cablesInsulated conductorsAcrylonitrileEngineering

The invention discloses a shock-resistant tearing-resistant high-weather-resistant cable comprising a conductor, an insulating layer, a filling layer, a shielding layer, an armor layer and an outer sheath; the outer sheath comprises the raw materials in parts by weight: 55-58 parts of butadiene-acrylonitrile rubber 2707, 23-27 parts of ethylene propylene rubber, 14-17 parts of natural rubber, 10-12 parts of p-aramid fibers, 7-10 parts of composite flame-retardant phase-change microcapsules, 13-15 parts of hard argil, 2-4 parts of magnesium oxide, 27-32 parts of magnesium carbonate, 8-11 parts of sepiolite, 11-14 parts of lanthanum oxide, 20-23 parts of a mica powder, 2-4 parts of furnace carbon black, 3-5 parts of a monoalkoxy type titanate coupling agent, 4.3-6.5 parts of sulfur, 1.7-2.2 parts of an accelerant TT, 2.1-2.5 parts of an accelerant DM, 4-7 parts of aromatic oil, 1-3 parts of castor oil, 4-6 parts of coumarone, 3-6 parts of naphthenic oil, 2.8-3.3 parts of an anti-aging agent BLE, and 4.3-4.6 parts of an anti-aging agent OD.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

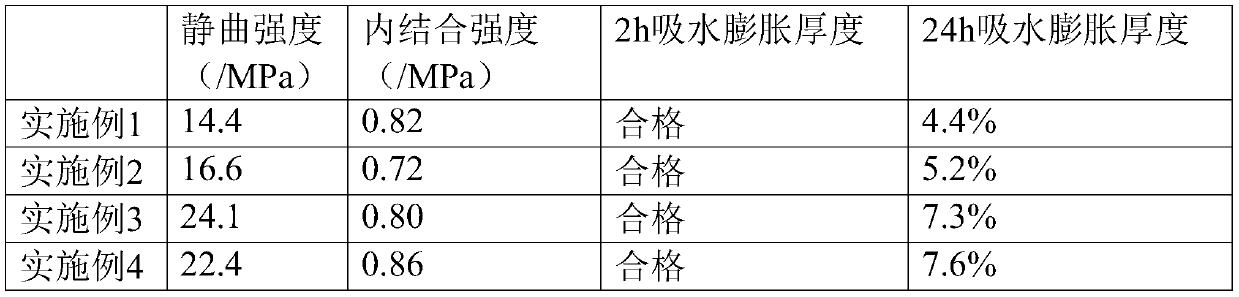

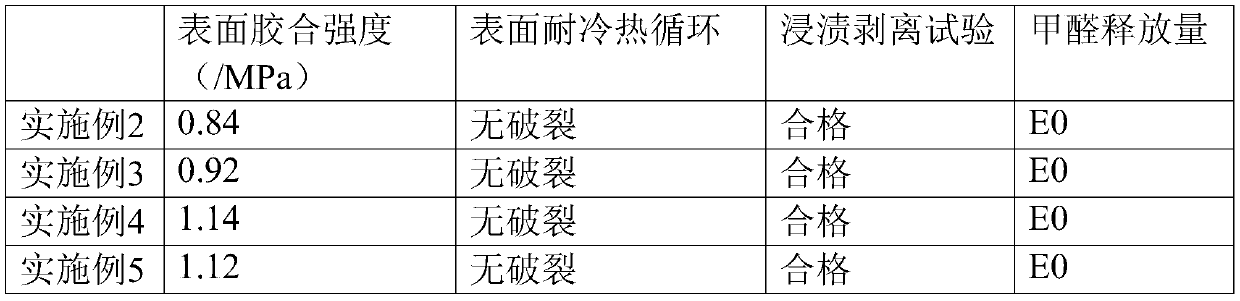

Mg/Al-LDHs (Layered Double Hydroxides) medium density fiberboard and preparation method thereof

ActiveCN105729611AGood flame retardant effectLow costDomestic articlesFlat articlesChemistryMedium density fiberboard

The invention relates to a medium density fiberboard, in particular to a Mg / Al-LDHs (Layered Double Hydroxides) medium density fiberboard and a preparation method thereof. The Mg / Al-LDHs medium density fiberboard comprises the following substances in parts by mass: 100 parts of wood fiber, 8-15 parts of Mg / Al-LDHs, 0.01-0.02 part of a coupling agent, 12-15 parts of an adhesive, 0.15-0.2 parts of a curing agent and 1-2 parts of a waterproof agent. The preparation method comprises the following steps: (1) first drying the Mg / Al-LDHs and grinding the Mg / Al-LDHs to 20-50 mu m, then hydrolyzing the coupling agent with a mass percent concentration of 20-30% at room temperature for 25-35 min, next adding the hydrolyzed coupling agent into an 80-90 DEG C aqueous solution of the ground Mg / Al-LDHs, and after a reaction for 0.5-1.5 h, performing suction filtration, washing, drying and grinding; and (2) adding the urea-formaldehyde resin adhesive, in which the curing agent is added, and the modified Mg / Al-LDHs into the wood fiber, and performing paving, pre-pressing forming, hot pressing and cooling to obtain the Mg / Al-LDHs medium density fiberboard. The Mg / Al-LDHs medium density fiberboard provided by the invention is environment-friendly and non-toxic and has no obvious hygroscopicity, and the oxygen index of the Mg / Al-LDHs medium density fiberboard is up to 34%.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

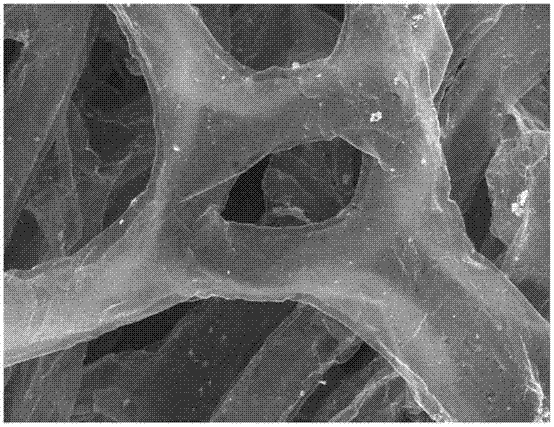

Preparation method of high-strength flexible graphene foam body

The invention relates to a preparation method of a high-strength flexible graphene foam body, and belongs to the technical field of graphene materials. The preparation method comprises the following steps: loading carbon nanoscale toughening agents on the surface of foam metal uniformly, and performing CVD and removing the matrix to obtain the high-strength flexible graphene foam body. The carbon nanoscale toughening agents and graphene generate covalent bond combination to realize in-situ toughening of the graphene foam body, so that the mechanical property of the graphene foam body is improved, and assistance of the polymer in the metal matrix removing and transferring processes is not needed. The method has the characteristics of simple process, convenience in operation, controllable product appearance, suitability for large-scale production, convenience in popularization and application, low production cost and the like. The graphene foam body prepared by the method has excellent mechanical property, has the characteristics of small specific gravity, large specific surface area, high flexibility, high electric conductivity, high heat conductivity and the like, and can be widely applied in the fields of adsorption, electric catalysis, high-sensitivity sensors, energy storage, flexible electronic devices and the like.

Owner:CHONGQING UNIV

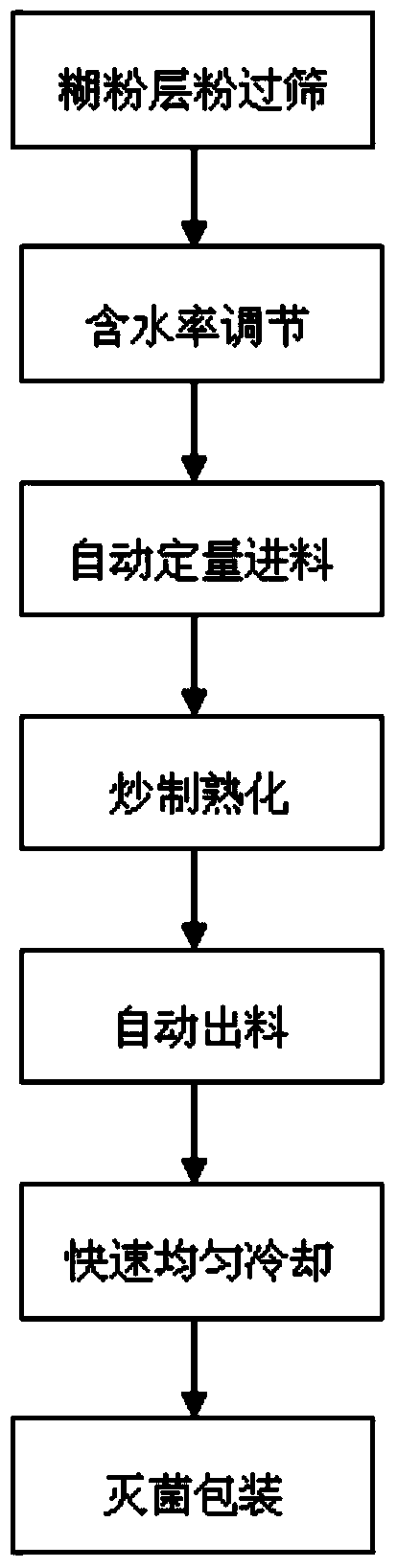

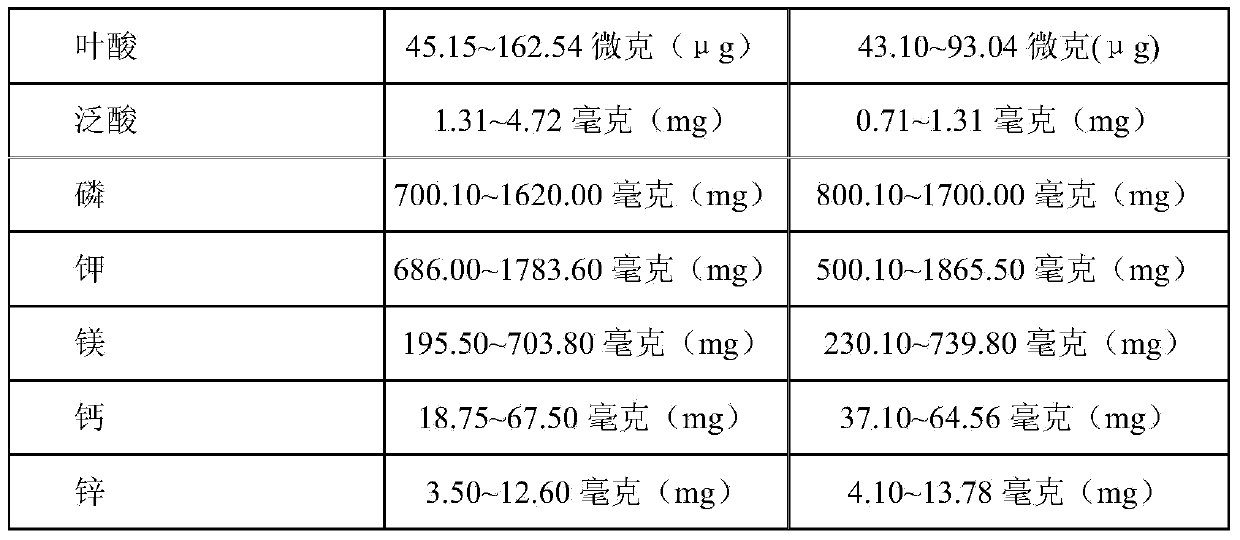

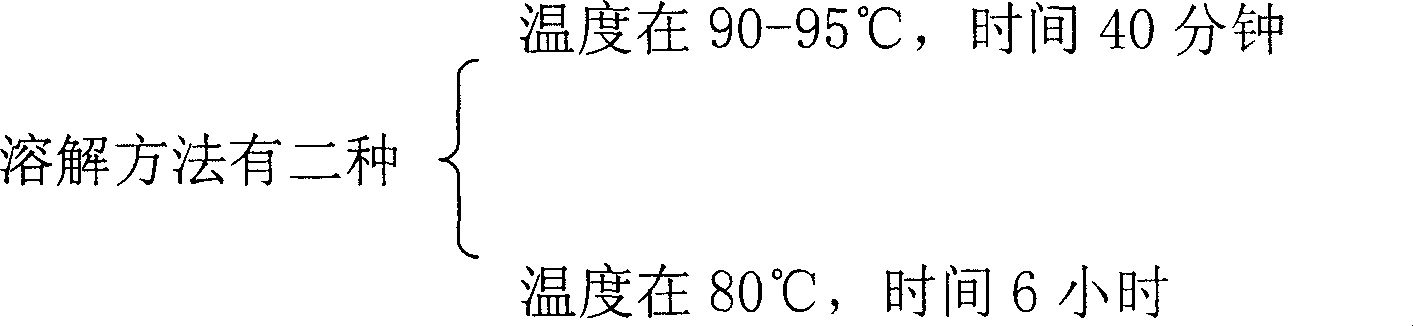

Ripening process for wheat aleurome layer content, and product thereof

The invention discloses a ripening process for wheat aleurome layer content (wheat aleurome layer powder) and a production thereof, and belongs to the food processing field. The process comprises the following steps of screening the wheat aleurome layer content with average particle size smaller than 75 [mu]m and moisture content lower than 16%; feeding materials automatically and quantitatively; roasting while controlling a temperature below 143 DEG C while roasting and a moisture content in a roasting device within 42-76%; discharging the material automatically when a temperature reaches the temperature set by the roasting step; cooling rapidly and uniformly; and sterilizing and packaging. The wheat aleurome layer content roasted powder produced by the process has an excellent taste, is convenient for subsequent processing and treatment, has thick wheat fragrance, and can retain nutritional ingredients of the wheat aleurome layer content to the maximum degree. Meanwhile, physical properties and nutritional characteristics of the product of the wheat aleurome layer content roasted powder prepared by the process are stable; and the wheat aleurome layer content roasted powder prepared by the process has relatively long quality guarantee period and wide applications.

Owner:JIAXING SION RUSSIAN TECH TRANSFORMATION CENT +1

High weather resistant and flame-retardant cable

InactiveCN105504405AImprove toughnessIncrease heat transfer areaRubber insulatorsInsulated cablesNatural rubberButadiene-styrene rubber

The invention discloses a high weather resistant and flame-retardant cable, which comprises a conductor, an insulating layer cladding the conductor, a packing layer cladding the insulating layer, a shielding layer cladding the packing layer, an armor layer cladding the shielding layer and an outer sheath cladding the armor layer. The outer sheath comprises the following raw materials by weight part: 45-48 parts of styrene butadiene rubber, 25-27 parts of chloroprene rubber, 17-20 parts of natural rubber, 10-13 parts of phase change control microcapsule, 0.8-1.2 parts of sulfur powder, 1.6-2.4 parts of an accelerator AA, 2.5-2.8 parts of an accelerator MZ, 8-11 parts of hard clay, 6-9 parts of sepiolite, 6-8 parts of lanthanum oxide, 5-7 parts of mica powder, 2.6-3 parts of a monoalkoxy pyrophosphate type titanate coupling agent, 2.4-2.8 parts of coconut oil, 3-6 parts of naphthenic oil, 4-6 parts of antimony trioxide, 3-5 parts of melamine, 4-6 parts of red phosphorus masterbatch, 5-8 parts of barium stearate, 1.5-2.5 parts of an anti-aging agent H, and 1.3-1.6 parts of an anti-aging agent DFC-34.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

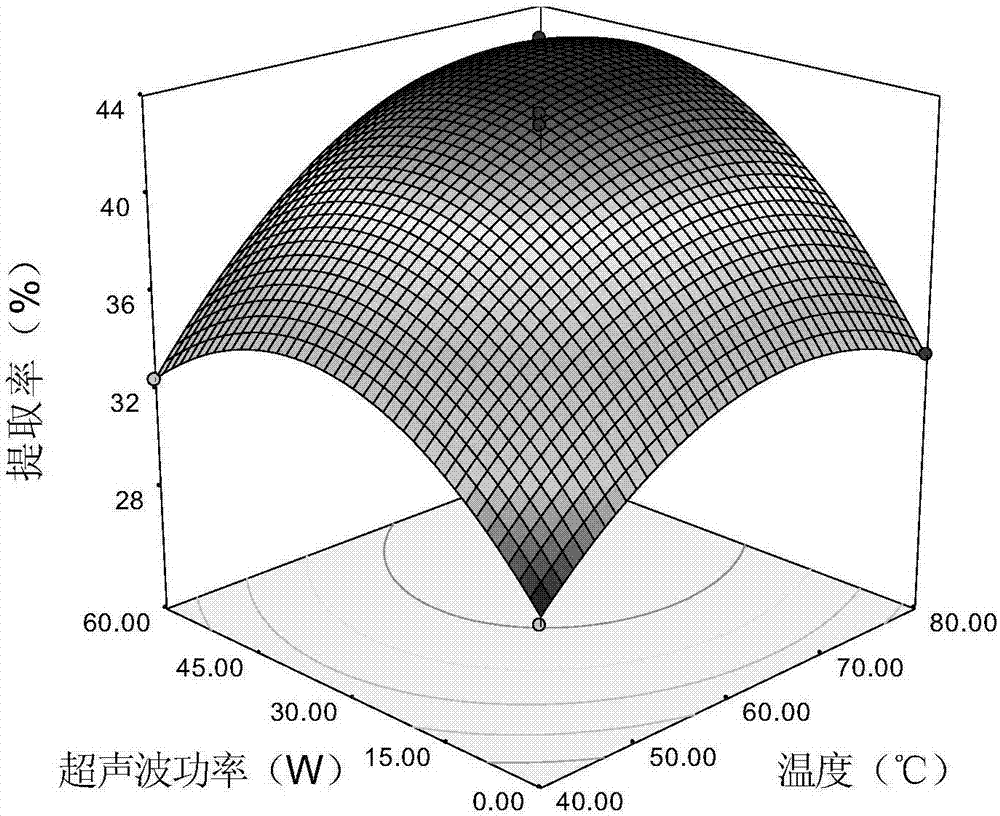

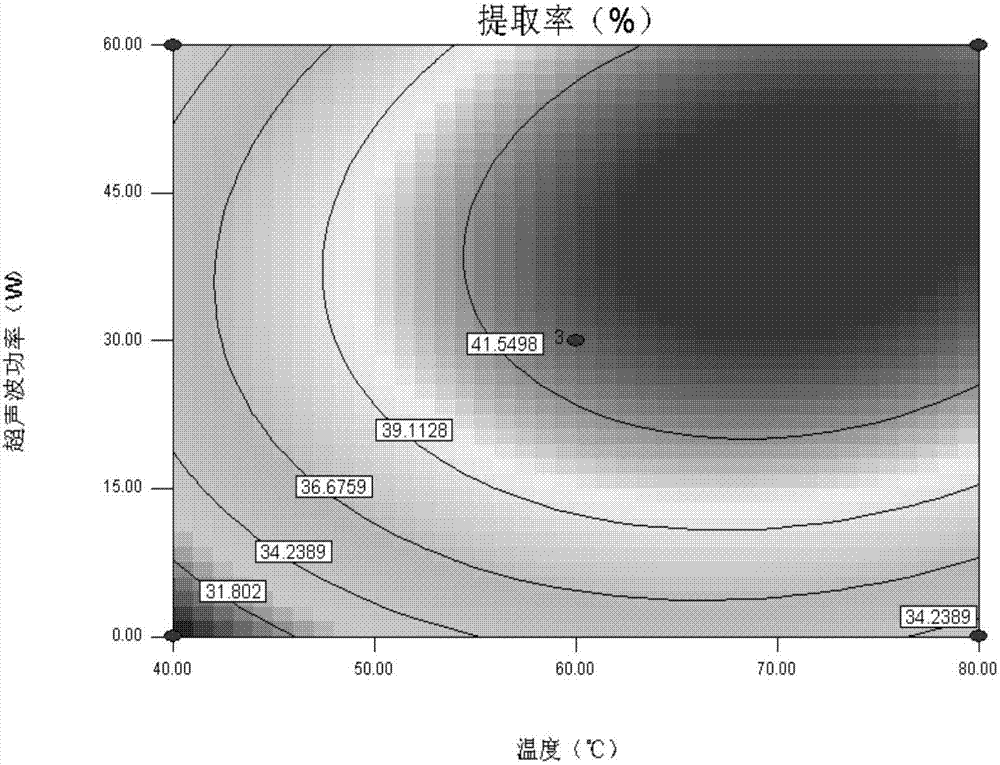

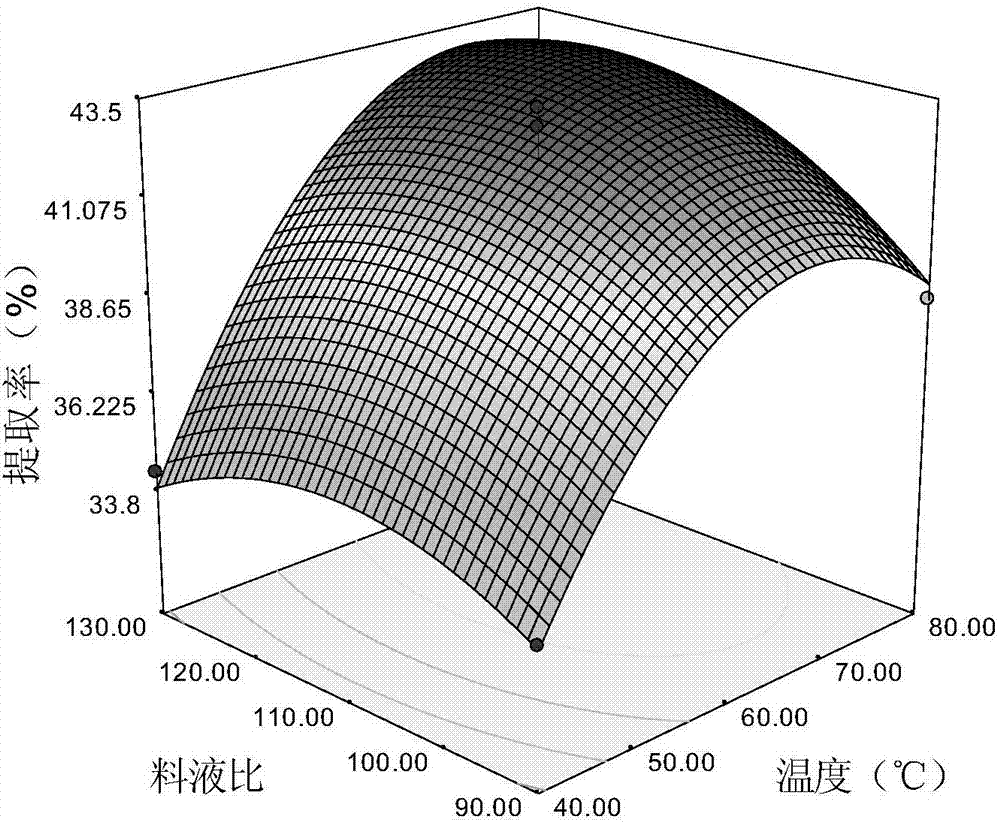

Technology for ultrasonic-assisted extraction of konjac glucomannan through response surface method optimization

InactiveCN107298724AOptimizing Extraction ParametersPhysical and chemical properties do not cause damageUltrasonic assistedChemical property

The invention relates to the technical field of plant ingredient extraction, and particularly relates to a technology for ultrasonic-assisted extraction of konjac glucomannan through response surface method optimization. The technology comprises the following steps of (1) soaking konjac into a bactericide and drying and crushing to obtain konjac powder; (2) carrying out degreasing treatment on the konjac powder; (3) removing free revertose from the degreased konjac powder; (4) carrying out ultrasonic-assisted extraction of konjac glucomannan; (5) determining the content and the extraction rate of the konjac glucomannan; and (6) selecting three factors, such as a temperature, a solid-liquid rate and ultrasonic power for response surface experiment design on the basis of a single-factor experiment to obtain the optimal extraction process parameters: the ultrasonic wave power is 43.67w, the temperature is 72.69 DEG C, the solid-liquid rate is 1:120.3g / mL and the prediction extraction rate is 44.38%. The extraction parameters are effectively optimized, the physical and chemical properties of the konjac glucomannan are not destroyed, and the technology is high in extraction efficiency, simple in operation and easy to produce.

Owner:BAISE UNIV

Cement particle board, and preparation process and application thereof

InactiveCN110181645AGood surface appearanceImprove finishing effectWood treatment detailsThermal wood treatmentFiberWood shavings

The invention discloses a cement particle board, and a preparation process and application thereof. The cement particle board comprises a core layer and surface layers on two sides of the core layer;and wood particles in the surface layers and the core layer are added after being first pretreated by (a) separately immersing the corresponding wood particles in alkali liquor to be degraded, takingout the degraded wood particles and thoroughly draining the wood particles; and (b) drying the drained wood particles until the water content is close to the fiber saturation point and then taking outthe wood particles, spraying water on the surfaces of the wood particles, performing high-temperature pretreatment, cooling to 103 DEG C, and drying until the water content is 4%-12%. The wood particles used in the cement particle board disclosed by the application need to be preheated at first, the alkali treatment can reduce the moisture absorption performance of the cement particle board, andthe size stability is improved; and the high-temperature thermal treatment can enable the density of the wood particles and the cement particle board to be reduced, the mechanical strength is improved, the permeability of the cement particle board is improved, the penetration and flow expansion of an adhesive are facilitated, and the direct facing ability, the peel strength and the surface adhesion strength of the cement particle board are greatly improved.

Owner:TREEZO NEW MATERIAL TECH GRP CO LTD

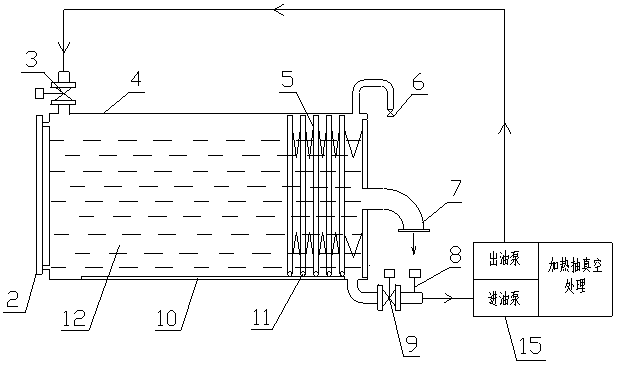

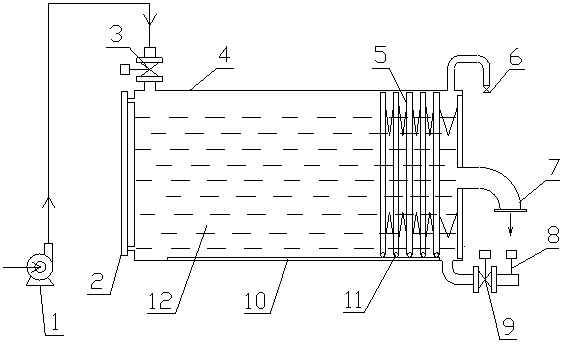

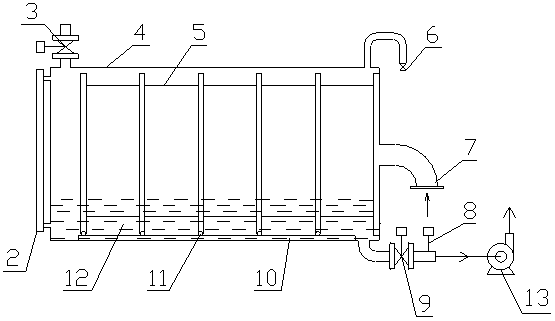

Intelligent dynamic sealed liquid storage tank equipped with metal ripple compensator and use method of intelligent dynamic sealed liquid storage tank

ActiveCN103515061AFor long-term storageSafe storageTransformers/inductances coolingSolenoid valveControl engineering

The invention relates to an intelligent dynamic sealed liquid storage tank equipped with a metal ripple compensator and a use method of the intelligent dynamic sealed liquid storage tank. A liquid inlet solenoid valve is arranged at the liquid inlet of the liquid storage tank; a discharge valve is arranged at the discharge opening; a liquid outlet solenoid valve and an on-line moisture detection instrument are sequentially arranged at the liquid outlet of the liquid storage tank in the liquid outlet direction; the metal ripple compensator is mounted inside the liquid storage tank; wheels are mounted at the bottom of the metal ripple compensator; a guide rail matched with the wheels are mounted in the liquid storage tank; a breathing tube communicated with the metal ripple compensator is arranged at one end of the liquid storage tank; an electric contact liquid level meter is arranged at the other end of the liquid storage tank; the liquid inlet solenoid valve, the liquid outlet solenoid valve, the on-line moisture detection instrument and the electric contact liquid level meter are electrically connected with a control module. According to the invention, the cavity of the metal ripple compensator is communicated with the outer atmosphere through the breathing tube; the breathing action of the metal ripple compensator can perform the functions of compensating and balancing volume change in the liquid storage tank. caused by change in liquid level, so as to achieve dynamic sealing.

Owner:STATE GRID CORP OF CHINA +3

Carrying device of throwing type fire-fighting grenade

ActiveCN103131097AGuaranteed physical and chemical propertiesThe fire was successfully extinguishedAmmunition projectilesFire rescuePolyvinyl chlorideParathion

The invention relates to a carrying device of a throwing type fire-fighting grenade. The carrying device comprises, by weight, 100 parts of polyvinychlorid resin, 4 parts of dioctyl-phthalate, 2parts of MBS enhancement, 2.5 parts of stearic acid. A parathion method of the carrying device includes the following steps of adding the dioctyl-phthalate to the polyvinychlorid resin at the temperature of 38EDG C-42DEG C, evenly stirring and enabling the dioctyl-phthalate and the polyvinychlorid resin to coexist for 10 minutes, adding the MBS enhancement to mixture of the polyvinychlorid resin and the dioctyl-phthalate, evenly stirring and enabling the MBS enhancement and the mixture of the polyvinychlorid resin and the dioctyl-phthalate to coexist for 10 minutes, adding the stearic acid to mixture of the MBS enhancement, the polyvinychlorid resin and the dioctyl-phthalate, evenly stirring the stearic acid and the mixture of the MBS enhancement, the polyvinychlorid resin and the dioctyl-phthalate to coexist for 10 minutes, putting mixture of the MBS enhancement, the polyvinychlorid resin, the dioctyl-phthalate and the stearic acid in an extruder, heating the mixture to reach from 160 DEG C to 180 DEG C, plastify the mixture for one hour, and forming the carrying device in a granule-cutting mode. The carrying device of the throwing type fire-fighting grenade has the advantages of being abundant in number, favorable for taking of the throwing type fire-fighting grenade, easy to use and the like.

Owner:江苏及时雨消防器材有限公司

Technology for preparing natural dye by means of plant flower pedals

InactiveCN105153742ACreate pollutionMeet the requirements of safe and green productionNatural dyesBiotechnologyHazardous substance

The invention discloses a technology for preparing natural dye by means of plant flower pedals. The technology for preparing the natural dye by means of the plant flower pedals is characterized by comprising the following steps of one-step drying, one-step smashing, mixing, extracting, filtering, distilling and two-step drying. The technology for preparing the natural dye by means of the plant flower pedals has the advantages that the raw materials and solvent used in the technology do not contain hazardous substances and can not cause pollution to the environment, the solvent can be reused through recycling, and the requirements of safe and green production are met. By means of smashing for two times, plant cells can be destroyed to the maximum extent, pigment compositions in the cells can be dissolved rapidly to obtain extract liquor with high concentration, the extraction rate is greatly increased, and raw material waste is reduced. The raw materials needed by preparing the dye adopt the plant flower pedals which are common and single and rich in color, the plant flower pedals can be obtained through large-area planting or by purchasing from growers, the sources are wide, and the situation that production can not be conducted due to lack of the raw materials can be avoided.

Owner:ZHANGJIAGANG TIANLONG KITTING GARMENTS WEAVING

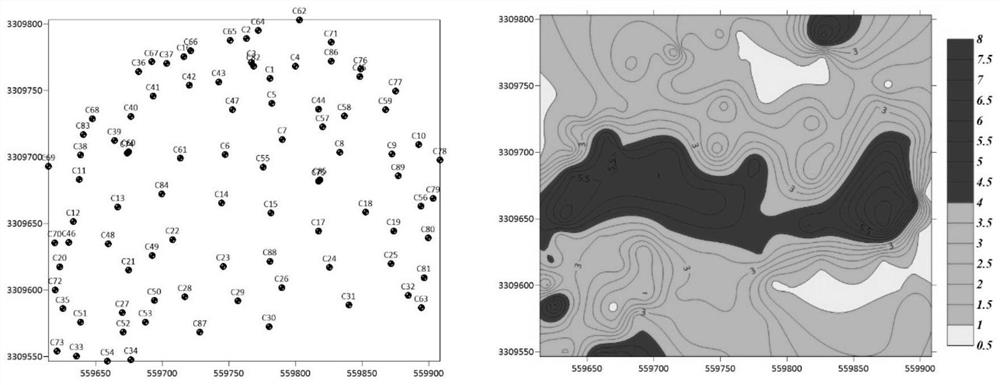

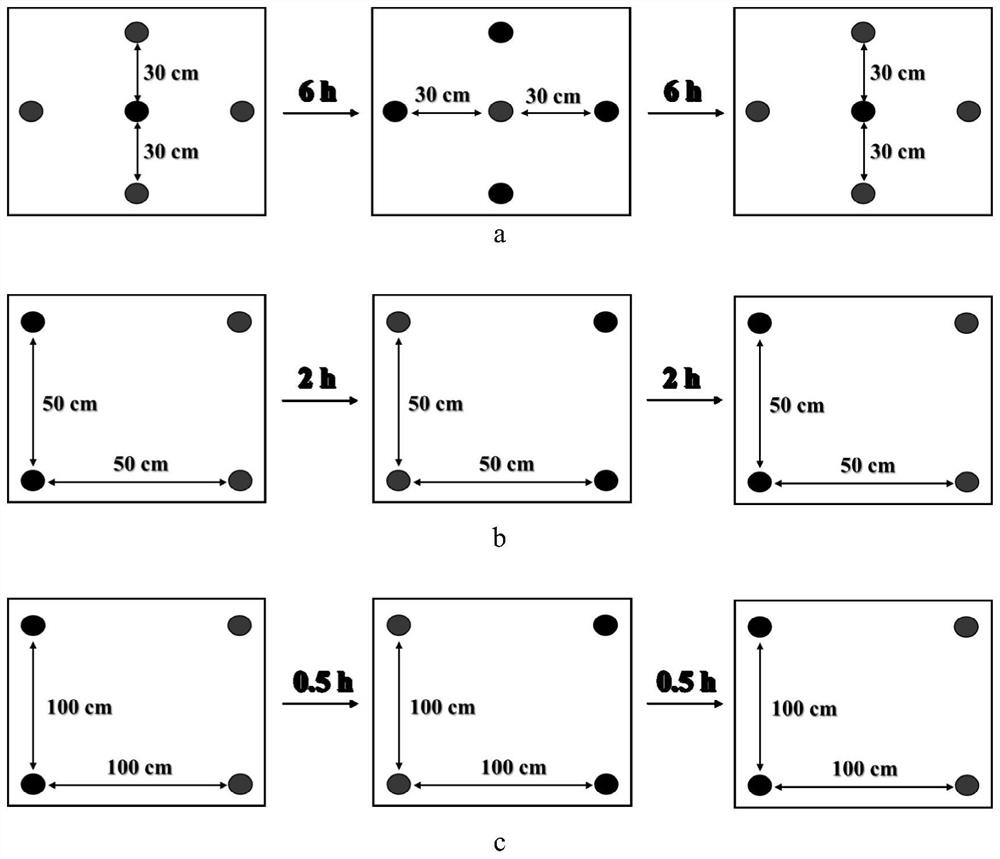

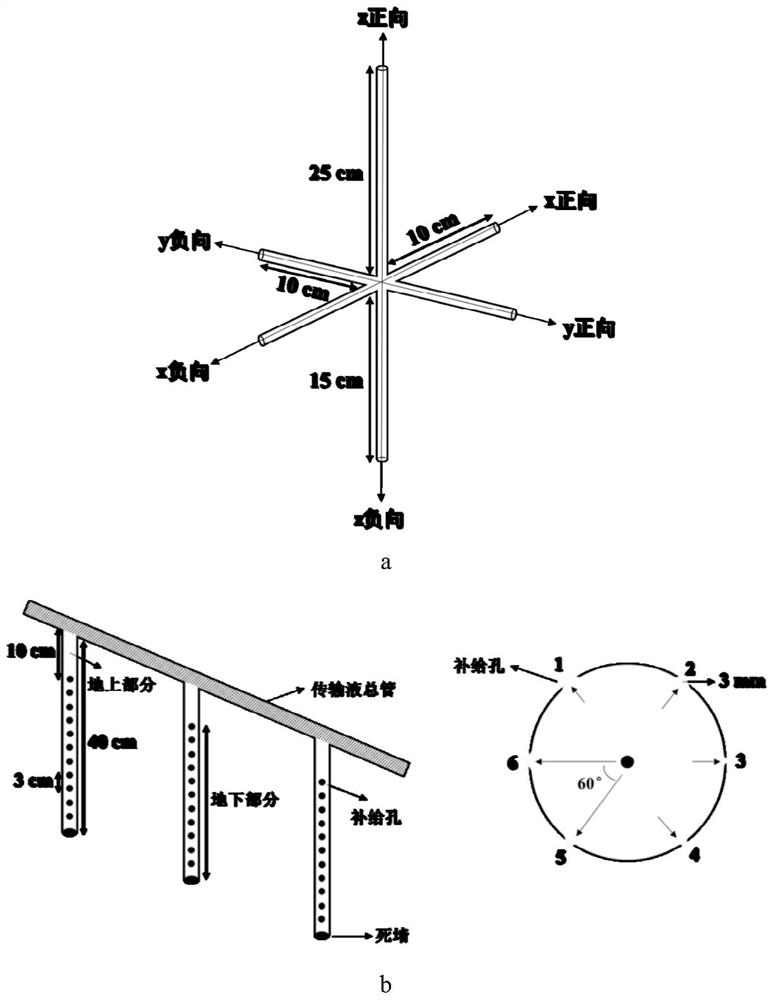

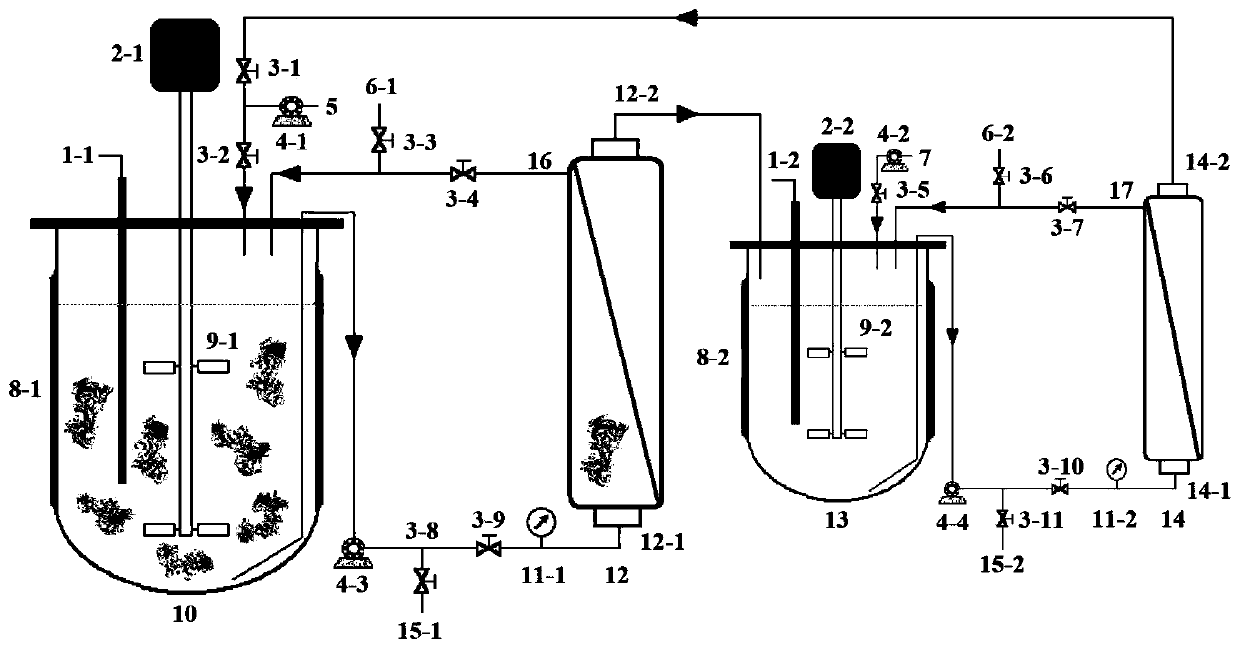

Electric-microbial combined in-situ remediation method for contaminated soil

ActiveCN112588814ANotable Targeted Governance FeaturesImplementing a Uniformity Restoration ProcessContaminated soil reclamationChemistryContaminated soils

The invention belongs to the technical field of electric-microbial in-situ remediation of petroleum hydrocarbon contaminated soil, and particularly relates to an in-situ electric-microbial combined remediation technology based on petroleum hydrocarbon concentration difference in a contaminated area and application of the in-situ electric-microbial combined remediation technology. Investigation andpollution range analysis are conducted on a polluted site, high-concentration petroleum hydrocarbon polluted soil, medium-concentration petroleum hydrocarbon polluted soil and low-concentration petroleum hydrocarbon polluted soil are divided, and then an electric-microbial combined remediation material composed of an anode densification electrode set, an electric-microbial synergistic electrode set and a biological enhancement electrode set and an application mode are designed for soil of different pollution degrees. Technical parameters including the voltage intensity, a pole inversion period, an electrode spacing, an acid liquid supply amount and the like are designed in a matched manner, and power output of a variable frequency pump, an acid liquid storage tank and a bacterial liquid storage tank is utilized, so that high-concentration petroleum hydrocarbon contaminated soil is removed through a chemical oxidation effect, the medium-concentration petroleum hydrocarbon contaminatedsoil is degraded through a synergistic effect of chemical oxidation and microbial metabolism, and the low-concentration petroleum hydrocarbon contaminated soil is removed through enhanced microbial metabolism. The invention constructs a set of complete electric-microbial combined remediation technical system for in-situ soil with different pollution degrees.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Production process of high-nickel and high-chromium heat-resistant and abrasion-resistant vehicle chassis parts

ActiveCN108251738AGuaranteed physical and chemical propertiesAvoid crackingFurnace typesProcess efficiency improvementFerrosiliconUltimate tensile strength

The invention discloses a production process of high-nickel and high-chromium heat-resistant and abrasion-resistant vehicle chassis parts and relates to the field of vehicle part machining. The production process comprises the following steps that raw materials are prepared, specifically, the raw materials comprise scrap returns and steel scraps with the weight ratio being 1:1, and molten liquid is obtained by melting the scrap returns and the steel scraps; the raw materials are discharged out of a furnace to a steel ladle, ferrochromium, ferronickel, ferromolybdenum, ferrosilicon and ferrotungsten are sequentially added, then an alloy line and a carburant are added into the steel ladle through a spheroidizing device, and pouring liquid is formed again in an inoculation mod; deoxidized aluminum is added into the pouring liquid, the pouring liquid is poured into a mold, and an inoculation agent is added in the pouring process; an exhaust hood and a sprue cup are removed within 3-5 min after pouring is completed, a tank is opened in another 20-24 h, the parts are pushed aside, sand shakeout treatment is conducted, and castings are obtained; and the castings are heated to form blanks,the blanks are subjected to deep processing, and accordingly the finished vehicle chassis parts are obtained.

Owner:河南淮海精诚工业科技有限公司

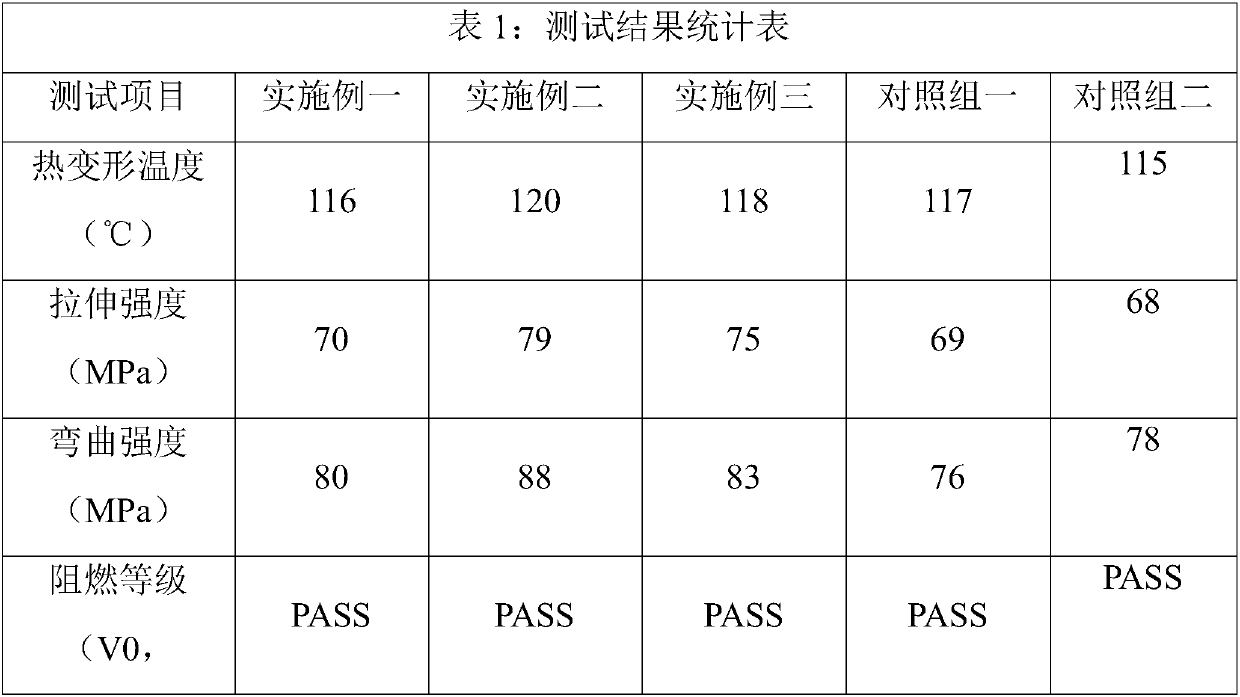

Wearproof flame retardant and antibacterial PC material and preparation method thereof

The invention relates to the field of plastic raw materials, in particular to a wearproof flame retardant and antibacterial PC material and a preparation method thereof. The wearproof flame retardantand antibacterial PC material is composed of the following components by mass percentage: 65-85% of PC; 5-25% of PTFE; 5-8% of a toughening agent; 4-8% of a flame retardant; 1-5% of a compatilizer; 1.0-3.0% of a nano antibacterial agent; and 0.2-0.5% of an antioxidant. The wearproof flame retardant and antibacterial PC material provided by the invention has the advantages of good wear resistance,long service life, good flame retardance, low potential safety hazard and good antibacterial properties, is beneficial to user health, and is environment-friendly and non-toxic.

Owner:东莞市优特美工程塑料有限公司

Fire-retardant medium density fiberboard and preparation method thereof

ActiveCN105690536AReduce the impact of physical and chemical propertiesGuaranteed physical and chemical propertiesDomestic articlesFlat articlesFiberFiltration

The invention relates to medium density fiberboards, in particular to a fire-retardant medium density fiberboard and a preparation method thereof. The fire-retardant medium density fiberboard is prepared from, by mass, 100 parts of wood fibers, 8-15 parts of magnalium nanometer layered double hydroxide, 0.01-0.02 part of a coupling agent, 12-15 parts of a modified MUF adhesive and 1-2 parts of a waterproof agent. The preparation method comprises the steps that 1, the magnalium nanometer layered double hydroxide is firstly dried and finely ground to range from 20 micrometers to 50 micrometers, then the coupling agent with the mass percent concentration ranging from 20% to 30% is hydrolyzed for 25 min-35 min at room temperature and then added to a water solution with the temperature ranging from 80 DEG C to 90 DEG C of the finely-ground magnalium nanometer layered double hydroxide, and after reacting is carried out for 0.5 h-1.5 h, suction filtration, washing, drying and grinding are carried out; and 2, the modified MUF adhesive and modified Mg / Al-LDHs are added to the wood fibers, and the medium density fiberboard is obtained through pavement, pre-pressing forming, hot pressing and cooling. The provided medium density fiberboard is environment-friendly, non-toxic and free of obvious moisture absorption, and the oxygen index reaches up to 34%.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Oxidation process of preparing wool keratin solution

InactiveCN1986561AGuaranteed physical and chemical propertiesImprove solubilityPeptide preparation methodsUrea hydrogen peroxideWool

The present invention discloses oxidation process of preparing wool keratin solution, and the preparation process can maintaining the physical and chemical performance of wool and has raised solubility and lowered wool dissolving temperature. The preparation process includes the following steps: washing and stoving wool; preparing wool dissolving solution through adding urea into H2O2 to obtain adduct, mixing the adduct with distilled water and adding anionic surfactant via stirring to obtain transparent liquid as the wool dissolving solution; mixing wool dissolving solution and wool in the weight ratio of 5-20 to 1 via stirring, heating to 65-85 deg.c and maintaining for 4-6 hr to obtain yellowish translucent liquid and filtering to eliminate insoluble impurity and obtain wool keratin solution. The process is simple and low in cost.

Owner:ZHEJIANG HAPPY CHEM

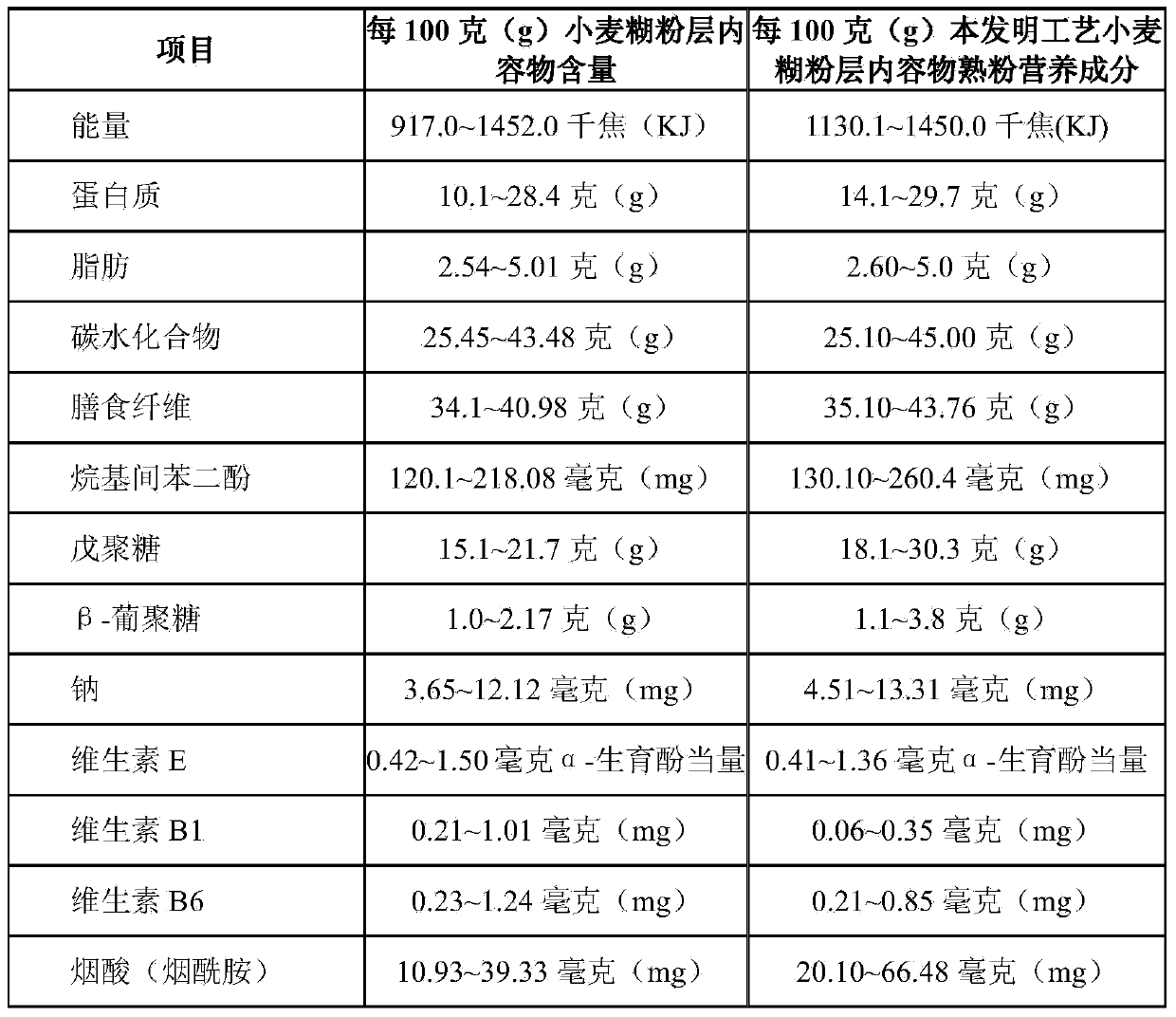

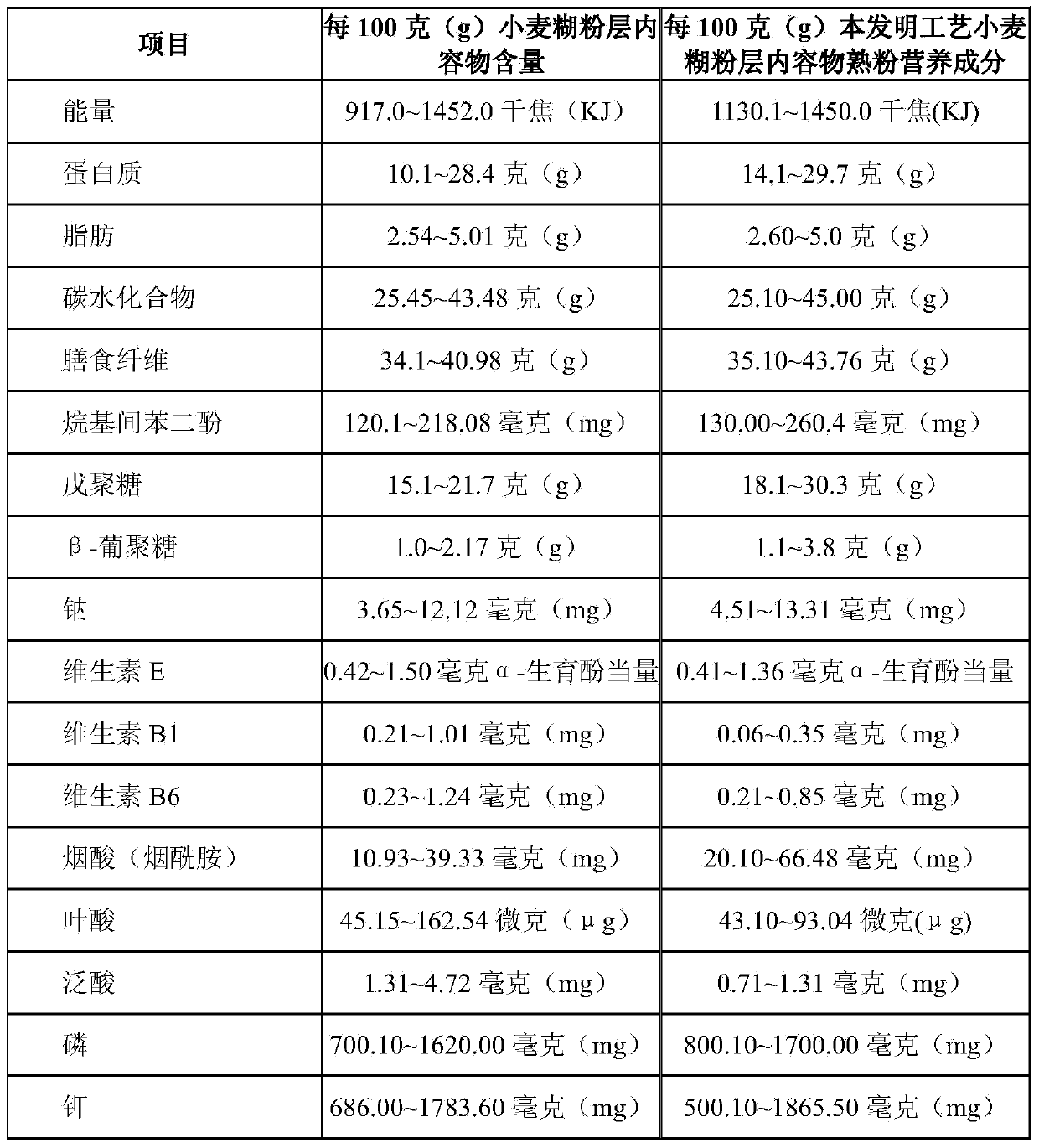

Wheat aleurone layer content cooked powder product and application thereof

InactiveCN104171837AHigh purityGreat tasteFood ingredient functionsFood preparationGranularityBULK ACTIVE INGREDIENT

The invention discloses a wheat aleurone layer content (namely wheat aleurone layer powder) cooked product and application thereof. The wheat aleurone layer content cooked product is a powder product which has a moisture content of less than 8% and is obtained by cooking a wheat aleurone layer content, the average granularity of the wheat aleurone layer content cooked product is less than 75 microns, and every 100g of the wheat aleurone layer content cooked product contains not lower than 35g of dietary fiber, not lower than 130mg of alkylresorcinol, not lower than 800mg of phosphorus and not lower than 18g of pentosan. The wheat aleurone layer content cooked product is formed through the steps of screening of the wheat aleurone layer content, full-automatic quantitative feeding, stir-frying, automatic discharging, quick cooling, metal detection, sterilization packing and the like. The wheat aleurone layer content cooked product can be used as a fluid beverage additive, puffed food, a health-care dietary fiber product, a functional health-care product or a nutritional health-care product rich in wheat physiological active ingredient with high nutritional value.

Owner:SHANDONG ZHISHIFANG FOOD TECH

Technology for extracting pigment from plant petals for preparing plant dyes

InactiveCN105153744ACreate pollutionMeet the requirements of safe and green productionNatural dyesHigh concentrationDistillation

The invention discloses a technology for extracting pigment from plant petals for preparing plant dyes. The technology is characterized by comprising the following steps of 1, mixing, 2, first-step extraction, 3, first-step filtering, 4, second-step extraction, 5, second-step filtering, 6, distillation, 7, drying and 8, smashing. The technology has the advantages that adopted raw materials and solvents contain no hazardous substances and will not pollute the environment, the solvents can be recycled and repeatedly utilized, and the requirement for safe and environment-friendly production is met. Due to the fact that two-time extraction and filtering are performed, pigment components in plants can be dissolved to the maximum extent, a high-concentration extract is obtained, the extraction rate is greatly increased, and raw material waste is reduced. The raw materials needed for preparing the dyes are common, single-color and rich plant petals, the plant petals can be obtained through large-area planting and can also be obtained by purchasing from farmer households, sources are wide, and the phenomenon that production cannot be performed due to raw material lack is avoided.

Owner:ZHANGJIAGANG TIANLONG KITTING GARMENTS WEAVING

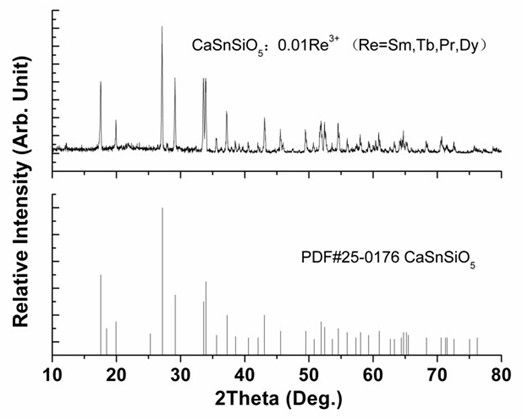

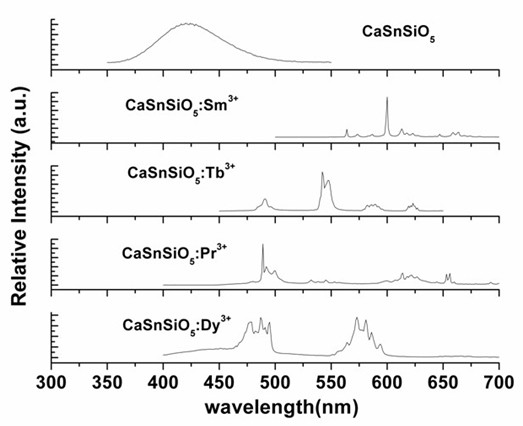

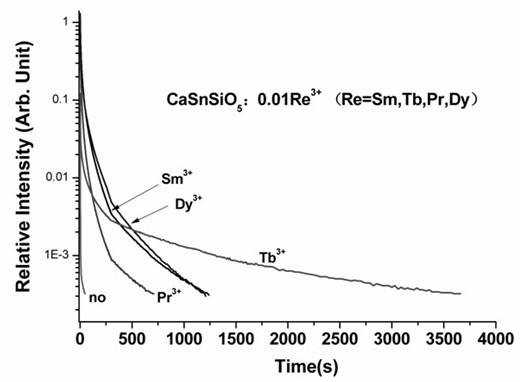

Multicolour long-afterglow luminescent material for single matrix and preparation method thereof

InactiveCN102660271AGuaranteed physical and chemical propertiesSolve the problem of different wavelength ranges of excitation lightLuminescent compositionsSilicic acidRare earth ions

The invention provides a multicolour long-afterglow luminescent material for a single matrix and a preparation method thereof. The multicolour long-afterglow luminescent material for the single matrix comprises the chemical constitution of Ca1-xOSnO2SiO2:xRe<3+>, wherein CaSnSiO5 is the matrix, Re<3+> is a rare earth ion which serves as an activator ion, x is more than or equal to 0 and is less than or equal to 0.02, and R is any one of Pr, Sm, Tb and Dy. Calcium carbonate, silicic acid, tin oxide and rare earth oxide serve as raw materials; and after all components are weighed and evenly mixed at the chemical dose ratio of a target product, the mixture is calcined for 3-6h at the temperature of 1000-1380DEG C and is naturally cooled to the room temperature to obtain the multicolour long-afterglow luminescent material. The long-afterglow emision of blue light, red light, green light and white light can be respectively realized in the single matrix, and the multicolour long-afterglow luminescent material continuously lights above the luminescent luminance (0.32mcd / m<2>) which can be distinguished by human eyes. The preparation method is simple and is easy to operate.

Owner:KUNMING UNIV OF SCI & TECH

Environment-friendly non-toxic paint

InactiveCN102876208AGuaranteed physical and chemical propertiesPolyester coatingsPentaerythritolZincate

The invention relates to an environment-friendly non-toxic paint. The paint comprises the following components: 200-300 parts of unsaturated oleic acid, 150-200 parts of pentaerythritol, 100-200 parts of glycerol, 100-150 parts of abietic diacid, 100-200 parts of trimethylolpropane, 0.5-1.5 parts of cobalt caprylate and 600-1200 parts of solvent, wherein the solvent is turpentine; and 0.5-0.8 parts of calcium zincate are further added. According to the environment-friendly non-toxic paint disclosed by the invention, due to the components, either macromolecular film forming materials or assistants and solvent, are all derived from non-toxic organic or inorganic matters, the paint has the same physiochemical performance as the existing short oil alkyd paint, and is pollution-free and does not harm the environment and human bodies.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

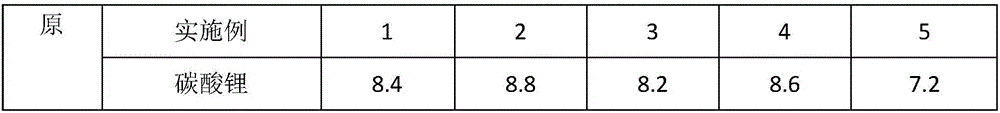

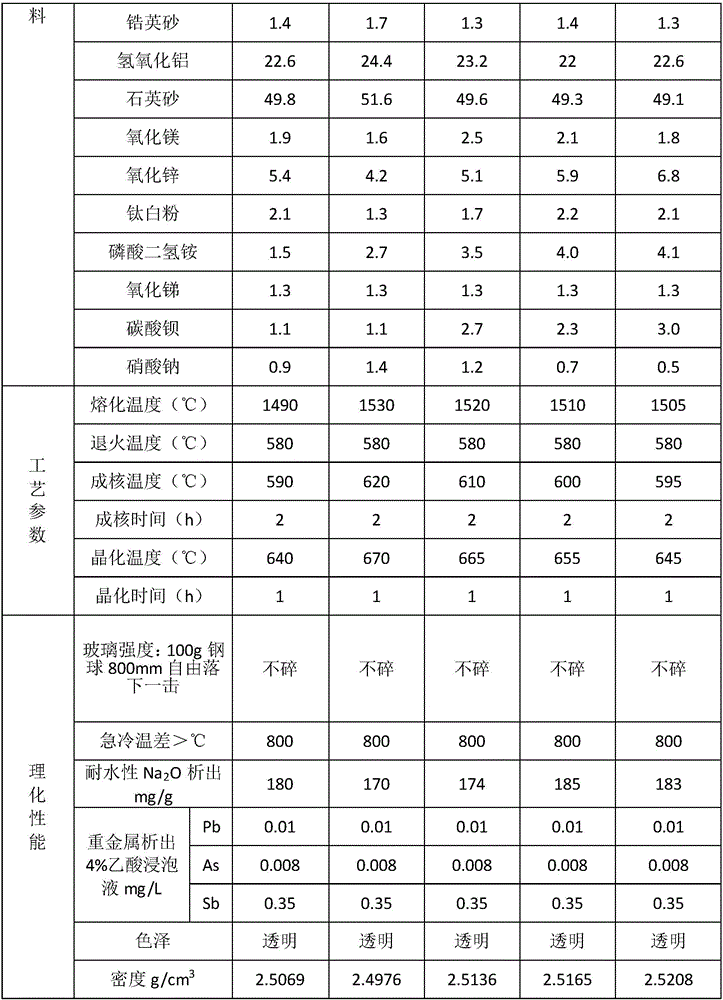

Preparation method for heat-resistant microcrystalline glass capable of being molten at low temperature

InactiveCN106565097AGuaranteed physical and chemical propertiesBreak through the production bottleneckGlass furnace apparatusAluminium hydroxideZircon

The invention discloses a preparation method for heat-resistant microcrystalline glass capable of being molten at a low temperature. The heat-resistant microcrystalline glass is prepared from the following raw materials in percentage by weight: 7.2%-8.8% of lithium carbonate, 22%-24.4% of aluminium hydroxide, 49-51.6% of quartz sand, 1.6%-2.5% of magnesium oxide, 4.2%-6.8% of zinc oxide, 1.3%-2.2% of titanium dioxide, 1.5%-4% of ammonium dihydrogen phosphate, 1.3% of antimony oxide, 1.1%-2.7% of barium carbonate, 0.5%-1.4% of sodium nitrate and 1.2%-1.8% of zircon sand. In order to solve the technical problems that Li2O-AL2O-SiO2 heat-resistant microcrystalline glass has the characteristics of a high melting temperature, great viscosity of molten glass and short material characteristics, the invention provides a method capable of reducing a melting temperature of LAS base glass on the premise of not changing main physical and chemical properties of glass.

Owner:JIANGSU JIELONG GLASSWARE TECH

Method for preparing purple sweet potato pigment microcapsules

InactiveCN101817998BGuaranteed physical and chemical propertiesGood biocompatibilityNatural dyesMicroballoon preparationGelatinBotany

The invention discloses a method for preparing purple sweet potato pigment microcapsules. The method comprises the following steps of: mixing purple sweet potato pigment serving as a core material and sodium alginate and gelatin serving as a wall material in a buffer system with pH value of 2.0 to 4.0 and uniformly stirring the mixture; adding the mixture into the coagulator calcium chloride; andcuring, filtering and drying the mixture to obtain the microcapsules. The method has no toxic effect on a human body, ensures the physicochemical property of the core material and has biocompatibility with the core material by selecting proper encapsulating wall material. The preparation method of the invention has simple operation, improves the stability of the purple sweet potato pigment, enhances the coloring effect, expands the application range, effectively overcomes the defect existing in the use of the purple sweet potato pigment and has great economic value.

Owner:SOUTH CHINA NORMAL UNIVERSITY

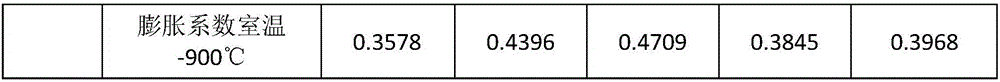

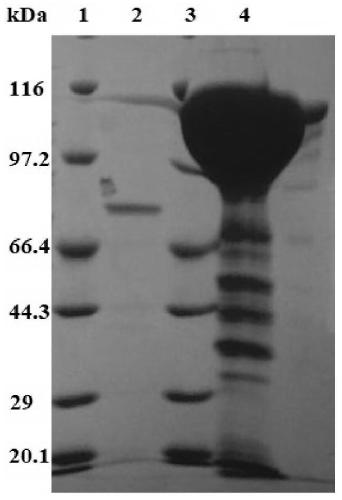

Chondroitinase ABC producing recombinant yeast strain and structuring and applying methods thereof

ActiveCN109988723AMeet health careFulfil requirementsBioreactor/fermenter combinationsFungiPichia pastorisBiotechnology

The invention discloses a chondroitinase ABC producing recombinant yeast strain and application thereof and belongs to the technical field of bioengineering. According to the chondroitinase ABC producing recombinant yeast strain, chondroitinase ABC from Proteus vulgaris ATCC33420 is subjected to heterogeneous expression, and with pPIC9K carriers and through induction of methanol, secretory expression of the chondroitinase ABC in pichia pastoris GS115 can be achieve; by means of a designed chondroitinase ABC-enzymatic membrane reactor, efficient and continuous production of small-molecular chondroitin sulfate can be achieved, the chondroitinase ABC can be recycled and reutilized, and the production cost can be greatly reduced. By taking food-grade yeast as host strains, the chondroitinase ABC producing recombinant yeast strain can be safe and reliable, provide effective references for industrialized and green production of small-molecular chondroitin sulfate A, B and C, and meanwhile, save energy, reduce emission and achieve significant economic and social benefits.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

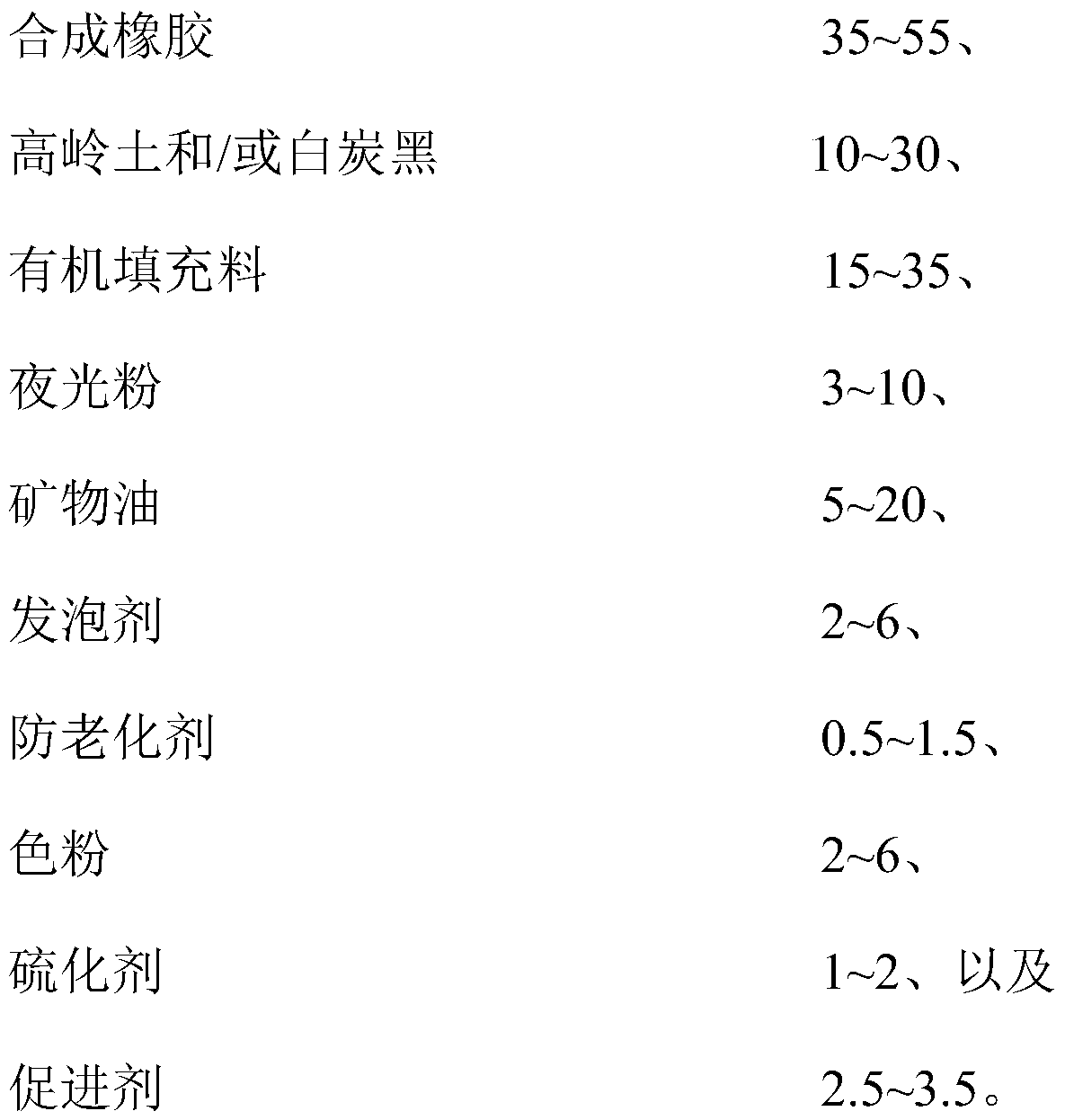

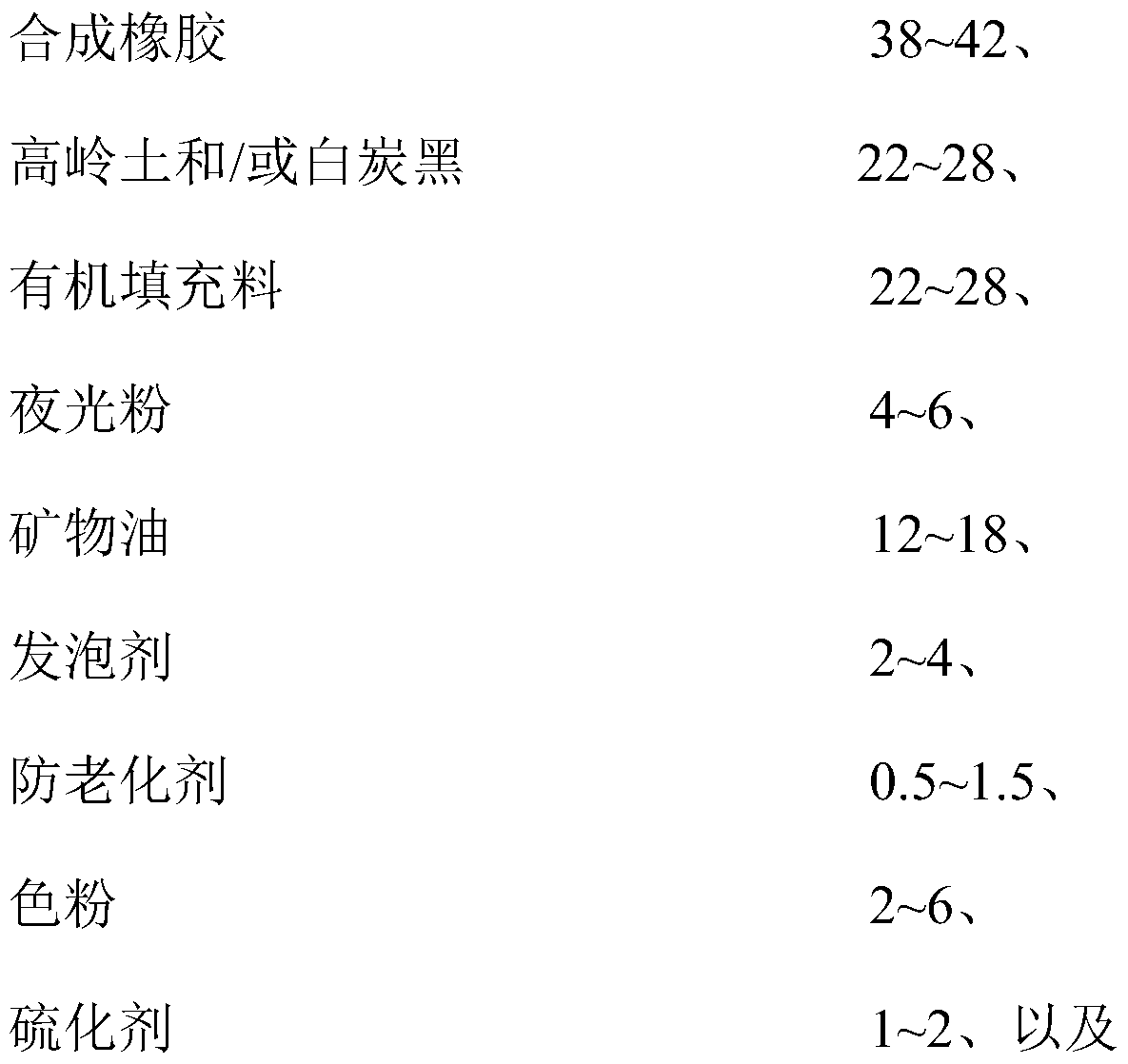

Luminous prefabricated sports surface layer, luminous prefabricated sports paving material, and preparation method of paving material

ActiveCN110467763AGood light storage during the dayGuaranteed physical and chemical propertiesGround pavingsTraffic signalsFoaming agentLight energy

The invention relates to a luminous prefabricated sports surface layer, a luminous prefabricated sports paving material, and a preparation method of the paving material. The luminous prefabricated sports surface layer is prepared from, by weight, 35-55 parts of synthetic rubber, 10-30 parts of kaolin and / or white carbon black, 15-35 parts of an organic filler, 3-10 parts of luminous powder, 5-20 parts of mineral oil, 2-6 parts of a foaming agent, 0.5-1.5 parts of an anti-aging agent, 2-6 parts of a toner, 1-2 parts of a vulcanizing agent and 2.5-3.5 parts of an accelerator. The prefabricated sports surface layer meets the requirements of relevant national standards for the physical and chemical properties of prefabricated sports paving materials, has the functions of absorbing and reserving light energy during the day and emitting light at night, and is convenient for sports people to perform night sports.

Owner:广州同欣体育股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com