Electrical device placement equipment with variable-volume installation cavity

An electrical device and installation cavity technology, which is applied in the installation of electrical components, electrical equipment enclosures/cabinets/drawers, and support structures, etc., can solve the problems such as the difficulty of reasonable placement of electrical cabinets, the large overall volume, and the inability of the electrical cabinets to meet the needs. To achieve reasonable placement, expand the scope of application, and meet the needs of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

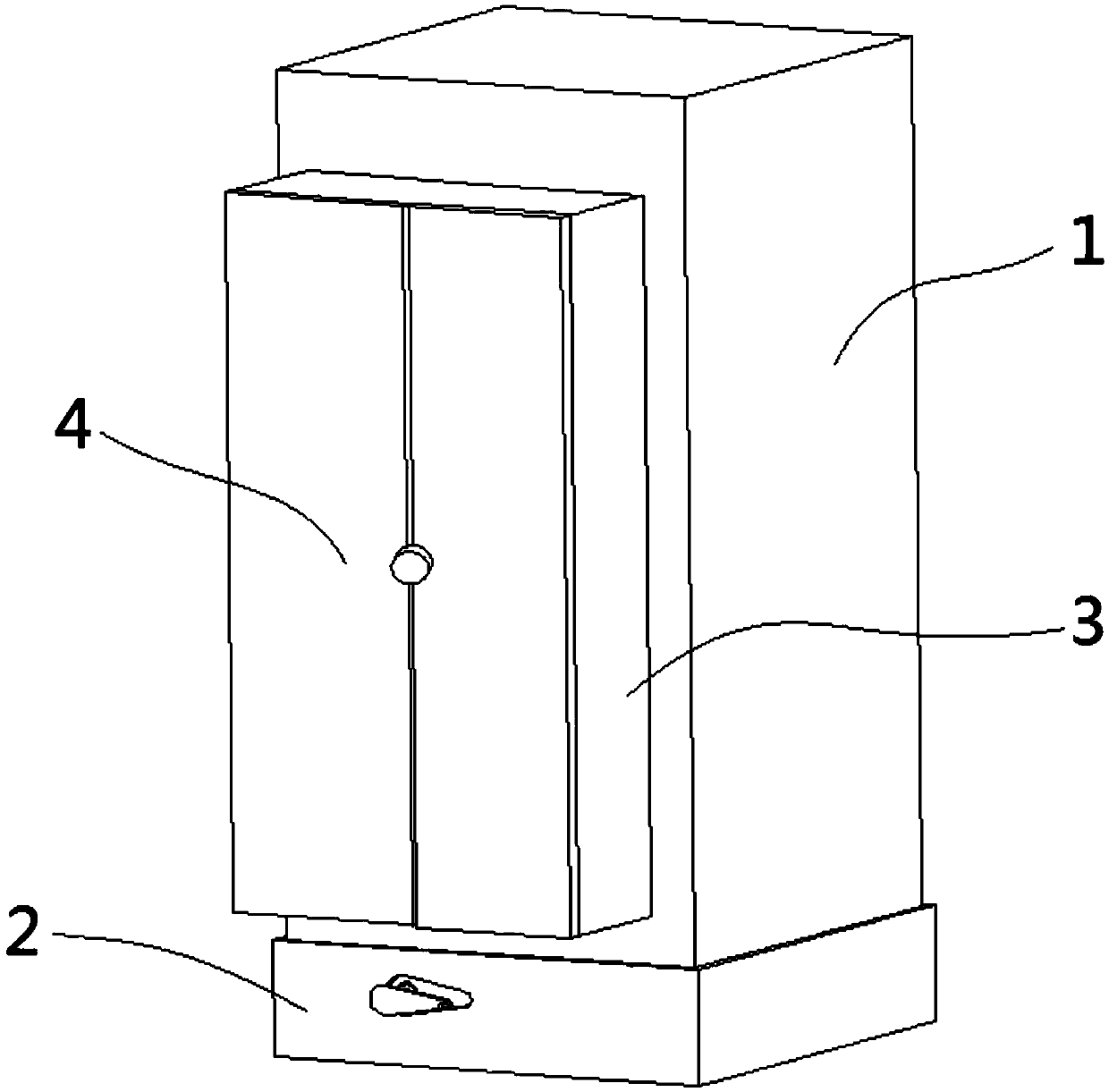

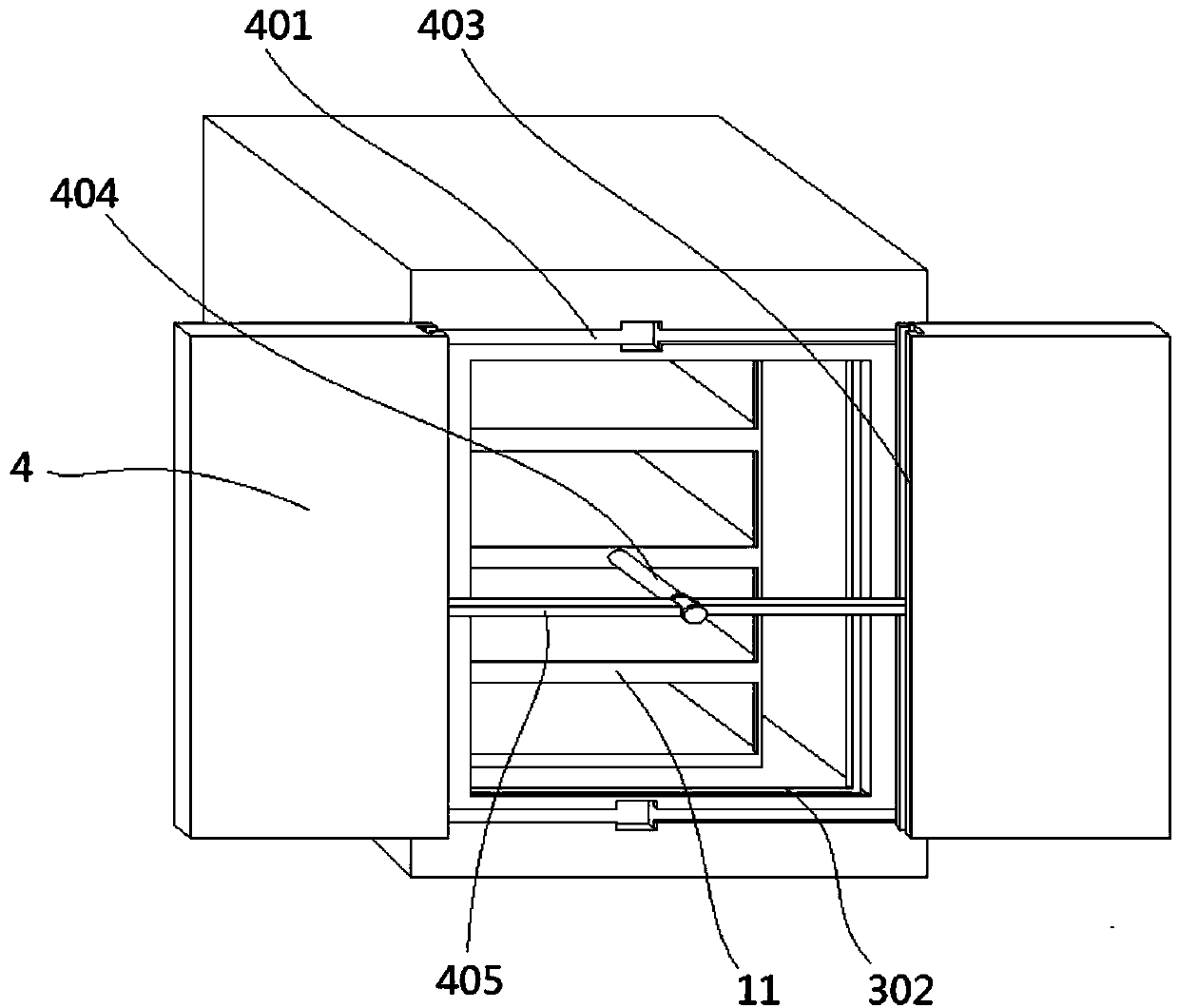

[0034] Electrical device placement equipment with variable volume mounting cavities, such as figure 1 As shown, it includes a cuboid-shaped equipment body 1 with a built-in cavity, a bracket 11 is placed in the cavity of the equipment body 1, and required components are installed on the bracket 11 .

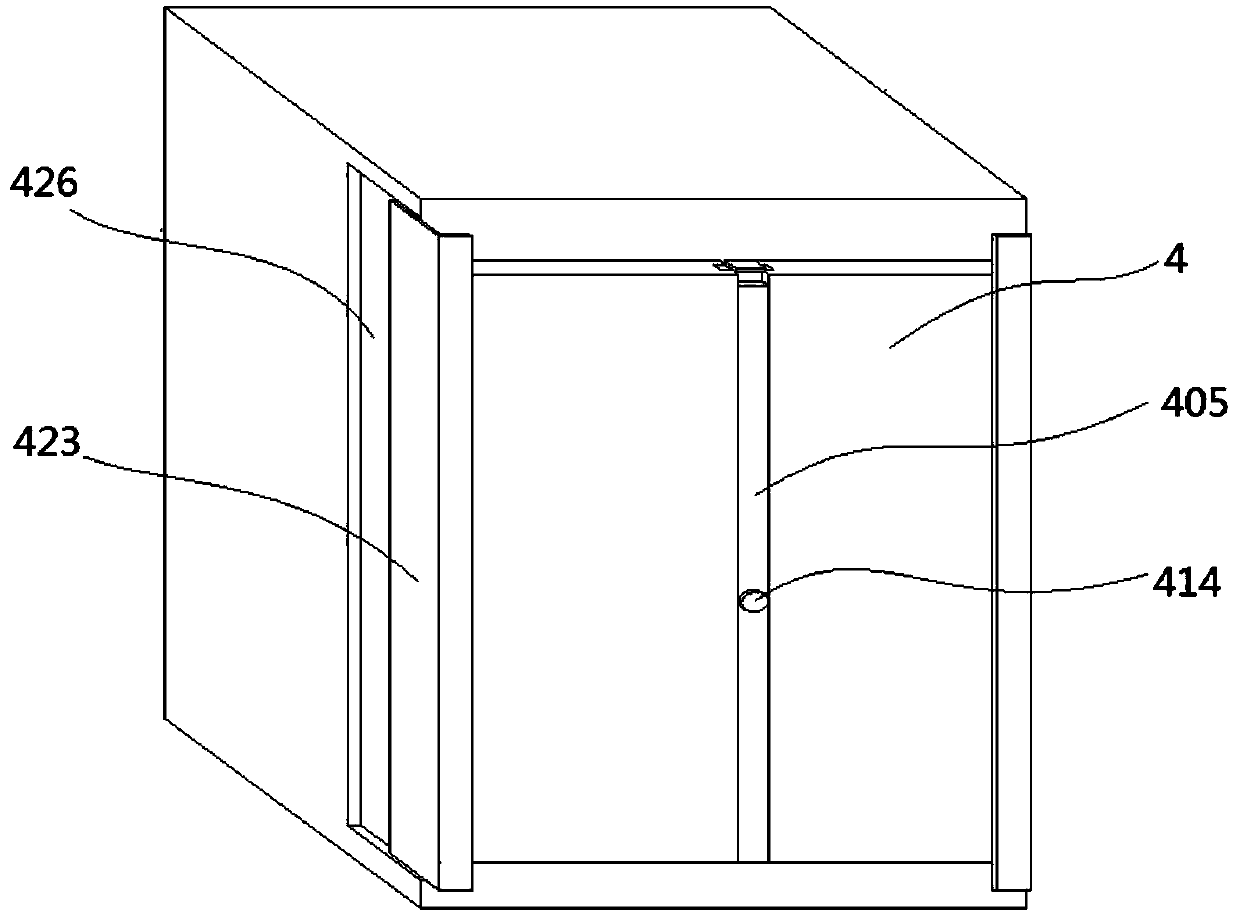

[0035] The bottom of the device body 1 is provided with a base 2, and the device body 1 is fixed on the base 2. The device body 1 is provided with a volume expansion body 3 that can protrude from the front end of the device body 1 and perform linear reciprocating motion along the width direction of the device body 1. The volume The extension body 3 is a rectangular frame body including four side panels and a door body 4 is provided on the front surface. The cavity of the body 1 forms a cavity. After opening the door body 4, the components in the device body 1 and the volume expansion body 3 can be observed, and then the internal components can be installed, repaired, replaced and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com