Multicolour long-afterglow luminescent material for single matrix and preparation method thereof

A long afterglow luminescence and matrix technology, applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems such as the luminous intensity and afterglow time of red long afterglow materials cannot meet the requirements, and achieve the effect of easy operation and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

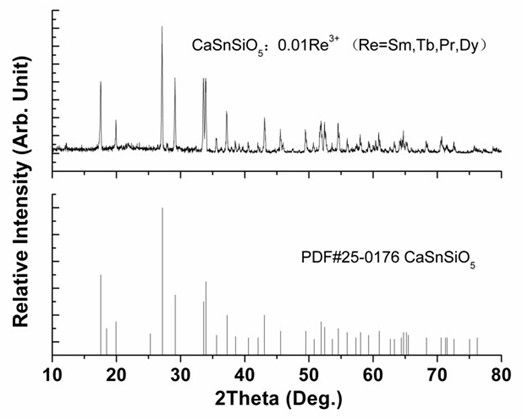

[0014] CaCO 3 0.5000 g, silicic acid H 2 SiO 3 0.3905 g, tin oxide SnO 2 0.7536 g as the raw material, according to the stoichiometric ratio of the target product (Ca ion: Sn ion: Si ion = 1: 1: 1), weigh each component and mix evenly, then calcined at 1380 ° C for 4 hours and then naturally cooled to room temperature , that is, the multicolor long afterglow luminescent material is prepared, and its chemical composition is: CaOSnO 2 SiO 2 .

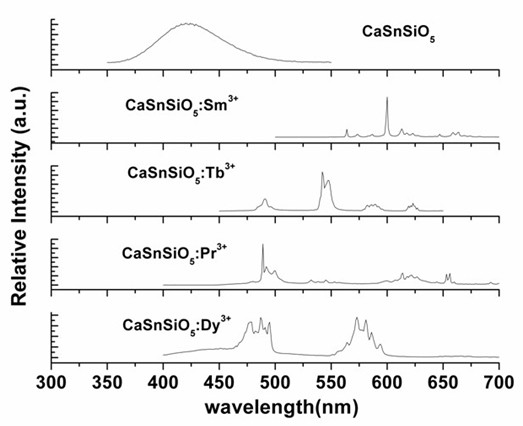

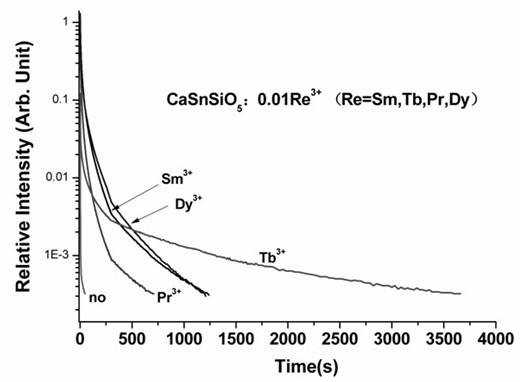

[0015] The appearance of the material is light white, and it is identified as CaSnSiO by XRD 5 Phase. After being irradiated by sunlight or ultraviolet rays, it shows a blue afterglow glow in the dark, and the material can distinguish the luminous brightness of the human eye (0.32mcd / m 2 ) above can also emit light for more than 3 minutes. Spectroscopic tests were performed on the example material with an emission wavelength at 420nm.

Embodiment 2

[0017] CaCO 3 0.495 g, silicic acid H 2 SiO 3 0.3905 g, tin oxide SnO 2 0.7536 g, samarium oxide Sm 2 o 3 0.00872 grams as the raw material, according to the stoichiometric ratio of the target product (Ca ions: Sn ions: Si ions: Re ions = 0.99: 1: 1: 0.01) Weigh the components and mix them uniformly, then calcinate at 1200°C for 6h After naturally cooling to room temperature, the multicolor long afterglow luminescent material is produced, and its chemical composition is: Ca 0.99 OSo 2 SiO 2 ︰0.01Sm 3+ .

[0018] The appearance of the material is white, and the XRD test results show that it is CaSnSiO 5 Phase. After being irradiated by sunlight or ultraviolet rays, it will show an orange-red afterglow in the dark, and the material can distinguish the brightness of the human eye (0.32mcd / m 2 ) above can also emit light for more than 20 minutes ( image 3 ). Spectral testing is carried out on the example material, its emission wavelength is located at 600nm ( figu...

Embodiment 3

[0020] CaCO 3 0.495 g, silicic acid H 2 SiO 3 0.3905 g, tin oxide SnO 2 0.7536 g, terbium oxide Tb 4 o 7 0.00935 g as the raw material, according to the stoichiometric ratio of the target product (Ca ion: Sn ion: Si ion: Re ion = 0.99: 1: 1: 0.01), weigh each component and mix them evenly, then calcinate at 1000 ° C for 3 hours After naturally cooling to room temperature, the multicolor long afterglow luminescent material is produced, and its chemical composition is: Ca 0.99 OSo 2 SiO 2 : 0.01Tb 3+ .

[0021] The appearance of the material is light white, and the XRD test results show that it is CaSnSiO 5 Phase. After being irradiated by sunlight or ultraviolet rays, it presents a green afterglow glow in the dark, and the luminance of the material can be distinguished by the human eye (0.32mcd / m 2 ) above can also emit light for more than 1 hour. Spectroscopic tests were performed on the example material with an emission wavelength at 542nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com