Wearproof flame retardant and antibacterial PC material and preparation method thereof

A technology of flame retardant and antibacterial agent, which is applied in the field of wear-resistant, flame-retardant and antibacterial PC materials and its preparation, can solve the problems of non-flame retardant properties of PC materials, poor wear resistance of electronic appliances, and low hardness of PC materials, and achieves a high performance. Beneficial to user health, prolonging service life and improving antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

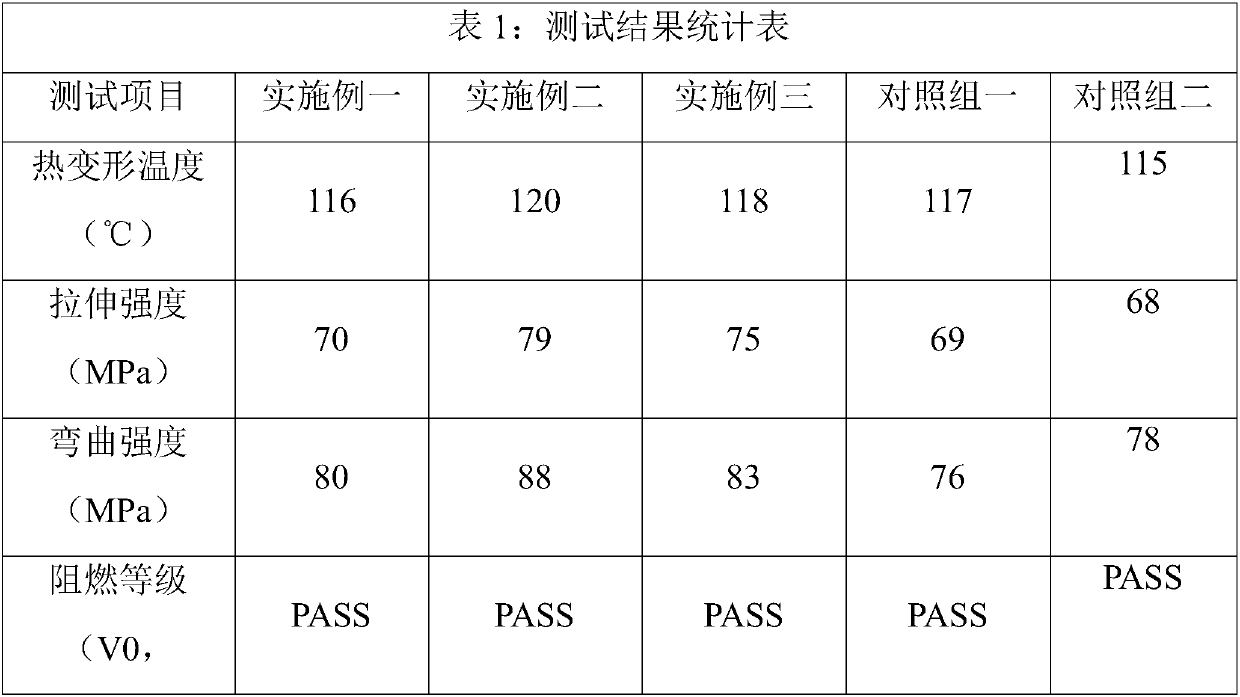

Embodiment 1

[0027] Wear-resistant, flame-retardant and antibacterial PC material is composed of the following components by mass percentage: PC 80%; PTFE 5%; toughening agent 6%; flame retardant 6%; compatibilizer 1%; Oxygen 0.5%.

Embodiment 2

[0029]Wear-resistant, flame-retardant and antibacterial PC material is composed of the following components by mass percentage: PC 70%; PTFE 15%; toughening agent 6%; flame retardant 4%; compatibilizer 3%; Oxygen 0.5%.

Embodiment 3

[0031] Wear-resistant, flame-retardant and antibacterial PC material is composed of the following components by mass percentage: PC 60%; PTFE 25%; toughening agent 4%; flame retardant 4%; compatibilizer 5%; Oxygen 0.5%.

[0032] control group one

[0033] The wear-resistant, flame-retardant and antibacterial PC material is composed of the following components by mass percentage: 85% PC; 4% toughening agent; 9% flame retardant; 1.5% nano antibacterial agent; 0.5% antioxidant.

[0034] Control group two

[0035] The wear-resistant and flame-retardant PC material is composed of the following components by mass percentage: 85% PC; 5% toughening agent; 9% flame retardant; 1.0% antioxidant.

[0036] Above each embodiment, PC is bisphenol A type polycarbonate, PTFE is polytetrafluoroethylene micropowder, toughening agent is methacrylate-acrylic acid ester copolymer, and flame retardant is sulfonate flame retardant, corresponding The compatibilizer is maleic anhydride grafted ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com