Patents

Literature

108results about How to "Improve injection molding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polypropylene-base resin composition and products of injection molding thereof

Owner:SUMITOMO CHEM CO LTD +1

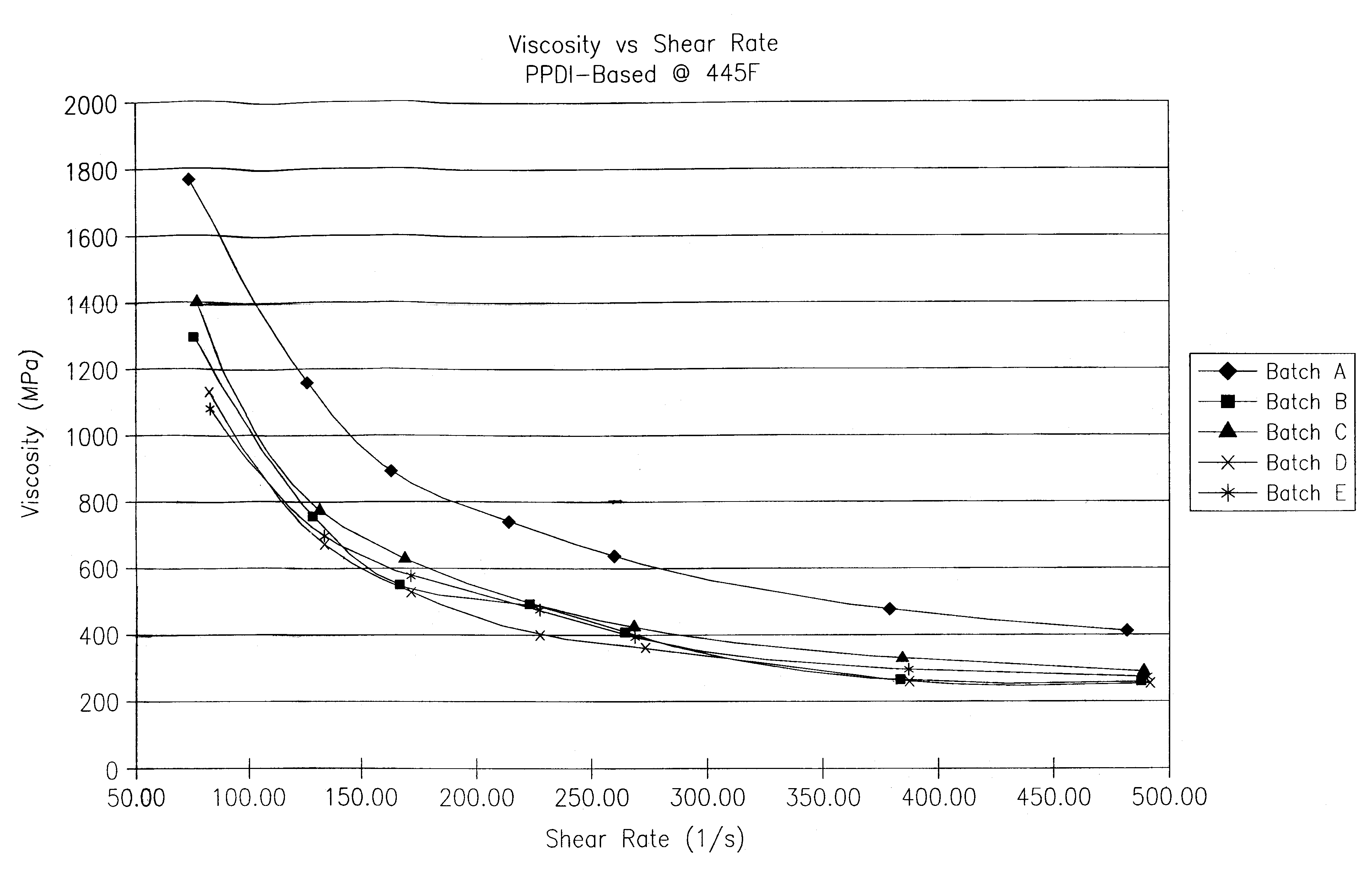

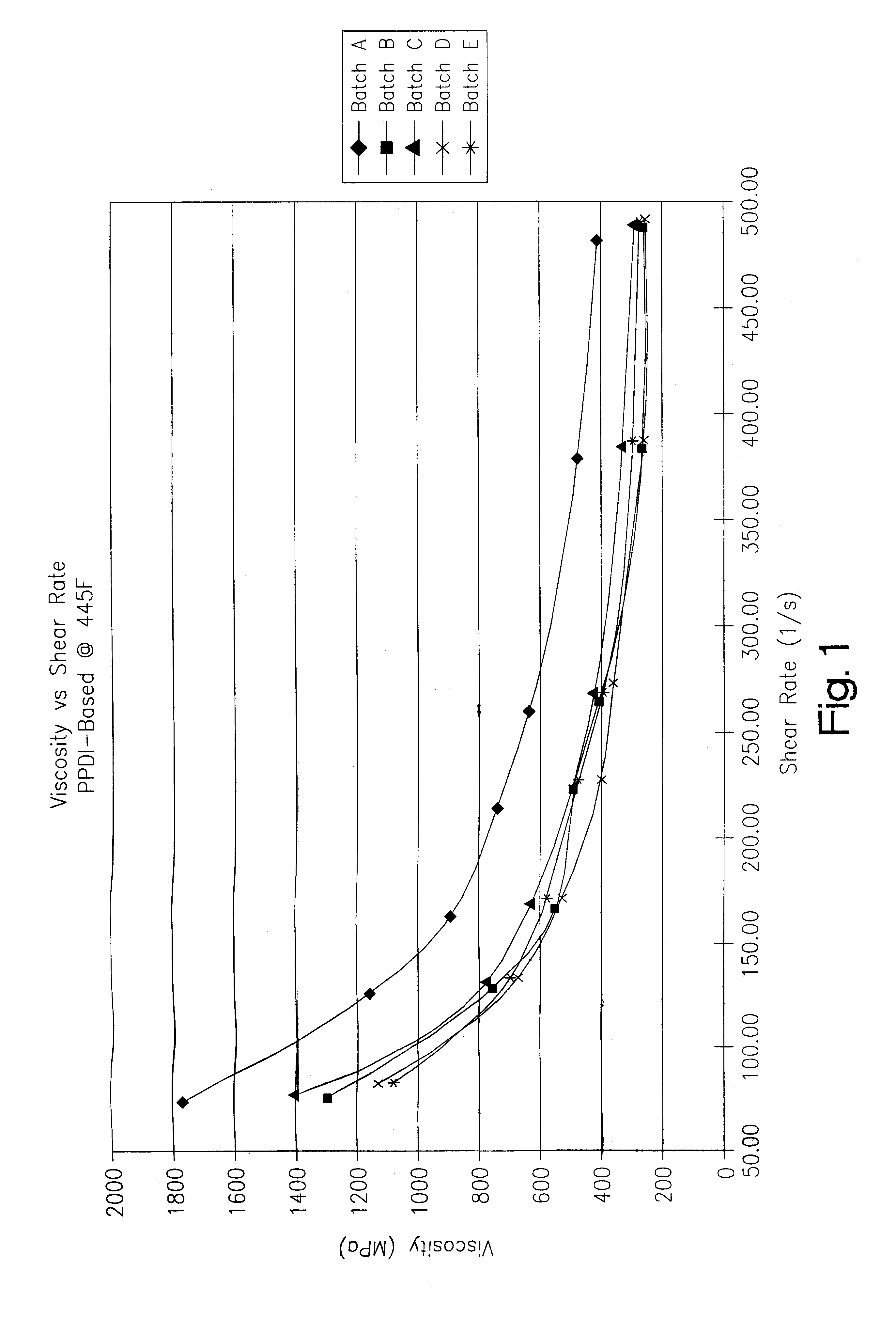

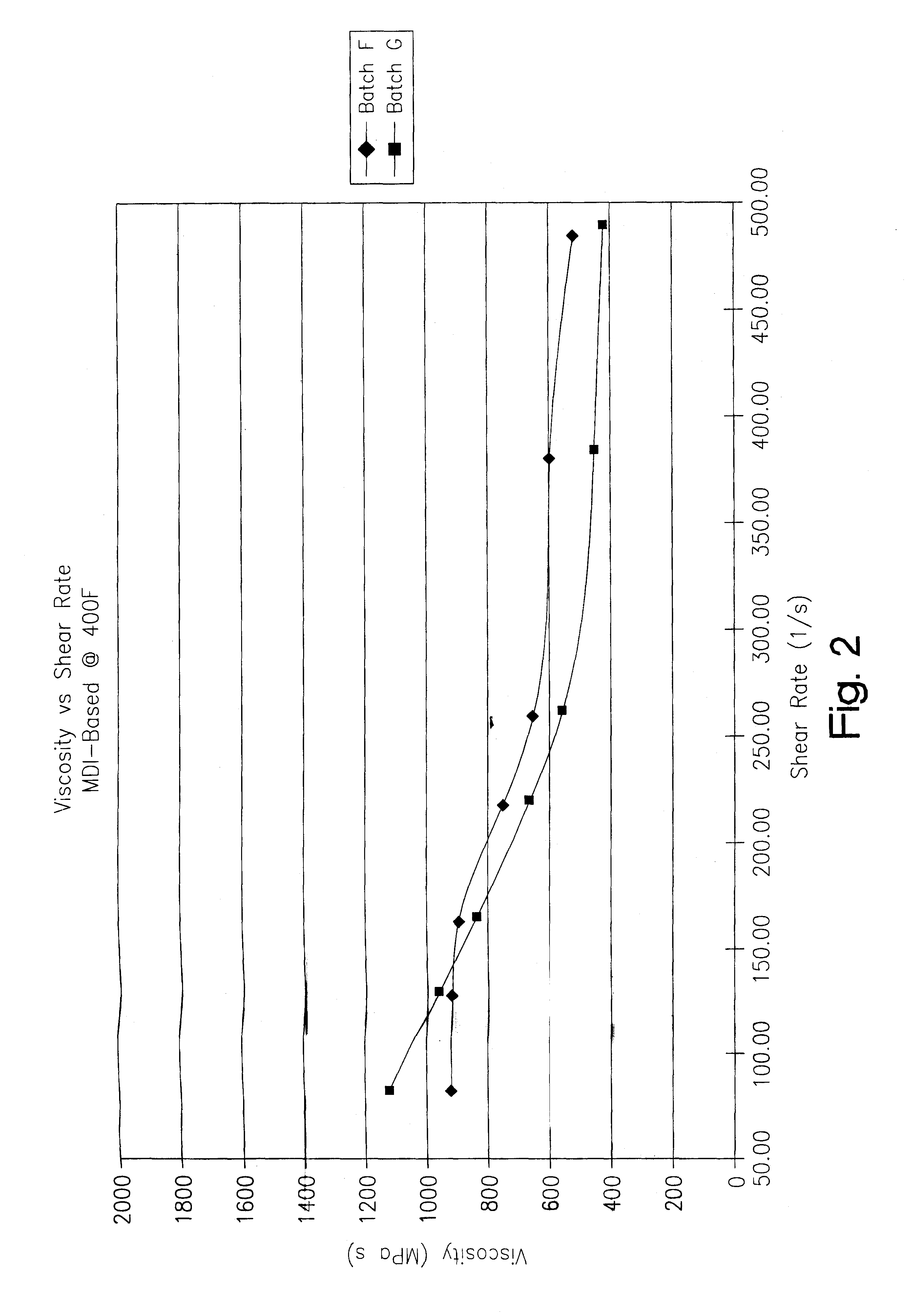

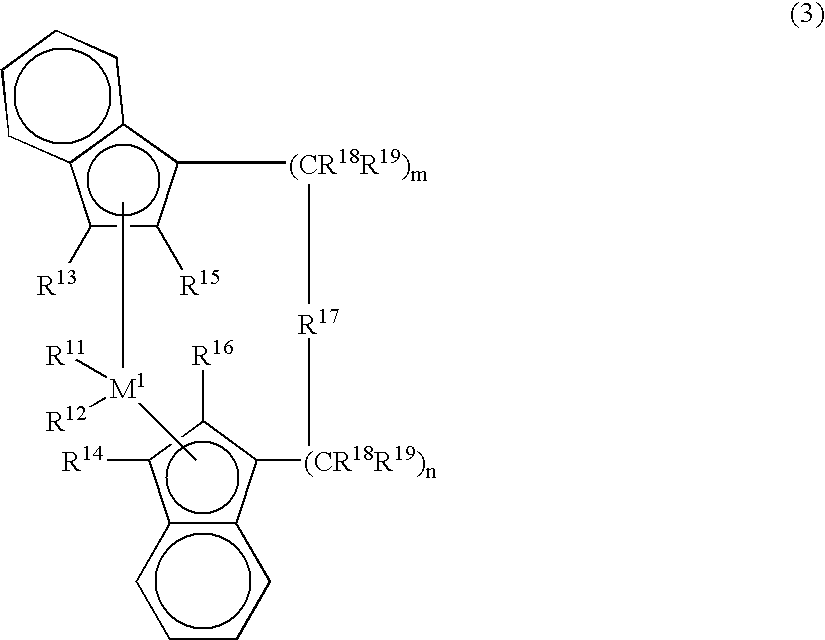

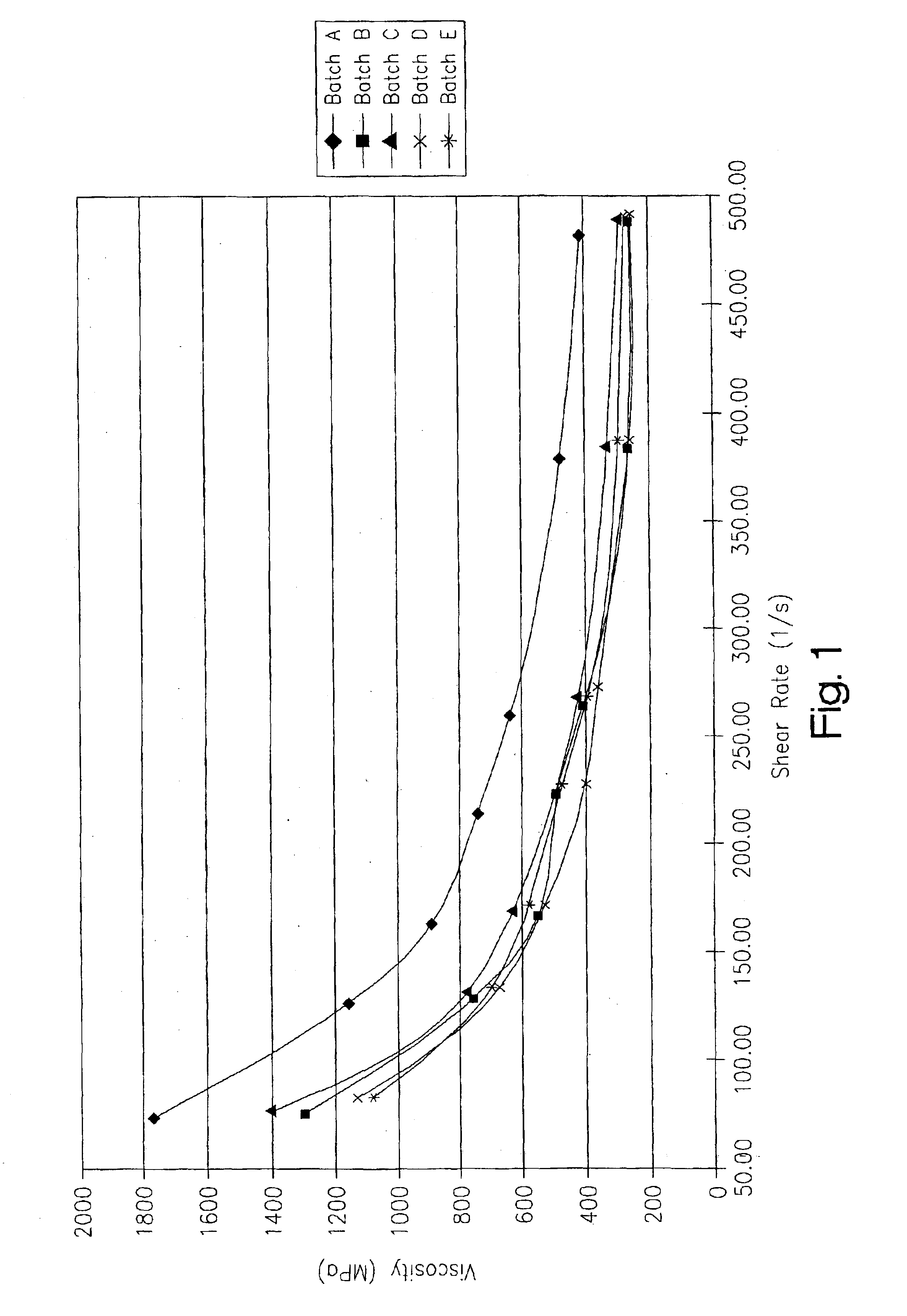

Injection-moldable thermoplastic polyurethane elastomer

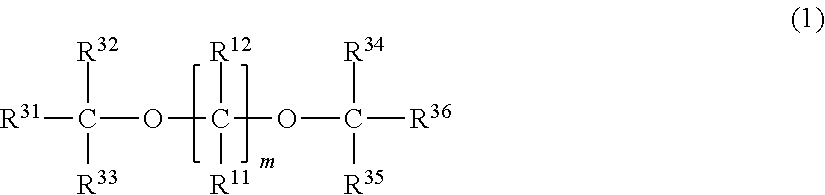

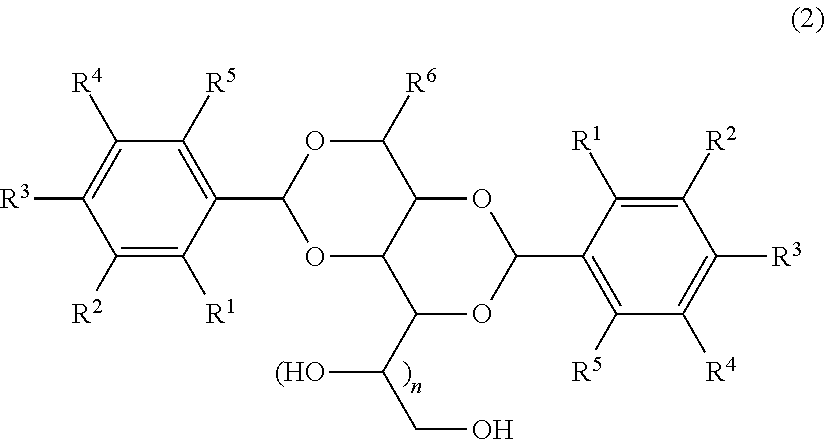

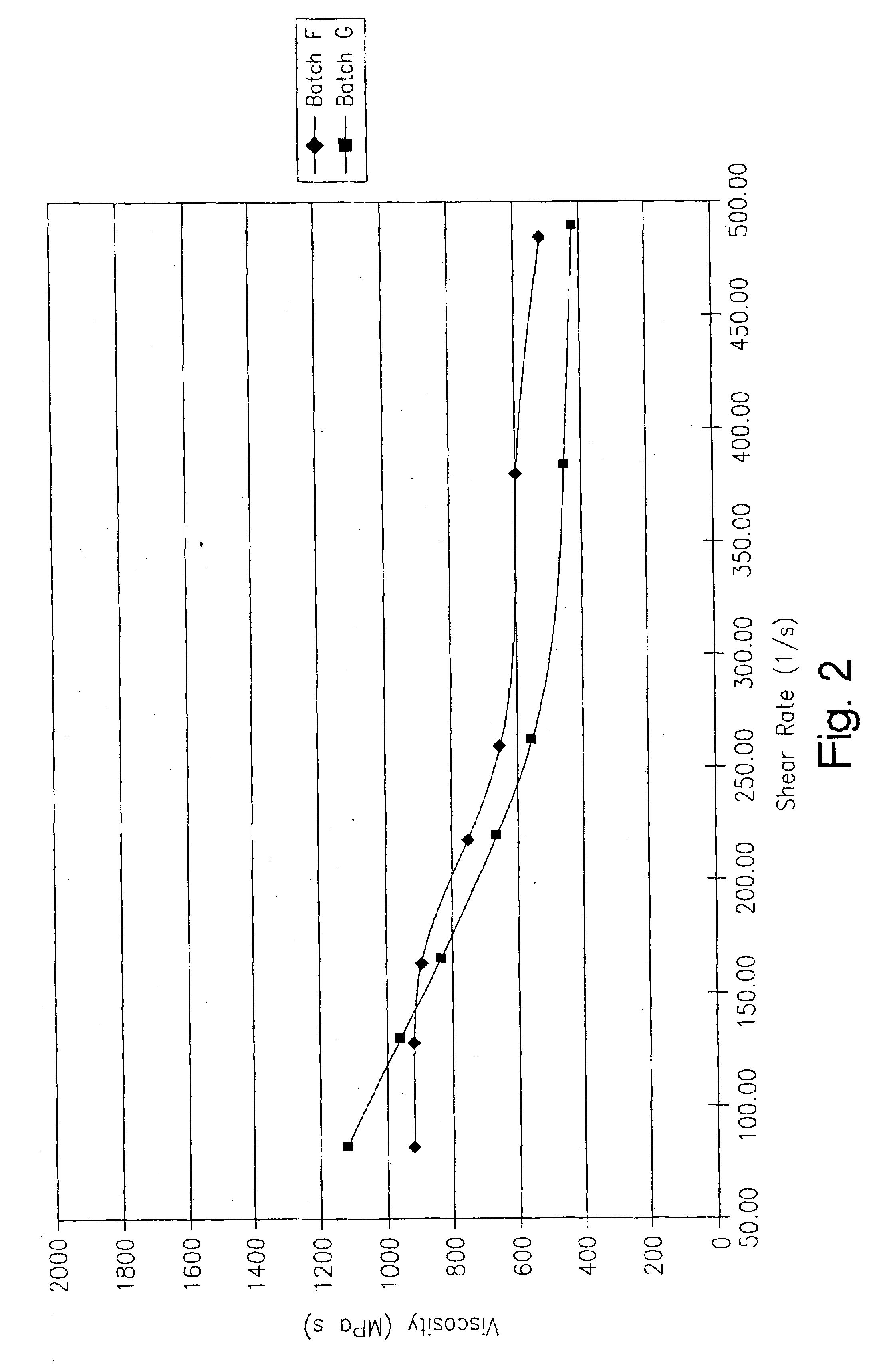

InactiveUS6521164B1Reduces intermolecular hydrogen bondingPromote sportsCoatingsThermoplastic polyurethaneDiol

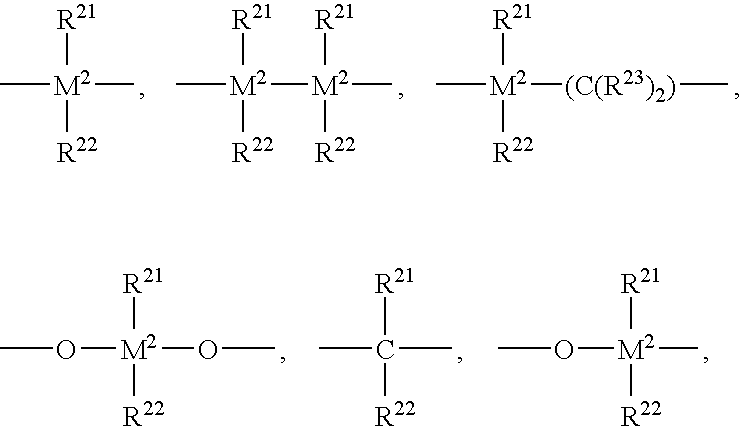

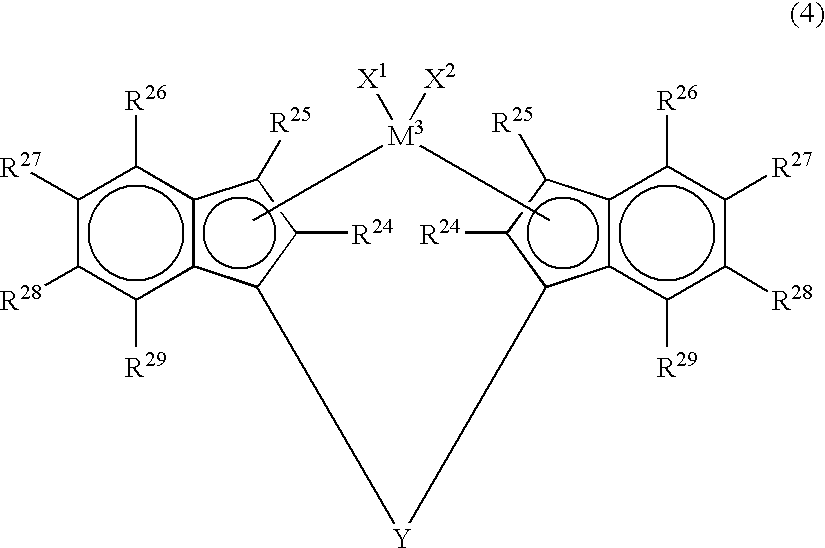

A thermoplastic polyurethane (TPU) elastomer and p-phenylene diisocyanate (PPDI) / polycaprolactone-based composition therefor having a unique chain extender combination for improved injection moldability. The elastomer is formed as the reaction product of: (A) from about 60 to 80% by weight of a hydroxyl-terminated poly(caprolactone) diol; (B) from about 17 to 22% by weight of a p-phenylene diisocyanate; (C) from about 3 to 10% by weight of a first hydroxyl-functional chain extender; and (D) less than about 2% by weight of a second hydroxyl-functional chain extender different from the first chain extender, the second chain extender being selected as effective to modify the crystallinity of the elastomer.

Owner:PARKER INTANGIBLES LLC

Process for producing injection molded product

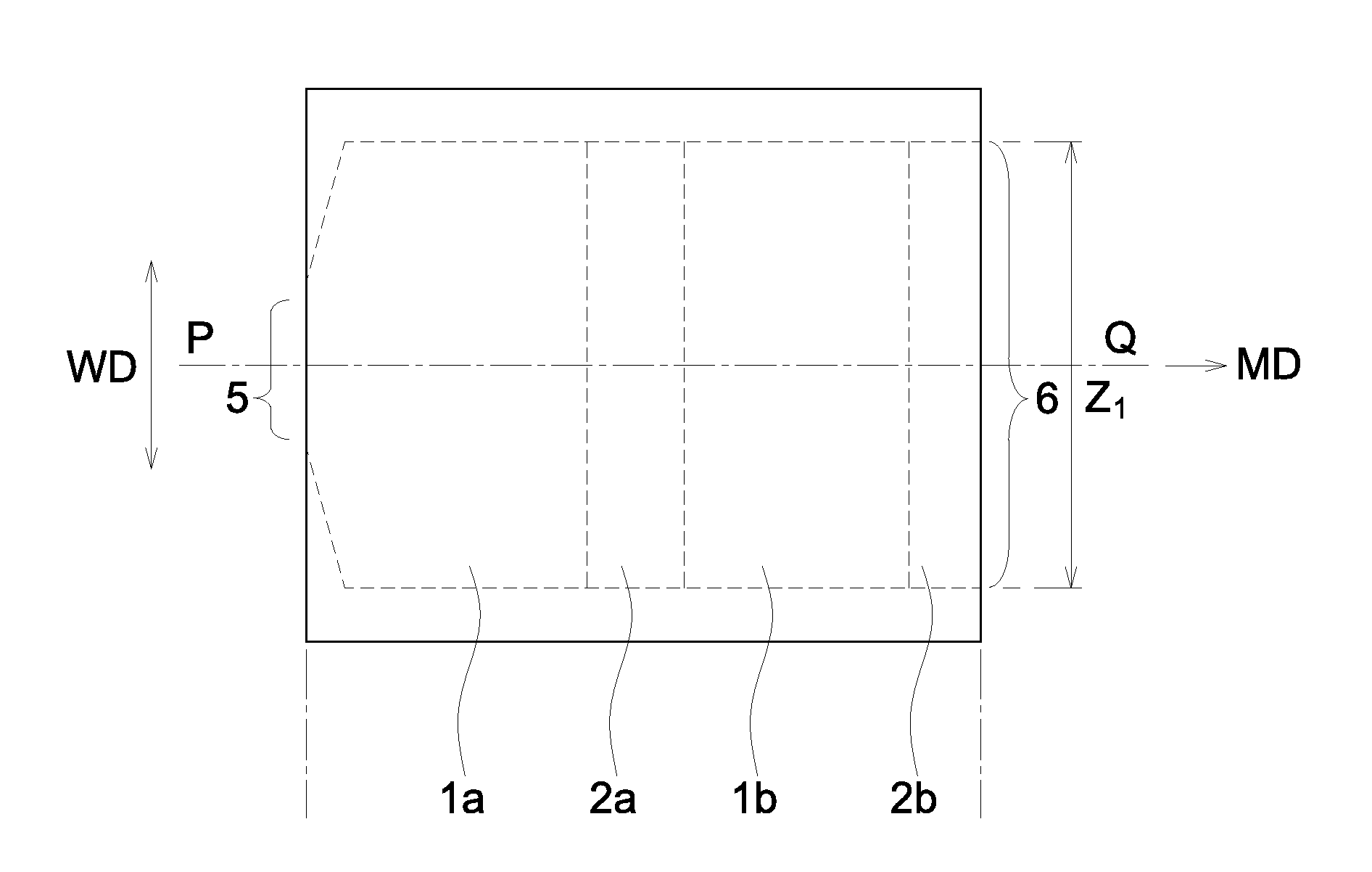

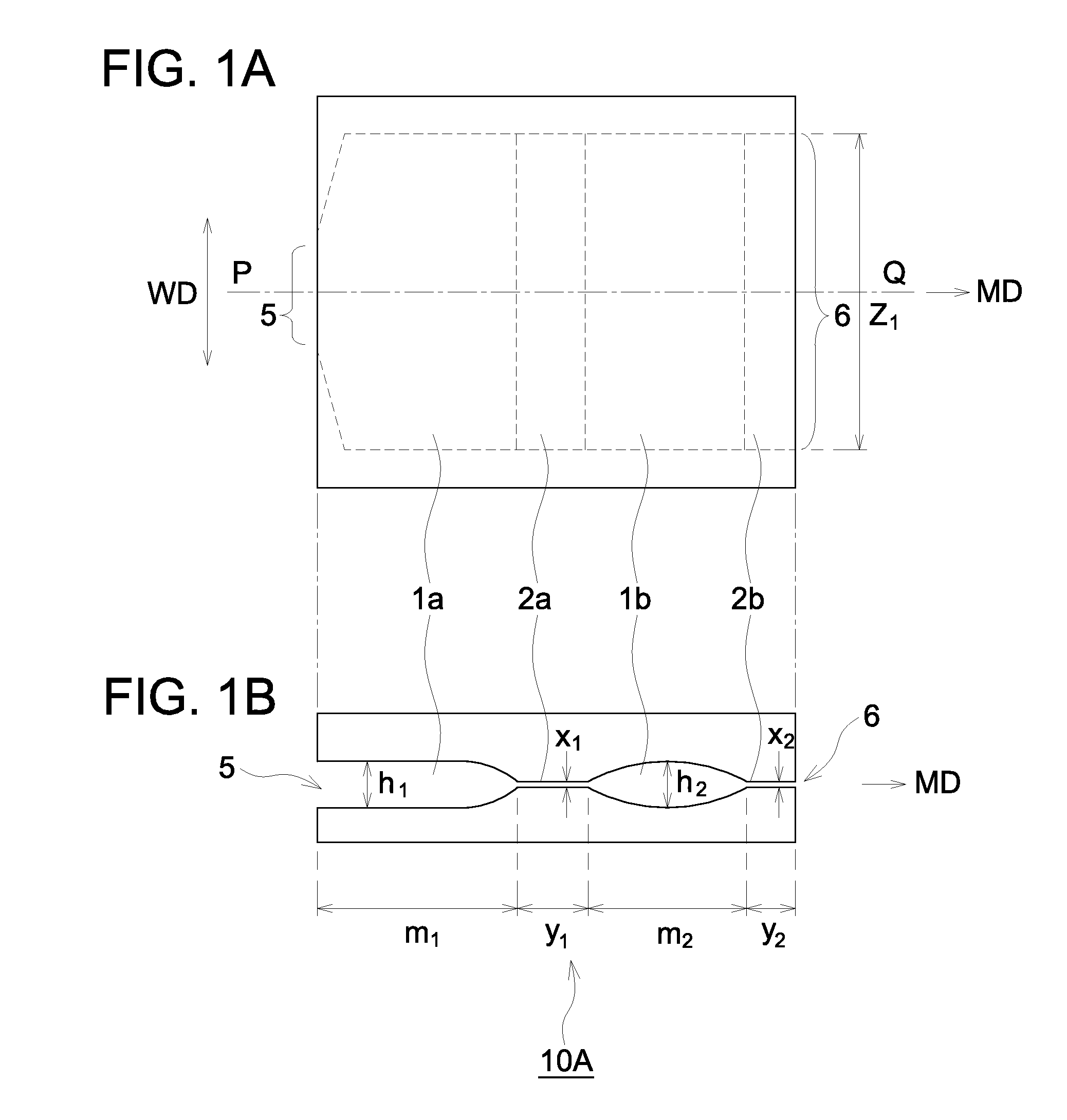

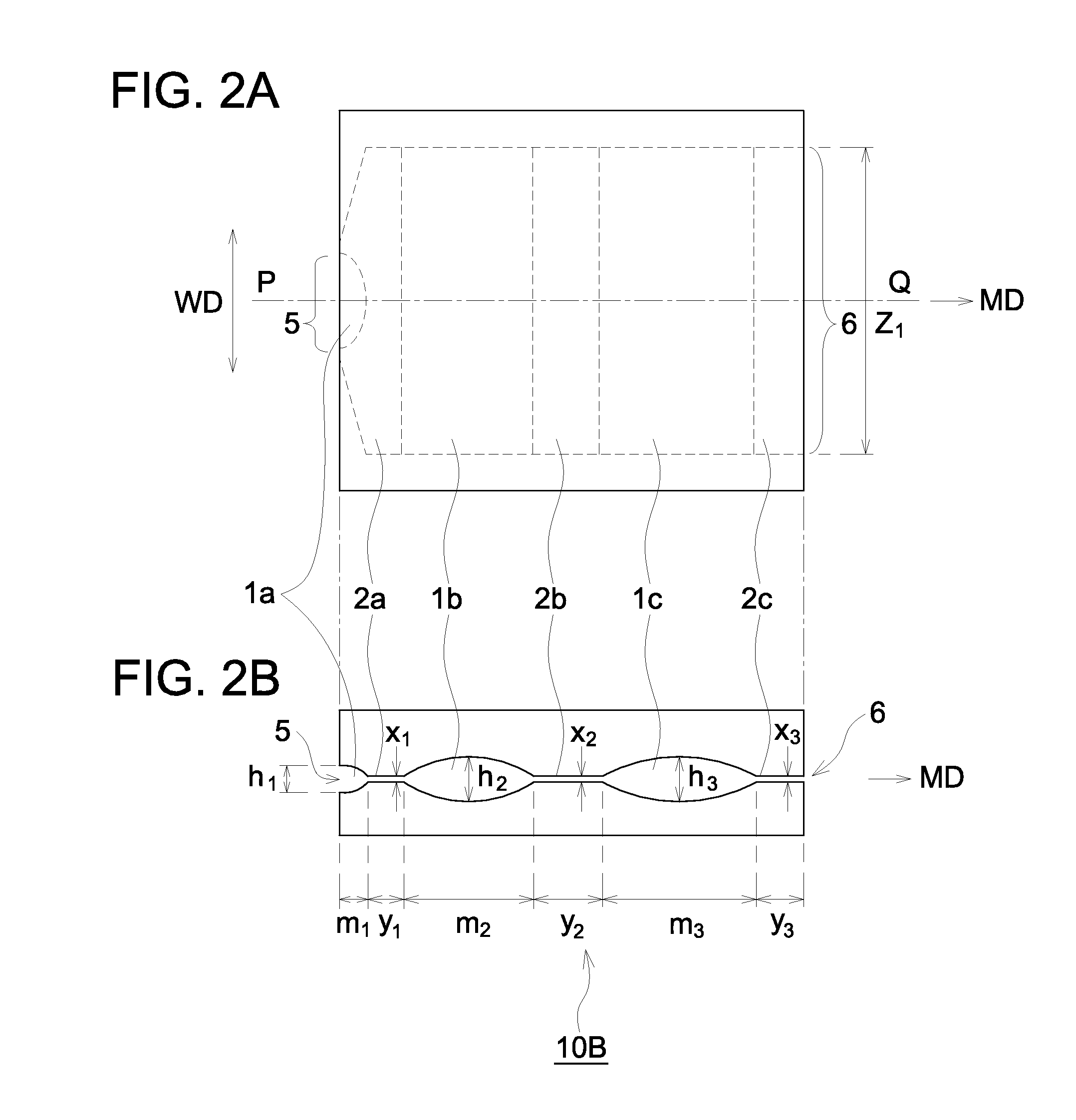

InactiveUS20080064805A1Thin moldingImprove productivityCeramic shaping apparatusCoatingsWaxPolymer science

The present invention provides a process for producing an injection molded product comprising injection molding a mixture containing a thermoplastic resin (A) and a polyolefin wax (B), wherein the mixture has L / L0≧1.05, the L being a flow length in the case where the mixture contains the polyolefin wax and the L0 being a flow length in the case where the mixture contains no polyolefin wax, the L and L0 being measured under the conditions of a mold temperature of 40° C. and a resin temperature, Tr, as determined by the following expression: Tr=3 / 4×Tm+100 (wherein Tm represents a melting temperature (° C.) of the thermoplastic resin), using a spiral flow mold having a thickness of 1 mm and a width of 10 mm. According to the invention, by adding the polyolefin wax, a flow length of a thermoplastic resin can be lengthened, and releasability can be improved, and thus the thermoplastic resin can be thin molded or precision molded by injection molded without deteriorating the characteristics of the molded product to be obtained.

Owner:MITSUI CHEM INC

Injection-moldable, thermoplastic polyurethane elastomer

InactiveUS20030122282A1Reduces intermolecular hydrogen bondingPromote sportsCoatingsThermoplastic polyurethaneDiol

A thermoplastic polyurethane (TPU) elastomer and p-phenylene diisocyanate (PPDI) / polycaprolactone-based composition therefor having a unique chain extender combination for improved injection moldability. The elastomer is formed as the reaction product of: (A) from about 60 to 80% by weight of a hydroxyl-terminated poly(caprolactone) diol; (B) from about 17 to 22% by weight of a p-phenylene diisocyanate; (C) from about 3 to 10% by weight of a first hydroxyl-functional chain extender; and (D) less than about 2% by weight of a second hydroxyl-functional chain extender different from the first chain extender, the second chain extender being selected as effective to modify the crystallinity of the elastomer.

Owner:PARKER INTANGIBLES LLC

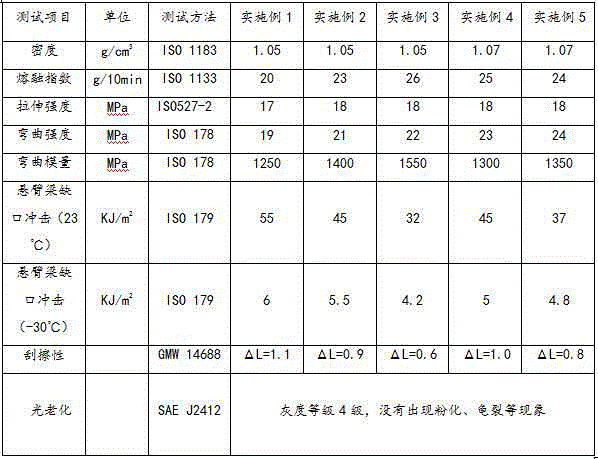

Polypropylene composite material for seamless instrument board and preparation method thereof

The invention discloses a polypropylene composite material for a seamless instrument board and a preparation method thereof. The polypropylene composite material for the seamless instrument board is prepared from, by weight parts, 40-60 parts of polypropylene, 10-20 parts of high density polyethylene, 15-25 parts of polyolefin elastomer, 20-30 parts of talc, 0.2-0.6 part of antioxidant, 0.4-1 part of light stabilizer, 0.5-3 parts of anti-scratching agent, 0.2-0.6 part of lubricant and 1-3 parts of toner. The prepared polypropylene composite material has high rigid-tough balance, low temperature impact, weather resistance and scraping resistance and can meet the performance requirements of automobile main engine plant seamless instrument boards. The polypropylene composite material further has excellent injection molding performance, and injection molding parts are excellent in appearance and free of defects such as tiger skin and gas marks.

Owner:ORINKO NEW MATERIAL CO LTD

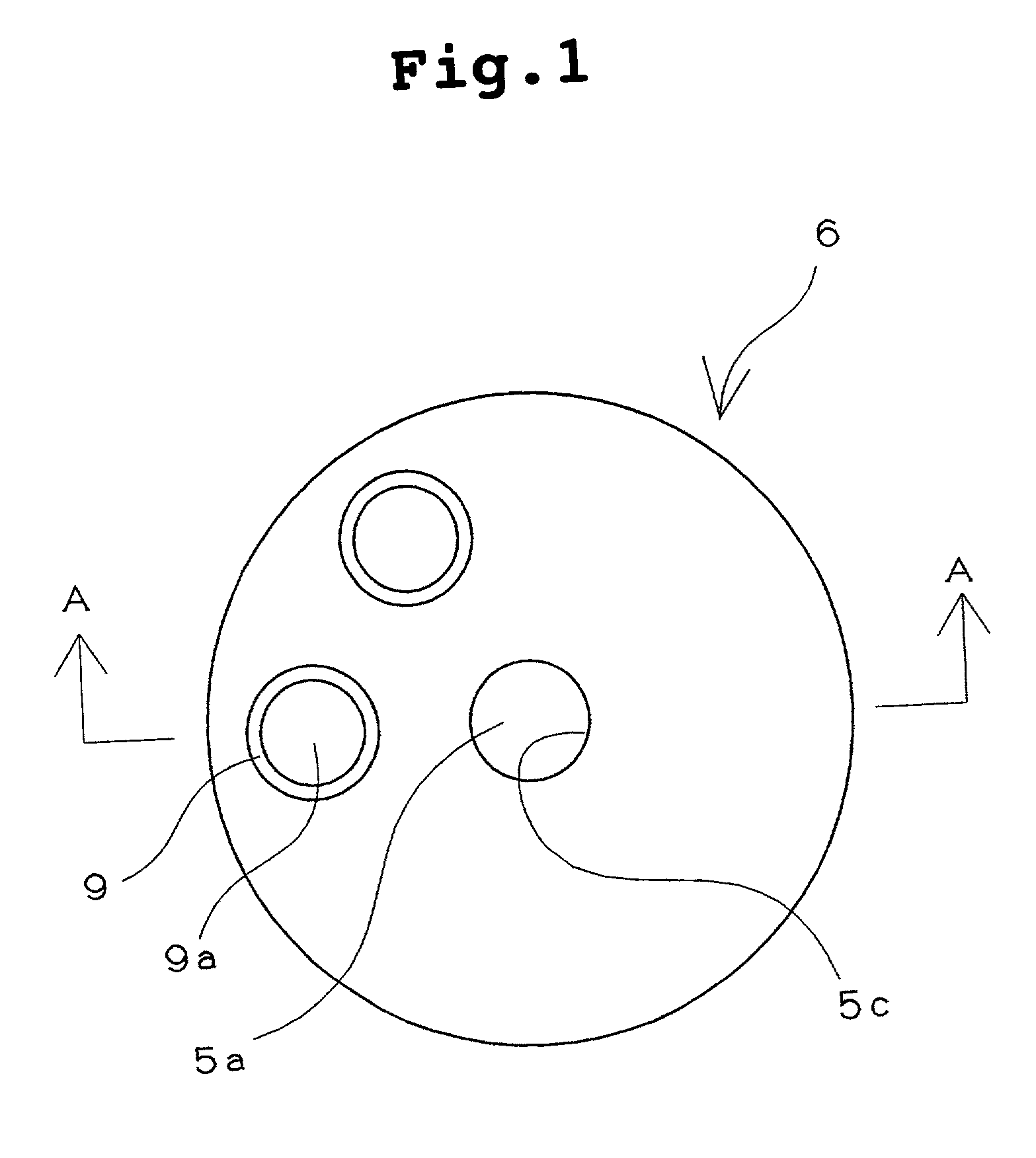

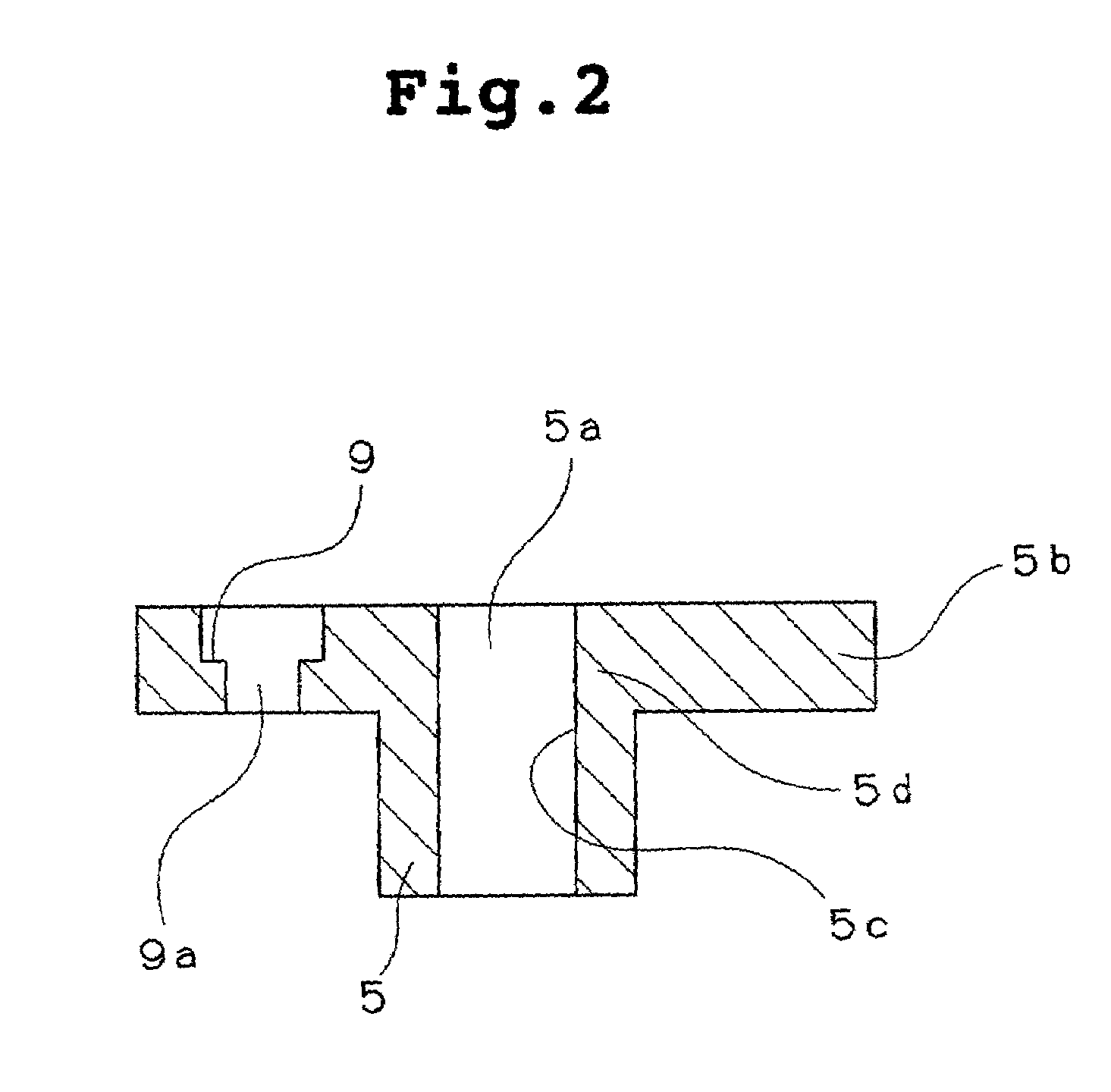

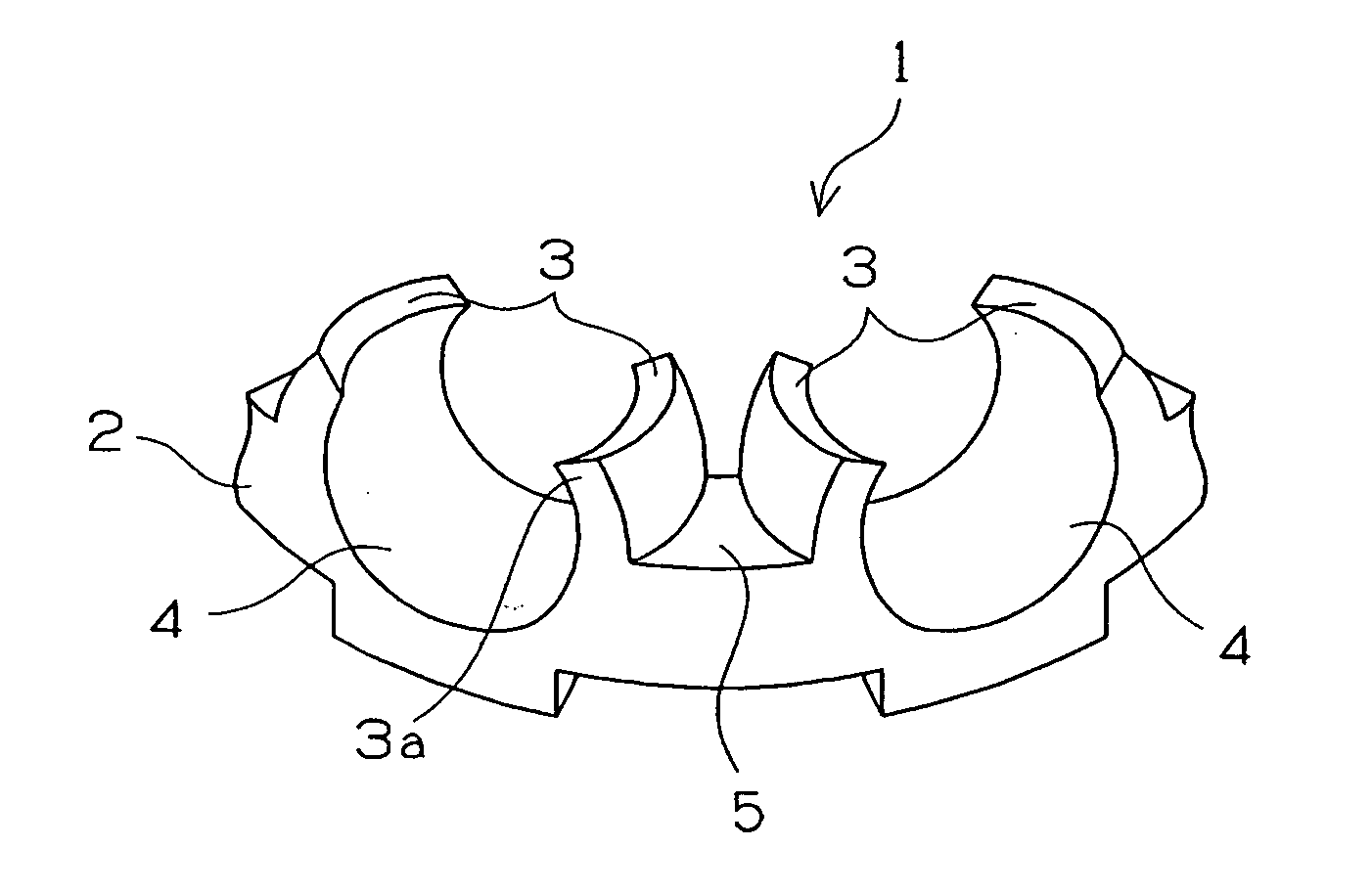

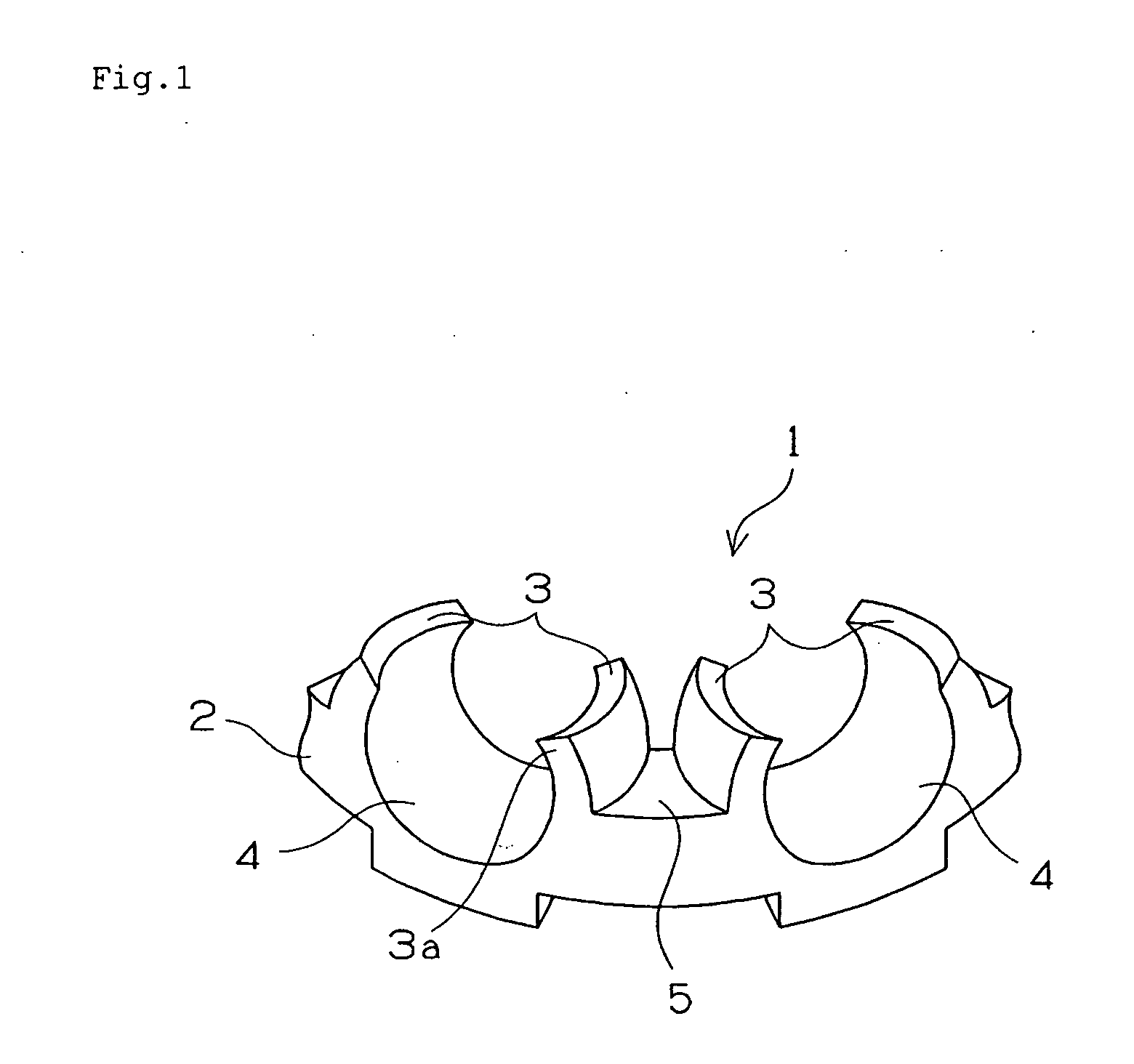

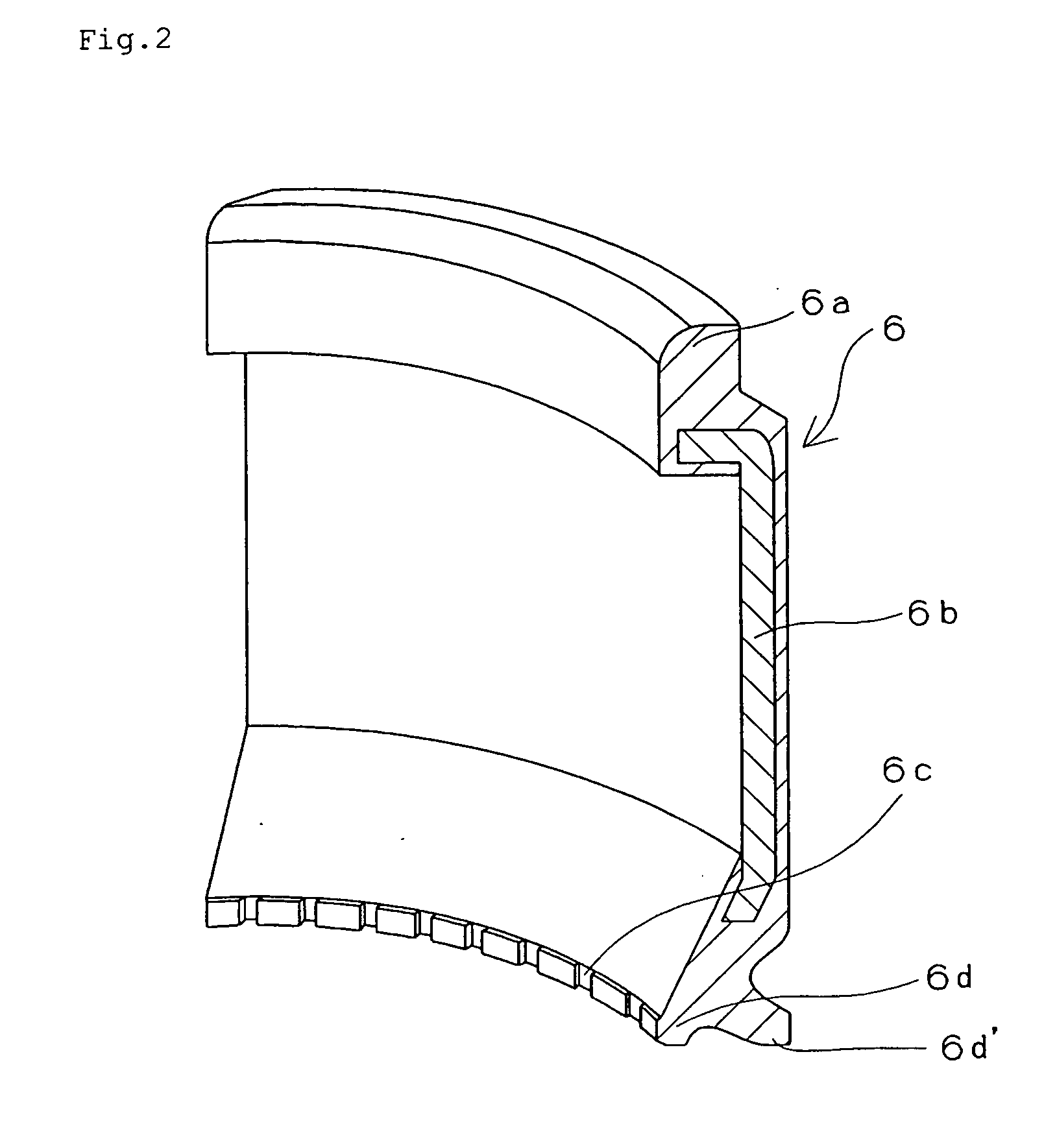

Optical pick-up

InactiveUS7012768B2High mechanical strengthImprove roundnessRecord information storageOptical beam guiding meansOptical pickupHigh density

An optical pick-up allows a lens to be supported at high dimensional accuracy for a high-density recording medium, and suppresses resonance for a high-speed access. The optical pick-up includes a supporting shaft, and a lens holder which fits on a supporting shaft rotatably, wherein the supporting shaft is formed of ceramics containing zirconia, and wherein the lens holder is formed of a liquid crystal resin composition. The optical-pickup includes a lens holder having a shaft hole which fits on a rotating shaft and a plurality of object lens holes, wherein the lens holder is a molded product of a resin composition of a liquid crystal resin or a polyphenylene ether resin mixed with a fibrous filler. The molded product has flexural elastic modulus of 10 GPa or more. The lens holder includes a bearing part formed vertically to a lens receiving surface with an excellent inner diameter roundness and excellent mechanical strength.

Owner:NTN CORP

High-performance nano-crystalline soft magnetic composite material and preparation method thereof

InactiveCN102543344AImprove dispersion uniformityImprove injection molding performanceInorganic material magnetismPolypropyleneBall mill

The invention relates to a high-performance nano-crystalline soft magnetic composite material and a preparation method thereof. The high-performance nano-crystalline soft magnetic composite material is characterized in that the proportion of raw materials Fe: Cr: Si: B: C: polypropylene: lubricant: coupling agent: melt index regulator is equal to (40-59):(8-40): (8-20):(4-10):(1-5):(8-50):(4-10):(3-5):(3-8):(2-8) by mass percentage. The preparation method includes primary blending, high-speed water atomization, passivation, annealing process, primary grinding by a ball mill, secondary grinding by the ball mill, secondary blending, tertiary grinding by the ball mill, tertiary blending, high-speed mixing, granulating by extrusion and injection molding. The preparation method of the high-performance nano-crystalline soft magnetic composite material is suitable for production of magnetic circuit elements complicated in shape and high in precision requirements. The material prepared by the preparation method has the advantages of high magnetic conductivity, high-saturated magnetic induction strength, low coercivity and loss and high stability.

Owner:南京深宁磁电有限公司 +2

Light emitting device

InactiveCN101047222AImprove acquisition efficiencyImprove cooling effectSolid-state devicesSemiconductor devicesLight emitting deviceElectrical conduction

An object of the present invention is to provide a light-emitting device in which the light-acquisition efficiency of a light-emitting element is less likely to be lowered even if a resin substrate having good thermal conductivity is used. The first aspect of the present invention is characterized by comprising a resin substrate 14 having a thermal conductivity of 1.0 to 9.0 W / m·K, a white insulating layer 15 provided on the resin substrate, and a circuit pattern provided on the insulating layer. Layer 16, light-emitting element 13 disposed on the insulating layer and electrically connected to the circuit layout layer.

Owner:TOSHIBA LIGHTING & TECH CORP

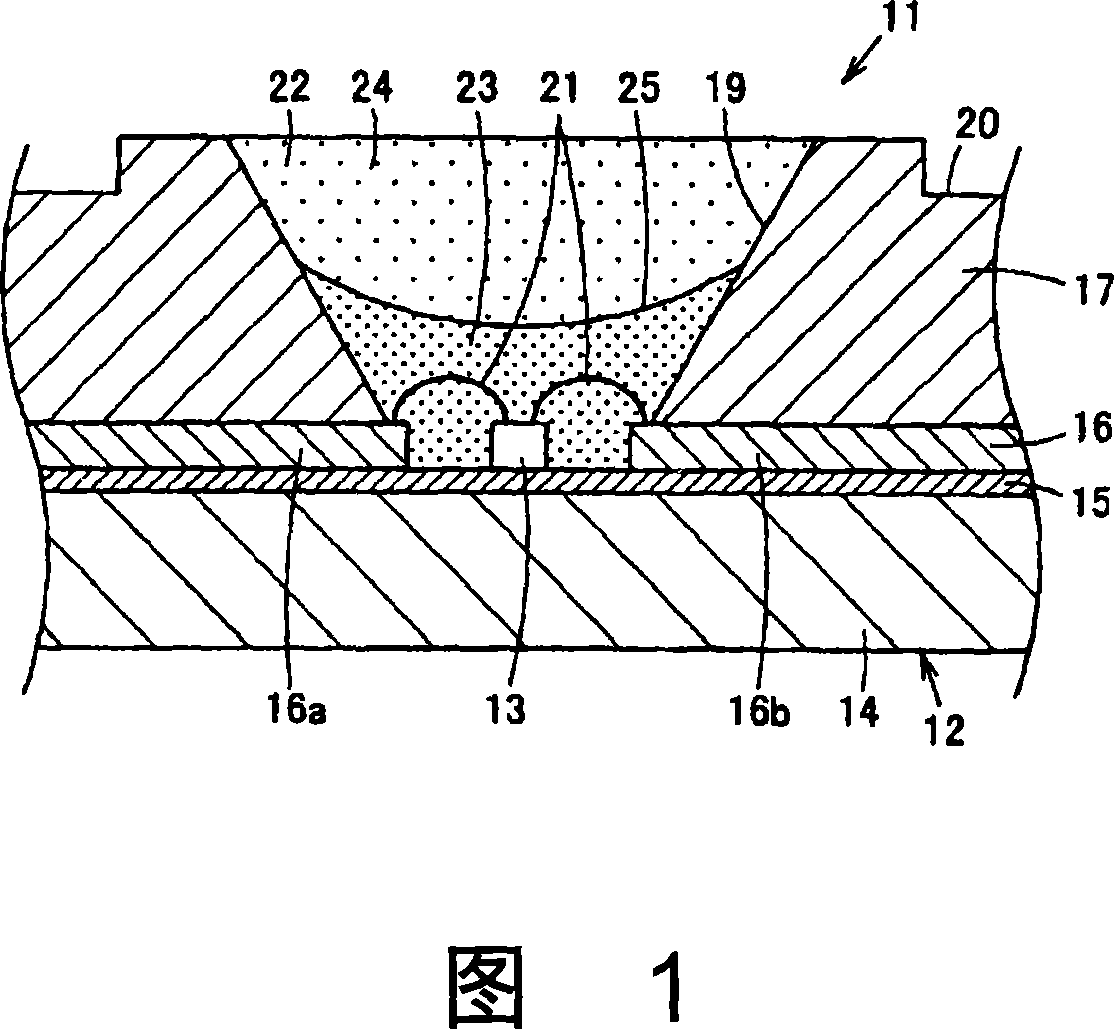

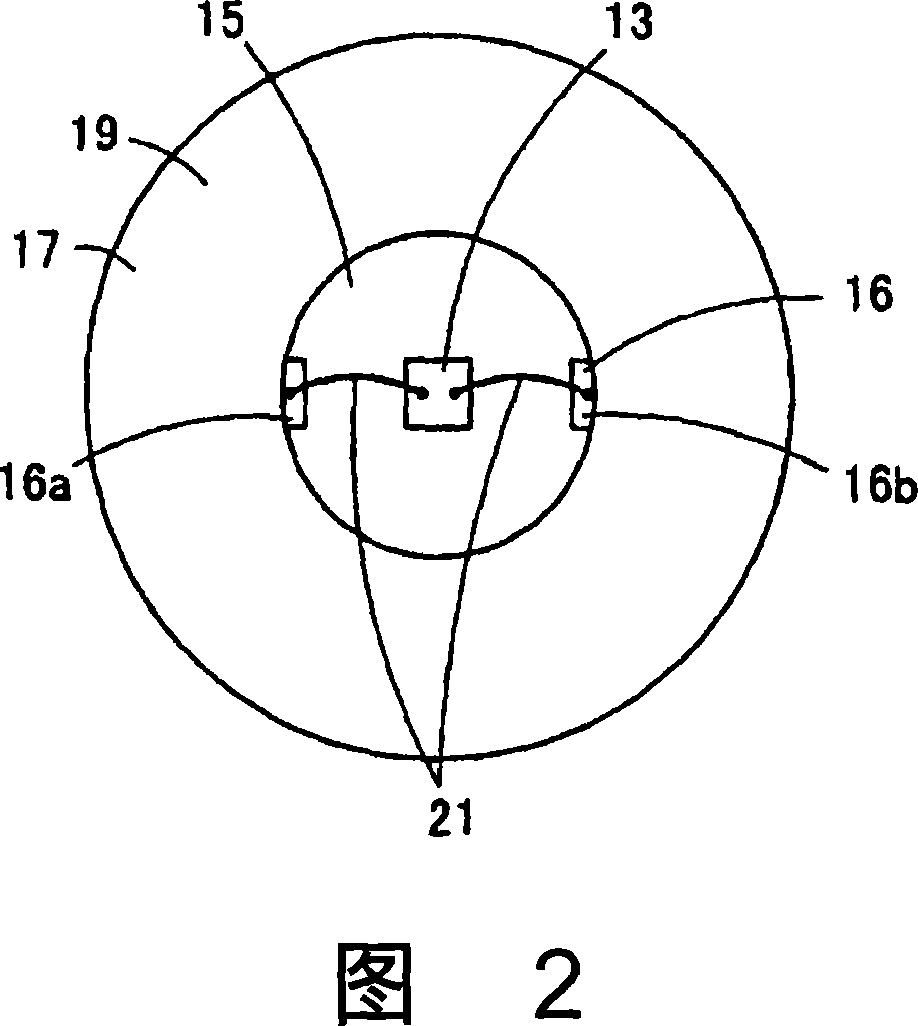

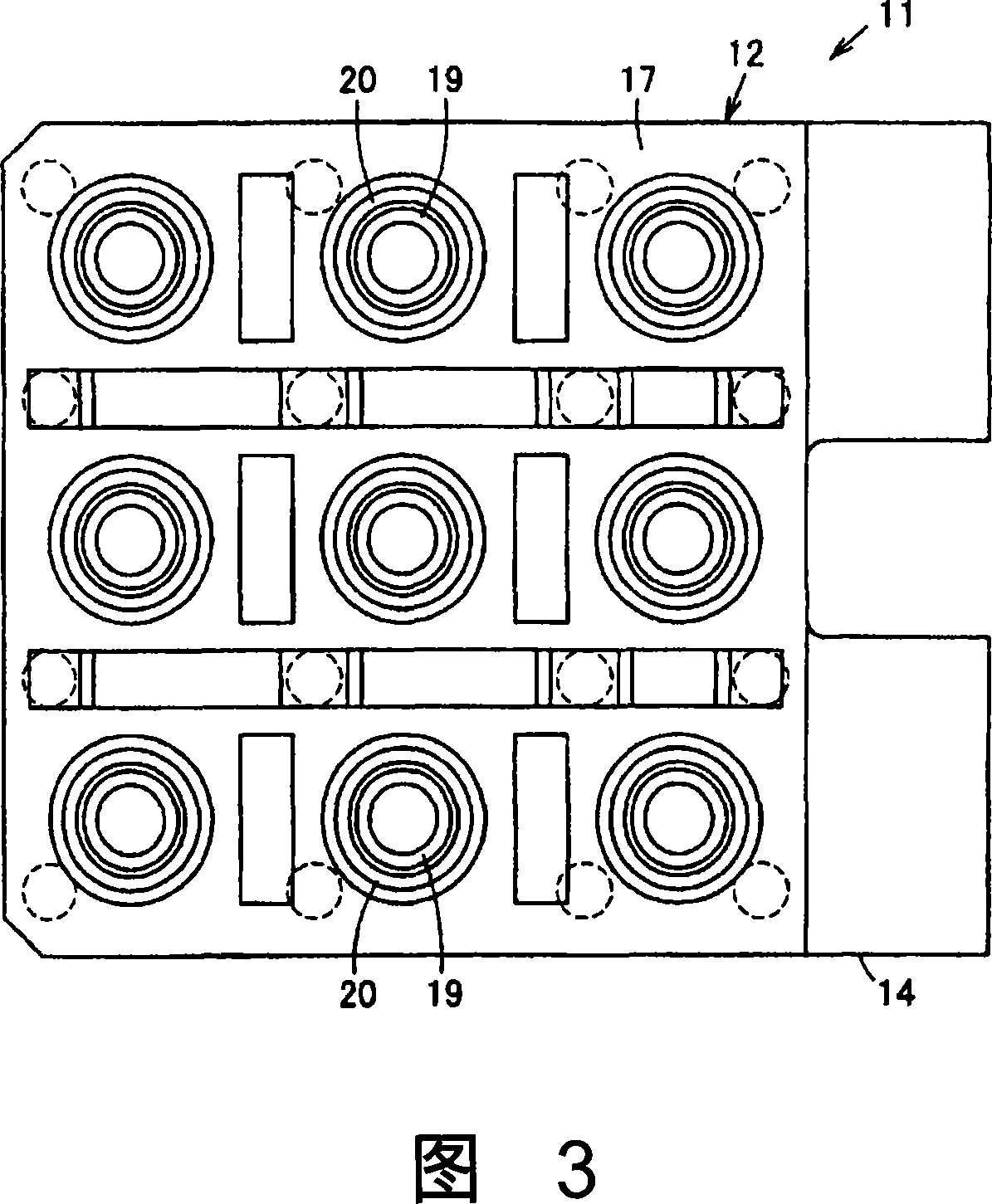

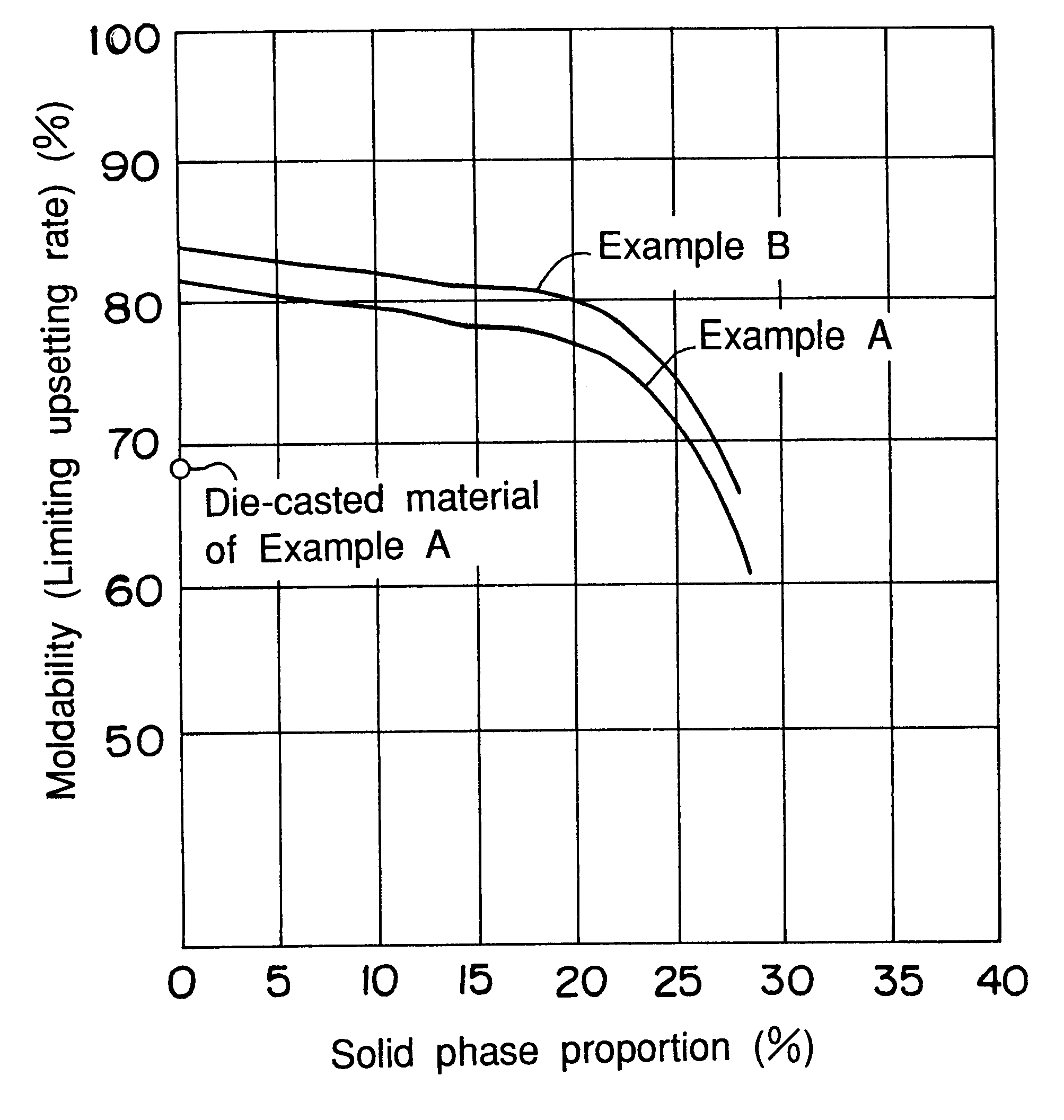

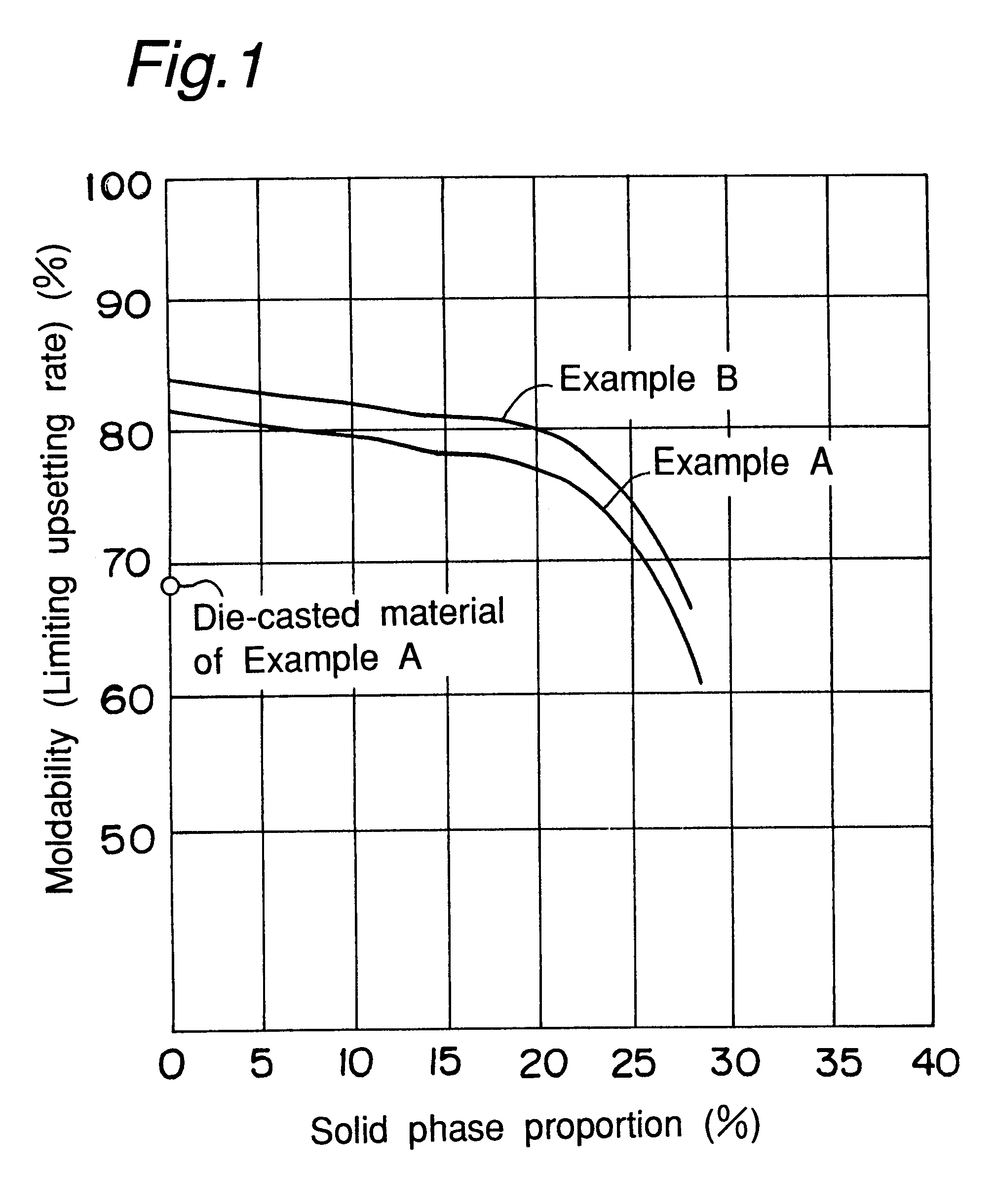

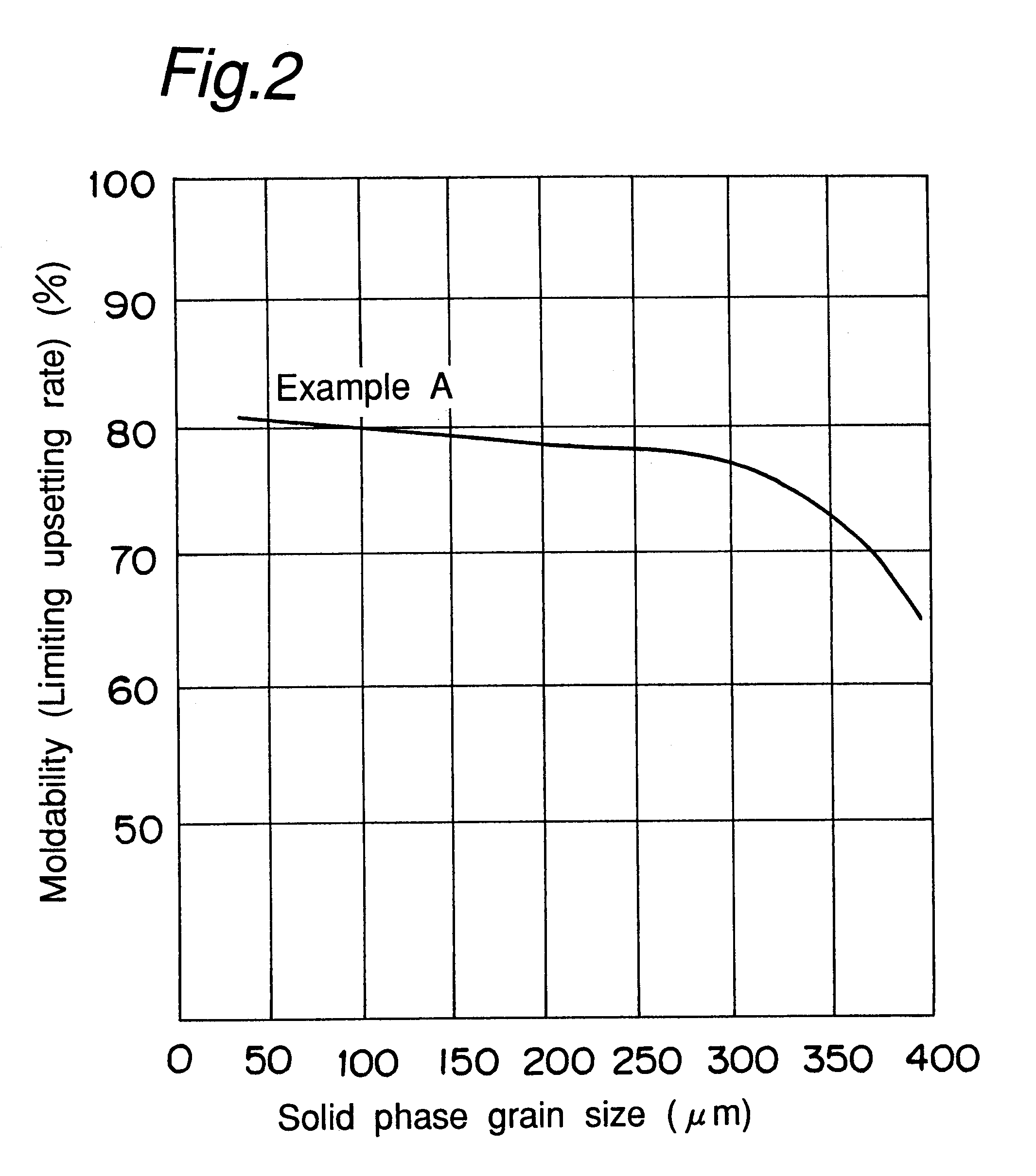

Method of producing light metal alloy material for plastic working and plastic-worked product

InactiveUS6306231B1Good molding effectImprove injection molding effectFoundry mouldsFoundry coresInjection mouldingMaterials science

A light metal alloy material has excellent plastic workability. The method of producing the light metal alloy material comprises a light metal as a matrix, which is injection-molded at a solid phase proportion of not more than 20%. The injection molded material has a limiting upsetting rate of not more than 70% and excellent moldability. This injection molded material can be molded into a final molded article by means of single-step forging.

Owner:MAZDA MOTOR CORP

Compositions for injection moulding

Use of a filled polymer resin in the manufacture of an article therefrom by injection moulding, a method of manufacturing an article by injection moulding a filled polymer resin, a method for enabling or improving the injection mouldability of a polymer resin comprising recycled polymer, wherein the polymer resin comprises recycled polymer and functional filler, the use of a functional filler in a polymer resin comprising recycled polymer to improve the injection mouldability of the polymer resin, an article of manufacture obtained by injection moulding a filled polymer resin, and a filled polymer resin.

Owner:IMERTECH SAS

Polypropylene-based resin composition

PendingUS20180327580A1Improve injection molding effectMaintain good propertiesPolymer scienceVolumetric Mass Density

Disclosed are a polypropylene-based resin composition comprising 5 to 47 parts by mass of a propylene-based polymer (A) having an MFR of 50 to 150 g / 10 min and an amount of a decane-soluble part of 6% by mass or more, 0 to 30 parts by mass of a propylene homopolymer (B) having an MFR of 10 to 500 g / 10 min, 23 to 30 parts by mass of an ethylene-α-olefin copolymer (C) which is a random copolymer composed of ethylene and an α-olefin having 4 to 8 carbon atoms, and has a density of 0.850 to 0.890 g / cm3 and an MFR of 0.5 to 30 g / 10 min, and 30 to 40 parts by mass of an inorganic filler (D) having an average particle size of over 3.0 μm and less than 5.0 μm [the total amount of the components (A) to (D) is 100 parts by mass]; and an automobile exterior member obtained by injection-molding or press-molding the composition.

Owner:PRIME POLYMER CO LTD

Durable polyoxymethylene composition

InactiveUS20120238680A1Easy to processReduce coefficient of frictionMaterial nanotechnologyPolyoxymethyleneAntistatic agent

A durable polyoxymethylene composition includes a polyoxymethylene copolymer with 1,3-dioxolane as a comonomer, a lubricant, an inorganic filler, a nucleating agent including a sodium salt, a stabilizer, an anti-static agent. A ramp is made of the durable polyoxymethylene. The ramp and the durable polyoxymethylene have excellent micro-wear-resistant property.

Owner:MIN AIK TECH

Durable polyoxymethylene composition

InactiveUS8759431B2Weaken energyImprove mechanical stabilityFibre treatmentSolid ballsPolyoxymethyleneAntistatic agent

A durable polyoxymethylene composition includes a polyoxymethylene copolymer with 1,3-dioxolane as a comonomer, a lubricant, an inorganic filler, a nucleating agent including a sodium salt, a stabilizer, an anti-static agent. A ramp is made of the durable polyoxymethylene. The ramp and the durable polyoxymethylene have excellent micro-wear-resistant property.

Owner:MIN AIK TECH

Flame-retardant polyester resin composition and blow molded container

InactiveUS20110229673A1Good appearanceExcellent performanceLayered productsBottlesPolycarbonatePolymer chemistry

Provide is a flame-retardant polyester resin composition exhibiting excellent flame-retardant performance, specifically flame self-extinction performance and excellent injection moldability and blow moldability by biaxially-stretch blow molding method, by solving problem of poor injection moldability of the conventional polyester. A flame-retardant polyester resin composition comprising: (A) 50-80% by mass of a polyester resin, (B) 10-40% by mass of a polycarbonate resin, (C) 5-30% by mass of a polymer of a glass transition temperature Tg of less than 35° C., and (D) 0.5-5% by mass of a polymer of a carbon residue rate resin of at least 15%.

Owner:KONICA MINOLTA BUSINESS TECH INC

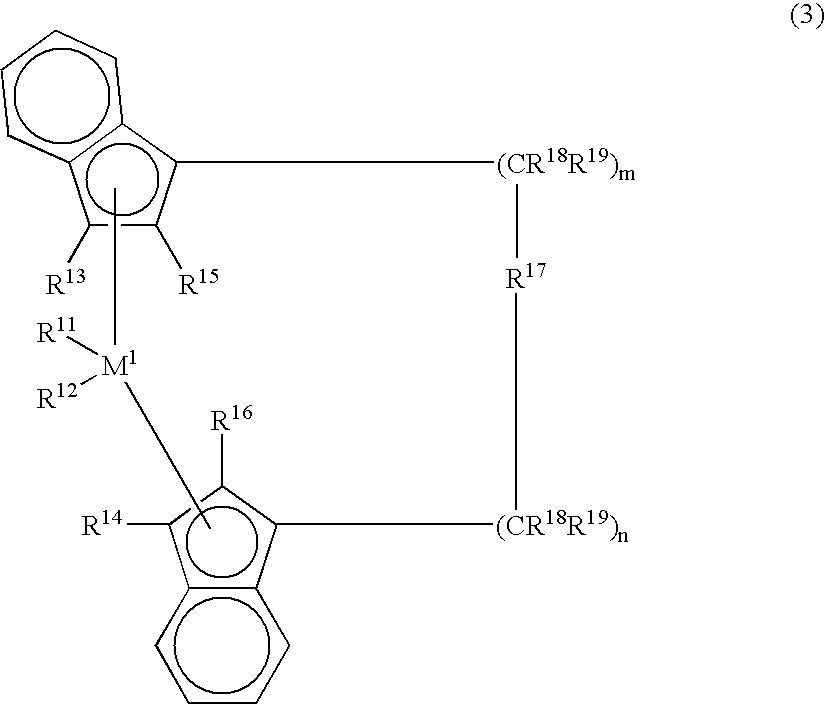

Injection-moldable, thermoplastic polyurethane elastomer

InactiveUS6740727B2Reduces intermolecular hydrogen bondingPromote sportsCoatingsThermoplastic polyurethaneDiol

A thermoplastic polyurethane (TPU) elastomer and p-phenylene diisocyanate (PPDI) / polycaprolactone-based composition therefor having a unique chain extender combination for improved injection moldability. The elastomer is formed as the reaction product of: (A) from about 60 to 80% by weight of a hydroxyl-terminated poly(caprolactone) diol; (B) from about 17 to 22% by weight of a p-phenylene diisocyanate; (C) from about 3 to 10% by weight of a first hydroxyl-functional chain extender; and (D) less than about 2% by weight of a second hydroxyl-functional chain extender different from the first chain extender, the second chain extender being selected as effective to modify the crystallinity of the elastomer.

Owner:PARKER INTANGIBLES LLC

Injection molded article, resin-made sliding bearing, resin-made gear, resin-made crown-shaped cage, resin-made seal and rolling

InactiveUS20110160384A1Improve injection molding effectHigh mechanical strengthEngine sealsPiston ringsPoly(butylene succinate)Biodegradable polyester

It is an object of the present invention to provide an injection-molded article such as a resin-made cage, a resin-made seal, a resin-made sliding bearing, and a resin-made gear having reliable flowability, enhanced mechanical strength and toughness, and improved wear resistance. A resin composition is composed of a biodegradable polyester polymer particularly polybutylene succinate to which not less than 10 wt % nor more than 40 wt % of a fibrous inorganic reinforcing material and not less than 0.5 wt % nor more than 10 wt % of polycarbodiimide resin are added. The injection-molded article is obtained by injection molding the resin composition.

Owner:NTN CORP

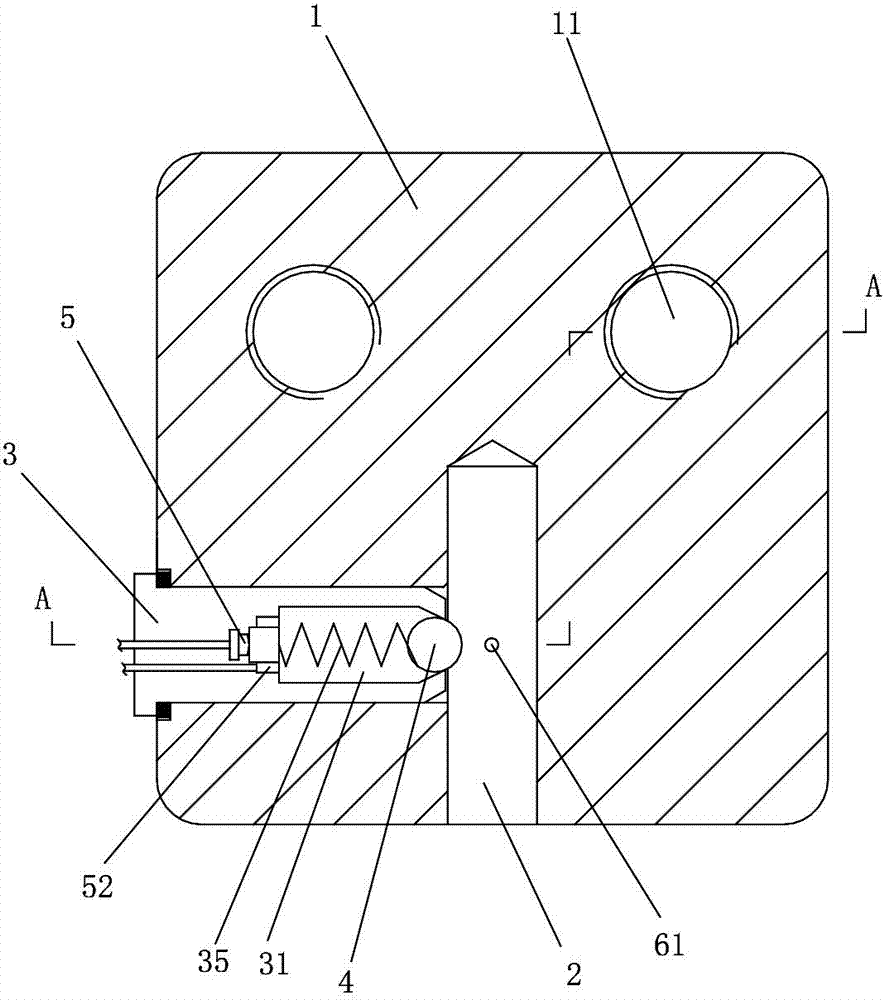

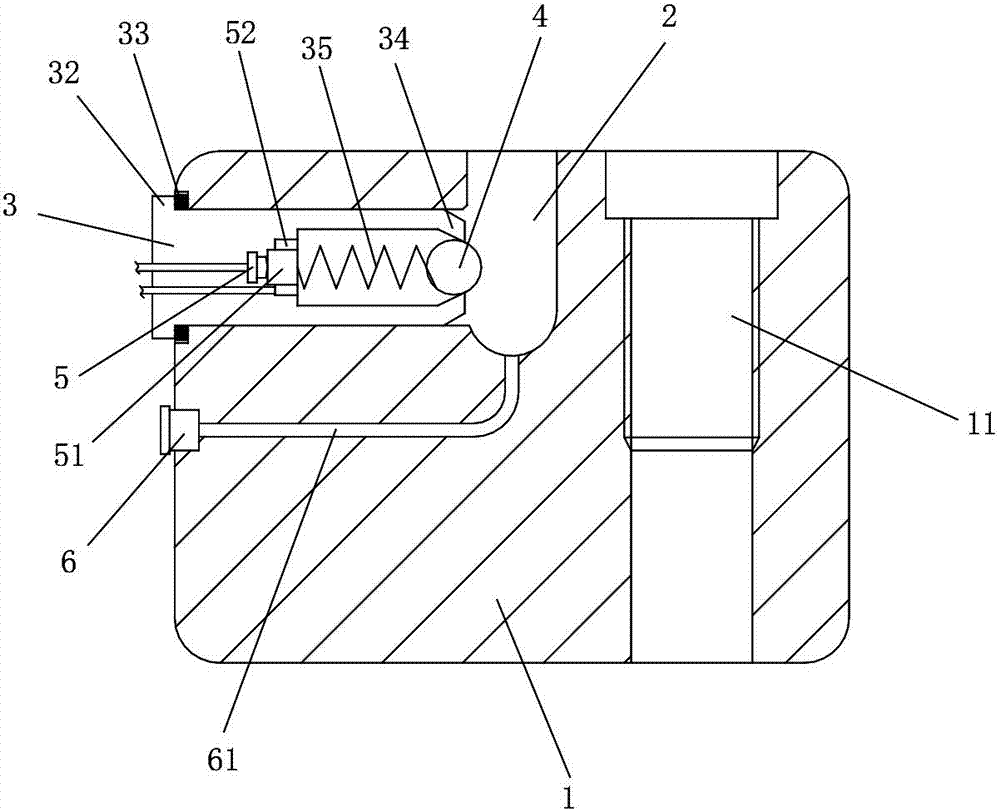

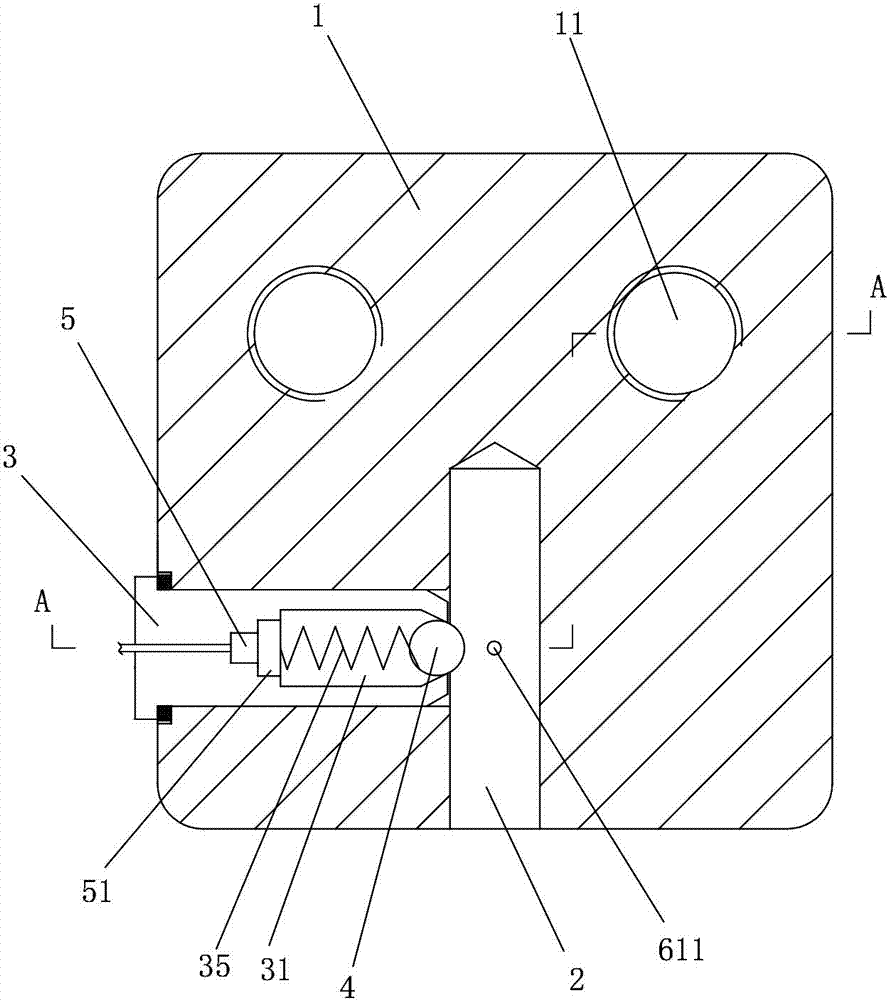

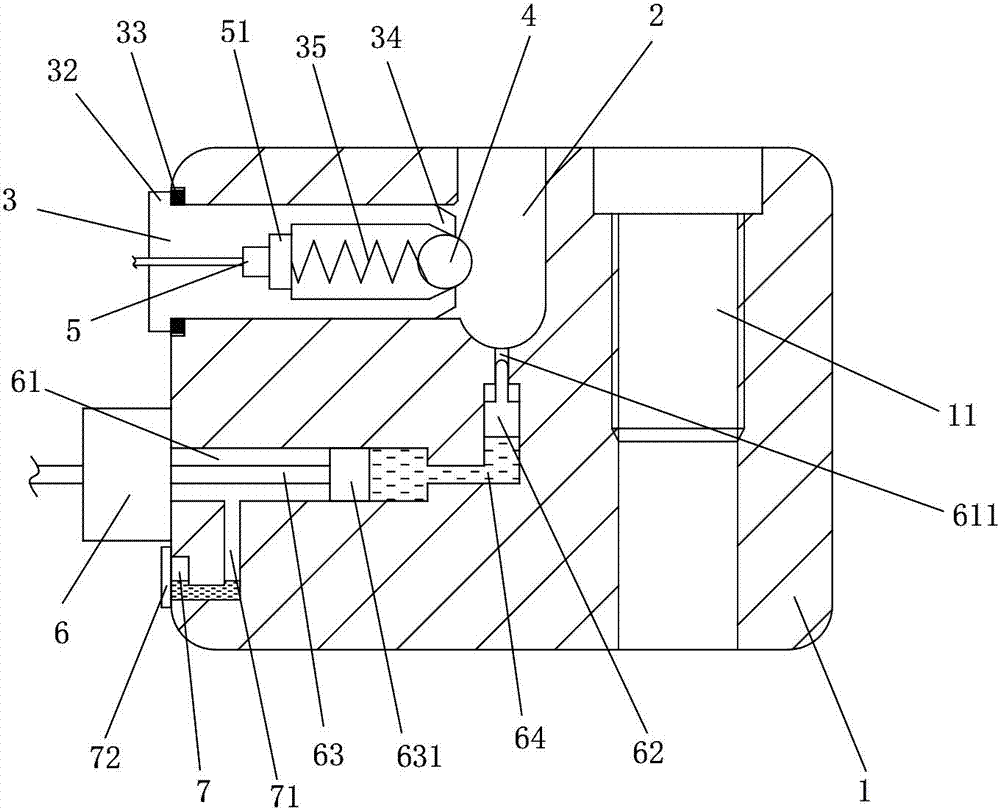

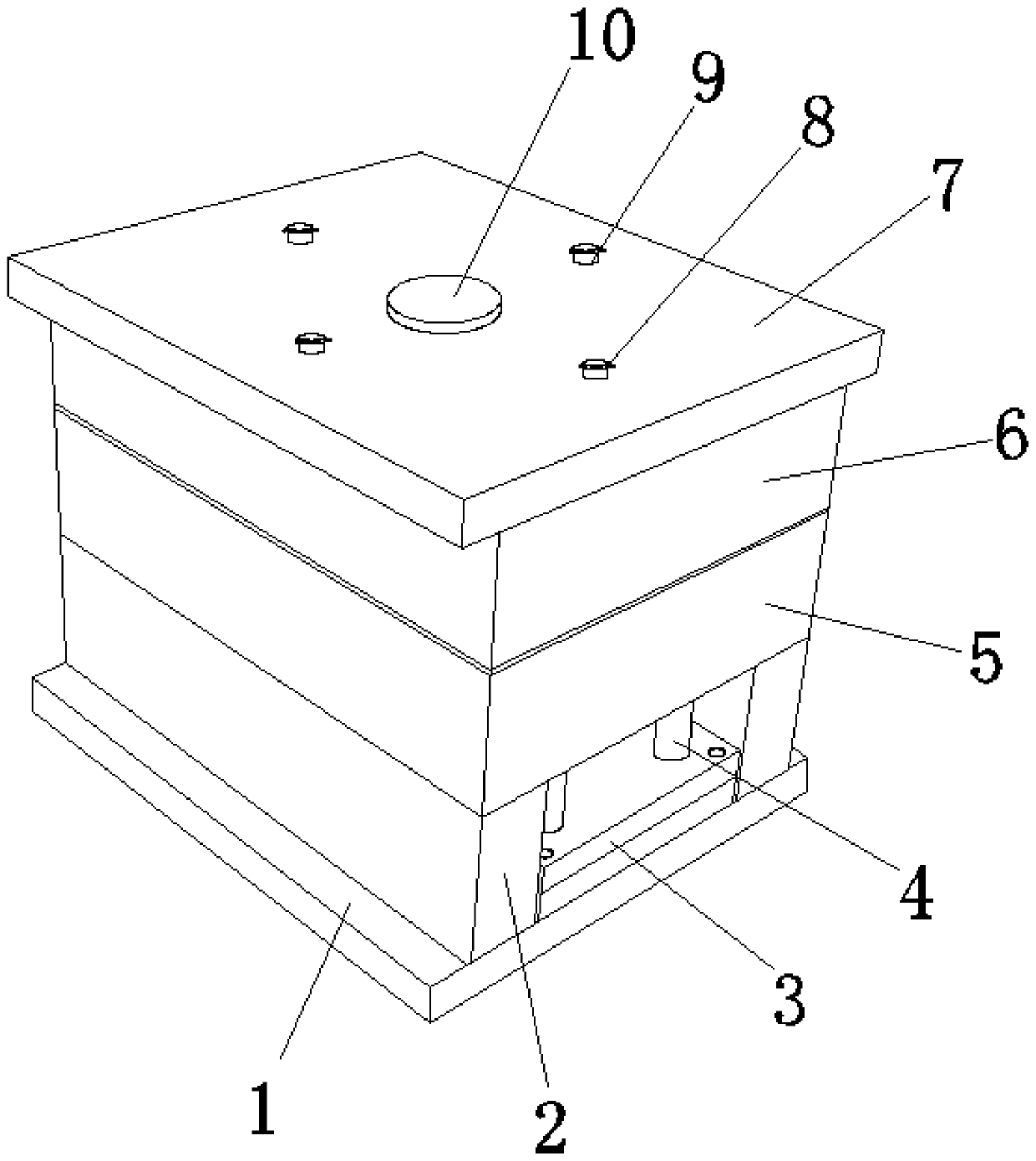

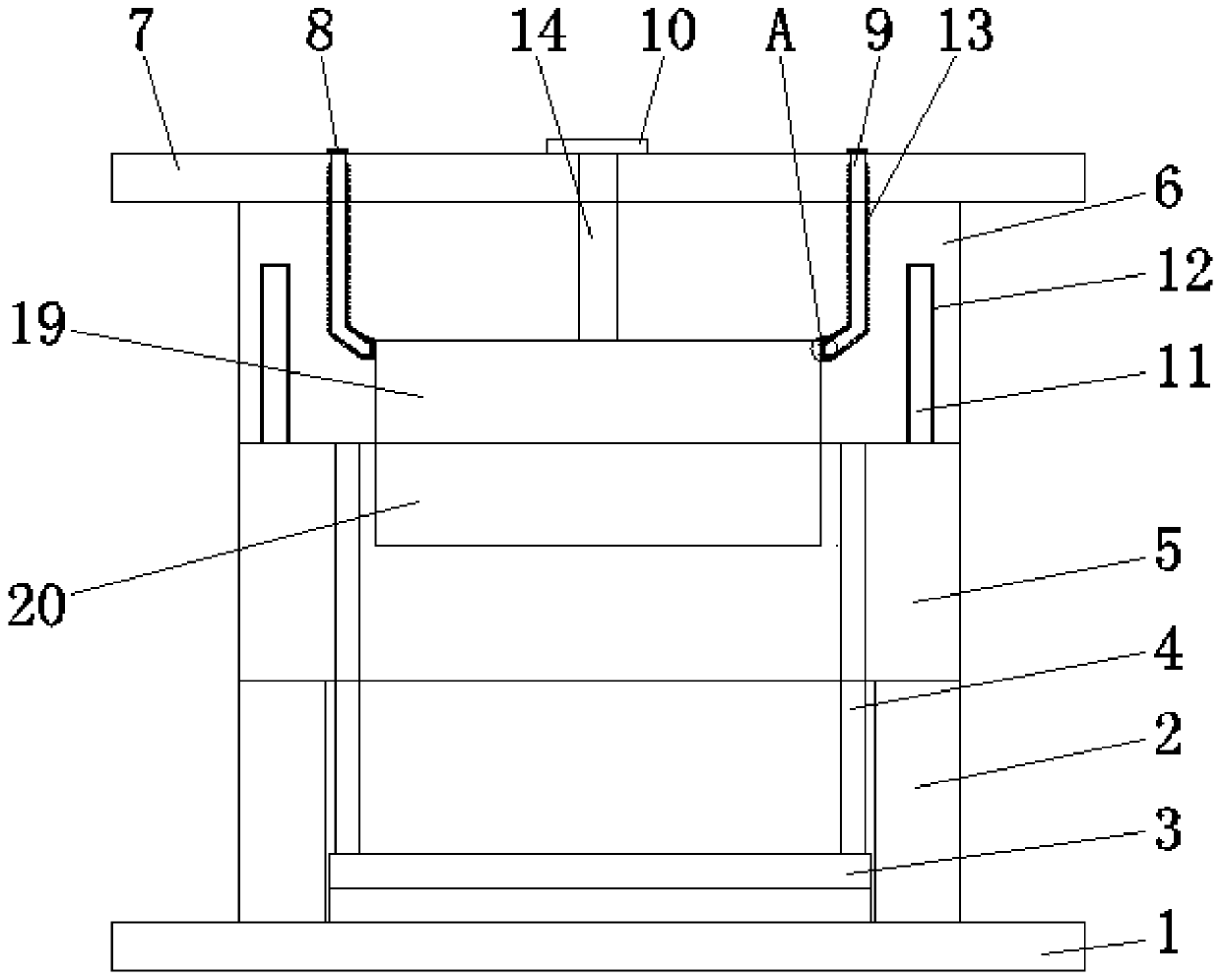

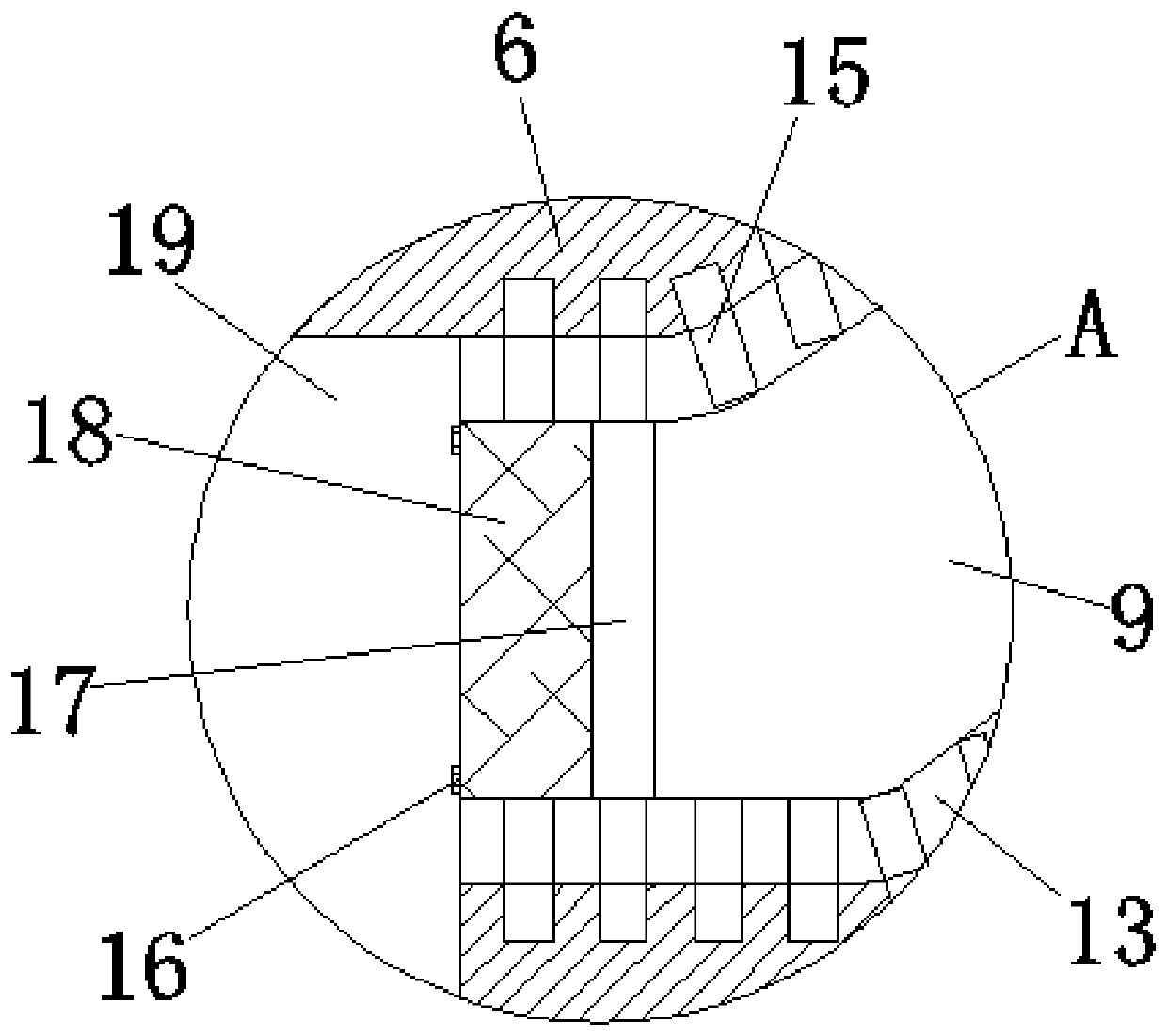

Injection mold with insert positioning function

The invention discloses an injection mold with the insert positioning function. The injection mold comprises an insert mounting part; the insert mounting part is provided with threaded holes and is arranged on a mold body in a threaded connection mode; an insert mounting groove is formed in the insert mounting part; an insert positioning part is arranged at the side edge of the insert mounting groove; a storage cavity is formed in the insert positioning part; a limiting ball and a spring are arranged in the storage cavity; the spring abuts against the limiting ball to enable the limiting ballto be in a working state; an electromagnet and a heating body are arranged in the insert positioning part; the electromagnet is electrified and then attracts the limiting ball so as to enable the limiting ball to be separated from the working state; after the heating body heats a heat conductive part, the heat is transmitted to the limiting ball through the spring so that a metal insert can be heated when the limiting ball works; a vent hole is formed in the bottom of the insert mounting groove and is connected with an air inlet part; and the air inlet part is connected to an air pump. Compared with the prior art, the injection mold with the insert positioning function has the advantages that the metal insert can be limited at a preset position, and therefore accidents caused by disengagement of the metal insert can be avoided.

Owner:ZHEJIANG BUSINESS TECH INST

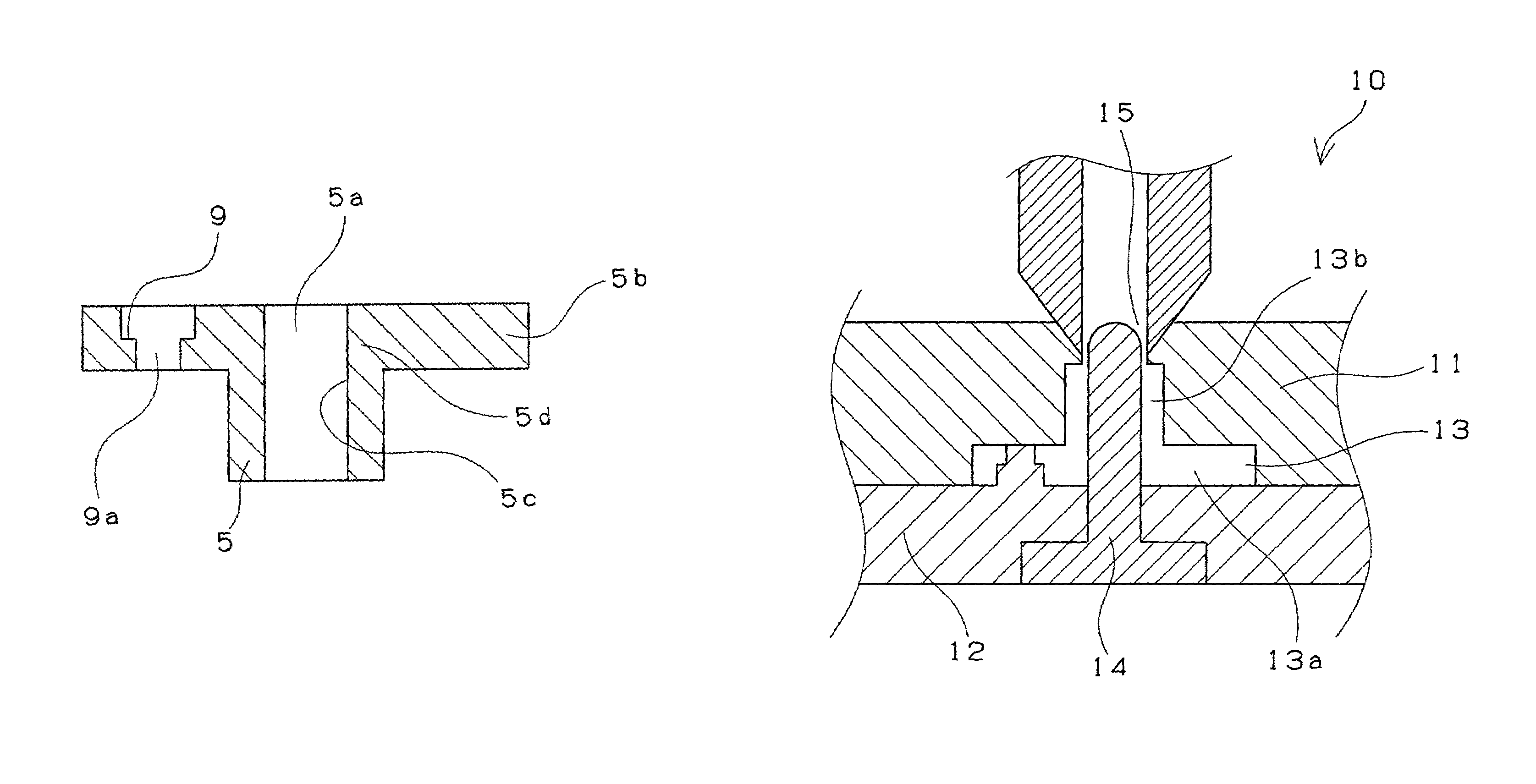

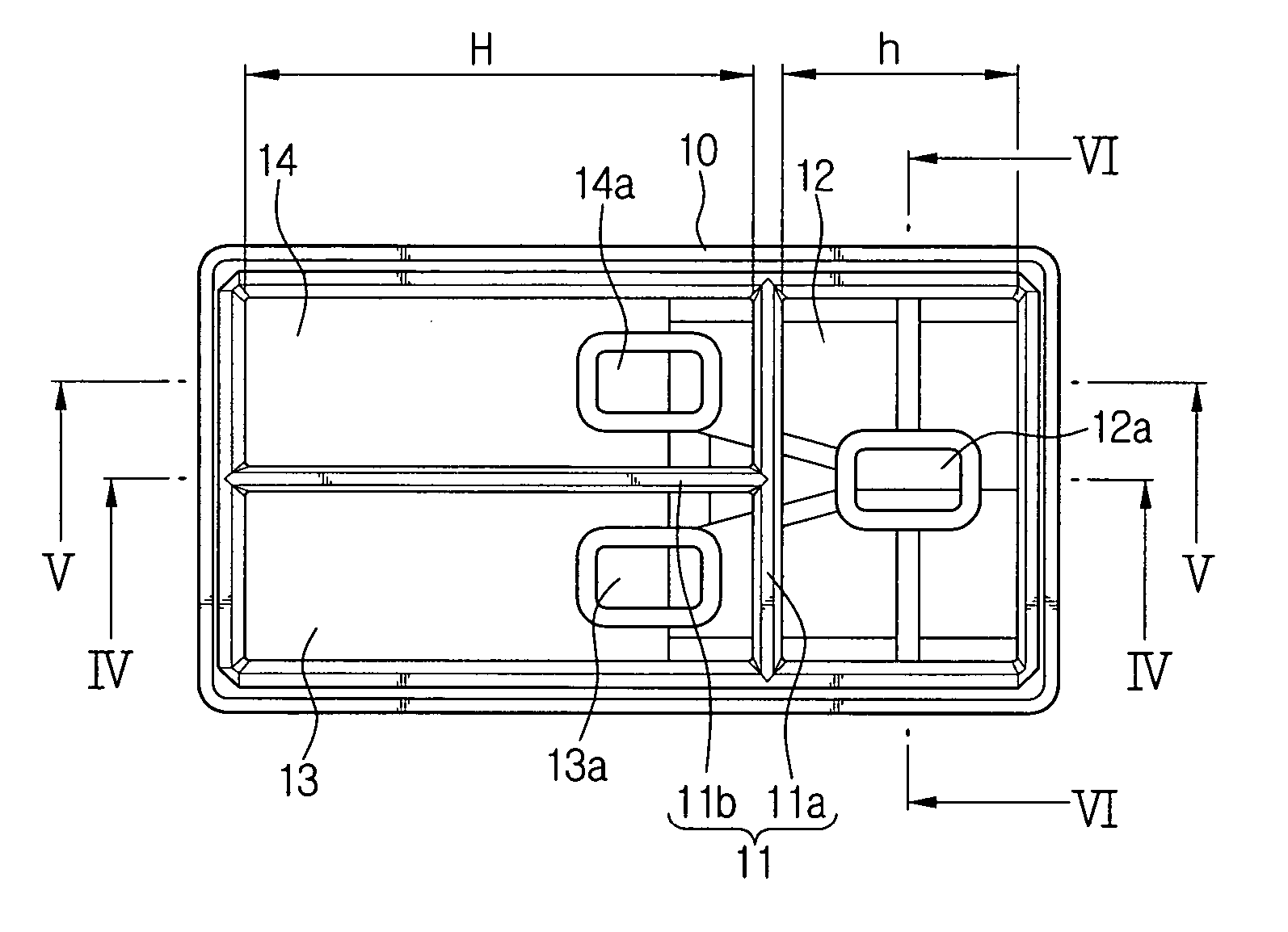

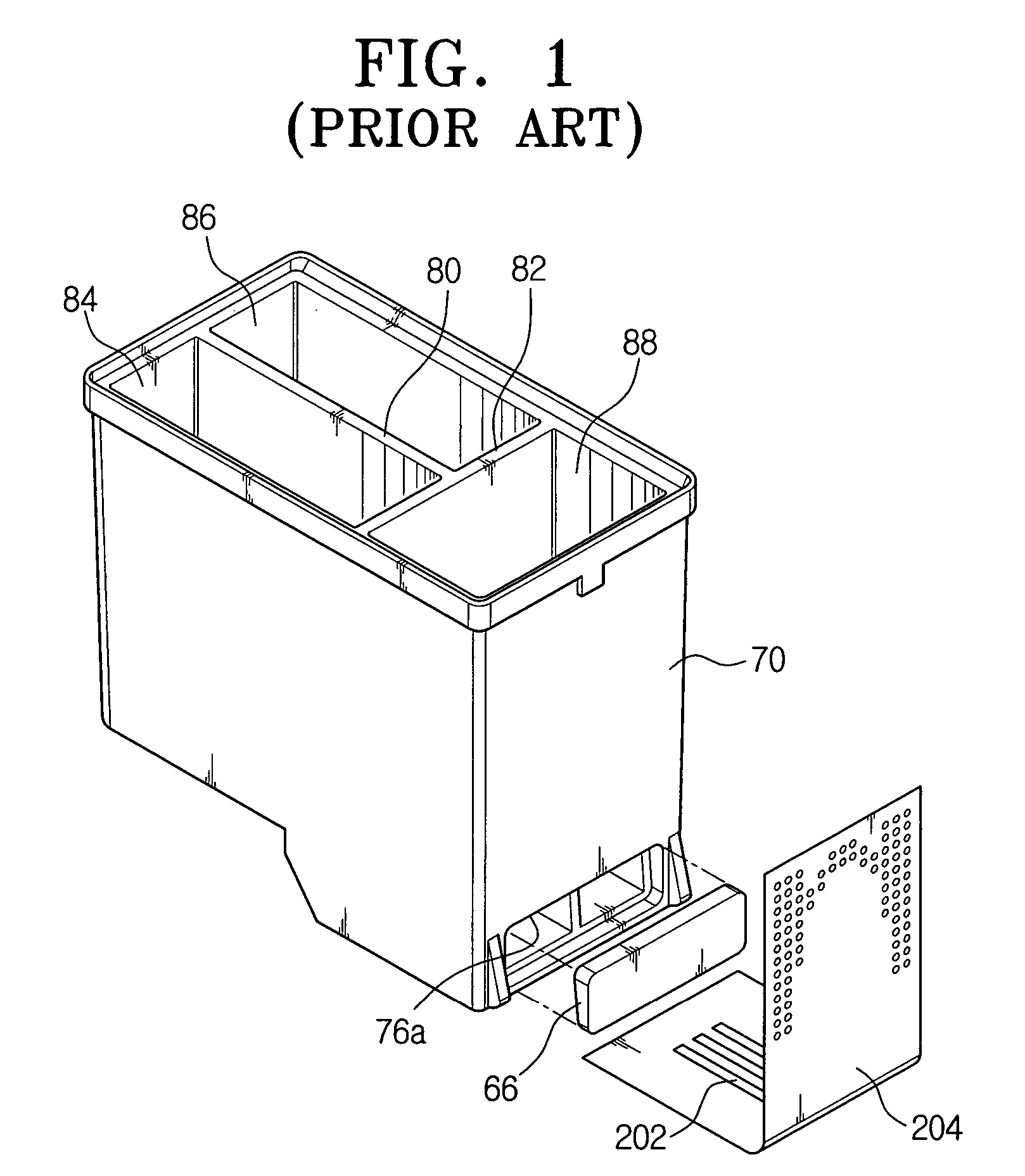

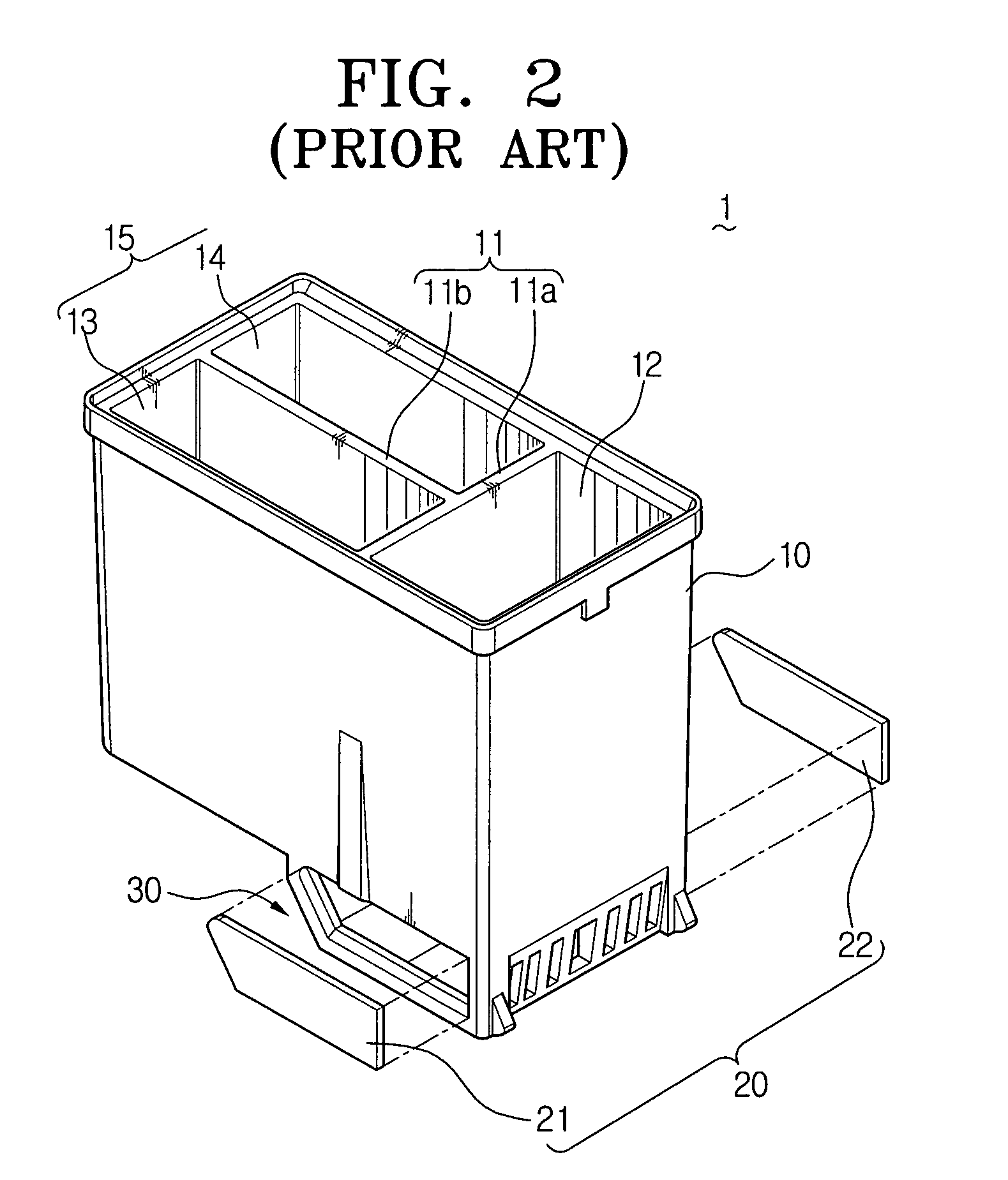

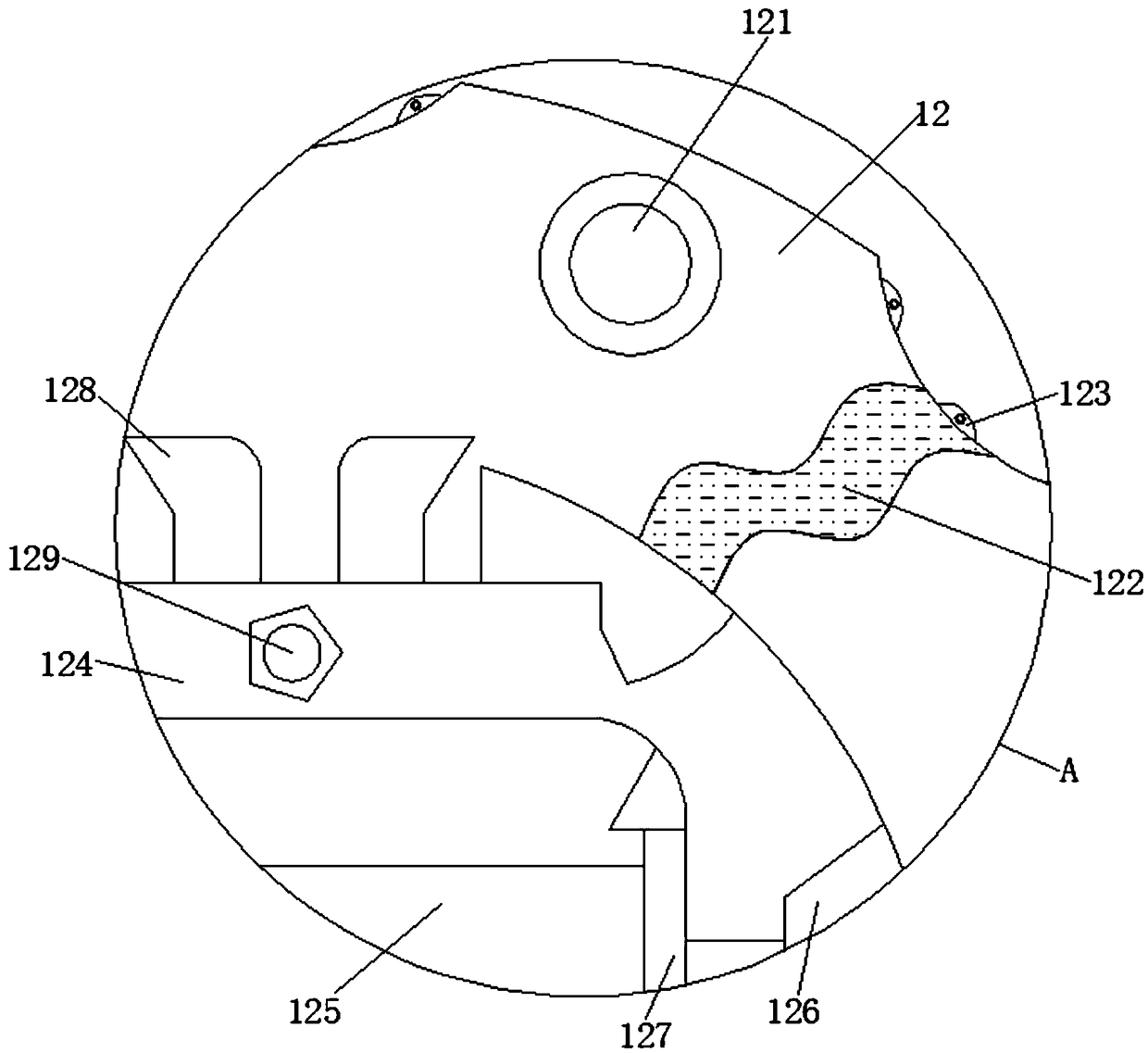

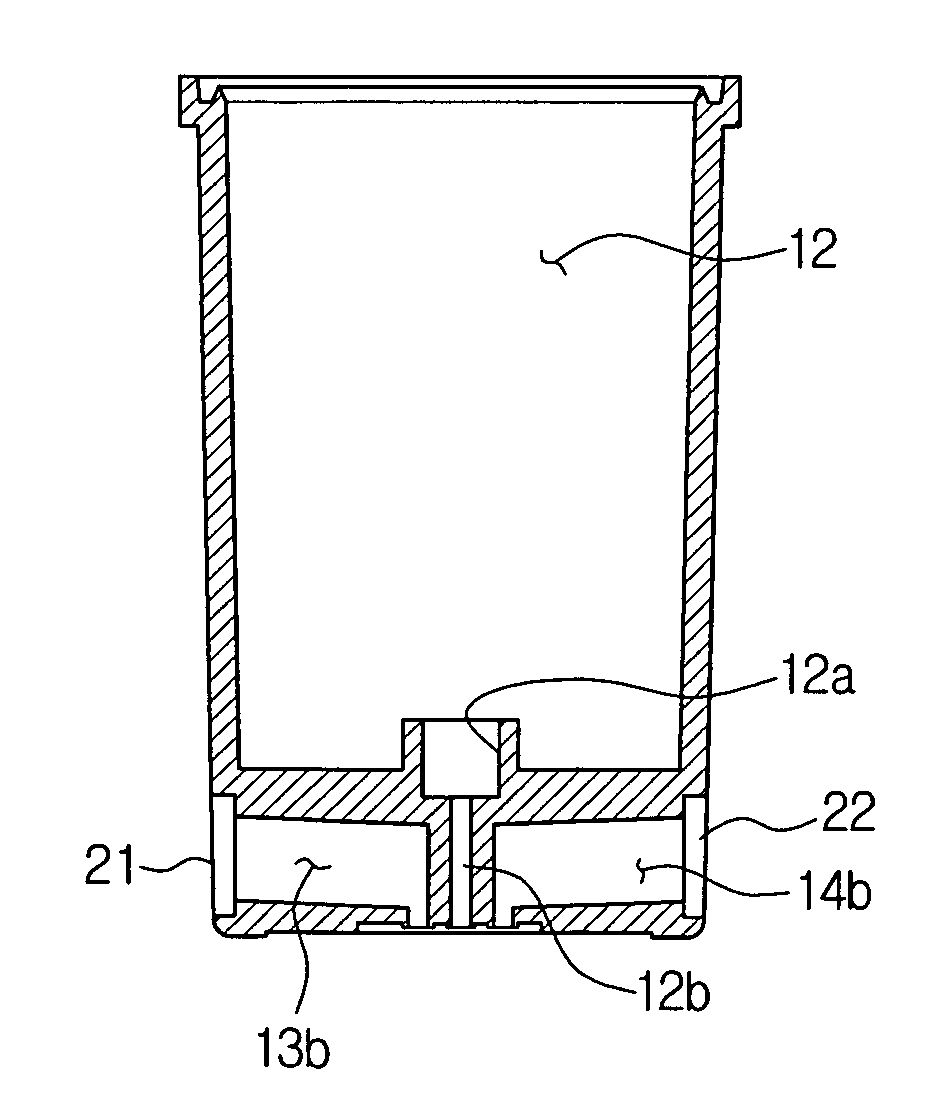

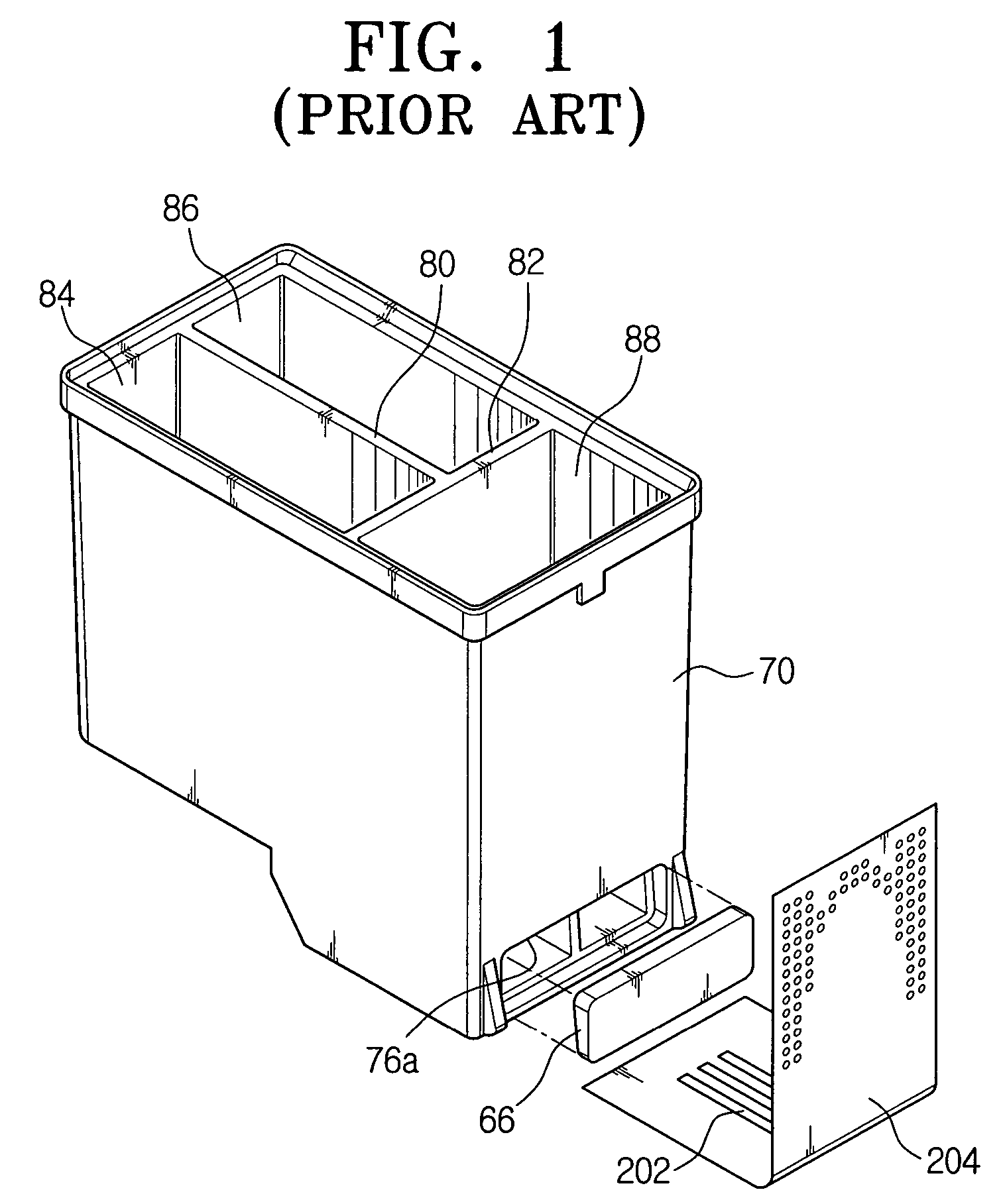

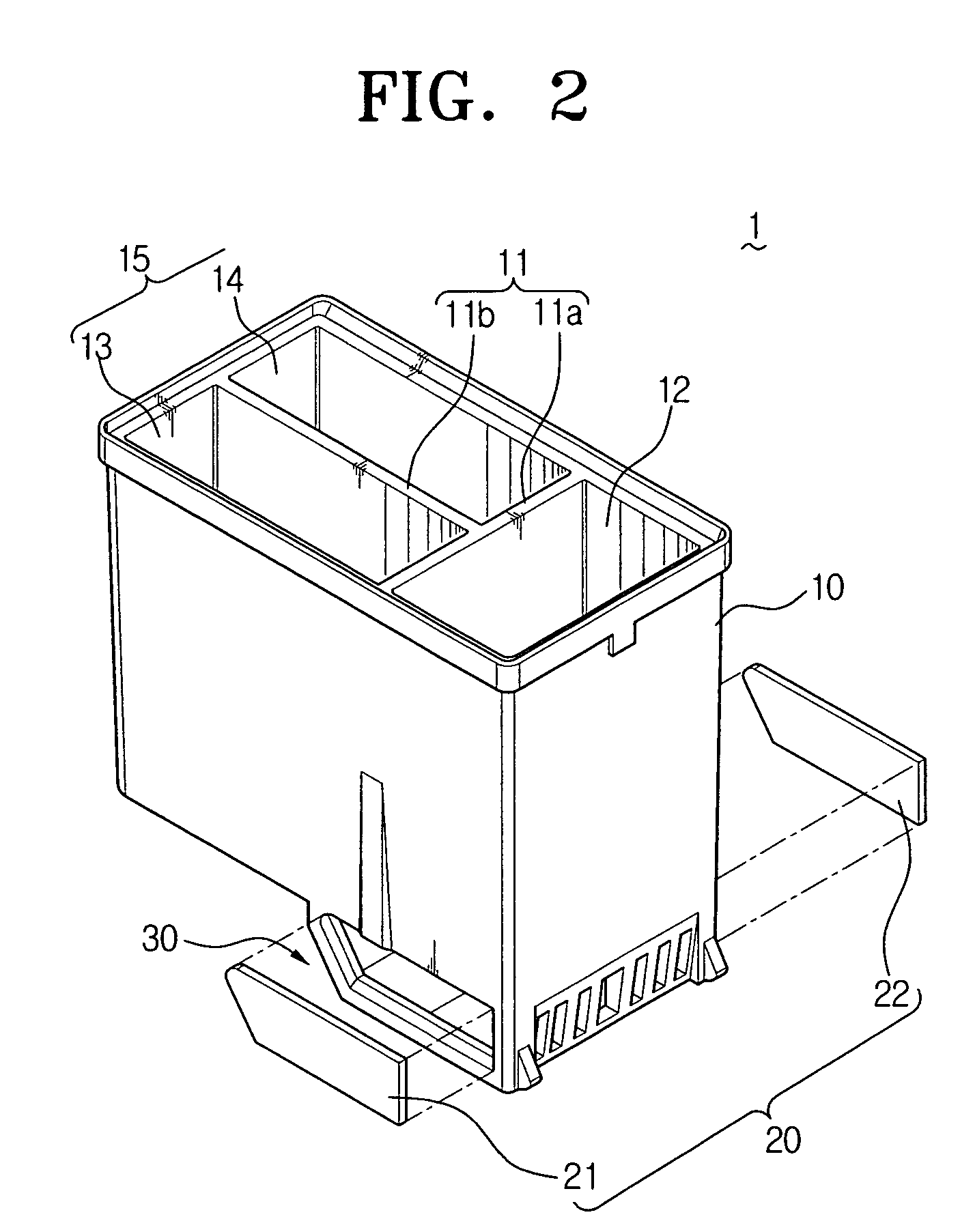

Ink cartridge

InactiveUS20050174401A1Improve injection molding effectReduce manufacturing costPrintingEngineeringMechanical engineering

Disclosed is an ink cartridge for an ink-jet image forming apparatus. The ink cartridge comprises an ink cartridge body having a plurality of ink chambers. The ink chambers are formed by two or more partitioning walls orthogonally intersected with each other within the ink cartridge body. A nose is formed at a position adjacent to the bottom surfaces of the ink chambers. The nose includes openings formed in the opposite sides and a plurality of ink feeding channels forming the central area between the openings and connected to the ink feeding channels, respectively. Sealing members seal each corresponding one of the nose openings.

Owner:S PRINTING SOLUTION CO LTD

Injection mold

The invention discloses an injection mold which comprises an insert mounting part. The insert mounting part is provided with threaded holes and is mounted on the mold through a threaded connection manner. An insert mounting groove is formed in the insert mounting part. An insert locating part is arranged on the side edge of the insert mounting groove. A containing cavity is formed in the insert locating part. A limiting ball and a spring are arranged in the containing cavity. The spring abuts against the limiting ball so that the limiting ball can be in a working state. A heating body is arranged in the insert locating part. A prospect hole is formed in the bottom of the insert mounting groove. A hydraulic oil cavity is formed in the insert mounting part. The prospect hole is connected with the hydraulic oil cavity. An ejection block and a piston block are arranged in the hydraulic oil cavity. An ejection rod is arranged on the ejection block. The ejection rod can stretch out of the prospect hole, and therefore a metal insert is jacked up. The piston block is connected with a push rod, the push rod is driven by a motor to work, and therefore the piston block is driven to move. Compared with the prior art, according to the injection mold, the metal insert can be stably limited at a preset position, and the situation that the metal insert is separated, and consequently accidents happen is avoided.

Owner:ZHEJIANG BUSINESS TECH INST

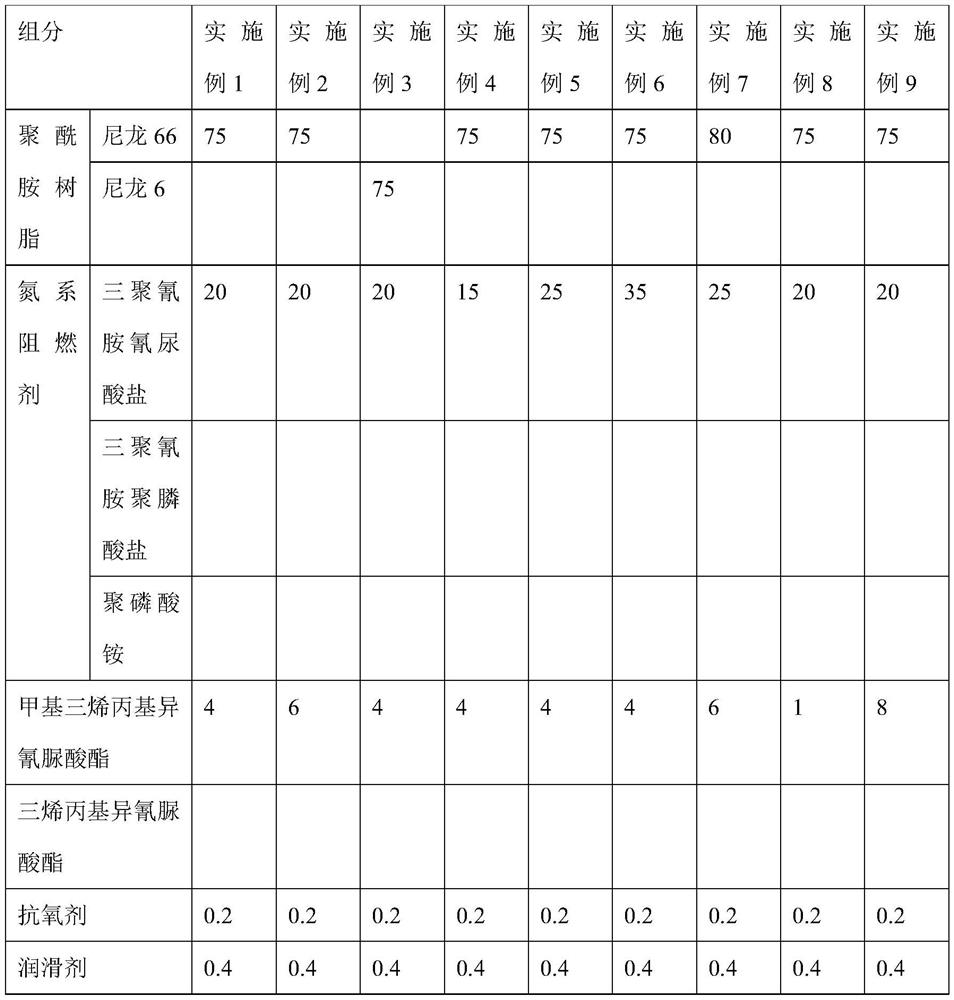

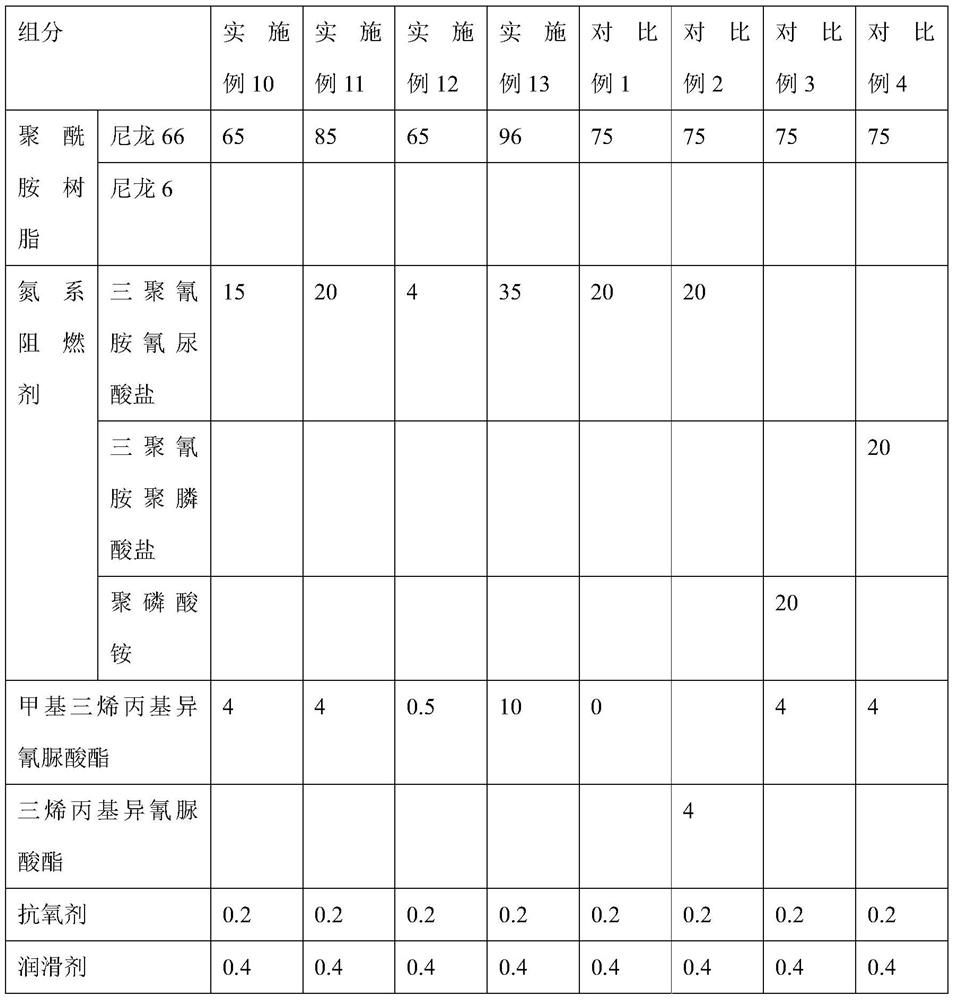

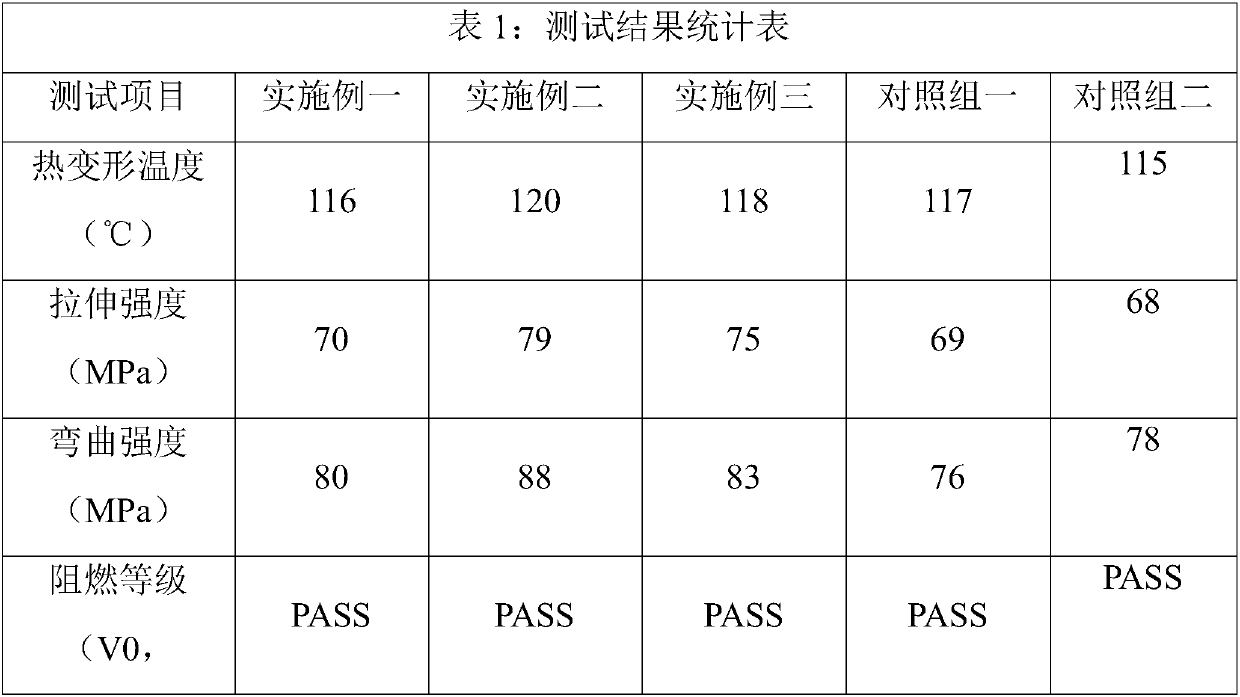

Halogen-free flame-retardant polyamide composite material as well as preparation method and application thereof

ActiveCN112745675AGood compatibilityRaise the crystallization temperaturePolymer sciencePropyl isocyanide

The invention provides a halogen-free flame-retardant polyamide composite material as well as a preparation method and application thereof. The halogen-free flame-retardant polyamide composite material is prepared from the following components in parts by weight: short-carbon-chain aliphatic polyamide resin, a nitrogen flame retardant and methyl triallyl isocyanurate, and the nitrogen flame retardant is melamine cyanurate. According to the halogen-free flame-retardant polyamide composite material disclosed by the invention, methyl triallyl isocyanurate and melamine cyanurate are added for compounding, so that the glowing filament expression of the material is improved, the halogen-free flame-retardant effect is realized, the GWIT test at 775 DEG C is passed, the crystallization temperature and the crystallization speed of the halogen-free flame-retardant polyamide composite material can be increased, and thus, the injection molding performance of the halogen-free flame-retardant polyamide composite material is improved.

Owner:KINGFA SCI & TECH CO LTD

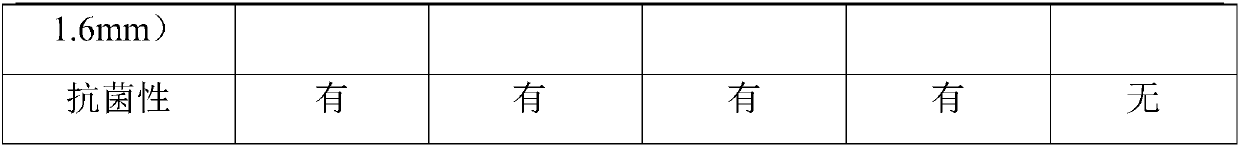

Wearproof flame retardant and antibacterial PC material and preparation method thereof

The invention relates to the field of plastic raw materials, in particular to a wearproof flame retardant and antibacterial PC material and a preparation method thereof. The wearproof flame retardantand antibacterial PC material is composed of the following components by mass percentage: 65-85% of PC; 5-25% of PTFE; 5-8% of a toughening agent; 4-8% of a flame retardant; 1-5% of a compatilizer; 1.0-3.0% of a nano antibacterial agent; and 0.2-0.5% of an antioxidant. The wearproof flame retardant and antibacterial PC material provided by the invention has the advantages of good wear resistance,long service life, good flame retardance, low potential safety hazard and good antibacterial properties, is beneficial to user health, and is environment-friendly and non-toxic.

Owner:东莞市优特美工程塑料有限公司

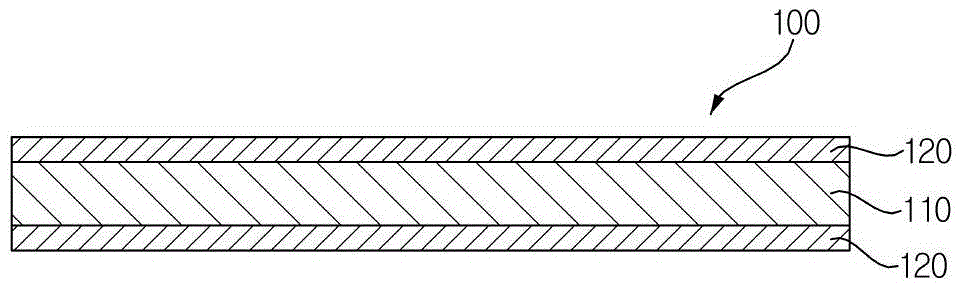

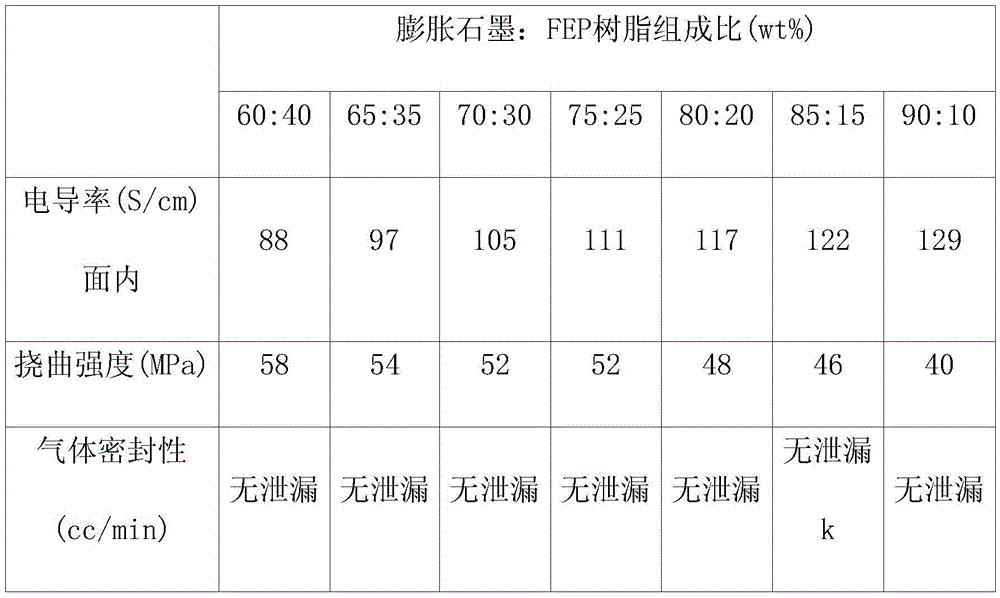

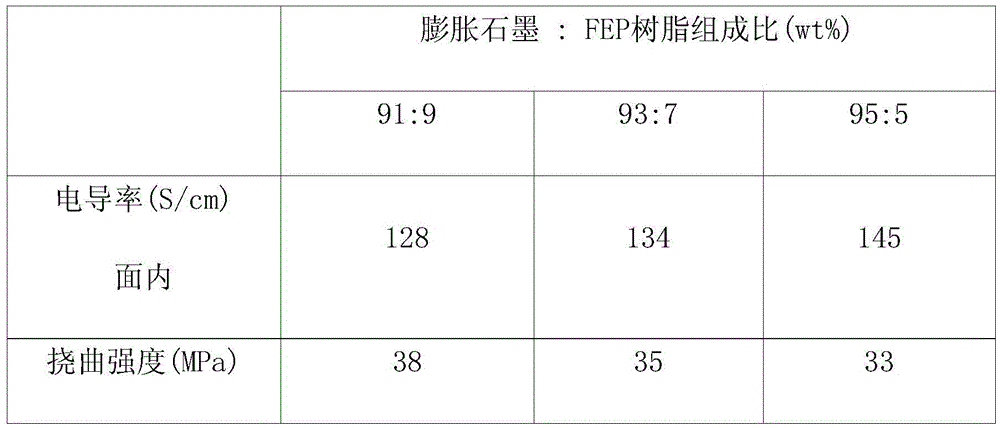

Fuel Cell Separating Plate And Method Of Manufacturing The Same

InactiveCN105762381ADoes not reduce conductivityReduce usageFinal product manufactureFuel cellsFuel cellsGraphite

Disclosed are a fuel cell separating plate having high temperature and acid resistance, and a method of manufacturing the same. The fuel cell separating plate includes a molded product manufactured from a mixture of expanded graphite and thermoplastic resin. The fuel cell separating plate and the method of manufacturing the same according to the present invention do not lower conductivity of the separating plate while decreasing a use amount of a conductive material. In addition, the fuel cell separating plate and the method of manufacturing the same simplify a manufacturing process and shorten manufacturing time.

Owner:HANKOOK TIRE WORLDWIDE

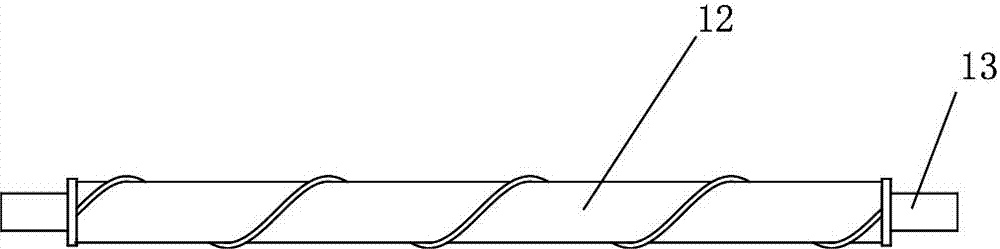

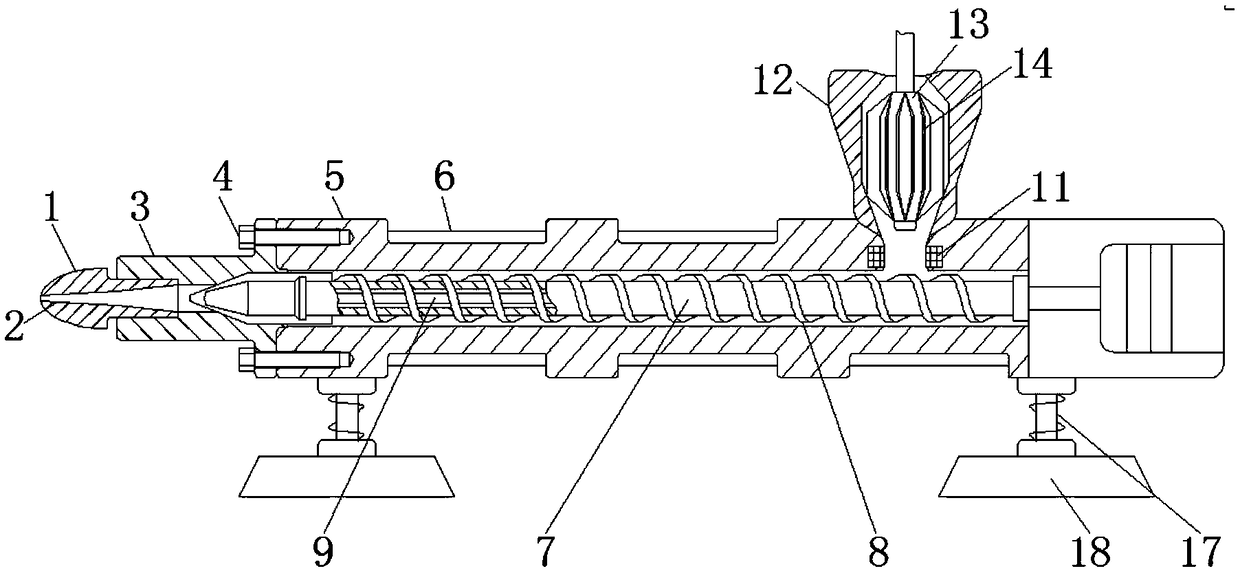

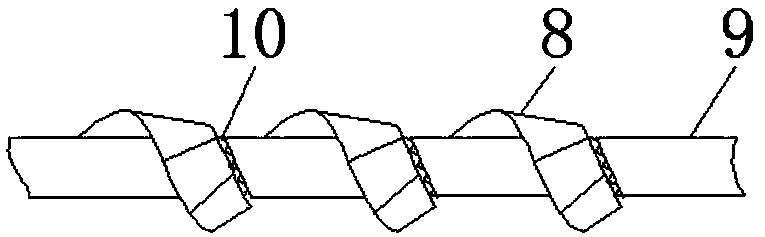

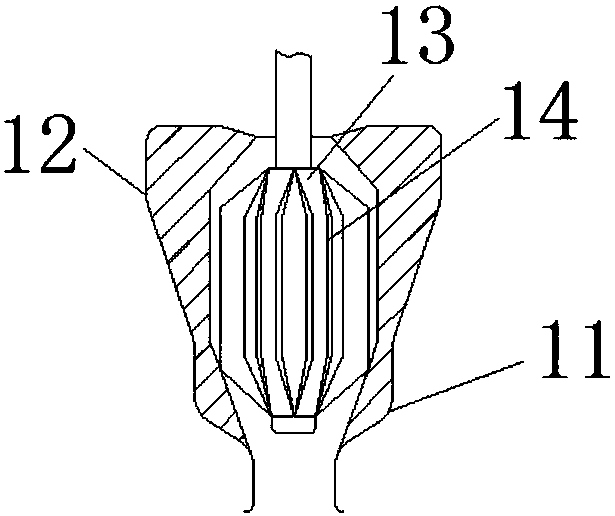

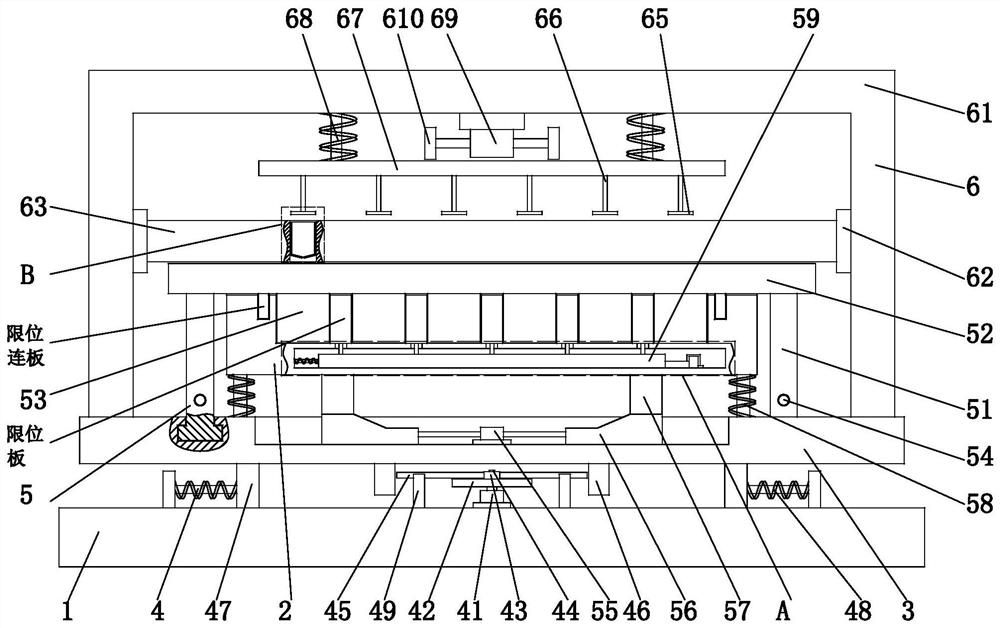

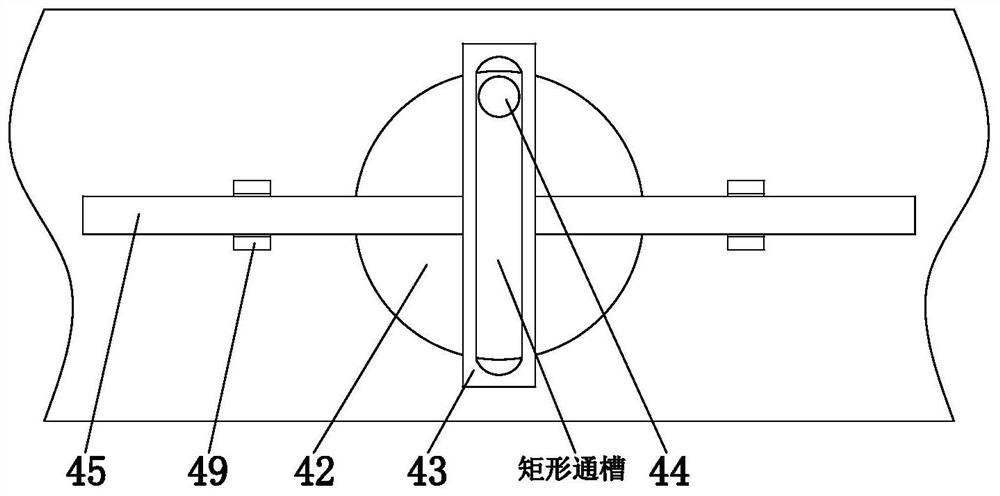

Screw-type injection molding machine for injection molding

The invention discloses a screw-type injection molding machine for injection molding. The screw-type injection molding machine comprises a nozzle, a screw and a material crushing head. An injection molding flow pass is formed in the nozzle, and a nozzle flange is mounted on the right side of the nozzle. Inner hexagon screws are arranged on the upper side and the lower side of the nozzle flange correspondingly, and a charging barrel is mounted on the right side of the nozzle flange. A heat transfer metal ring is fixed to the outer wall of the charging barrel, and screw teeth are arranged on theouter wall of the screw. The screw is located in the middle of the charging barrel, and a control rod is arranged in the middle of the screw. Balls are inlaid in the outer wall of the control rod, and an electric heating wire sleeve is mounted on the upper portion of the right side of the screw. A material opening is formed in the upper portion of the electric heating wire sleeve, and a fine crushing knife is mounted on the outer side of the material crushing head. The material crushing head is located in the middle of the material opening. According to the screw-type injection molding machine for injection molding, the propulsion area of the screw can be adjusted, the propulsion angle of molten plastic by the screw can be adjusted, and the plastic can be finely crushed in advance.

Owner:黄子奇

Process for producing injection molded product

The present invention provides an injection molding process of a thermoplastic resin which is capable of thin molding or precision molding by improving injection moldability, particularly releasability or fluidity, without deteriorating the characteristics of the injection molded article of the thermoplastic resin. The process for producing an injection molded product comprises injection molding a mixture containing a thermoplastic resin and a polyolefin wax, wherein the mixture has L / L0≧1.05, the L being a flow length in the case where the mixture contains the polyolefin wax and the Lo being a flow length in the case where the mixture contains no polyolefin wax, the L and L0 being measured under the conditions of a mold temperature of 40° C. and a resin temperature, Tr, as determined by the following equation: Tr=¾×Tm+100(wherein Tm represents a melting temperature (° C.) of the thermoplastic resin), using a spiral flow mold having a thickness of 1 mm and a width of 10 mm.

Owner:MITSUI CHEM INC

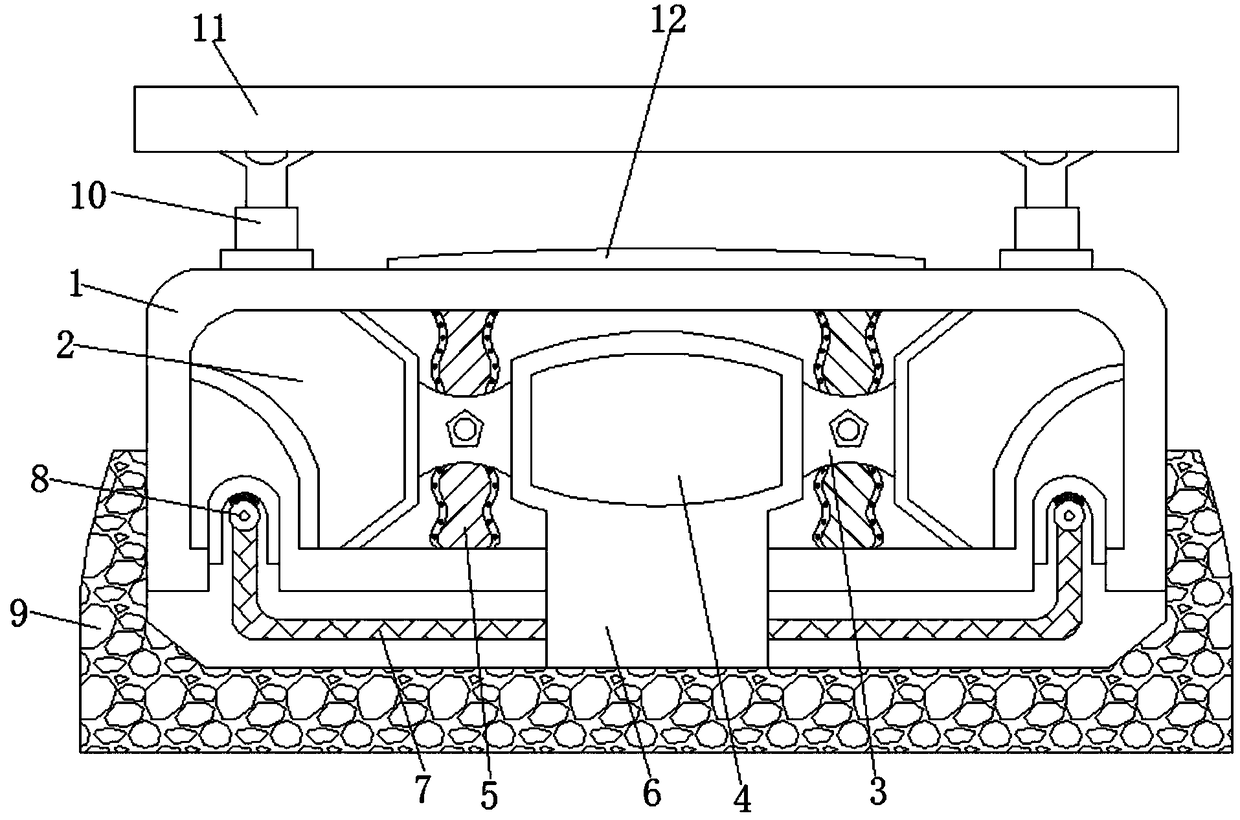

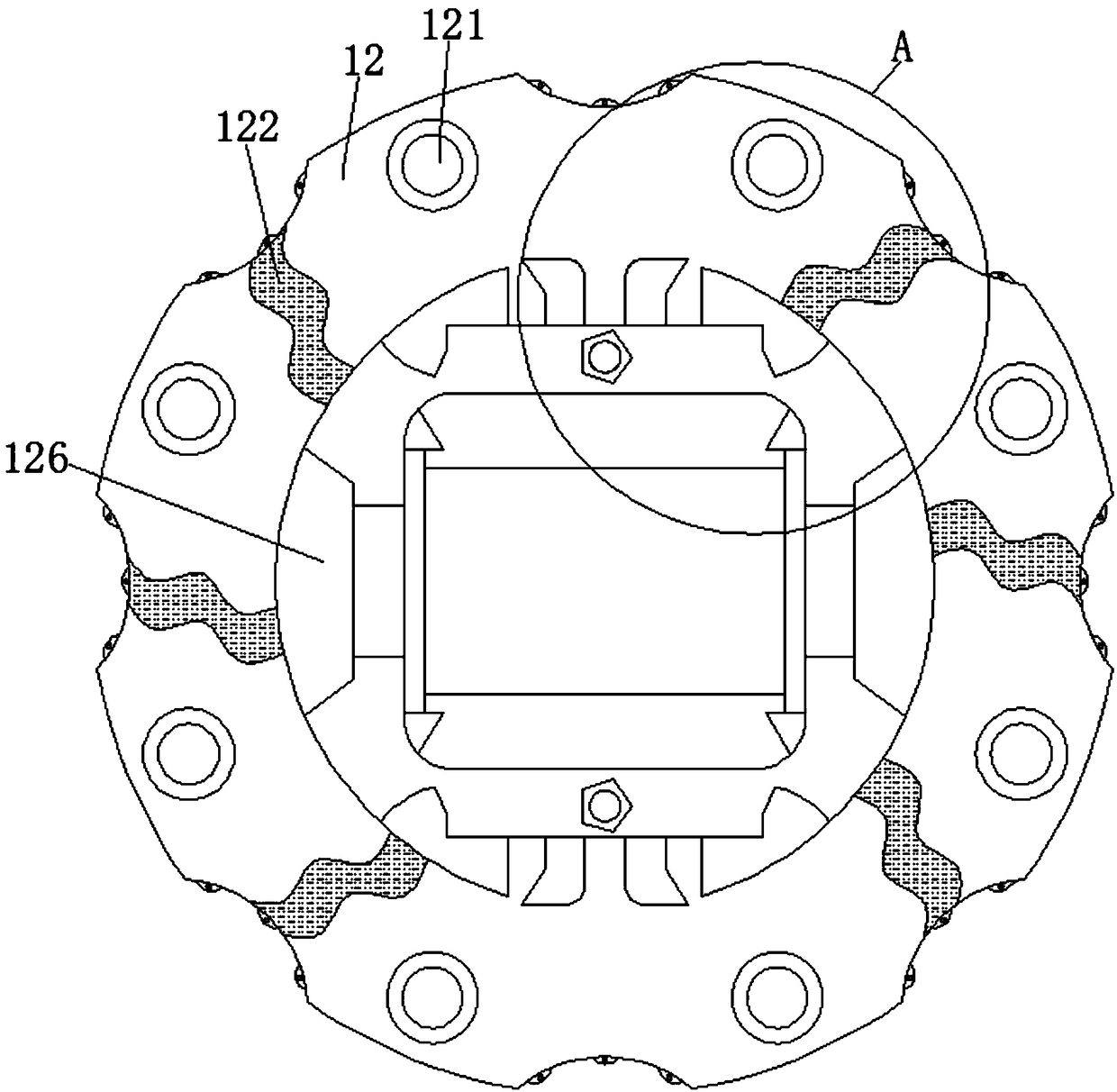

Plastic injection mold

ActiveCN110861272AImprove injection molding effectEasy to replaceDispersed particle separationActivated carbonInjection molding process

The invention discloses a plastic injection mold, and relates to the technical field of injection molding. A rear formwork bottom plate is included. A rear formwork on the rear formwork bottom plate is detachably connected with a front formwork on a front formwork bottom plate. A cavity for mold injection molding is formed by a rear mold core formed by the upper portion of the rear formwork and afront mold core formed at the lower portion of the front formwork. Each exhaust assembly comprises a pipe cavity, wherein one end of the pipe cavity communicates with the cavity, the other end of thepipe cavity upwards extends out of the top face of the front formwork bottom plate, meanwhile, the pipe cavity is internally provided with a matched exhaust pipeline, and one end of the exhaust pipeline communicates with the cavity and is provided with a ventilation micro hole ring. According to the plastic injection mold, surplus air in the cavity is exhausted in time, accordingly, the phenomenonof air hole generation in the injection molding process is avoided, and the mold injection molding effect is improved; and an activated carbon adsorption plate can be utilized for adsorbing harmful molecules contained in hot melting plastic raw materials, and accordingly the body health of workers is facilitated while exhausting is guaranteed.

Owner:NINGBO SHUANGLIN IND PROD MFG CO LTD

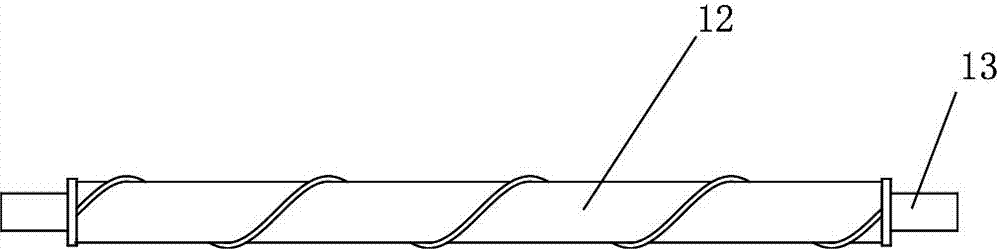

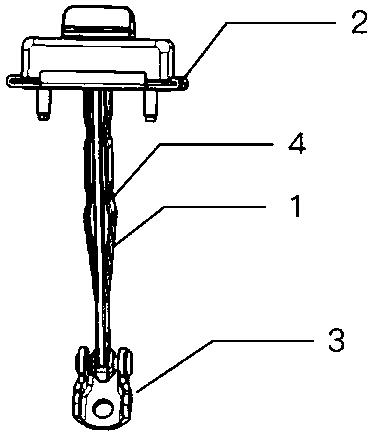

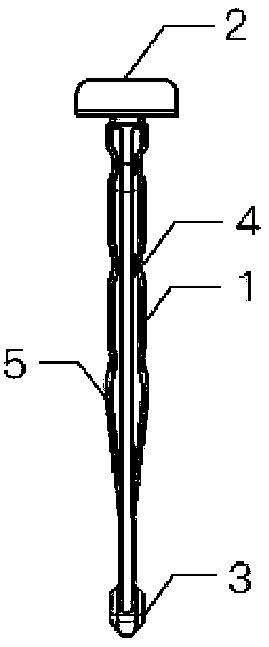

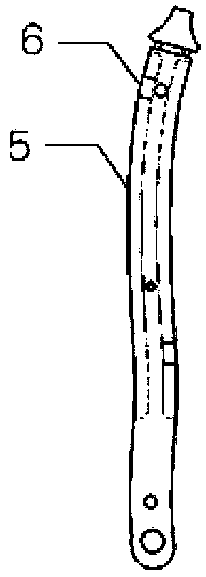

Novel limiting arm structure of side door limiter

InactiveCN109209079AImprove injection molding effectAvoid accumulationWing accessoriesWing fastenersEngineeringInjection moulding

The invention provides a novel limiting arm structure of a side door limiter. The novel limiting arm structure comprises a limiting arm, a sliding block is connected to the upper end of the limiting arm, a limiting device support is connected to the lower end of the limiting arm, the limiting arm is provided with gear grooves at equal intervals, the two sides of the limiting arm are provided withmore than one concave groove, and the concave grooves are arranged at equal width and at equal intervals. According to the novel limiting arm structure, on the premise that the overall strength of thelimiting arm is guaranteed, the two sides of the limiting arm are subjected to hollowing-out treatment so as to form the concave grooves, and therefore the injection molding property of the limitingarm is improved, and the product weight is decreased.

Owner:FENGYE TIMS WUHU AUTO PARTS CO LTD

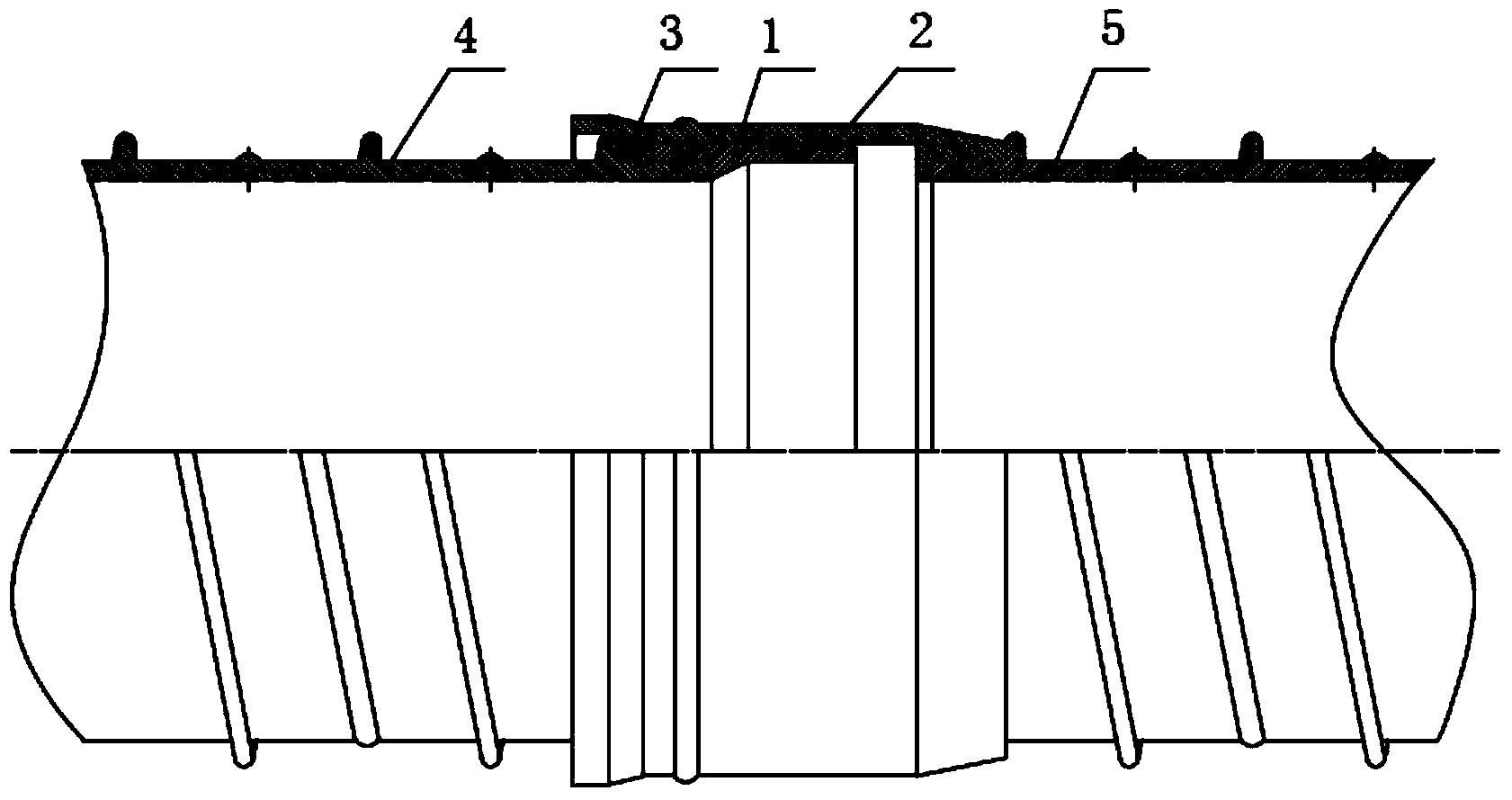

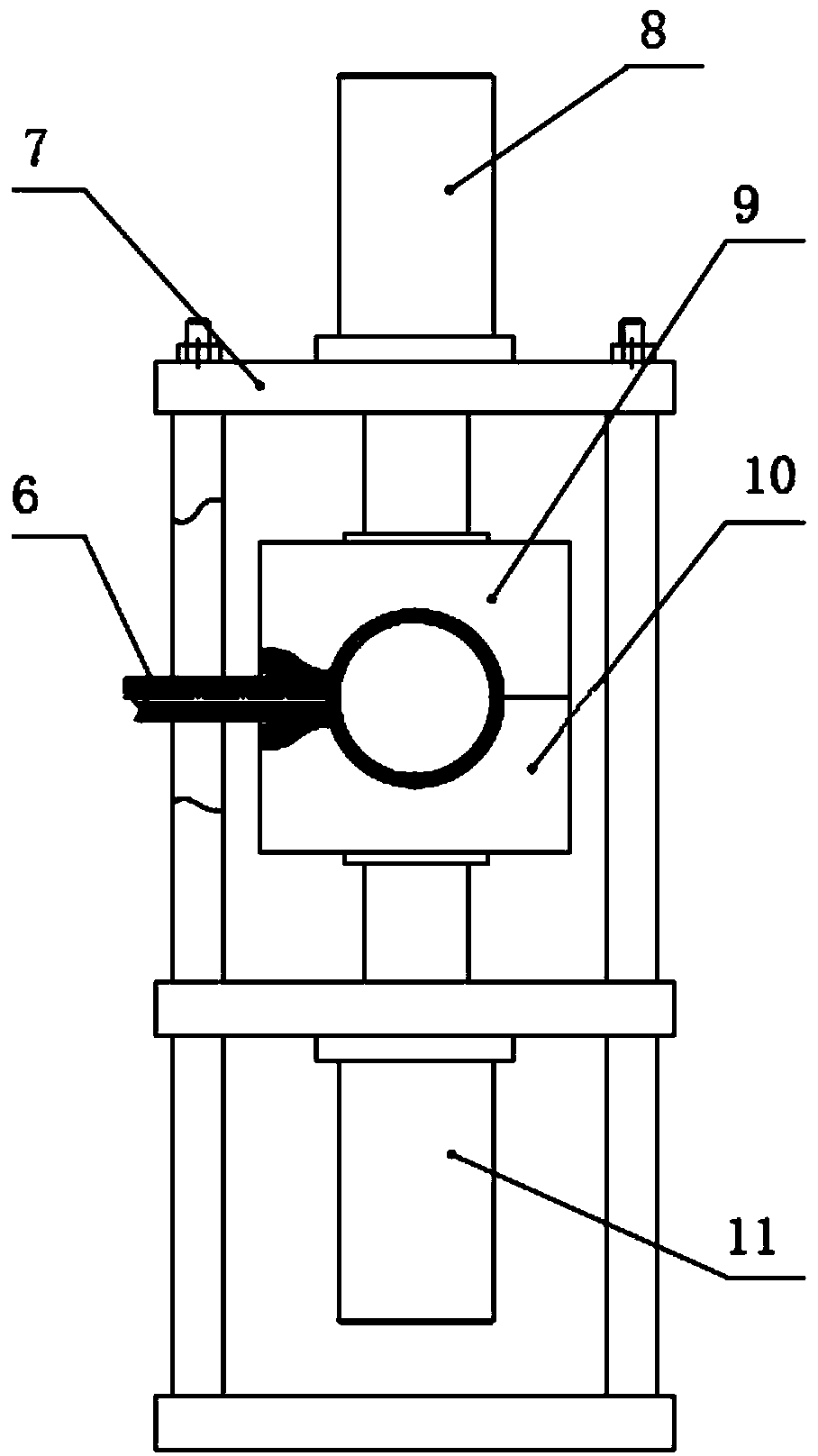

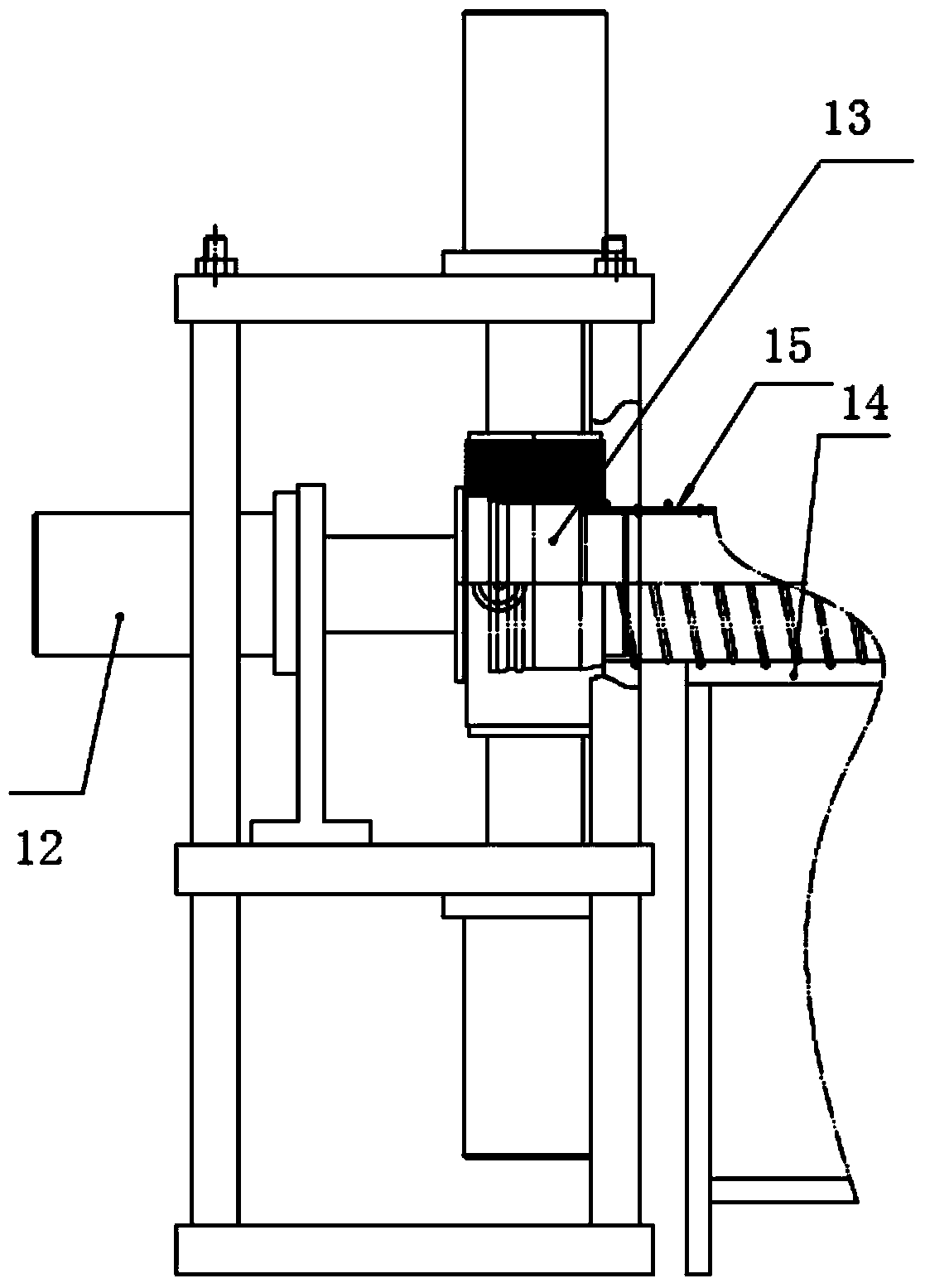

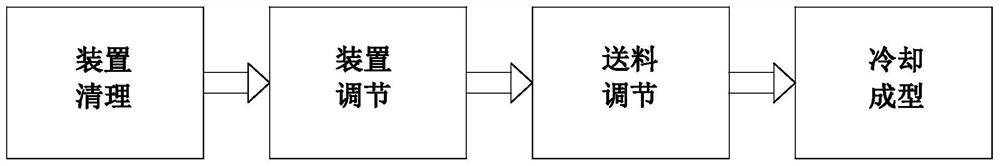

Plastic pipeline connector and production device for plastic pipeline connector

ActiveCN104329528AAchieve connectionImprove construction efficiencyDomestic articlesPipe connection arrangementsPlastic pipeworkStructural engineering

The invention discloses a plastic pipeline connector and a production device for the plastic pipeline connector. The plastic pipeline connector comprises an inner pipe joint, an outer pipe joint and a seal ring; the inner pipe joint is subjected to injection molding at one end of an inner pipe by an injection mold; the outer pipe joint is subjected to injection molding at one end of an outer pipe by the injection mold; the seal ring is arranged between the inner pipe joint and the outer pipe joint; the production device comprises an injection molding pipe head, a support, an upper oil cylinder, an upper die, a lower die, a lower oil cylinder, a back oil cylinder, a back mandrel and a pipe workpiece positioning frame; the upper oil cylinder is connected with the upper die; the lower oil cylinder is connected with the lower die; the back oil cylinder is connected with the back mandrel; the upper die, the lower die and the back mandrel are combined to form a die cavity; the upper oil cylinder, the upper die, the lower die, the lower oil cylinder, the back mandrel and the back oil cylinder are arranged on the support; the pipe workpiece positioning frame is arranged in front of the support. According to the plastic pipeline connector, one end of the inner pipe and one end of the outer pipe are respectively provided with the inner pipe joint and the outer pipe joint through injection molding, the inner pipe joint is inserted into the outer pipe joint at the construction field, and the pipeline connection is easy to realize; the production device for the plastic pipeline connector is simple in structure, low in cost and safe and convenient to operate.

Owner:ANHUI HUAQI PIPE

Injection molding method for polymer rubber plate

The invention relates to an injection molding method for a polymer rubber plate. A polymer rubber plate injection molding device is adopted, and comprises a bottom rack, a molding plate, a molding workbench, a vibrating mechanism, an adjusting mechanism and a feeding mechanism. According to the injection molding method, the problems existing in the injection molding process of the polymer rubber plate can be solved: a, in the traditional injection molding process of the polymer rubber plate, the size of a mold is fixed; if the specifications of the polymer rubber plates required for production are different, molds with different specifications are needed, and the molds need to be frequently replaced in the traditional injection molding process; the production cost is high, and the process is complex; b, in the traditional injection molding process of a molecular rubber plate, only a single polymer rubber plate can be subjected to injection molding, the yield is low; in the traditional injection molding process of the molecular rubber plate, the demolding efficiency is low, and the injection molding efficiency is low; and the yield of the polymer rubber plate is influenced.

Owner:广东省恩齐尼迩特种塑料股份有限公司

Stop-loss-based air conditioner shell injection mold capable of achieving flexible operation

The invention relates to the technical field of injection molding equipment and discloses a stop-loss-based air conditioner shell injection mold capable of achieving flexible operation. The stop-loss-based air conditioner shell injection mold capable of achieving flexible operation comprises a mold platform. The two sides of an inner cavity of the mold platform are connected with oil accumulationbins in a welded manner. The middles located on one sides of the two oil accumulation bins are connected with oil guide pipes in a welded manner. One ends of the two oil guide pipes are connected to the two sides of the exterior of a collection bin. The two sides of the top of the mold platform are connected with positioning supporting devices in a welded manner. The ends, located on the tops, ofthe two positioning supporting devices are connected with the two sides of the bottom of an upper mold plate in a welded manner. The middle of the top of the mold platform is connected with an upper mold plate. According to the stop-loss-based air conditioner shell injection mold capable of achieving flexible operation, by means of the cooperative using of a vernier device and an operation positioning device, a user can carry out fine adjustment according to a style of an air conditioner shell to be machined, meanwhile, the user can also carry out oil rubbing treatment on the interior throughthe operation positioning device, and the maintaining effect of the vernier device and the operation positioning device is improved.

Owner:东莞顶钧塑胶模具有限公司

Ink cartridge

InactiveUS7517068B2Improve injection molding effectPrevent leakagePrintingEngineeringMechanical engineering

Disclosed is an ink cartridge for an ink-jet image forming apparatus. The ink cartridge comprises an ink cartridge body having a plurality of ink chambers. The ink chambers are formed by two or more partitioning walls orthogonally intersected with each other within the ink cartridge body. A nose is formed at a position adjacent to the bottom surfaces of the ink chambers. The nose includes openings formed in the opposite sides and a plurality of ink feeding channels forming the central area between the openings and connected to the ink feeding channels, respectively. Sealing members seal each corresponding one of the nose openings.

Owner:S PRINTING SOLUTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com