Patents

Literature

86 results about "Propyl isocyanide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butyronitrile/acrylate rubber sealing gasket for transformer and preparation method thereof

The invention discloses a butyronitrile / acrylate rubber sealing gasket for a transformer and a preparation method thereof. The butyronitrile / acrylate rubber sealing gasket is prepared from the following raw materials in parts by weight: 60-80 parts of butadiene-acrylonitrile rubber, 20-40 parts of acrylic rubber, 10-15 parts of ethylene-vinyl acetate copolymer, 4-6 parts of magnesium methacrylate, 2-3 parts of zinc stearate, 25-35 parts of carbon black N550, 0.5-1 part of dicumyl peroxide, 2-3 parts of trimethylolpropane trimethacrylate, 1.5-2.5 parts of triallyl isocyanurate, 5-10 parts of chlorinated paraffin, 10-15 parts of dibutyl phthalate, 4-8 parts of calcined clay, 5-10 parts of nanometer barite powder, 3-6 parts of composite filler, 1-2 parts of anti-aging agent MBZ, 0.5-1 part of accelerant DPTT and 0.5-1 part of accelerant NA-22. The prepared sealing gasket has the performances of excellent mechanical strength, compression resilience, high-temperature ageing resistance, impact resistance, wear resistance and oil resistance, and the service life of the butyronitrile / acrylate rubber sealing gasket is greatly prolonged.

Owner:ANHUI KELIN ELECTRONICS

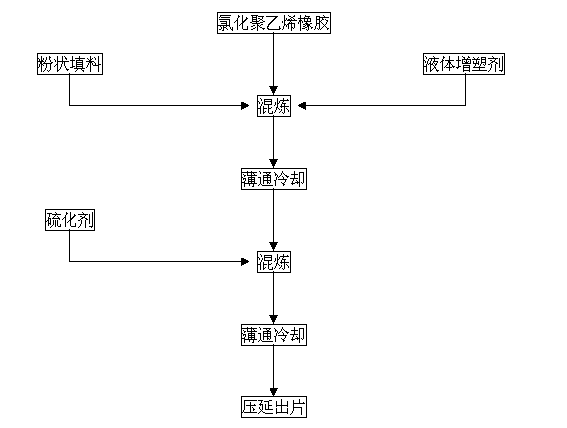

Preparation method of environmental low temperature resistant and acid and alkali resistant cable sheath rubbers

InactiveCN103613870AFully meet the needsSuit one's needsRubber insulatorsInsulated cablesMicrocrystalline waxPropyl isocyanide

The invention discloses two environmental low temperature resistant and acid and alkali resistant cable sheath rubbers, and a preparation method thereof. The environmental low temperature resistant and acid and alkali resistant cable sheath rubbers are mainly prepared from the following components in parts by weight: 100 parts of chlorinated polyethylene rubber, 5-10 parts of high-activity magnesium oxide, 3-5 parts of environmental stabilizer, 4-6 parts of microcrystalline wax, 70-100 parts of acid and alkali resistant filler, 5-10 parts of antimonous oxide, 3-5 parts of DCP (dicumyl peroxide), 3-5 parts of TAIC (triallyl isocyanurate), 1-2 parts of RD (2,2,4-trimethyl-1,2-dihydrogen quinoline polymer),15-20 parts of DOS (dioctyl sebacate), 15-25 parts of carbon black, 10-20 parts of nano clay and 3-5 parts of hansa yellow or fast red. The environmental low temperature resistant and acid and alkali resistant cable sheath rubbers can meet the acid and alkali resistant requirements of the rubber sheath cables, and also have the environmental performance and the low temperature resistance.

Owner:WUXI HUANCABLE

Preparation method of tackifier as well as polyamideadhesion type mixed silicone rubber and preparation method of silicone rubber

The invention discloses a preparation method of a tackifier. The preparation method comprises the steps as follows: hydrogen-containingsilicone oil and triallyl isocyanurate react fully in the presence of a platinum catalyst and are subjected to vacuum devolatilizationto the constant weight after the reaction is finished.Polyamideadhesion type mixed silicone rubber comprises raw materials as follows: the tackifier and addition type mixed solid silicone rubber. The preparation method of the polyamideadhesion type mixed silicone rubber comprises the step that the tackifier and the addition type mixed solid silicone rubber are mixed. The synthesized tackifier is environment-friendly and non-toxic, usage of a silane coupling agent containing a toxic solvent is reduced or avoided, and environmental protection and clean production are facilitated; the prepared polyamideadhesion type mixed silicone rubber has the better adhesion performance to a polyamide material after being vulcanized and is simple in technology and low in production cost.

Owner:阳江市万丰实业有限公司 +1

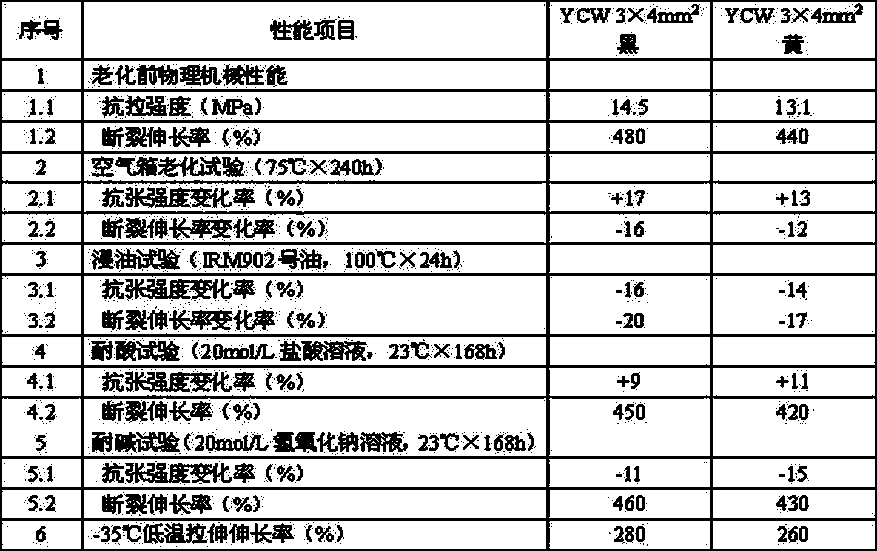

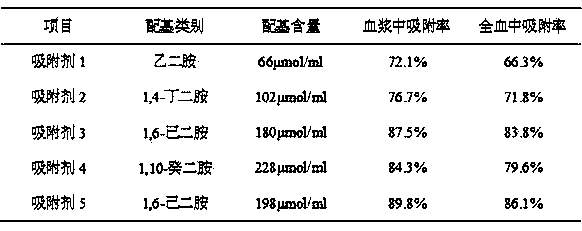

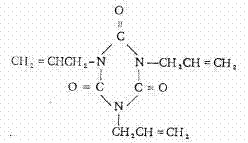

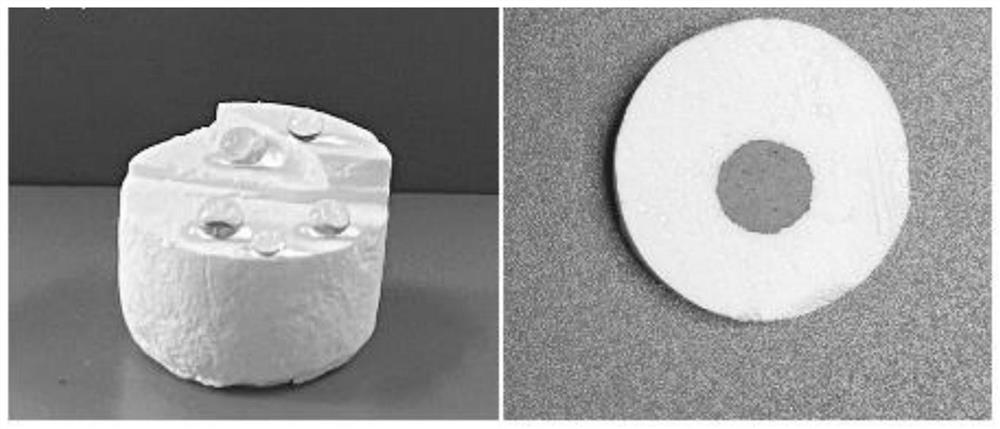

Adsorbent for removing endotoxin by blood perfusion and preparation method thereof

InactiveCN103406111AHigh mechanical strengthImprove mechanical stabilityOther chemical processesAlkali metal oxides/hydroxidesPropyl isocyanidePolyvinyl alcohol

The invention relates to an adsorbent for removing endotoxin by blood perfusion and a preparation method thereof. The adsorbent uses a porous spherical synthesized high molecular material polyvinyl alcohol-triallyl isocyanurate copolymer as a carrier which has a rigid structure, great aperture and hydrophilic surfaces. The ligand is aliphatic diamine, and the carrier activated is coupled with the ligand by way of covalent bonds. The adsorbent is simple to prepare, good in stability, high in content of ligands and good in blood compatibility. The adsorbent is used by way of plasma or whole blood perfusion in blood purification to remove endotoxin in excessive content in blood of patients.

Owner:TIANJIN YOUNASI BIOTECH

High-performance fluorine rubber gasket and manufacturing method thereof

The invention discloses a high-performance fluorine rubber gasket. The high-performance fluorine rubber gasket comprises, by weight, 40-80 parts of binary fluorine rubber, 20-30 parts of silane-modified fluororubber, 12-20 parts of atomized carbon black, 5-10 parts of barium sulfate, 5-15 parts of calcium hydroxide, 1-5 parts of calcium titanate, 1-3 parts of chelate titanate coupling agents, 2-6 parts of molybdenum disulfide, 2-6 parts of phenyl methylpolysilicone resin, 1-2 parts of magnesium oxide, 1-3 parts of dicumyl peroxide, 0.5-1.2 parts of dibenzothiazyl disulfide, 0.5-1.2 parts of triallyl isocyanurate, 1-1.8 parts of bisphenol A, 1-3 parts of hexafluoride isopropylidene diphenol, 1-3 parts of benzyl triphenyl phosphoric chloride, 1-2 parts of sodium stearate, 1-3 parts of palm wax, 1-3 parts of fluorinated polyamide and 1-2 parts of fatty alcohol. The invention further discloses a manufacturing method of the high-performance fluorine rubber gasket. The compression deformation and high-temperature steam resistance of the fluorine rubber gasket are excellent, and the manufacturing method is simple.

Owner:ANHUI JINYANG FLUORINE CHEM

Preparation method of triallyl isocyanurate

ActiveCN102887868ANot hydrolyzedImprove product qualityOrganic chemistryPolymer sciencePtru catalyst

The invention relates to the synthesis field of triallyl isocyanurate, and specifically provides a method for preparing triallyl isocyanurate by using a catalytic system. The isocyanurate and a catalyst are added into solvent. Chloropropene is dropwise added under the temperature of 70-105 DEG C for reaction. After reacting for 4-8 hours, the reactant is cooled to room temperature and filtered to remove solid phases. The filtrate subjected to solvent recovery is distilled under 113-115 DEG C / 133.3Pa to obtain the triallyl isocyanurate product, wherein the catalyst is the catalytic system of a copper catalyst and a phase transfer catalyst. According to the invention, a solvent method is adopted, and no water is brought in the reaction solution, so that the raw material chloropropene cannot be hydrolysized, the excessive chloropropene can be recycled at the end of the reaction, and the triallyl isocyanurate product obtained by the reaction has good quality.

Owner:江苏科利新材料有限公司

EVA shoe sole and preparation process thereof

PendingCN111154173AImprove flexural toughnessImprove crack resistanceLow-density polyethylenePolymer science

The invention relates to an EVA shoe sole and a preparation process thereof. The EVA shoe sole comprises the following components in parts by weight: 50-70 parts of EVA, 20-30 parts of modified low-density polyethylene, 10-20 parts of a filler, 10-15 parts of a flame retardant, 5-8 parts of color master batch, 2-4 parts of a foaming agent, 0.4-0.8 part of a bridging agent, 0.2-0.4 part of an accelerant, 0.5-0.6 part of stearic acid, 0.3 to 0.5 part of N,N'-ethylene bisstearamide, and 0.1 to 0.2 part of triallyl isocyanurate, wherein the modified low-density polyethylene is a jute fiber / nitrilerubber / low-density polyethylene compound. The preparation process comprises the steps: S1, banburying; S2, open milling; S3, cooling; S4, slitting; S5, mold pressing; and S6, edge trimming. The produced shoe sole has good anti-cracking performance.

Owner:FUJIAN JOYYOU SPORTS GOODS

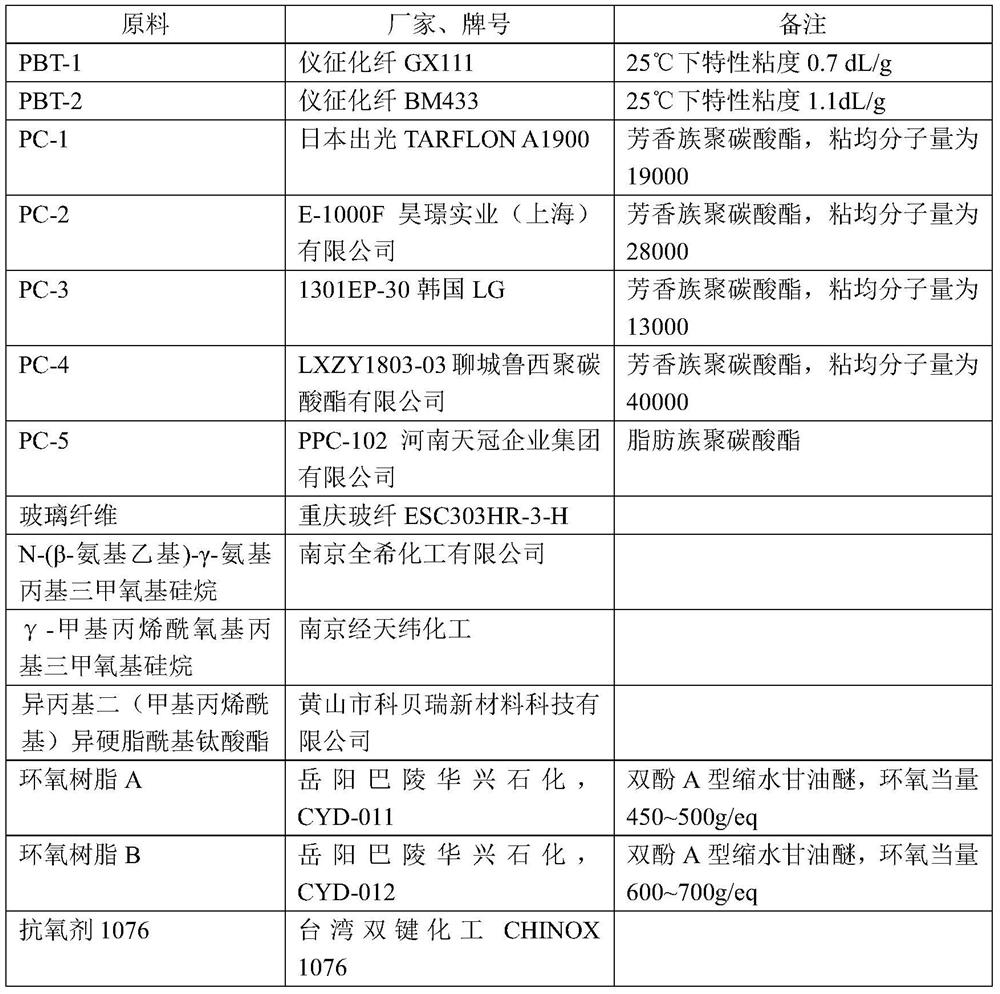

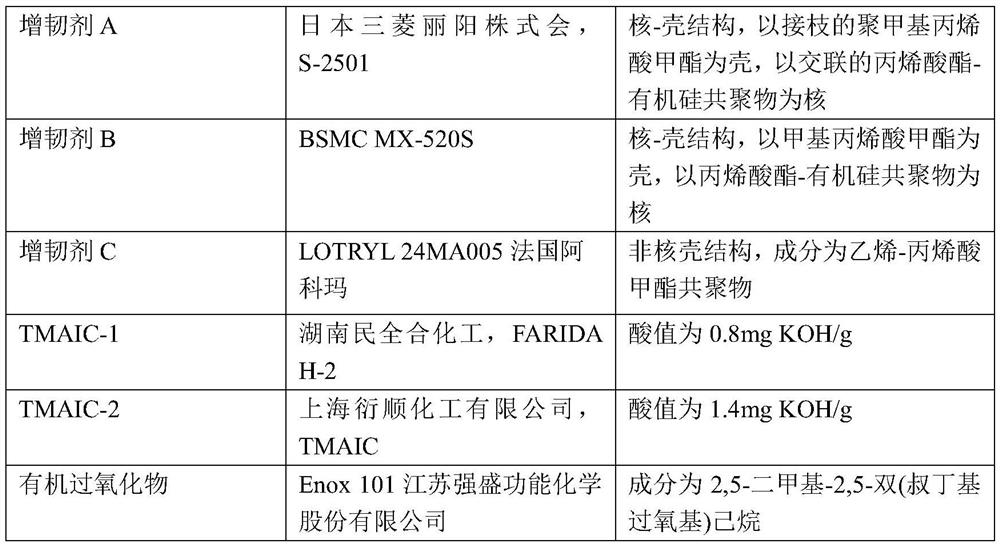

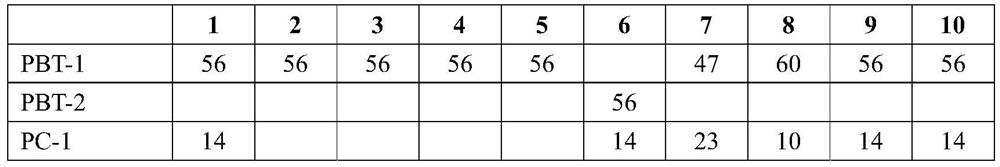

PBT/PC alloy with stable mechanical property and preparation method and product ofPBT/PC alloy

ActiveCN113652062AHigh retention rate of mechanical propertiesImprove the stability of mechanical propertiesEpoxyGlass fiber

The invention discloses PBT / PC alloy with stable mechanical property and a preparation method of the PBT / PC alloy. The PBT / PC alloy is prepared from the following components in parts by weight: 50 to 80 parts of PBT / PC mixture, 10 to 40 parts of glass fiber, 2 to 5 parts of epoxy resin, 0.1 to 0.3 part of antioxidant, 4 to 8 parts of flexibilizer and 2 to 4 parts of trimethylallyl isocyanate; the weight ratio of PBT to PC in the PBT / PC mixture is (2-6): 1, and the flexibilizer is an organic silicon-acrylate core-shell structure flexibilizer. Through the synergistic effect of the trimethylallyl isocyanate, the flexibilizer agent with the core-shell structure and the epoxy resin, the mechanical property retention rate of the PBT / PC alloy after multiple times of injection molding is effectively improved. The mechanical property retention rate of the PBT / PC alloy is larger than or equal to 95% after secondary injection molding, the mechanical property retention rate of the PBT / PC alloy is larger than or equal to 90% after three-time injection molding, and the PBT / PC alloy can be used for multiple times of cyclic injection molding.

Owner:KINGFA SCI & TECH CO LTD

Modified PP automobile wheel casing and preparation method thereof

The invention discloses a modified PP automobile wheel casing and a preparation method thereof. The preparation method of the modified PP automobile wheel casing comprises the following steps: weighing PP, SBS, EPDM, LLDPE, LDPE, PET, a crosslinking agent, sodium benzoate, triallyl isocyanurate, PA6, a plasticizer, SEP, diatomite, EPP and calcium carbonate according to a ratio in parts by weight, mixing, then extruding and pelletizing, and plastifying, so that the modified PP automobile wheel casing is obtained; the modified PP automobile wheel casing product has the properties that tensile strength is 35-55MPa, shore hardness is 94-98, elongation at break is 600-800%, notch impact strength is 600-800kJ / m, a heat distortion temperature is 140-150 DEG C, elastic modulus is 850-900MPa, and bending strength is 55-65MPa.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

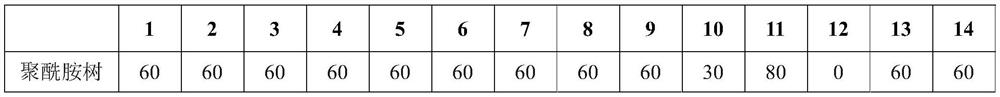

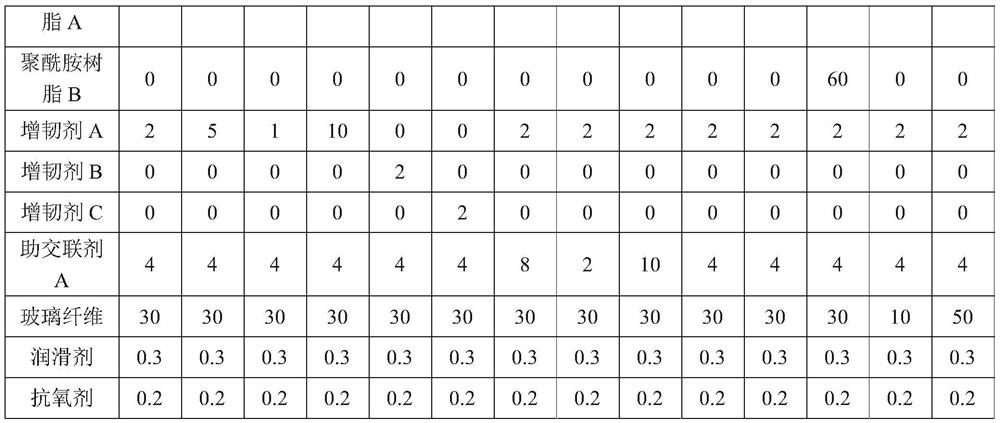

High-wear-resistance high-weather-resistance polyamide composition as well as preparation method and application thereof

The invention discloses a high-wear-resistance high-weather-resistance polyamide composition as well as a preparation method and application thereof. The polyamide composition comprises the followingcomponents: polyamide resin, a toughening agent, methyl triallyl isocyanurate, glass fibers and an auxiliary agent. According to the invention, methyl triallyl isocyanurate is used as an assistant cross-linking agent to promote efficient intermolecular cross-linking of the polyamide material under irradiation, and the toughening agent and the glass fibers have a synergistic effect, so the comprehensive performance of the polyamide composition is improved. The polyamide composition has excellent wear resistance and weather resistance, and a polyamide product prepared through irradiation crosslinking treatment is suitable for being used as a wear-resistant part in the automobile industry or rail transit in a severe environment with large temperature difference.

Owner:KINGFA SCI & TECH CO LTD

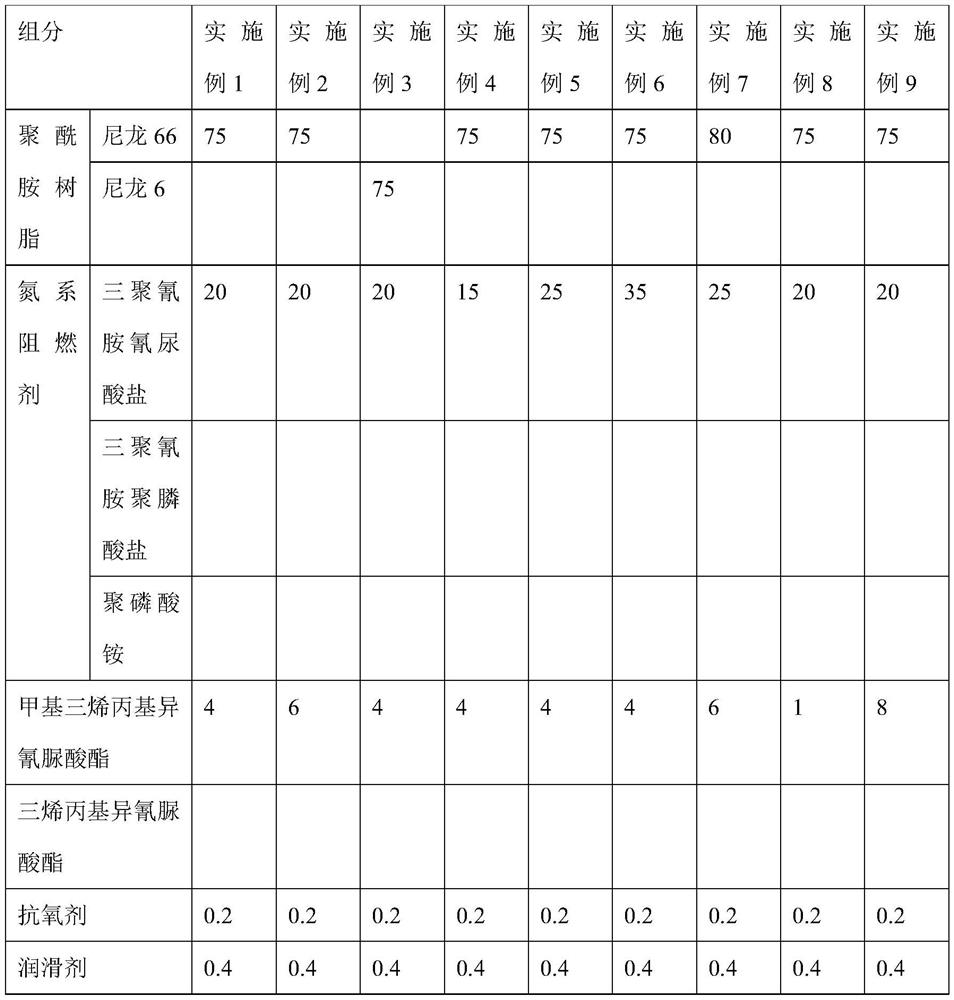

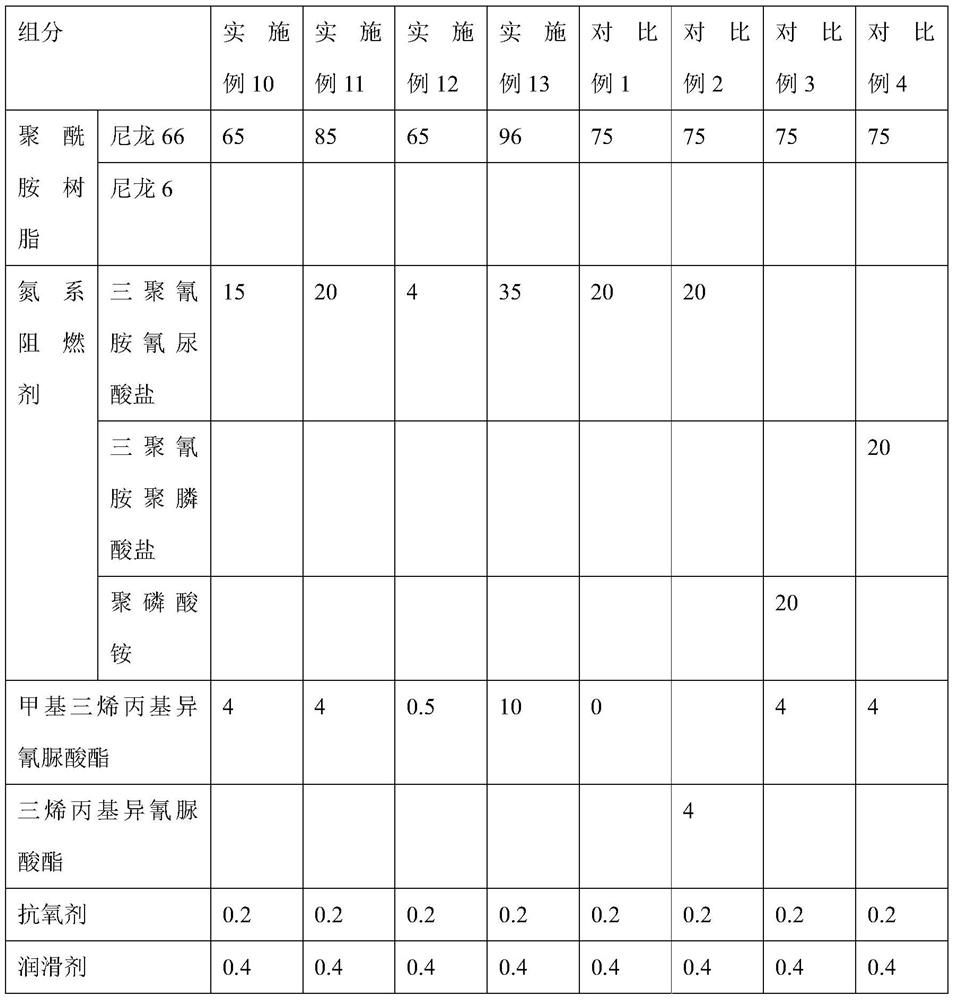

Halogen-free flame-retardant polyamide composite material as well as preparation method and application thereof

ActiveCN112745675AGood compatibilityRaise the crystallization temperaturePolymer sciencePropyl isocyanide

The invention provides a halogen-free flame-retardant polyamide composite material as well as a preparation method and application thereof. The halogen-free flame-retardant polyamide composite material is prepared from the following components in parts by weight: short-carbon-chain aliphatic polyamide resin, a nitrogen flame retardant and methyl triallyl isocyanurate, and the nitrogen flame retardant is melamine cyanurate. According to the halogen-free flame-retardant polyamide composite material disclosed by the invention, methyl triallyl isocyanurate and melamine cyanurate are added for compounding, so that the glowing filament expression of the material is improved, the halogen-free flame-retardant effect is realized, the GWIT test at 775 DEG C is passed, the crystallization temperature and the crystallization speed of the halogen-free flame-retardant polyamide composite material can be increased, and thus, the injection molding performance of the halogen-free flame-retardant polyamide composite material is improved.

Owner:KINGFA SCI & TECH CO LTD

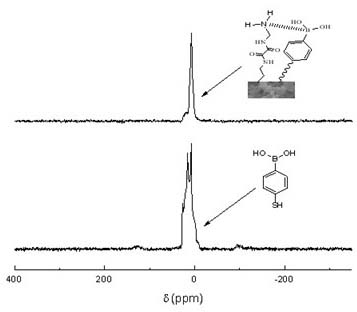

Biomimetic monolithic material with affine selectivity similar to that of protein A and preparation method and application thereof

InactiveCN102675602AEasy to makeSafe preparationPeptide preparation methodsImmunoglobulinsEpoxyPhenylboronic acid

The invention discloses a biomimetic monolithic material with the affine selectivity similar to that of a protein A, and a preparation method thereof, wherein the material is capable of purifying, separating and immobilizing antibodies. N, N'-di-(2-aminoethyl) oxamide and 4-mercapto-phenylboronic acid are used as common functional monomers, tri-(2, 3- epoxy group propyl group) isocyanate is used as a monomer, polyethylene glycol is used as a porogenic agent, and reaction is carried out in a mode of in-situ ring-opening polymerization to prepare the biomimetic monolithic material with the affine selectivity similar to that of the protein A. The material can be combined with antibodies specifically, and can be applied to the fields of antibody purification, separation, immobilization and the like. The material has the advantages of high selectivity, low cost, good stability, easiness in elution, reusability and the like, and the immunity affinity and the selectivity of the antibodies are not affected.

Owner:NANJING UNIV

Halogen-free flame-retardant polyamide composite material as well as preparation method and application thereof

The invention discloses a halogen-free flame-retardant polyamide composite material which comprises the following components: 20-80 parts of short-carbon-chain aliphatic polyamide resin; 15-20 parts of a halogen-free flame retardant; 0.01-10 parts of trimethallyl isocyanurate; and 10-50 parts of glass fiber. Polyamide molecules in the halogen-free flame-retardant polyamide composite material havea cross-linked structure. Aliphatic polyamide with a short carbon chain is selected, the halogen-free flame retardant with a specific ratio and a specific amount of methyl triallyl isocyanurate are synergistically combined for irradiation crosslinking treatment, the flame retardant requirement can be met, and the thermal compression resistance, the aging resistance and the heat resistance are remarkably improved.

Owner:KINGFA SCI & TECH CO LTD

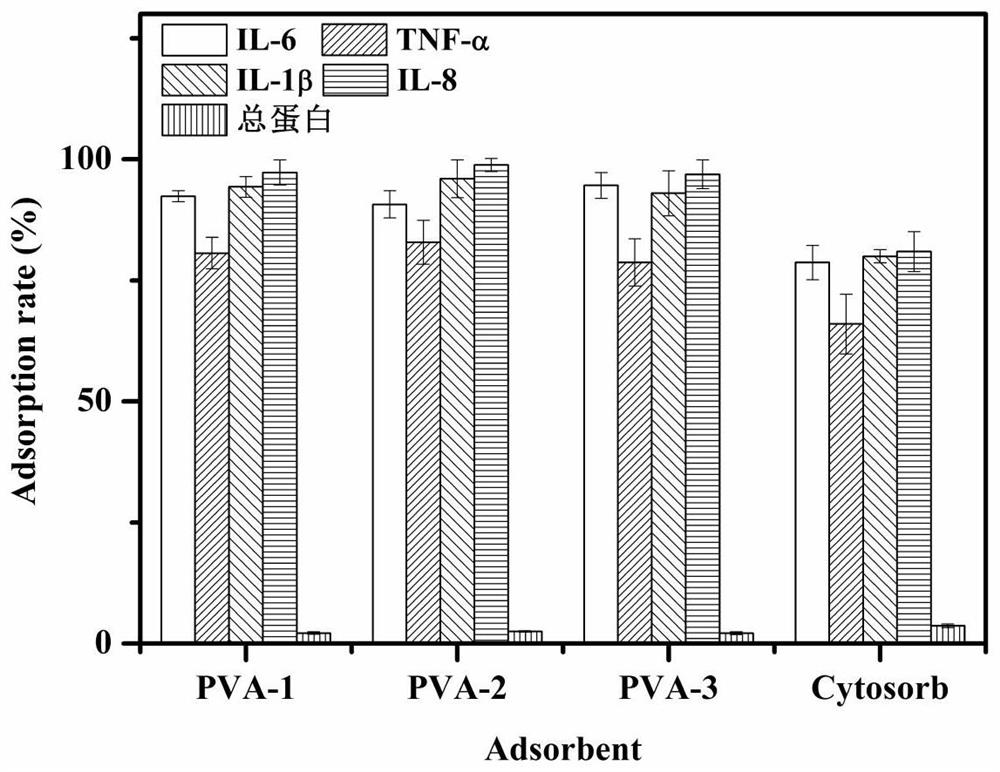

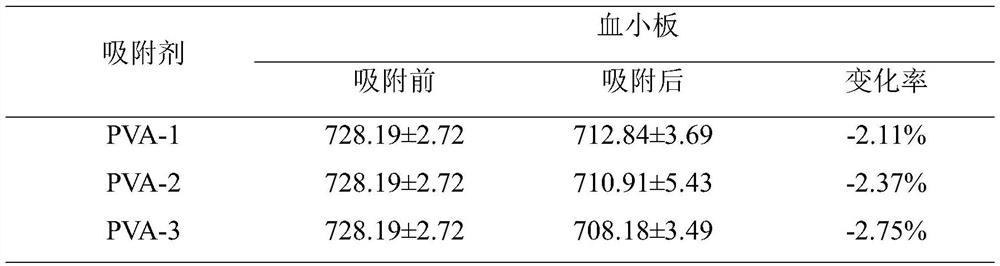

Immunosorbent for removing inflammatory factors in blood and preparation method thereof

ActiveCN108855003BGood blood compatibilityGood biocompatibilityOther blood circulation devicesOther chemical processesAlkaneInflammatory factors

Owner:NANKAI UNIV

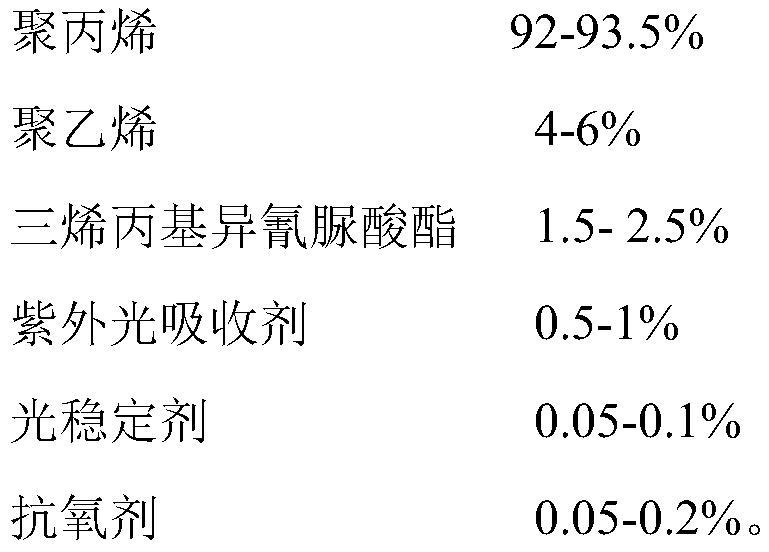

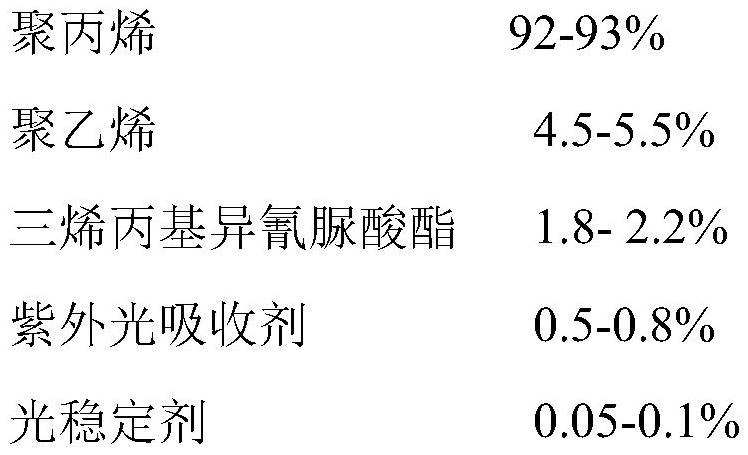

Irradiation-resistant melt-blown polypropylene composite material as well as preparation method and application thereof

PendingCN112063043AAchieve radiation resistanceExcellent and suitable fluidityNon-woven fabricsMonocomponent polyolefin artificial filamentPolypropylene compositesPolymer science

The invention discloses an irradiation-resistant melt-blown grade polypropylene composite material as well as a preparation method and application thereof. The polypropylene composite material comprises the following raw materials in percentage by mass: 90-95% of polypropylene; 3-8% of polyethylene; 1.5-3% of triallyl isocyanurate; 0.1-2% of an ultraviolet absorber; 0.01-0.5% of a light stabilizer; and 0.01-0.5% of an antioxidant. The preparation method comprises the following steps of: mixing the raw materials according to the formula, carrying out melt extrusion, and granulating. The invention also discloses application of the composite material in preparation of polypropylene melt-blown non-woven fabrics. The composite material provided by the invention has excellent and appropriate fluidity while realizing irradiation resistance, and is suitable for polypropylene melt-blown non-woven fabrics sterilized by irradiation.

Owner:中国同辐股份有限公司 +2

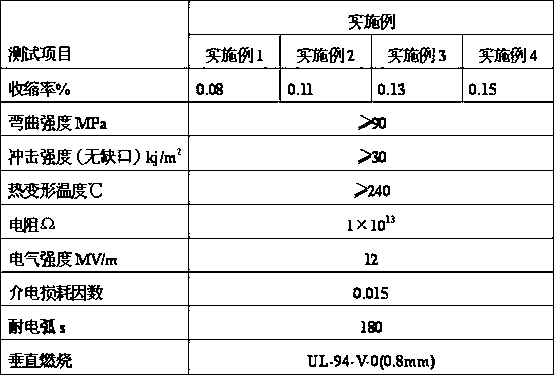

High fire retardation unsaturated polyester molding compound

The invention relates to a high fire retardation unsaturated polyester molding compound, and belongs to the technical field of thermosetting molding compounds. The high fire retardation unsaturated polyester molding compound comprises the following raw materials, by weight, 41-46 parts of an unsaturated polyester resin, 28-32.6 parts of a low shrinkage additive, 6-9 parts of triallyl isocyanurate, 0.65-1.2 parts of an initiator, 0.006-0.011 part of a polymerization inhibitor, 0.16-0.5 part of a metal oxide, 115-160 parts of a filler, 10-15 parts of a fire retardation agent, 5-8 parts of a fire retardation master batch, 2.4-3.2 parts of a mold release agent, and 28-37 parts of 3 mm reinforcing fibers. The high fire retardation unsaturated polyester molding compound has characteristics of good strength, low shrinkage and excellent fire retardation, and can be applicable for products such as switches, household electrical appliance housings, and the like. In addition, test results show that a bending strength is 90 MPa, an impact strength is 30 KJ / m<2>, a shrinkage rate is less than 0.15%, resistance is 1*10<13> omega, an electrical strength is 12.0 MV / m, a dielectric loss factor is 0.015, electrical arc resistance is 180 s, a comparative tracking index is 600 V, and vertical burning achieves (UL-94-V-00.8mm)V-0.

Owner:CHANGSHU CHIKUSHI MACHINERY

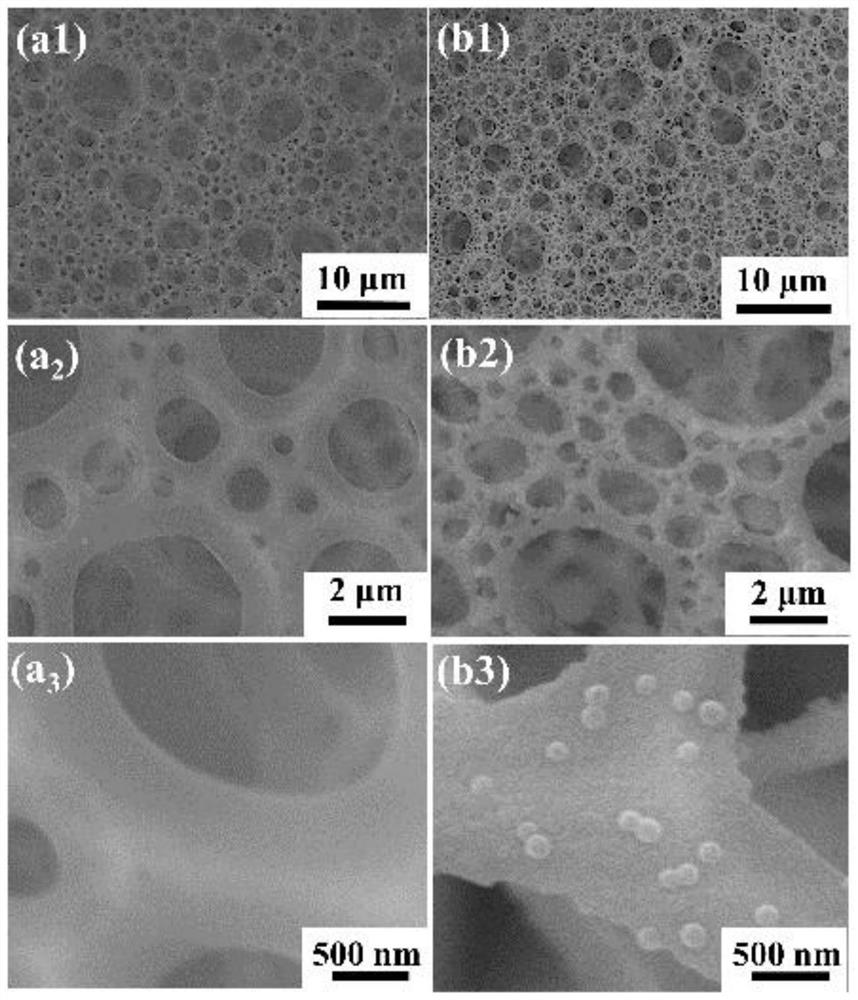

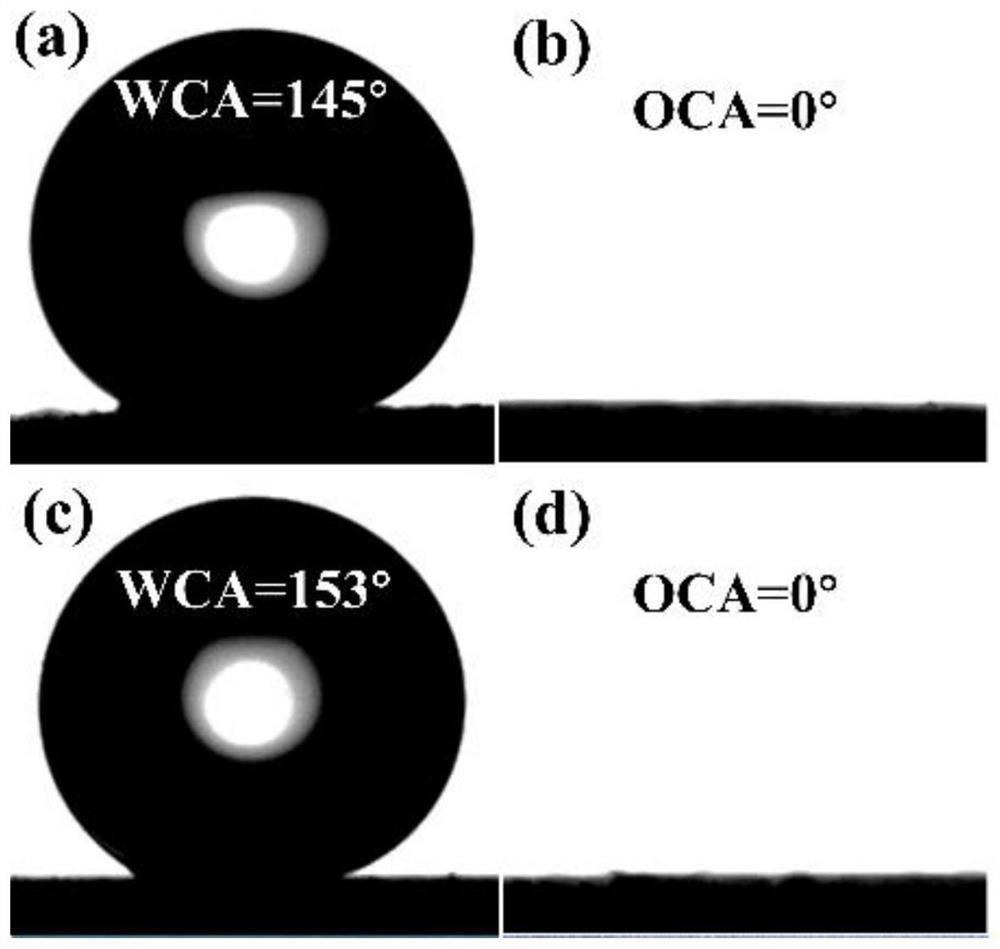

Method for preparing super-hydrophobic porous material based on double-emulsion template

ActiveCN114369278AAchieve preparationSimple processFatty/oily/floating substances removal devicesGeneral water supply conservationPropyl isocyanideMeth-

The invention discloses a method for preparing a super-hydrophobic porous material based on double emulsion templates, which comprises the following steps: (1) dispersing a siloxane coupling agent, a hydrophilic emulsifier and an initiator in deionized water to obtain an emulsion template A; (2) adding the emulsion template A into a high internal phase emulsion template B consisting of styrene, a cross-linking agent A, a cross-linking agent B and a lipophilic emulsifier, and stirring and emulsifying for 5-60 minutes to obtain a double-emulsion template prepolymerization system; and (3) reacting the double-emulsion template prepolymerization system at 40-80 DEG C for 4-16 hours to obtain the super-hydrophobic porous material. The cross-linking agent A and the cross-linking agent B are respectively selected from one of divinyl benzene, triallyl isocyanurate, N, N-methylene bisacrylamide, trimethylolpropane triacrylate, ethylene glycol dimethacrylate and dipentaerythritol pentaacrylate. The porous material prepared by the invention can be used for continuously separating an oil-water immiscible mixture and continuously separating an oil-water emulsion with a stable surfactant in a suction filtration manner.

Owner:SOUTHWEST PETROLEUM UNIV

Rubber insulation material for rubber sleeve power cable with rated voltage of 35 kV or above

InactiveCN105504546AImprove lipophilicityAvoid reunionRubber insulatorsDicumyl peroxideParaffin oils

The invention discloses a rubber insulation material for a rubber sleeve power cable with the rated voltage of 35 kV or above. The rubber insulation material is prepared from, by weight, 70-90 parts of ethylene propylene diene monomers, 30-40 parts of methyl vinyl silicone rubber, 20-30 parts of ethylene-butene elastomers, 2-4 parts of paraffin, 11-15 parts of paraffin oil, 1-2 parts of an anti-aging agent MB, 1-2 parts of an anti-aging agent 264, 4-8 parts of zinc oxide, 0.5-1.5 parts of stearic acid, 10-15 parts of modified calcium carbonate, 110-130 parts of modified superfine kaolin, 2.5-4.5 parts of dicumyl peroxide, 1.5-3.5 parts of triallyl isocyanurate, 10-20 parts of epoxidized soybean oil, 8-10 parts of tributyl citrate, 8-12 parts of micro-capsulated red phosphorus, 10-15 parts of melamine cyanurate, 2-4 parts of a Ca-Zn compound stabilizer and 0.5-2 parts of vinyltriethoxysilane. The rubber insulation material is good in electrical insulating property and high in mechanical property.

Owner:ANHUI HONGHAI CABLE

Separation medium for purifying proteins, and preparation method thereof

InactiveCN104497205ASolve the problem of low purity and poor product qualityImprove performancePeptide preparation methodsPolymer scienceMeth-

The invention relates to a separation medium for purifying proteins, and a preparation method thereof, and belongs to the technical field of polymer materials. The separation medium for purifying proteins includes an oil phase and a water phase, wherein the oil phase comprises glycidyl methacrylate, ethylene dimethacrylate, triallyl isocyanurate, divinyl benzene, hydroxypropyl acrylate, toluene, gasoline, isoamyl alcohol and azoisobutyronitrile; and the water phase comprises deionized water, polyvinyl alcohol, gelatin, sodium chloride and methylene blue. The separation medium is prepared by selecting suitable monomers through a polymerization reaction, has the respective advantages of natural saccharide and synthetic polymer separation media, also has the advantages of macro-porous structure, high adsorption rate, large specific surface area and large adsorption capacity, and is separation medium having excellent performances and used for separating and purifying the proteins. The adsorption capacity of the medium provided by the invention to bovine serum albumin (BSA) can reach 171.20mg / g dry resin.

Owner:CHENGDU JINHUI TECH

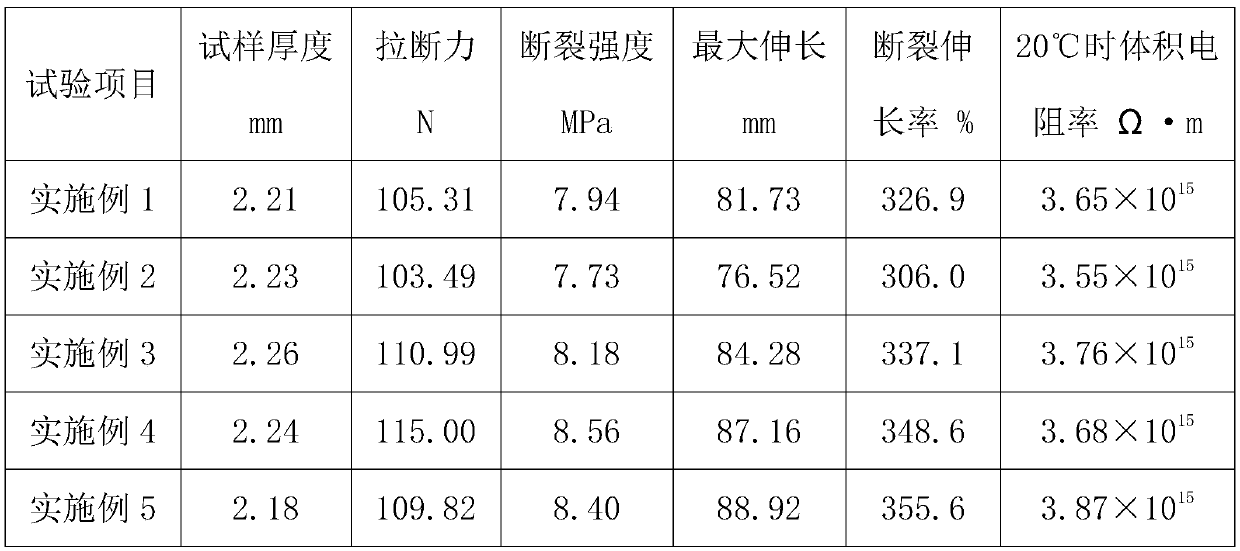

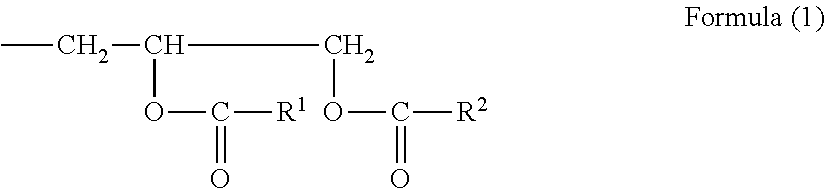

Highly soluble modified epoxy resin composition

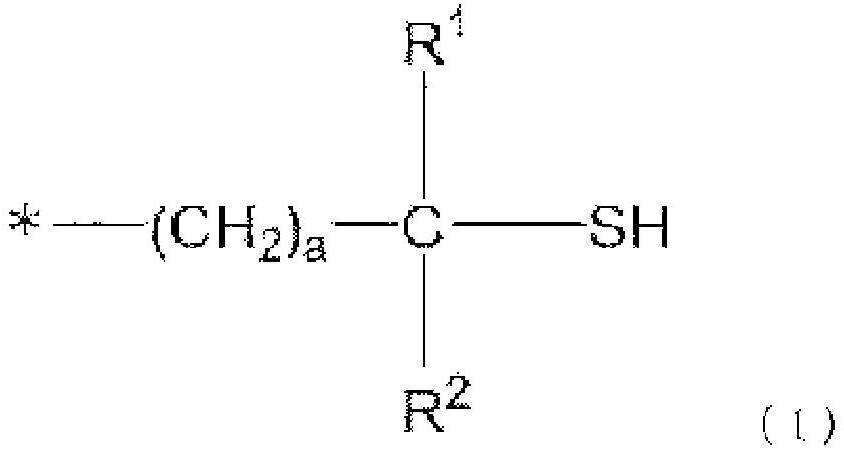

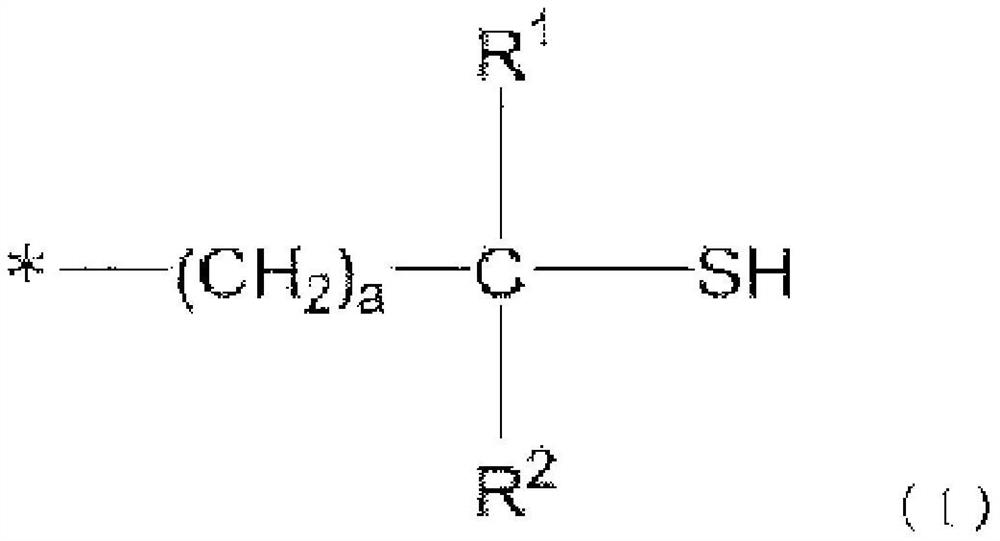

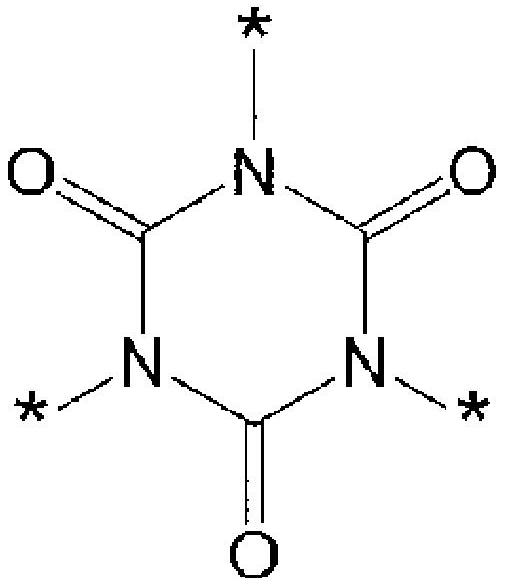

An epoxy resin composition in a liquid or solid state having excellent solubility and having high preservation stability. A modified epoxy resin composition including: Compound A containing tris-(2,3-epoxypropyl)-isocyanurate having 1 to 3 glycidyl group(s) in a molecule substituted with a functional group(s) of Formula (1):in which R1 and R2 are each independently an alkyl group, an alkenyl group, an alkynyl group, an aryl group, an aralkyl group, a heterocyclic group; or a halogenated derivative, an aminated derivative, or a nitrated derivative of these groups; and Compound B containing tris-(2,3-epoxypropyl)-isocyanurate, wherein tris-(2,3-epoxypropyl)-isocyanurate of Compound A before the substitution and tris-(2,3-epoxypropyl)-isocyanurate of Compound B comprise 2% by mass to 15% by mass of β-type tris-(2,3-epoxypropyl)-isocyanurate and a remaining percentage of α-type tris-(2,3-epoxypropyl)-isocyanurate based on a total mass of Compound A before the substitution and Compound B.

Owner:NISSAN CHEM IND LTD

Thiol-ene curable composition

Provided is a thiol-ene curable composition which achieves both sufficient elongation properties and elasticity, and ensures the preservation stability of a formulation. This thiol-ene curable composition is characterized by comprising at least one among a compound (A) having an isocyanuric skeleton and at least two mercapto groups in one molecule, and a compound (B) including diallyl maleate anddiallyl fumarate. The compound (A) is at least one selected from 1,3,5-tris(3-mercapto butyryloxy ethyl-1,3,5-triazine-2,4,6(1H, 3H, 5H)-trione, tris[(3-mercapto propionyloxy)-ethyl]-isocyanurate, andtris(mercapto propyl)isocyanurate.

Owner:SHOWA DENKO KK

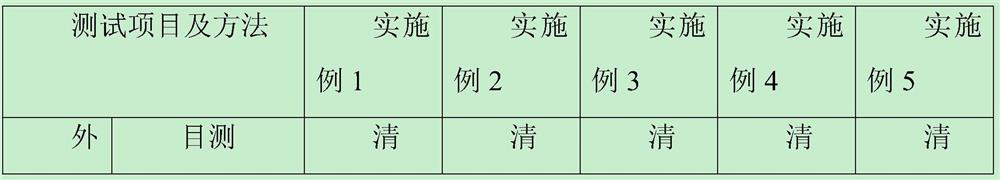

Thermosetting powder coating

InactiveCN111138970AImproves UV resistanceExcellent resistance to humidityPowdery paintsPolyester coatingsPolymer sciencePropyl isocyanide

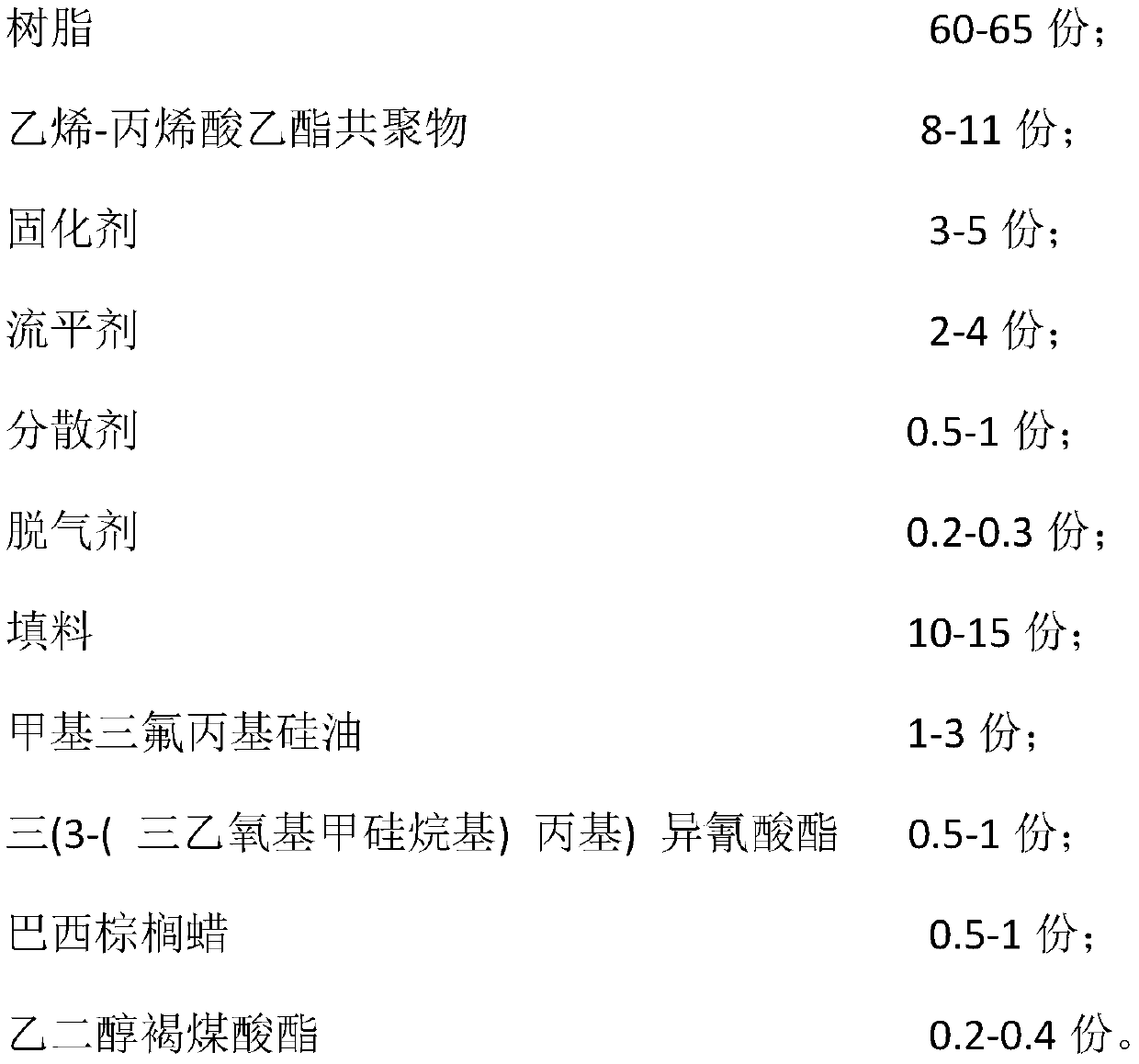

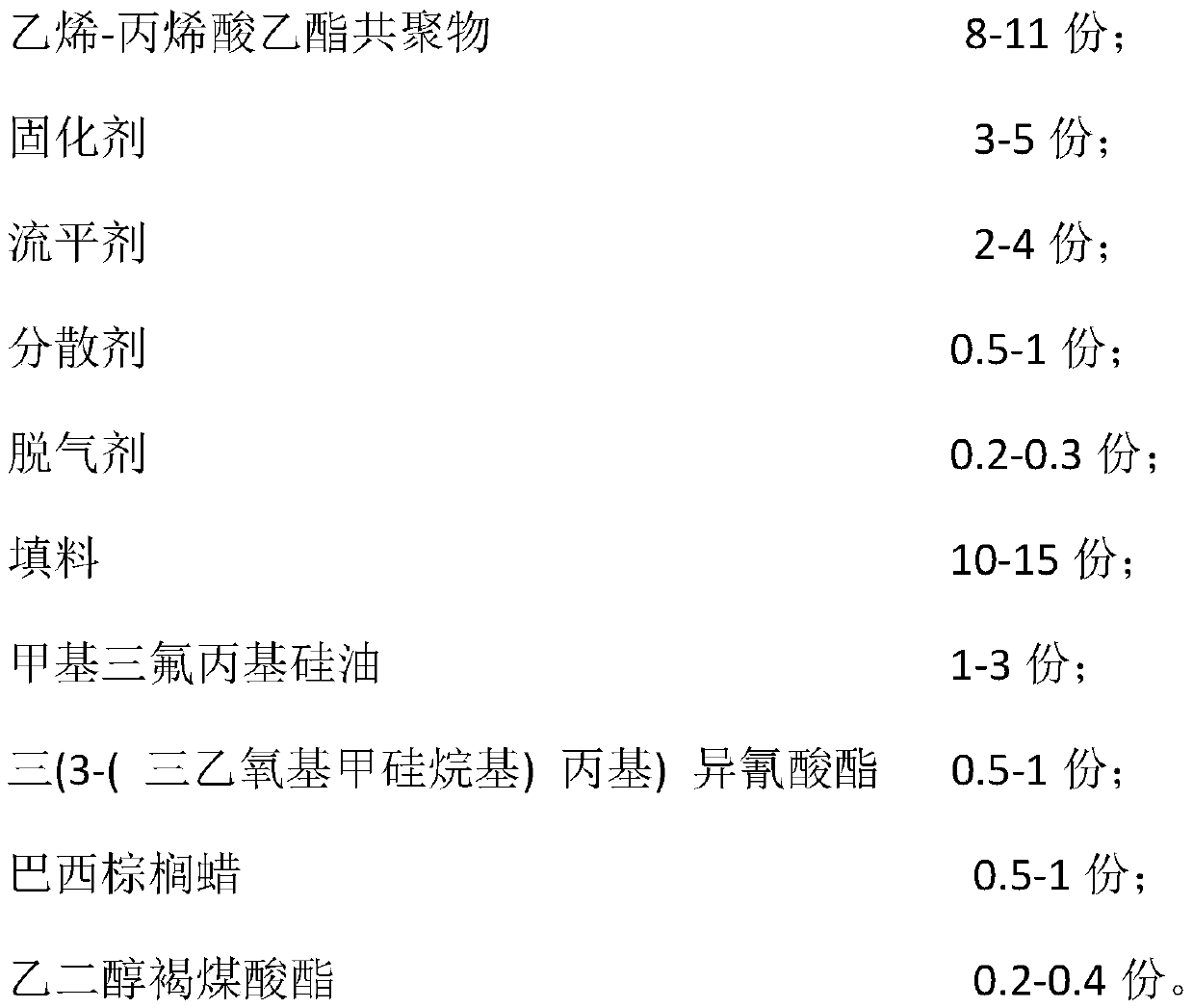

The invention discloses a thermosetting powder coating. The coating comprises, by weight, 60 to 65 parts of resin, 8 to 11 parts of an ethylene-ethyl acrylate copolymer, 3 to 5 parts of a curing agent, 2 to 4 parts of a leveling agent, 0.5 to 1 part of a dispersing agent, 0.2 to 0.3 part of a degassing agent, 10 to 15 parts of a filler, 1 to 3 parts of methyltrifluoropropyl silicone oil, 0.5 to 1part of tri(3-(triethoxysilyl)propyl)isocyanate, 0.5 to 1 part of carnauba wax and 0.2 to 0.4 part of ethylene glycol monophosphate. The thermosetting powder coating has excellent ultraviolet resistance, humidity resistance, ultraviolet resistance, outdoor exposure resistance, acid and alkali resistance and oil resistance, and the low-temperature crack resistance and high-temperature brittleness of a powder coating are improved.

Owner:江阴市玲珑高分子材料有限公司

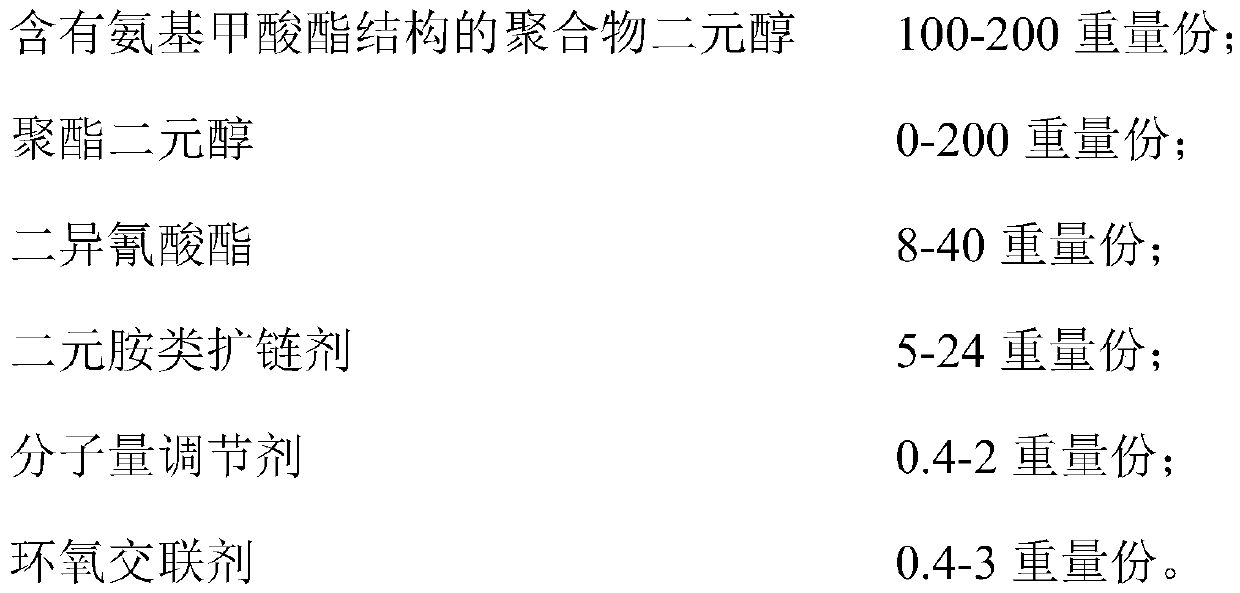

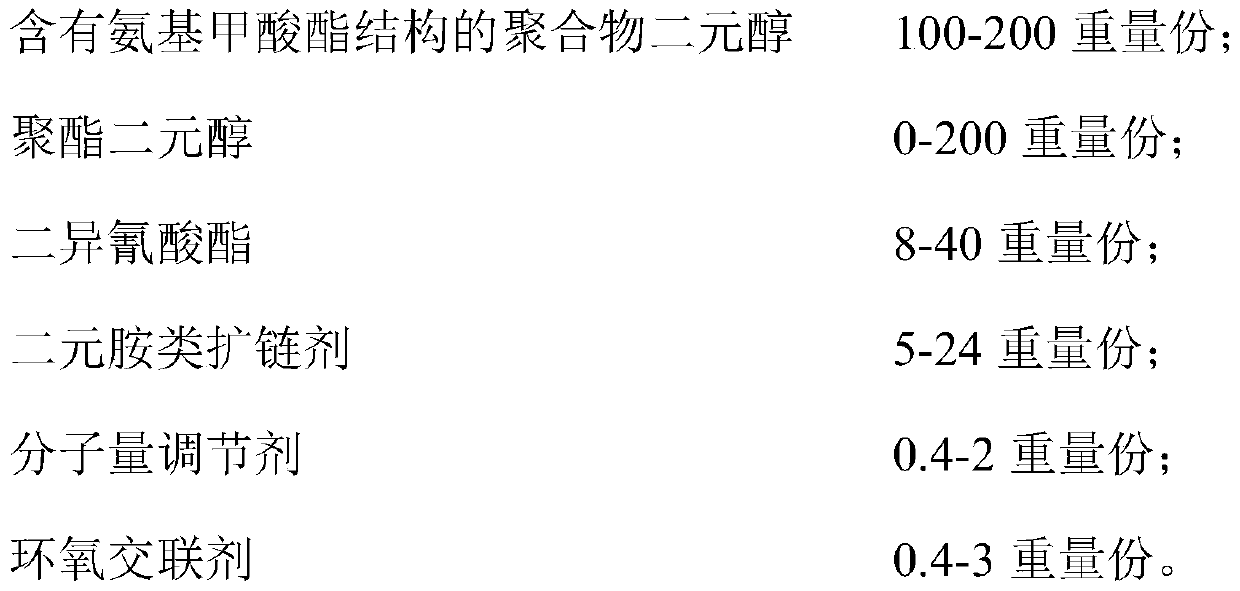

High-temperature-resistant polyurethane ink binder as well as preparation method and application thereof

The invention belongs to the technical field of ink printing, particularly relates to a high-temperature-resistant polyurethane ink binder, particularly relates to an intaglio printing polyurethane ink binder with excellent high-temperature resistance, heat sealing and pressing resistance and steaming and boiling resistance for food flexible packaging, and further discloses a preparation method ofthe polyurethane ink binder. The high-temperature-resistant polyurethane ink binder is a polyurethane polymer obtained by taking a polymer dihydric alcohol containing a carbamate structure, a polyester dihydric alcohol, a diisocyanate, a diamine chain extender, a molecular weight regulator and an epoxy cross-linking agent as raw materials and carrying out polymerization reaction. The polyurethaneink binder disclosed in the invention possesses the beneficial effects of the carbamate structure in the polymer dihydric alcohol, a thioether structure in the diamine chain extender and a rigid cross-linked structure of triepoxypropyl isocyanurate, so that the prepared ink has high temperature resistance, heat sealing and pressing resistance and steaming and boiling resistance, and excellent printing adaptability of the ink is guaranteed.

Owner:HUANGSHAN ZHONGZE NEW MATERIAL CO LTD

Preparation method of curable silicon-based hybrid resin

The invention relates to the field of silicon-based resin, in particular to a preparation method of curable silicon-based hybrid resin. The preparation method comprises the following steps: selecting amino-terminated linear polysiloxane with a specific molecular weight, firstly introducing a reactive group by using diisocyanate, and then introducing a reaction product of diallyl isocyanurate and isocyanatopropyltriethoxysilane for toughening and introducing a photocurable double bond at the same time. Thus, the cured product has excellent adhesiveness, and has the advantages of high surface drying speed, high hardness, high mechanical property, high salt spray resistance and the like. The method can be widely applied to outdoor super-weather-proof, hydrophobic and oleophobic and easy-to-clean protection fields.

Owner:广东致格纳米科技有限公司

Prepreg for high frequency, preparation method of prepreg, copper-clad plate and preparation method of copper-clad plate

ActiveCN111825955ALow dielectric constantLow dielectric loss tangentLamination ancillary operationsFibre typesXylylenePolymer science

The invention discloses a prepreg for high frequency, a preparation method of the prepreg and a copper-clad plate, and a preparation method of the copper-clad plate. Tge preparation method comprises the following steps: (1) making basalt fibers and aramid fibers into fiber cloth, and carrying out high-pressure treatment under the action of high temperature and high pressure; (2) dip-coating the papermaking cloth in a glue solution with the solid content of 50%, which consists of dicyclopentadiene phenol epoxy modified cyanate ester, novolac epoxy resin, heat-conducting powder, a cross-linkingagent triallyl isocyanurate (TAIC) and xylene, dip-coating for 30-90 seconds, and drying at 120-260 DEG C to obtain prepregs; and (3) superposing the prepreg and the copper foil, and carrying out hotpress molding. Therefore, the high-performance aramid fiber / basalt fiber-based copper-clad plate with low dielectric constant, low dielectric loss tangent value, good heat resistance, high thermal decomposition temperature and thermal shock resistance, good tensile strength and peel strength, excellent interface shear strength and excellent dimensional stability and meeting high-frequency use requirements is prepared.

Owner:HAINAN UNIVERSITY

Antistatic nano-carbon sol and nano-graphite irradiation grafting modified nylon single-filament filtration cloth and preparation method thereof

InactiveCN106544859AImprove densification performanceImprove heat resistanceStain/soil resistant fibresHeat resistant fibresMethacrylateIndium

The invention discloses an antistatic nano-carbon sol and nano-graphite irradiation grafting modified nylon single-filament filtration cloth, which is prepared from the following raw materials by weight: 100-105 parts of a nylon single-filament filtration cloth, 3-3.5 parts of a nano-carbon sol, 2.7-3 parts of nano-graphite, 0.8-0.9 part of FeSO4.7H2O, 24-26 parts of trifluoroethyl acrylate, 1.6-1.8 parts of nanometer stannous oxide, 2.8-3.2 parts of indium oxide nanometer ceramic fiber, 1.8-2.1 parts of triallyl isocyanurate, 24-26 parts of dodecafluoroheptyl methacrylate, and a proper amount of water. According to the present invention, the nylon single-filament filtration cloth is impregnated with the nano-carbon sol so as to improve the compactness, the heat resistance and the wear resistance of the filtration cloth and increase the filtration precision; and by carrying out mixing grinding on nanometer stannous oxide, indium oxide nanometer ceramic fiber and triallyl isocyanurate, the filtration cloth has advantages of excellent antistatic effect, improved wear resistance, improved deformation resistance, and improved filtration precision.

Owner:骆华军

Nanometer graphene ultraviolet light-moisture curing composition and preparation method thereof

The invention relates to a nano graphene ultraviolet light-moisture curing composition and a preparation method thereof, wherein the composition is prepared from an acrylic resin, ethyl isocyanate acrylate, isocyanate silane, an acrylic monomer, a photoinitiator, nano graphene and an auxiliary agent according to a certain ratio. According to the invention, mainly nano graphene is added to solve the high heat-conducting property requirement of the composition; a polymer resin, especially a hyperbranched oligomer, hydrophobic polyurethane acrylate, polybutadiene polyurethane acrylate, organosilicon polyurethane acrylate, ethyl isocyanate acrylate, 3-isocyanatopropylmethyldimethoxysilane, trimethoxysilyl propyl isocyanurate, is preferably selected, and different types of acrylic monomers, photoinitiators, auxiliary agents, fillers and the like are added, so that rapid curing and moisture curing of a shadow part are achieved, and after curing, the properties of high thermal conductivity, excellent adhesive force, high flexibility and excellent damp-heat aging resistance are achieved, and good application prospect is achieved.

Owner:苏州恩多科石墨烯科技有限公司

Modified PETG material with multilayer structure and preparation method of modified PETG material

PendingCN113022067AImprove environmental performancePromote degradationSynthetic resin layered productsFlat articlesPolymer sciencePropyl isocyanide

A provided modified PETG material with a multilayer structure comprises a PP layer and two modified PETG layers, and each modified PETG layer comprises the following components in parts by mass: 82-88 parts of PETG, 1-2 parts of an anti-blocking agent, 2-3 parts of toluene diisocynate, 3-4 parts of a toughening agent and 0.5-1 part of bamboo powder; and the PP layer is prepared from the following components in parts by mass: 78 to 82 parts of PP, 5 to 8 parts of triallyl isocyanurate, 1 to 3 parts of a solubilizer, 1 to 3 parts of a nucleating agent and 0.5 to 1 part of a dispersing agent. Toluene diisocynate is added into the modified PETG layer, triallyl isocyanurate is added into the PP layer, the crosslinking-chain extension effect can be achieved, the viscosity of the modified PETG layer and the viscosity of the PP layer are improved, the modified PETG layer and the PP layer can be better combined together, and the bamboo powder is added, so that the environment-friendly performance of the modified PETG material of the multi-layer structure is greatly improved.

Owner:HUIZHOU HAOMING SCI & TECH

Water based adhesives for high performance applications in flexible food packaging

Water-based acrylic adhesive compositions comprising (A) an acrylic emulsion comprising an acrylic copolymer particle dispersed in an aqueous medium, (B) a crosslinking agent comprising a hydrophilic aliphatic isocyanate, and (C) a silane compound incorporated into the crosslinking agent (B) are disclosed. In some embodiments, the silane compound (C) incorporated into the crosslinking agent (B) is selected from the group consisting of (3-Glycidyloxypropyl)trimethoxysilane, 3-(Triethoxysilyl)propyl isocyanate, and combinations thereof. Methods for preparing water-based acrylic adhesive compositions also disclosed. Methods for preparing a laminate structure suitable for use in a flexible food packaging article are still further disclosed. Flexible food packaging articles including the disclosed water-based acrylic adhesive compositions are also disclosed.

Owner:ROHM & HAAS CO

Co3O4-carbon nanotube modified polyurethane composite electromagnetic shielding material

InactiveCN110791079AReduce thicknessReduce weightMagnetic/electric field screeningPolymer sciencePropyl isocyanide

The invention relates to the technical field of electromagnetic shielding materials, and discloses a Co3O4-carbon nanotube modified polyurethane composite electromagnetic shielding material. Raw materials of the composite electromagnetic shielding material comprise magnetic cobaltosic oxide, single-walled carbon nanotubes, triallyl isocyanurate, polyurethane resin, an alkalizing agent, a foaming agent and a dispersing agent, wherein the magnetic cobaltosic oxide is of a spinel structure, and the polyurethane is polyether type polyurethane. According to the composite electromagnetic shielding material, the polyurethane is used as a matrix of the electromagnetic shielding material; the thickness and the weight of the electromagnetic shielding material are reduced and the production cost is reduced; the alkalized single-walled carbon nanotubes are added to modify the polyurethane, basic groups in the alkalized single-walled carbon nanotubes and carbonyl groups of the triallyl isocyanurateform hydrogen bonds, and the triallyl isocyanurate is thermally crosslinked with the polyurethane, so that the effects of heat resistance, impact toughness and mechanical properties of hardness of the composite electromagnetic shielding material are enhanced.

Owner:蔡娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com