Thermosetting powder coating

A thermosetting powder and coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of shortening the service life of the coating film, reducing the mechanical properties of the coating film, cracking and embrittlement, etc., to improve moisture resistance, Effect of improving compatibility and improving low temperature crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of thermosetting powder coating comprises the following steps:

[0037] 1) After mixing the filler evenly, add tris(3-(triethoxysilyl)propyl)isocyanate and solvent isopropanol, stir and mix evenly to obtain the first mixture;

[0038] 2) Add the leveling agent into the first mixed solution, stir and mix, then add the dispersant, degasser and methyl trifluoropropyl silicone oil, and mix evenly to obtain the second mixture;

[0039] 3) adding the resin, ethylene-ethyl acrylate copolymer, tetrapropylene fluororubber, and ethylene glycol montanate into the second mixture, stirring and mixing to obtain the third mixture;

[0040] 4) After the third mixture is dried, it is finely ground to reach 400 mesh or more, and sieved to obtain the fourth mixture;

[0041] 5) Add curing agent, triphenyl phosphite, and carnauba wax to the fourth mixture, put it into a high-speed mixer and stir to make the materials evenly mixed, and obtain the fifth mixture;

[0...

Embodiment 1

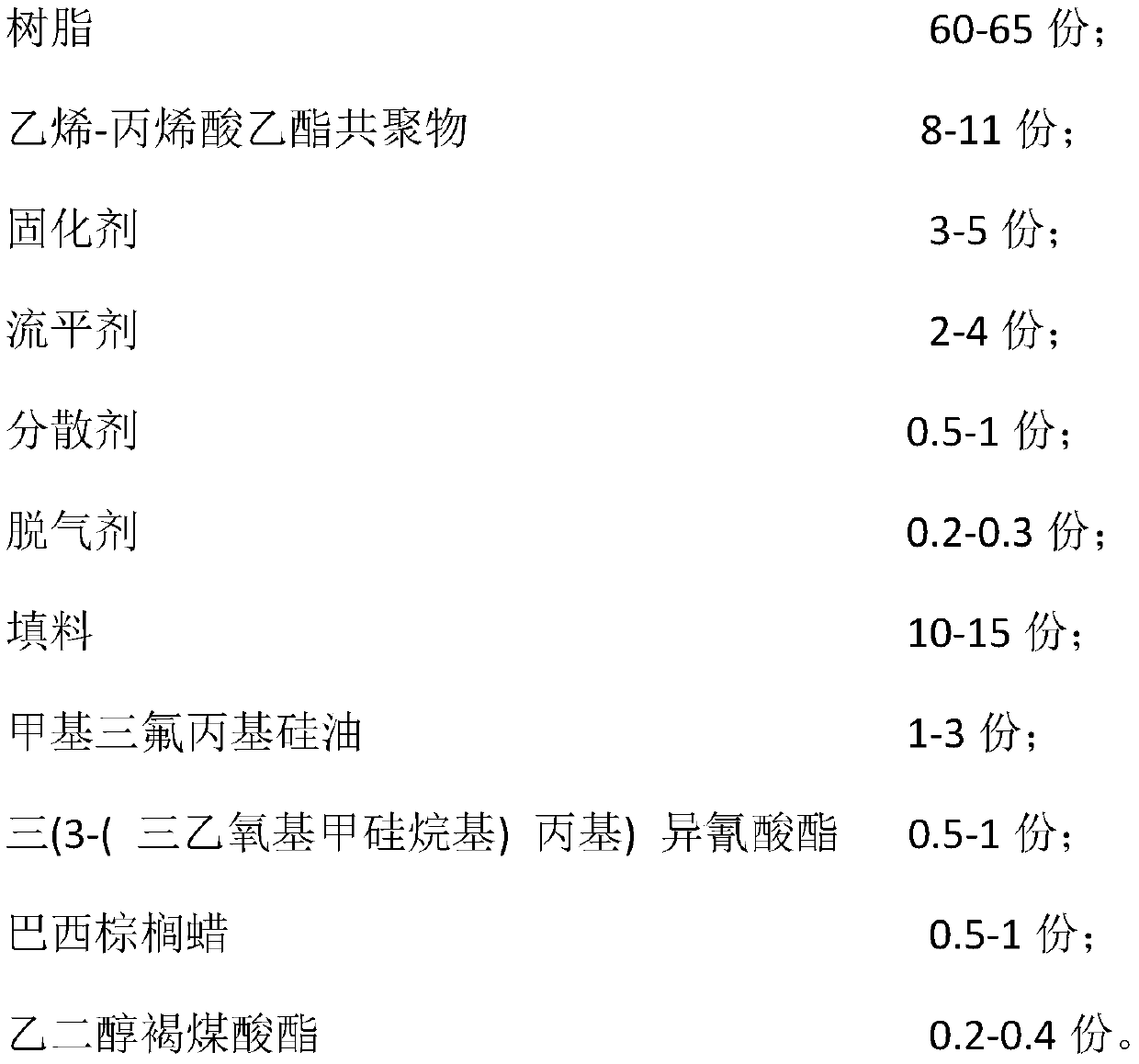

[0045] A thermosetting powder coating, by weight, comprises the following components:

[0046]

[0047]

[0048] The resin is a silicone resin; the curing agent includes 2 parts of vinyltriamine, 3 parts of 1-decyl-2-ethylimidazole, 2 parts of trimethylhexamethylenediamine, 2 parts of diaminodiphenylmethane And 0.5 part of 3-hydroxy dodecanedioic acid; The leveling agent is an acrylic leveling agent; The acrylic leveling agent contains epoxy groups; The dispersant is polyethylene glycol fatty acid ester; The degassing agent includes 3 parts of hard Calcium fatty acid, 0.5 parts of polyoxyethylene lauryl ether, 2 parts of perfluoroalkyl phosphate; fillers include 2 parts of antimony oxide, 1 part of talc, 0.5 parts of boron nitride, and 2 parts of calcium hexaboride.

Embodiment 2

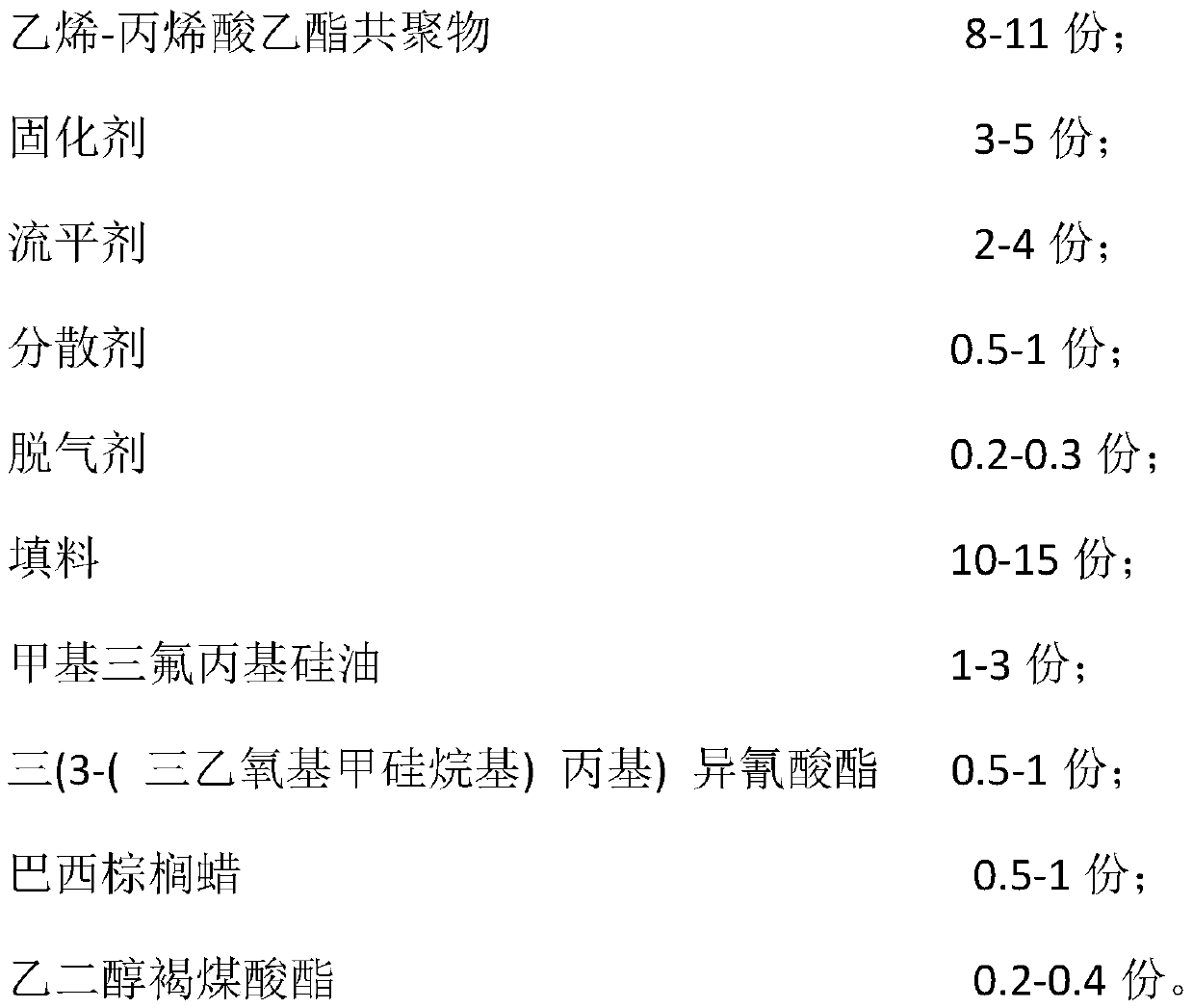

[0050] A thermosetting powder coating, by weight, comprises the following components:

[0051]

[0052]The resin is polyimide; the curing agent includes 3 parts of ethylenetriamine, 4 parts of 1-decyl-2-ethylimidazole, 3 parts of trimethylhexamethylenediamine, 3 parts of diaminodiphenyl Methane and 0.6 parts of 3-hydroxydodecanedioic acid; the leveling agent is an acrylic leveling agent; the acrylic leveling agent contains amide functional groups; the dispersant is sodium pyrophosphate; the degassing agent includes 4 parts of calcium stearate, 0.7 1 part of polyoxyethylene lauryl ether, 3 parts of perfluoroalkyl phosphate; fillers include 3 parts of antimony oxide, 2 parts of talc, 0.8 parts of boron nitride, and 3 parts of calcium hexaboride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com