A method of operating a packaging machine

A packaging and sealing packaging technology, applied in the field of sealing packaging of pourable food, to achieve the effect of expanding the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

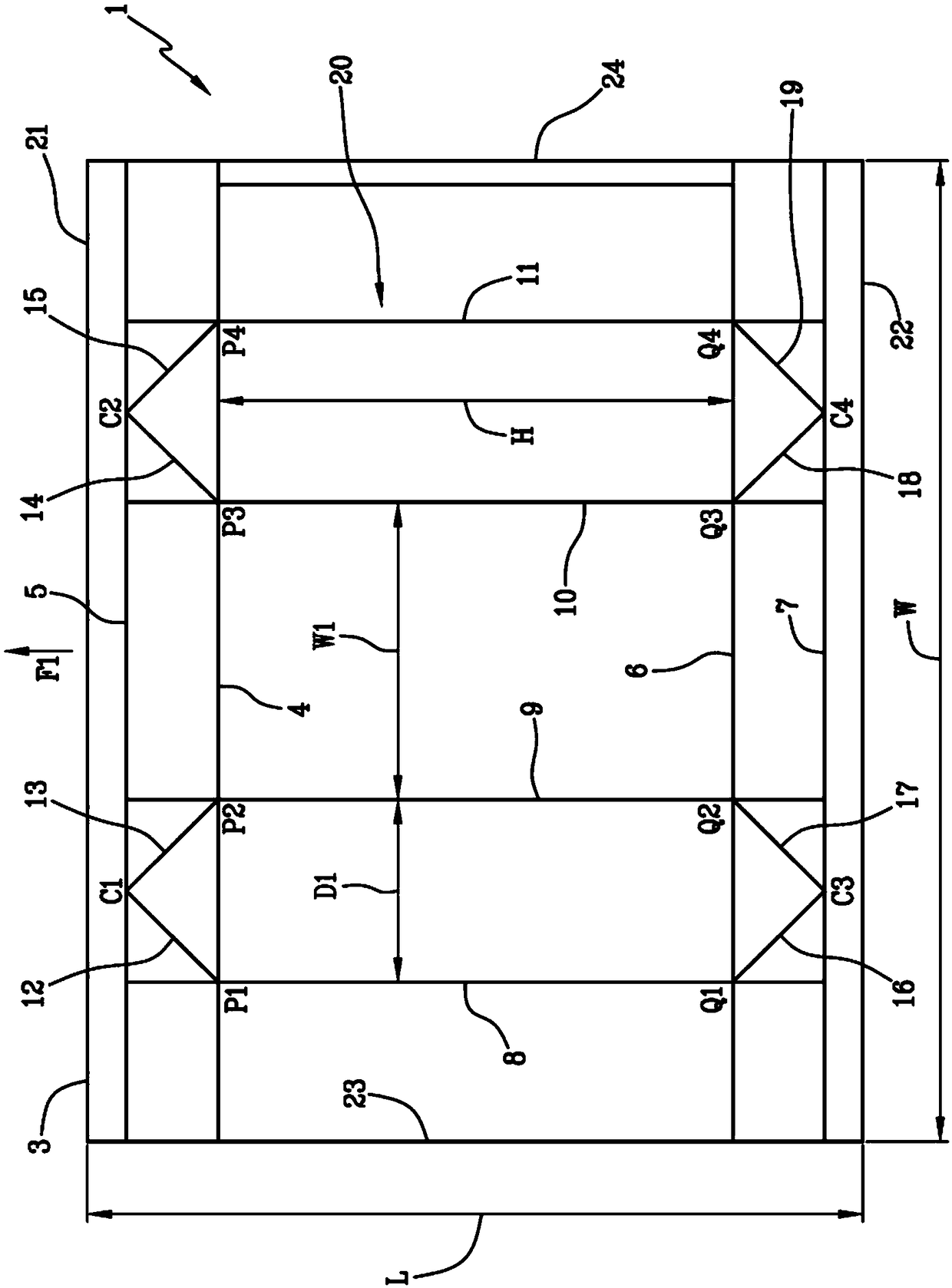

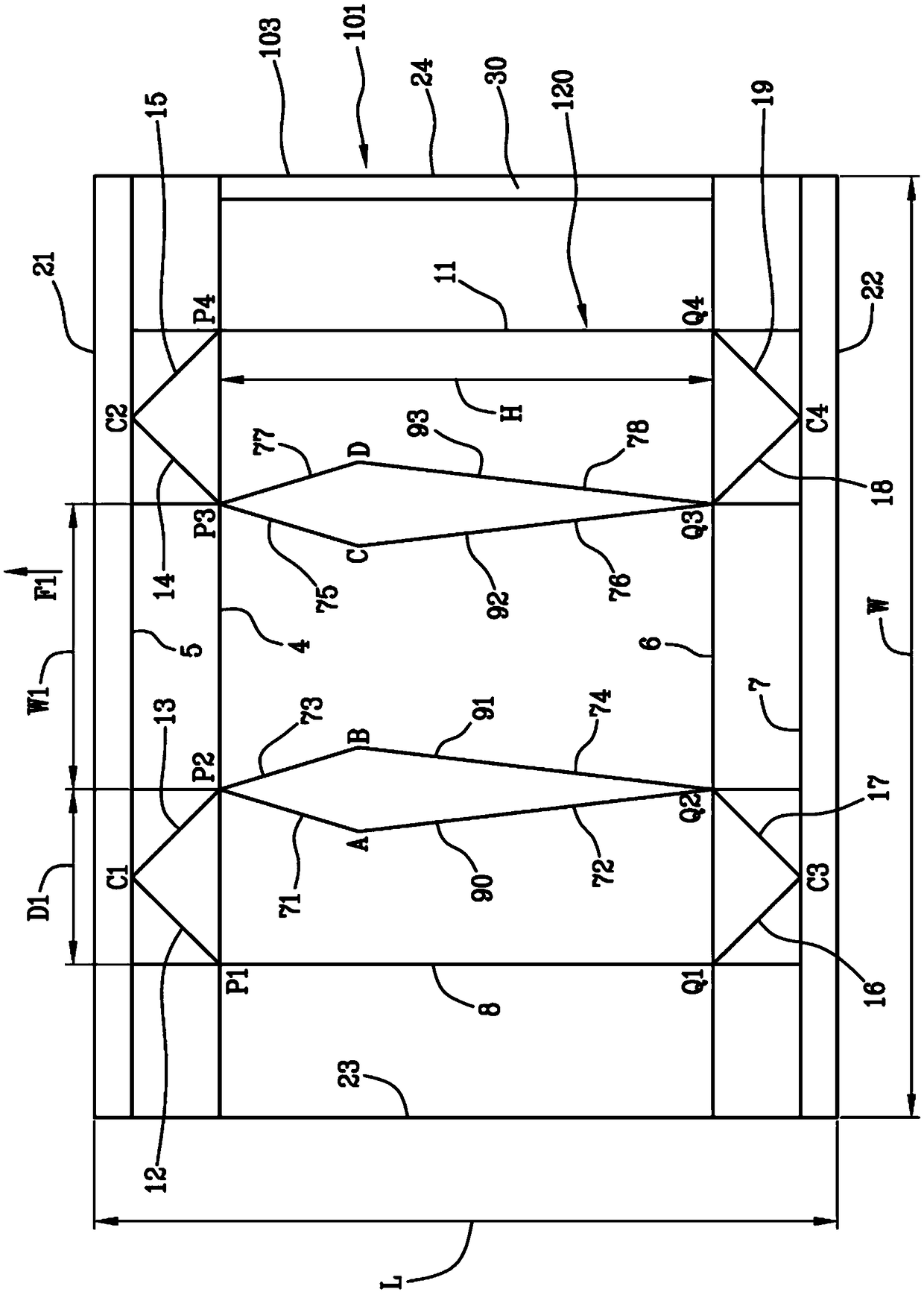

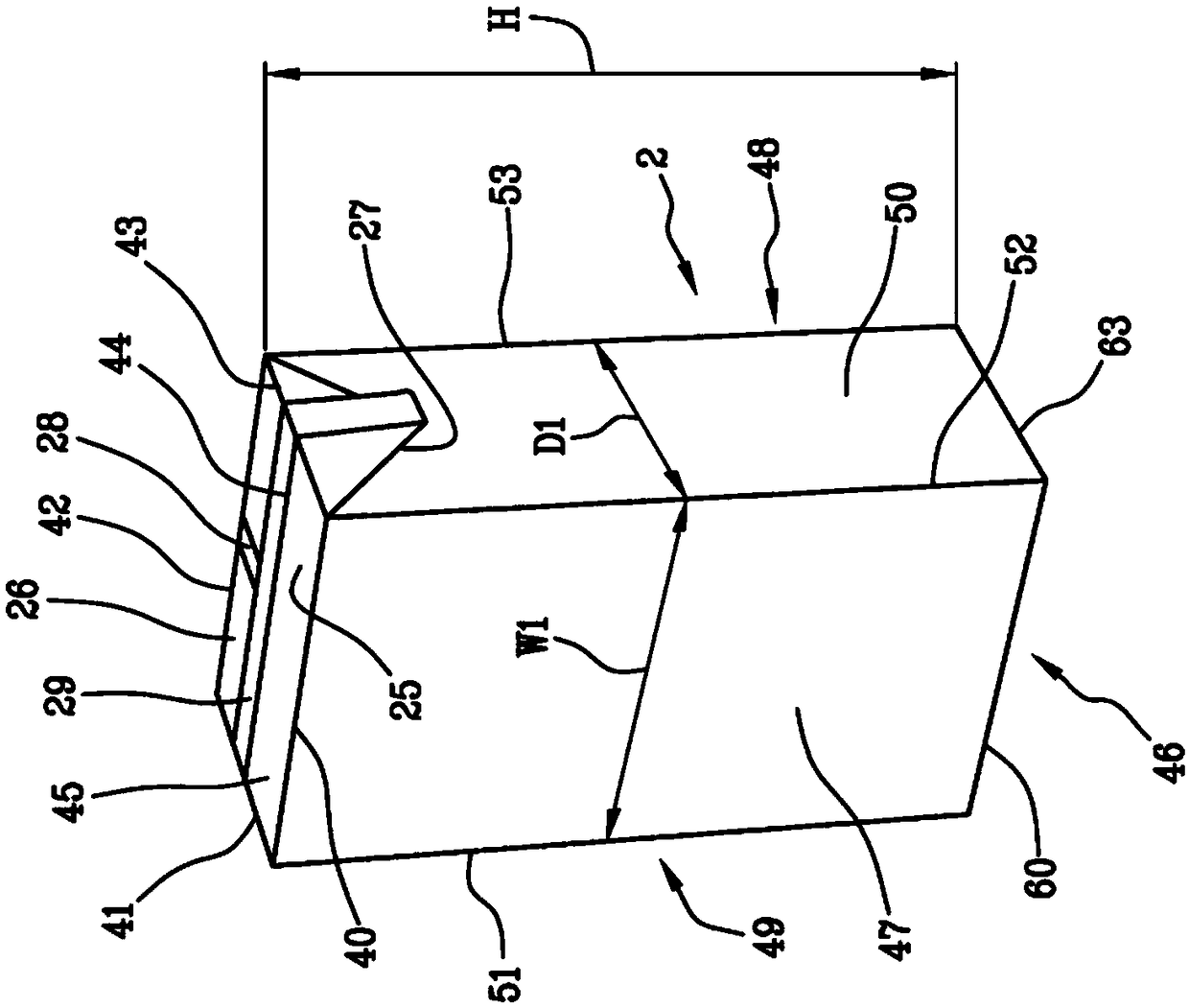

[0040] figure 1 is shown for the image 3 The first configuration shown produces sheet-like packaging material 1 for packaging 2 . Package 2 is a sealed package particularly suitable for containing products such as pourable food products.

[0041] The sheet-like packaging material 1 can be configured as a basic unit 3 that can be used to produce a package 2 . The base unit 3 may be a pre-cut blank or part of a web of packaging material comprising a series of base units.

[0042]If the base unit 3 is a pre-cut blank, the base unit 3 is folded over a folding mandrel, filled with food product, and sealed at the top to form a package.

[0043] If an elementary unit 3 is part of a roll of packaging material, that web comprising a series of elementary units 3:

[0044] - folded to form a vertical tube and sealed longitudinally;

[0045] - is continuously filled with food; and

[0046] - Sealed transversely and cut into sealed primary packaging units, which are then folded to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com