Preparation method of environmental low temperature resistant and acid and alkali resistant cable sheath rubbers

A cable sheath rubber, acid and alkali resistant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of high price, low service life and easy cracking of fluoroplastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

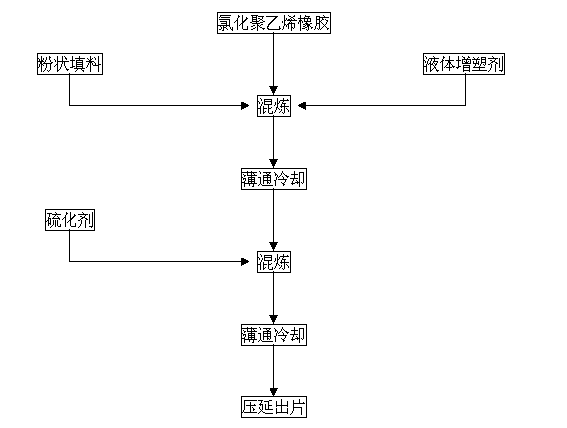

Method used

Image

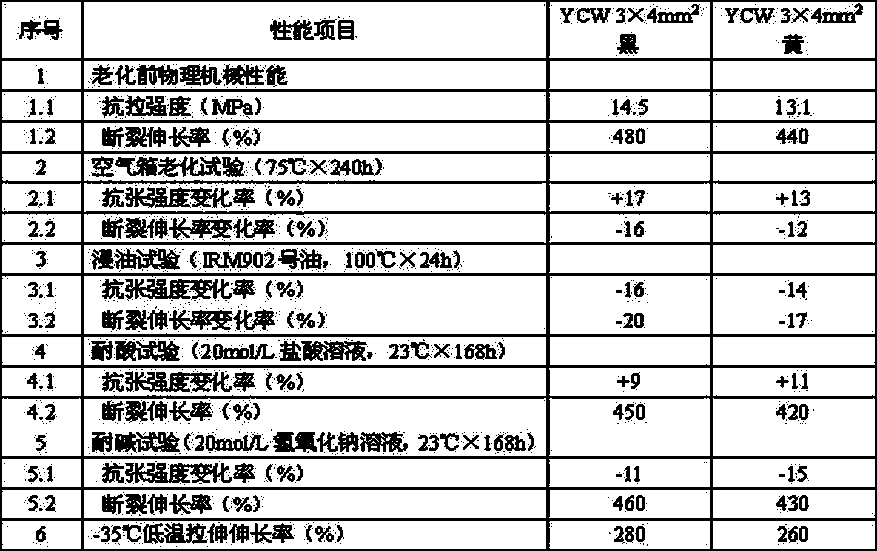

Examples

Embodiment 1

[0032] A black environmentally friendly low temperature resistant acid and alkali resistant cable sheath rubber formulation, comprising the following components and parts by weight: 100 parts of chlorinated polyethylene rubber, 5 parts of highly active magnesium oxide, 3 parts of environmental protection stabilizer, 4 parts of microcrystalline wax parts, 15 parts of carbon black, 70 parts of acid and alkali resistant filler, 5 parts of antimony trioxide, 3 parts of DCP, 3 parts of TAIC, 1 part of RD, and 15 parts of DOS.

[0033] Preparation:

[0034] Step 1: Ingredients

[0035] Weigh 25 kg of chlorinated polyethylene rubber, 1.25 kg of highly active magnesium oxide, 0.75 kg of environmental stabilizer, 1 kg of microcrystalline wax, 3.75 kg of carbon black, 17.5 kg of acid and alkali resistant filler, 1.25 kg of antimony trioxide, 0.75 kg of kg DCP, 0.75 kg TAIC, 0.25 kg RD, 3.75 kg DOS.

[0036] Step 2: One Kneading

[0037] 25 kg of chlorinated polyethylene rubber, 3.75...

Embodiment 2

[0053] A black environmentally friendly low temperature resistant acid and alkali resistant cable sheath rubber formulation, comprising the following components and parts by weight: 100 parts of chlorinated polyethylene rubber, 8 parts of highly active magnesium oxide, 4 parts of environmental protection stabilizer, 5 parts of microcrystalline wax parts, 20 parts of carbon black, 85 parts of acid and alkali resistant filler, 7 parts of antimony trioxide, 4 parts of DCP, 4 parts of TAIC, 1 part of RD, and 20 parts of DOS.

[0054] Preparation:

[0055] Step 1: Ingredients

[0056] Weigh 25 kg of chlorinated polyethylene rubber, 2 kg of highly active magnesium oxide, 1 kg of environmental stabilizer, 1.25 kg of microcrystalline wax, 5 kg of carbon black, 21.25 kg of acid and alkali resistant filler, 1.75 kg of antimony trioxide, 1 kg DCP, 1 kg TAIC, 0.25 kg RD, 5 kg DOS.

[0057] Step 2: One Kneading

[0058] 25 kg of chlorinated polyethylene rubber, 5 kg of carbon black, 21...

Embodiment 3

[0074] A black environmentally friendly low temperature resistant acid and alkali resistant cable sheath rubber formulation, comprising the following components and parts by weight: 100 parts of chlorinated polyethylene rubber, 10 parts of highly active magnesium oxide, 5 parts of environmental protection stabilizer, 6 parts of microcrystalline wax parts, carbon black 25 parts, acid and alkali resistant filler 100 parts, antimony trioxide 10 parts, DCP 5 parts, TAIC 5 parts, RD 2 parts, DOS 25 parts.

[0075] Preparation:

[0076] Step 1: Ingredients

[0077] Weigh 25 kg of chlorinated polyethylene rubber, 2.5 kg of highly active magnesium oxide, 1.25 kg of environmental stabilizer, 1.5 kg of microcrystalline wax, 6.25 kg of carbon black, 25 kg of acid and alkali resistant filler, 2.5 kg of antimony trioxide, 1.25 kg of kg DCP, 1.25 kg TAIC, 0.5 kg RD, 6.25 kg DOS.

[0078] Step 2: One Kneading

[0079] 25 kg of chlorinated polyethylene rubber, 6.25 kg of carbon black, 25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com