Halogen-free flame-retardant polyamide composite material as well as preparation method and application thereof

A flame-retardant polyamide and composite material technology, which is applied in the field of halogen-free flame-retardant polyamide composite materials and its preparation, can solve the problems of poor injection molding performance, inability to be used for injection molding, and restricting the application of halogen-free flame-retardant polyamide materials. , to achieve the effect of increasing the crystallization temperature and crystallization speed, improving the compatibility, and improving the performance of the glow wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

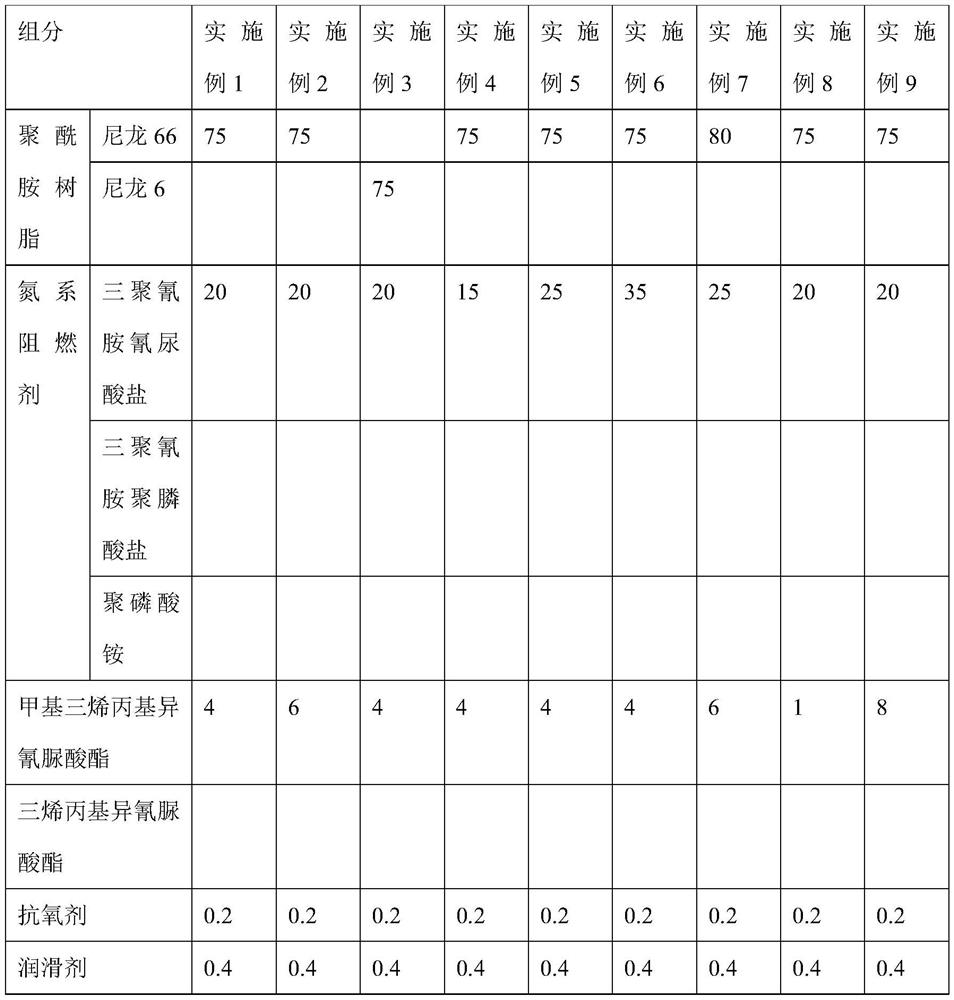

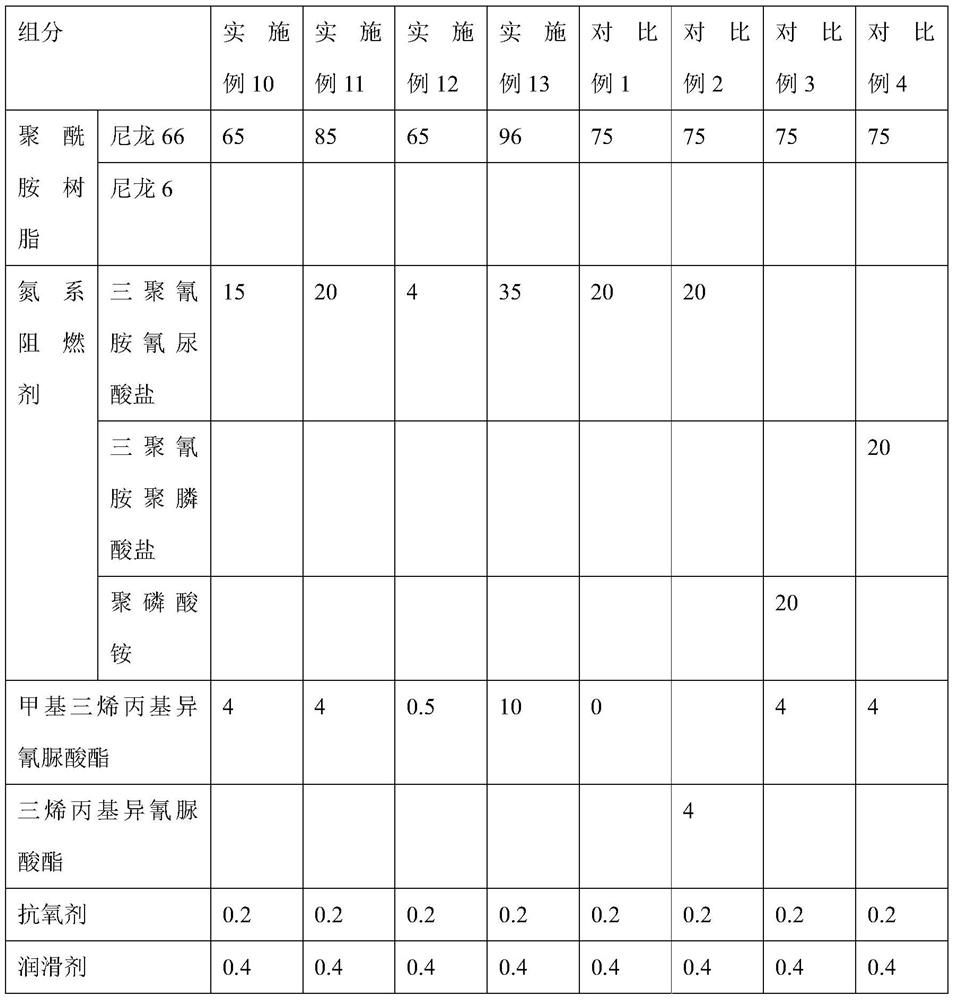

[0029] The present invention will be further described below in combination with specific embodiments. The raw materials in Examples and Comparative Examples can be obtained commercially or can be prepared by known methods. In addition, "parts" and "%" in this specification represent "parts by weight" and "% by mass", respectively, unless otherwise specified.

[0030] The manufacturer and the trade mark of the raw material used in the following examples and comparative examples are as follows:

[0031] 1. Polyamide resin:

[0032] Nylon 66, melting point 265°C, PA66 EP-158, Zhejiang Huafeng Group;

[0033] Nylon 6, melting point 225°C, PA6 HY-2500A, Jiangsu Haiyang Chemical Fiber Co., Ltd.;

[0034] 2. Nitrogen-based flame retardants:

[0035] Melamine cyanurate: the brand name is melamine cyanurate MCA, Shouguang Weidong Chemical Co., Ltd.;

[0036] Melamine polyphosphonate: Brand Budit 3141, BUDENHEIM company;

[0037] Ammonium polyphosphate: Brand APP, Shandong Changs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com